Advanced Protection against Electromagnetic Exposures and Electric Arc

NFPA 70e Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our NFPA 70E Fact Sheet – 2024 Electrical Safety Edition

- Understand how NFPA 70E works with NEC and NFPA 70B standards

- Clarify the shared responsibility between employers and employees

- Learn how NFPA 70E supports OSHA compliance

Advanced protection against electromagnetic exposures and electric arc delivers EMF shielding, RF attenuation, grounding, and arc flash PPE using dielectric barriers, conductive fabrics, IEC 61482 and NFPA 70E compliance for high-voltage safety.

What Is Advanced Protection Against Electromagnetic Exposures and Electric Arc?

Systems and PPE that shield from EMF and reduce arc flash risks via shielding, RF attenuation, and standards-based design.

✅ EMF and RF shielding using conductive fabrics and Faraday enclosures

✅ Arc flash PPE per NFPA 70E and IEC 61482, tested incident energy

✅ Grounding, bonding, and dielectric barriers for high-voltage safety

HAZARDS AROUND

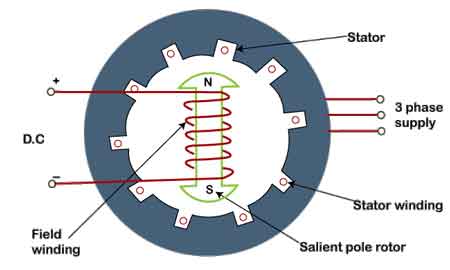

While working live in the energized grid, presence of voltage around the workers requires special attention. However, live-line (live working) techniques are widely applied for decades; several accidents in the past prove that the level of safety must be improved to minimize the number and seriousness of injuries in the future. In the high voltage grid, bare-hand method is a common technique for safe live work. In the surroundings of any energized equipment, high electric field occurs as the result of high voltage, which can be shielded effectively by conductive clothing acting as so-called Faraday-cages. The efficiency of these special PPE (personal protective equipment) is quite impressive: the screening efficiency [1] of a high-quality conductive clothing is above 99%. Although working methods guarantee the proper level of safety, some North-American examples prove that an electric arc is a real source of danger on the worksite, especially while working with hot sticks [2]-[4]. On the other hand, regular conductive clothing is not arc protective but only flame retardant. So the end user companies practicing bare-hand or hot stick methods face a dilemma (or need to choose) – ignore one of the risks of arc flash or electric field or apply an arc protective underwear, suit under the conductive clothing. Neither of these options is proper, since the first one leads to the additional risk to the human life and health and the second one reduces working comfort that strongly influences to the working safety. Beyond the combination of screening and arc protection, there are special and unique conductive clothing available by Electrostatics Ltd. with rated Arc Thermal Performance Value (ATPV). For context on selecting garments that address both electric field exposure and arc hazards, see this overview of arc-flash clothing options and best practices.

Test Your Knowledge About Arc Flash!

Think you know Arc Flash? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

ELECTROSTATICS ARC PROTECTIVE CONDUCTIVE CLOTHING

InteGREATed® protection is a combination of a special material and design to reach ATPV level of 10 cal/cm2 with a single layer suit and even 78 cal/cm2 with a combination of a conductive garment, a winter lining and a NOMEX upper suit, while the special accessories, like conductive shoes/socks, gloves guarantee the maximal safety and comfort of work. Several studies have shown that face mesh is an essential component to protect the most sensible parts of the body [5]-[10]. IEC’s limits are based on the EU-level regulation for the occupational exposure of electric field, which is 10 kV/m. As the following Figure shows, face mesh is essential: even at 75 kV, without any protection, peak values of electric field exceed the limit significantly.

When building a head-to-toe solution, many utilities reference arc-flash PPE clothing categories to align hoods, gloves, and footwear selections with task energy levels.

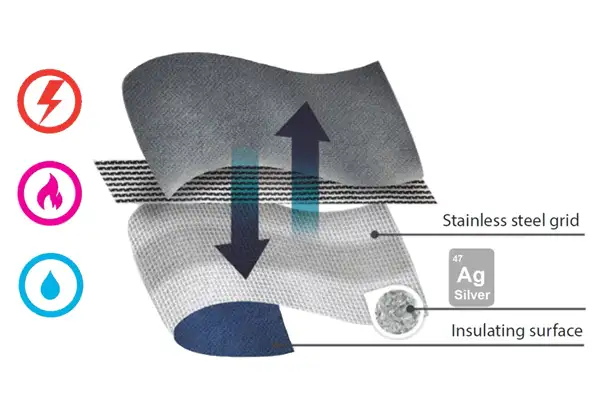

The double-sided material of this single-layer clothing is also unique: The combination of silver-coated threads and a grid of steel stainless yarn shields high electric fields almost completely while the insulating of the inner surface of the fabric uncouples the metallized surface from the human body to provide previously unattainable comfort. This flame-retardant and arc protective material is resistant to a multiply washing and human sweat and also has an outstanding breathability. This selection guide to arc-rated clothing explains labeling and material performance considerations for field use.

| Electric resistance of the conductive garment, not more than IEC 60895:2002 + corrigendum 2003 modified | 1Ω |

| Electric resistance of the conductive gloves and socks, not more than IEC 60895:2002 + corrigendum 2003 modified | 30Ω |

| Electric resistance of the conductive shoes, not more than IEC 60895:2002 + corrigendum 2003 modified | 10kΩ |

| Shielding factor at 50 Hz frequency, not less than IEC 60895:2002 + corrigendum 2003 modified | 70dB |

Understanding how ATPV values translate into tasks is easier with summaries of arc-flash levels of protection that map clothing systems to incident energy ranges.

"This flame-retardant and arc protective material is resistant to a multiply washing and human sweat and also has an outstanding breathability."

Procurement teams often compare fabrics using arc-flash rated clothing specifications to verify durability, laundering cycles, and comfort in service.

| Arc Thermal Performance Value – ATPV (IEC 61482) | |

| Conductive garment | 10 cal/cm2 |

| Conductive garment + Nomex upper suit | 22.4 cal/cm2 |

| Conductive garment + Winter lining + Nomex upper suit | 78 cal/cm2 |

| Nomex upper suit | 8 cal/cm2 |

| Nomex upper suit + Winter lining | 64 cal/cm2 |

For tasks classified as not live work but with induction risks, guidance on arc-flash PPE selection helps maintain consistency across crews.

Strengthened high-current paths from the head cover to the shoes ensure to carry extra high currents, which is essential from the aspects of protection against induced currents. A so-called “equipotential suit” is a special type of conductive clothing designed to protect working personnel against induced and capacitive voltage and current, while the job itself is not declared as live work.

CONCLUSION

Conductive clothing is inspected by several standards, like IEC 60895:2020 or IEEE 1067 [11] to test their electrical properties. However, nowadays arc protection is a hot topic [12]-[14] and OSHA 1910.269 prescribes, it is still not a common practice to categorize conductive clothing by their APTV level. Although, this way of thinking may reduce the risks of live working in the future: a single PPE to eliminate all electrical sources of danger is surely a proper choice to set a higher standard of safety in such cases, when special attention is required in every working moment. Organizations can further reduce uncertainty by training personnel on differences between arc-flash clothing for electricians and everyday flame-resistant apparel to ensure appropriate hazard coverage.

REFERENCES

[1] Live working - Conductive clothing, IEC 60895, 2020

[2] W. McDermid, J.C. Bromley, D.J. Dodds, D.R. Swatek, “Investigation of the Flashover of a FRP Hot Stick While in Use for Live Line Work at 500 kV, IEEE Transactions on Power Delivery, Vol. 14, No. 3, July 1999

Sign Up for Electricity Forum’s Arc Flash Newsletter

Stay informed with our FREE Arc Flash Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

[3] W. McDermid, D.R. Swatek, J.C. Bromley, “FRP Hot Stick Flashovers during EHV Live Line Work”, Electrical Insulation Conference and Electrical Manufacturing and Coil Winding Technology Conference, Indianapolis, Indiana, USA, USA, 25-25 Sept. 2003

[4] W. McDermid, D.R. Swatek, J.C. Bromley, “Progress in Resolving Flashovers of FRP Hot Sticks During EHV Live Line Work”, IEEE International Symposium on Electrical Insulation, Indianapolis, IN USA, 19-22 September, 2004

[5] Gábor Göcsei, Bálint Németh: New challenges in live-line maintenance, Electrical Insulation Conference (EIC), Seattle, USA, 2015.06.07-2015.06.10. IEEE, New York, USA

[6] Gábor Göcsei, Bálint Németh, Dr. István Berta: Electric fields and arc protection during live-line maintenance, 19th International Symposium on High Voltage Engineering (ISH), Plzen, Czech Republic, 2015.08.23-2015.08.28., CIGRÉ, Paris, France

[7] Gábor Göcsei, Bálint Németh, Ádám Tamus, Dr. István Kiss: Face Protection Investigation Against Electric Field On Live Line Workers, 2012 IEEE International Symposium of Electrical Insulation (ISEI) – keynote, San Juan, USA, 2012.06.10 -2012.06.13., IEEE, New York, USA

[8] Gábor Göcsei, Bálint Németh, Dániel Tarcsa: Extra low frequency electric and magnetic fields during live-line maintenance, Electrical Insulation Conference (EIC), Ottawa, Canada, 2013.06.02- 2013.06.05., IEEE, New York, USA

[9] Gábor Göcsei, Bálint Németh, Ádám Tamus, István Kiss, József Meixner: Shielding efficiency of conductive clothing during live-line maintenance, 11th International Conference on Live Maintenance (ICOLIM), Budapest, Hungary, 2014.05.21-2014.05.23., IEEE, New York, USA

[10] Gábor Göcsei, Dr. Bálint Németh: Current issues regarding to the inspection of conductive clothing, IEEE 13th International Conference on Transmission &Distribution Construction, Operation & Live-Line Maintenance (ESMO), Columbus, USA, 2016.09.11-2016.09.15., IEEE, New York, USA

[11] IEEE 1067-2012, IEEE Guide for In-Service Use, Care, Maintenance, and Testing of Conductive Clothing for Use on Voltages up to 765 kV AC and +/-750 kV DC

[12] IEEE Guide for Performing Arc-Flash Hazard Calculations IEEE Std. 1584., 2002

[13] G. Riquel and E. Durcik, “Thermal protection of Live Working operators for High voltage range,” in 10th International Conference on Live Maintenance, Croatia, Zagreb, 2011.

[14] Arc Flash Issues in Transmission and Substation Envinorments: Results from Tests with Long Arcs, EPRI, Palo Alto, CA: 2011. 1022632