Wire and Cable

Aerial Cable Explained

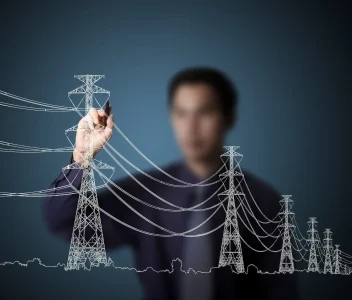

Aerial cable is an overhead electrical conductor suspended between poles or towers. Used in power distribution and telecom, it offers low-cost installation, reliable performance, and minimal ground disruption. Suitable for rural, utility, and industrial applications.

What is Aerial Cable?

Aerial cable plays a crucial role in delivering electricity across long distances by suspending power lines above the ground.

✅ Supports electrical power and telecommunication transmission over long distances

✅ Ideal for areas where underground installation is impractical or costly

✅ Offers ease of maintenance and rapid deployment for utility networks

These lines are often supported by poles or other structures, ensuring they remain elevated and safely transmit electrical energy. This type of installation is commonly used in both urban and rural areas, providing an efficient means of power distribution where underground cabling is impractical.

Advantages of Taking the High Road

Compared to underground cable, aerial cable offers several advantages that make it a preferred choice in many situations:

-

Lower Installation Costs: Installing aerial cable is generally less expensive than burying cable underground. This is because it avoids the need for extensive excavation, trenching, and backfilling, which can be time-consuming and costly.

-

Easier Maintenance and Upgrades: Accessing and maintaining it is simpler than accessing and maintaining underground cable. Faults can be easily located and repaired, and upgrades or modifications to the system can be implemented with less disruption.

-

Faster Deployment: It can be deployed more quickly than underground cable, especially in areas with challenging terrain or existing underground infrastructure. This makes it a suitable option for rapid expansion of power networks or restoration of power after natural disasters.

-

Reduced Risk of Damage from Excavation: Unlike underground cable, which can be accidentally damaged during excavation work, aerial cable is less susceptible to such incidents. This reduces the risk of service interruptions and costly repairs.

Common Types of Aerial Cable

There are various types used in power distribution, each designed to meet specific requirements:

-

Self-Supporting: This type of cable incorporates a built-in messenger wire, typically made of steel, which provides the necessary mechanical strength to support the cable's weight and withstand wind loads.

-

Dielectric Self-Supporting: This type of self-supporting cable is fully insulated, eliminating the need for additional insulation between the conductor and the messenger wire. It is often used in areas with limited space or where safety concerns require a higher degree of insulation.

-

Messenger-Supported: In this configuration, the cable is attached to a separate steel messenger wire that provides support. This allows for greater flexibility in cable design and installation.

Frequently Asked Questions

How is Aerial Cable Used in T&D Systems?

It is used to transmit power from one location to another, supported by poles or towers to remain above the ground. This design allows them to bypass obstacles like rivers, roads, and buildings. They help maintain a steady flow of power to homes, businesses, and industries by avoiding ground-level disruptions such as flooding or excavation work.

How do weather conditions affect the performance and durability?

Weather plays a major role in determining the lifespan and reliability of aerial installations. Strong winds can cause swaying, placing stress on the supporting structures. Ice buildup during winter adds weight, increasing the risk of sagging or breaking. Meanwhile, prolonged exposure to sunlight can degrade insulation materials. However, modern overhead designs are built with durable materials to resist these environmental challenges.

What are the safety considerations when installing and maintaining it?

Safety is critical when working with overhead power lines. Proper clearance must be maintained from nearby structures, such as trees and buildings, to avoid accidental contact. Regular inspections are necessary to detect wear, such as damaged insulation or corrosion on the supporting structures. Additionally, workers should be equipped with appropriate safety gear and follow established protocols to minimize the risk of electrical hazards.

Aerial installations are an important part of the electrical distribution infrastructure, especially in areas where underground cabling is impractical. These systems offer cost-effective and easily maintainable solutions for delivering power over long distances. By understanding the types of cables, their advantages, and how environmental factors impact performance, power providers can ensure reliable service to customers.

Related Articles

Download Our FREE Arc Flash Handbook

Our Electrical Safety and Arc Flash Handbook Volume 11 is the most popular handbook in our handbook series.

Our latest Arc Flash and Electrical Safety Handbook Volume 11 is a valuable source of information for electrical professionals working in Industrial, Commercial and Institutional power systems who are exposed to the risk of arc flash accidents, which can cause serious injury and death.

This 96-page FREE to download handbook examines important electrical safety issues faced by front line electrical workers.

Table of Contents

CHAPTER ONE - Arc Flash And Blast

CHAPTER TWO - Arc Flash Codes And Standards

CHAPTER THREE - Arc Flash In The Workplace

CHAPTER FOUR - Electrical Safety Procedures

CHAPTER FIVE - Lockout Tagout

CHAPTER SIX - Arc Flash PPE

CHAPTER SEVEN - Arc Flash Training

CHAPTER EIGHT - Arc Flash Anaylsis

CHAPTER NINE - Arc Flash Consulting

Download Today!

Latest Wire and Cable Articles

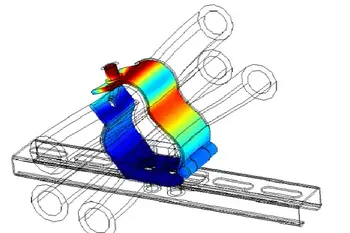

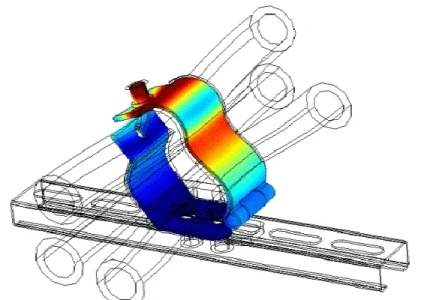

Cable Cleats Testing - Crucial to Cable Management

Cable cleats provide mechanical restraint for LV/MV/HV cables, securing bundles against short-circuit forces on ladder trays and cable ladders, compliant with IEC 61914, in stainless steel or polymer for industrial electrical installations.

What Are Cable Cleats?

Cable cleats are devices that mechanically secure cables, resisting short-circuit forces and vibration per IEC 61914.

✅ Tested to IEC 61914 for short-circuit and dynamic load performance

✅ Materials: stainless steel, aluminum, UV-stabilized polymer

✅ Secures single, bundled, or trefoil cables on trays and ladders

Essentially, cable cleats are devices designed to secure cables and to ensure the retention and support of them, reducing the load that the cable may be exposed to under its own weight. They are also designed to contain the cables under fault conditions, protecting the cables and the cable management system from damage. Following best practices for cable handling and testing procedures helps ensure cleats are applied to undamaged conductors for reliable service.

The first European cable cleat standard, EN 50368, highlighted the retention and support that cable cleats provided to cables. Most importantly, the standard highlighted the protection of the cable management system and the potential risk to human life that could occur without the use of cable cleats.

It was not until 2003, with the release of standard EN 50368 that any formal standard for cable cleats existed. Prior to this, both cable and cable cleat manufacturers provided their own testing to their own standards for many years all over the world. This standard was then followed up with the publication of IEC 61914:2009, which further focused on the importance of cable cleat products and correct cable cleating. It set the standardised method for testing and certification of cable cleats, to prove they can withstand one or more short circuit tests. IEC 61914:2009: “6.4.3 resistant to electromechanical forces, withstanding one short circuit, 6.4.4 resistant to electromechanical forces, withstanding more than one short circuit.” Complementary guidance on the installation of conductors and cables supports standard-compliant cleating practices across varied applications.

The crucial problem causing cable cleats being overlooked is that, at the moment, the implemented standards are advisory. Therefore, at times of cost cutting on cable management systems, reputable cable cleats are compromised for cheaper, lower quality versions, which aren’t certified to these standards.

Cable cleats protect the cable management system by reducing the mechanical load exerted, and ensuring the cables are fixed, retained and supported correctly. In many facilities, correct cleat spacing must account for the geometry of the cable tray so that loads are transferred safely.

The dangers of failing to use an appropriate cable cleat certified to IEC 61914:2009 become clear when you have seen the effects of a short circuit first hand. Without the cable cleats in place, the costs of a short circuit can be seen financially, in replacing a damaged cable management system, as well as the potential harm to individuals in the area. Integrating appropriately rated short-circuit protection further reduces arc energy exposure and collateral damage.

Typically, damage to the cables under fault conditions occurs within the first quarter cycle of the fault. A typical circuit breaker interrupts the fault after three cycles. Whilst this may protect the equipment, the cables may have already been damaged within this short duration and may need replacing. The replacement of any cables comes at a high price as this not only includes the expensive cable costs themselves, but the labour time of decommissioning, downtime and the reinstallation of the cable management system. Post-incident power cable diagnostics can verify insulation integrity and inform replacement decisions.

Cable cleats should be designed and tested so that in the event of short circuit fault conditions, they will contain the cables without causing damage, enabling the circuit to be restored once the fault has been rectified.

The most appropriate type to use depends on the set up of the cable management system. Calculating this relies on a number of variables, such as cable construction and includes type, ratings, diameter, system design, support structure and environment. Accurate selection begins with understanding conductor materials and constructions, and resources that help you know your electrical cables make sizing and restraint choices more defensible.

Live trial and error testing can determine the correct cable cleat; however this method is expensive and can take weeks or months to undertake. Most installation designs are based on dated calculations, rather than live short circuit simulations because of this, which is not the most accurate cable cleat selection method. There is a wide range of options to determine the most suitable cable cleat for a given cable management system; from offering simulated solutions, to using the experience of its technical experts together with tried and tested calculations. With the cost of live testing prohibitively expensive and often impractical, one alternative option is software modelling. When modelling is complete, adherence to proven practices for the installation of cable in cable trays ensures field execution matches the design intent.

Related Articles

Guidelines for the Installation of Cable In Cable Trays

Installation of Cable in Cable Trays involves precise routing on support systems, NEC/IEC compliance, grounding, ampacity derating, bend radius control, segregation of services, fire safety, labeling, and reliable cable management for industrial and commercial facilities.

What Is the Installation of Cable in Cable Trays?

The engineered process of routing and securing conductors on tray systems per codes for safety and performance.

✅ Comply with NEC/IEC, tray fill limits, ampacity derating, firestopping.

✅ Maintain bend radius, separation of power/data, EMC and thermal spacing.

✅ Use approved clamps and supports; bond, label, test continuity and insulation.

The use of ladder-type trays as raceways for insulated cables is becoming more prevalent. These raceways are being more heavily loaded with increasing number and size of cables being installed. With this growth in the use of tray, it is increasingly important that the tray and cable be installed within industry recognized practices. Discussed are the installation in tray of single and multi-conductor insulated cables with design limitations, example calculations, equipment, and equipment usage and its limitations. For an overview of tray system types and applications, see cable tray raceways for additional context.

For over thirty years, the use of a ladder-type tray as a rigid structural system for support of cables has grown dramatically. Accompanying this increase is the need for larger and longer cables to be installed. Designers and installers are continually faced with difficult challenges in the layout and installation of cable in tray. It is incumbent that pre-planning of an orderly sequence of events takes place to ensure that a successful installation occurs within recognized limits. Cable installed in tray is subject to many of the same considerations as cable being installed in conduit systems. Correctly calculated data and adherence to the design limits of the cables being installed with respect to tensions, sidewall pressures, and minimum bending radii increases the probability for a successful installation. Damage occurs more frequently as a result of improper handling during installation, or inadequate protection after installation. Cable tray layout must take into consideration the design limits of the cable. To minimize damage and verify integrity after installation, follow the practices outlined in cable handling and testing procedures for safer outcomes.

Installation Design Considerations and Formulas

Selecting the correct conductor materials and insulation ratings starts with understanding cable families as summarized in Know Your Electrical Cables before applying these formulas.

Tensions

The maximum allowable pulling tension that can be applied safely to a cable varies with the size and material of the conductor, the number of cables, and the method of attachment between the pulling line and cable.

Commissioning teams often validate these limits through acceptance and maintenance checks such as those described in power cable test methods to confirm performance.

A. For pulling eyes and bolts the maximum tension is expressed as:

Tmax = .008 * N * A Eq. (1)

(For copper conductors and full hard drawn aluminum.)

In medium- and high-capacity corridors, copper conductors are frequently used in subterranean runs like those discussed under copper underground transmission for reliable delivery.

Tmax = .006 * N * A (For soft aluminum) Eq. (2)

Where

Tmax = Maximum allowable pulling tension in lbs/(kg)

N = Number of conductors

A = Conductor area in circular Mils (mm2)

.006 or .008 = Allowable stress per circular Mil (mm2) area for referenced metals.

For pulling eyes and bolts, the tension generated in a straight section of cable tray is expressed as:

Practical techniques for pulling setups, sheave placement, and crew coordination are detailed in installation of conductors and cables to help manage calculated forces.

T = L x w x f Eq. (3)

Where

L = The length of the cable tray section in feet (m)

w = The total weight of the cable being pulled in pounds (kg).

f = The coefficient of friction.

A. Range of .15 to .25 is recommended for the coefficient of friction. This coefficient is a function of the condition and alignment of sheaves.

Where tray runs experience dynamic loads or short-circuit forces, secure conductors with appropriately rated cable cleats to control movement.

B. For basket grips, the limit is 1000 lbs (453.6 kg/m) per grip or the value calculated in equation (1) whichever is smaller. This limit applies to a single conductor cable, a multi-conductor cable with a common overall jacket, two or three twisted cables, or paralleled cables using one grip. It is desirable to pull the cable by the conductors if this choice can be made rather than other type grips.

C. For conductor wedge-type compression grips, the grip manufacturer should be consulted for design limits of these devices. The same limits apply to these devices as pulling eyes and bolts.

Found In: Wire and Cable and Wiring Methods Handbook - Vol. 3

Related Articles

Testing of Electrical Power Cable

Power cable test verifies insulation resistance, dielectric withstand, continuity, and partial discharge using VLF/hipot methods for HV/MV/LV cables, supporting diagnostics, commissioning, predictive maintenance, fault location, condition monitoring, and compliance with IEC/IEEE standards.

What Is a Power Cable Test?

A power cable test checks insulation, dielectric strength, and continuity to ensure safety and IEC/IEEE compliance.

✅ VLF/hipot withstand: kV step and hold to detect insulation defects

✅ IR/PI testing to assess moisture ingress and insulation health

✅ Partial discharge and tan delta for condition-based diagnostics

TYPE TESTS, ACCEPTANCE TEST, ROUTINE TESTS

The following tests are type test of wires used as conductors in electrical power cables.

Persulphate test (for copper):

Since the tinning process of copper can possibly produce pin holes on the copper, this test is done on tinned copper wire to determine the exposed copper. Typically a sample is taken and subjected to the persulfate solution; its conclusions should meet or not meet the required specifications (IS 10810, part 4 – 1984)

For broader procedural context, practitioners often consult the cable handling and testing procedures to align sampling, cleaning, and solution preparation steps.

Annealing test (for copper):

During construction/installation procedures, the conductor cables are subjected to twisting and bending. This test is carried out on a sample of the conductor cable prior to installation and subjected to a tensile test which will elongate the sample. The observations should meet or not meet the specified allowed elongation for that particulate gauge.

When correlating elongation limits with conductor construction, the Know Your Electrical Cables guide provides helpful context on materials and gauge selection.

Tensile test (for Aluminium):

This is a tensile test and is performed on aluminium wires only to verify the strength of the aluminium wire sample. The diameter of the sample and the breaking load of the sample is recorded, the tension strength is calculated and verified against the required specifications.

Specifying appropriate grips, extensometers, and load-cell ranges is aided by referencing electrical testing equipment practices to maintain traceability and repeatability.

Wrapping test (for Aluminium):

During the manufacturing and installation process the wire is subjected to torsion caused by axial twisting resulting on possible breakage. This is a test performed on a sample of aluminium wire to determine its ductility; the properties of how easily the material can be twisted and wrapped without breaking. This repeated procedure calls for wrapping the sample around diameter 8-6 turns, unwrap and inspect for breakage. If the sample wire does not break it is deemed as ductile.

Conductor resistance test (for all):

This test is performed to determine the direct current resistance of the wire and concludes how easily the current will flow through the wire. The accuracy of the specimen will be compared to either the Kelvin Double Bridge or the Wheatstone Bridge. A test sample is selected and connected to a measuring bridge, resistance and temperature is recorded. The results based on a calculation of observed resistance, particular temperature, sample length.

In service conditions, trending DC resistance is often integrated into power cable diagnostics to flag connector corrosion, strand damage, or thermal aging early.

Test for thickness of insulation (for all):

There are many voltage stresses and mechanical stresses place on power cable wires, this measurement test confirms the thickness of the wires insulation per wire gauge. The samples insulating sheathing is cut in several place along the sample. The inside diameter and outside diameter of the insulation sheathing is measured and compared to a thickness calculation.

Such dimensional checks support condition assessments in both legacy PILC and modern XLPE systems as outlined in assessment of XLPE and PILC cables for interpreting deviations against design.

Measurement of overall diameter (where specified)(for all) Physical tests for insulation and sheath:

- Tensile strength and elongation at break

- Ageing in air oven

- Ageing in air bomb

- Ageing in oxygen bomb

- Hot set

- Oil resistance

- Tear resistance

- Insulation resistance

- High voltage (water immersion) test

- Flammability test (only for SE-3, SE-4)

- Water abortion test (for insulation)

For technicians planning insulation resistance work, the fundamentals are clarified in insulation resistance explained to aid temperature correction, polarization time, and test voltage selection.

Acceptance testing: The following test methods are conducted on completed cable assemblies and are constituted as acceptance tests:

- Annealing test (for copper)

- Tensile test (for Aluminium )

- Wrapping test (for Aluminium )

- Conductor resistance test

- Test for thickness of insulation and sheath and overall diameter

- Tensile strength and Elongation at break of insulation and heath

- Hot set test for insulation and sheath

- High voltage test

- Insulation resistance test

During high-voltage acceptance activities, proper PPE and the use of certified electrical safety testers help mitigate arc-flash and shock hazards.

Routine testing: The following test methods are conducted on completed cable assemblies and are constituted as routine tests.

- Conductor resistance test

- High voltage test

- Insulation resistance test

Related Articles

Copper Underground Electrical Transmission Systems

Copper underground transmission delivers high-voltage power via buried copper cables with XLPE insulation, high ampacity, low I2R losses, robust shielding, thermal backfill, and reliable grid integration for urban corridors and constrained rights-of-way.

What Is Copper Underground Transmission in Electrical Grids?

Copper underground transmission uses buried copper cables to deliver high-voltage power efficiently with high ampacity.

✅ XLPE-insulated copper cables deliver high ampacity in constrained corridors.

✅ Superior conductivity lowers I2R losses versus aluminum alternatives.

✅ Requires thermal backfill, duct banks, and corrosion protection systems.

Copper-conductor underground transmission cables for 69 kV to 345 kV installations are generally referred to as High- Voltage Underground Transmission Cables. For installations above 345 kV (usually up to 735 kV) they are known as Extra- High-Voltage Underground Transmission Cables.

For readers needing an overview of cable types and ratings, see the concise guide in Know Your Electrical Cables for foundational context.

The most frequent installations for these cables are between generating and distribution systems such as, for example, between substations, for the main transmission of electrical power. The underground transmission system supplies electricity to the underground distribution network, which feeds industrial plants, office buildings, street lighting, residences, and so forth. Distribution and installation cables are covered in detail in Copper Medium-Voltage Power Cables and Copper Wire and Cable in Buildings. For network integration in dense urban settings, equipment such as underground transformers help step voltages and improve reliability.

Historical Background

In the field of underground wiring, by the time that the polyphase AC system was conceived in 1886, several major steps had been taken towards making possible a practical underground power transmission system. One was Borel’s invention of an efficient lead press in 1879, and another was MacCracken’s concept of helically applied paper insulating tapes in 1884. Finally, in 1890, Vincent de Ferranti produced his famous 10,000-volt concentric cable, which was installed in London, England.

Continuous progress in the development of underground power transmission has taken place since that time. The first 3- conductor 25 kV cables were installed in Montreal in 1902, and they operated successfully for over 50 years. Then, in 1917, Emanueli conceived a design for hollow-core oil-filled cables, a breakthrough which permitted eventual transmission of power at high and extra-high voltages.

Gradually, the voltage levels of underground power cables increased, to 66 kV in 1926 in Montreal and Philadelphia, 220 kV in 1936 in Paris, and in recent years, reaching 525 kV in Canada and 535 kV in the United States. Current technology permits underground transmission cable systems as high as 1,100 kV.

In some corridors, high-capacity point-to-point links use advanced direct-current technology to reduce losses and manage long-distance power flows.

Advantages of Underground Cable

The power requirements for the electrical services in our cities, towns and rural areas are produced by hydro, nuclear and fossil-fuel generating plants. Many of these generating plants are located at considerable distances from the places of electrical consumption. Over long rural distances, overhead lines are used for electrical transmission. However, when a built-up area is approached, or if the power plant is in proximity to a city or town, there are many advantages to be gained by installing underground cables for the transmission system. For context on overhead construction methods, modern aerial cable practices illustrate the tradeoffs versus underground routing.

Apart from the obvious aesthetic advantages of improved appearance and maintaining property values, underground cable transmission systems have many advantages over overhead lines.

These considerations are best understood alongside the characteristics of transmission lines that traverse rural areas and interconnect regional grids.

They include:

- Longer Life Expectancy: Underground systems normally last much longer than overhead wiring.

- Reduced Maintenance Costs: Components of underground systems, not being exposed, require less maintenance.

- Service Uninterrupted by Storms: Underground systems are protected from ice storms, lightning, and high winds.

- Conserve Valuable Land: Land is a valuable resource, particularly in urban areas. Underground systems permit the construction of buildings and other structures over and around them.

- Reduced Fire Fighting Hazards: Fire departments are not hampered, or endangered, by poles and overhead wires, when erecting their fire-fighting apparatus.

- Prevention of Accidents: Dangers to persons from the accessibility of high-voltage power, or from poles becoming hazardous to vehicles, and from fallen poles and live wires, are eliminated.

- Advantages of Copper Cables: In underground power transmission systems, copper and its alloys play a very important role, due to their inherent unique mechanical and physical properties.

Achieving these benefits depends on correct installation, and industry guidance on the installation of conductors and cables outlines proven practices for trenching, splicing, and terminations.

Copper has the highest electrical conductivity of the commercial metals, except silver. The electrical conductivity of annealed copper at 20°C (68°F) is the standard to which all other metals and alloys are compared. It is arbitrarily established at 100% IACS (International Annealed Copper Standard) and corresponds to a resistance of 1.7241 microhm-cm. Another manner of stating the standard of resistance is 0.15328 ohm-gram/metre2, which is the ohmic resistance of a wire, 1 metre long, weighing 1 gram. In the fully annealed condition, modern high conductivity copper frequently has a conductivity of 101% IACS, or even 102%, but heavy cold working can reduce this to slightly below 100%.

The high electrical conductivity of copper is not the only reason for it being the preferred cable material. Equally as important are its accompanying properties, including strength, formability, ease of joining, resistance to creep, high thermal conductivity, and resistance to corrosion.

As with all other pure metals, the electrical conductivity varies with temperature. If a metal becomes overheated from inadvertent electrical overload, then its conductivity is reduced, which aggravates the temperature situation. Copper is well known for its excellent performance under such adverse circumstances.

To maintain performance under thermal and mechanical stress, robust cable handling and testing procedures verify integrity before commissioning and throughout service life.

In summary, the important advantages of copper installations are the low maintenance that may be anticipated, high performance and reliability.

Found in: Overhead and Underground T&D Handbook - Vol.1

Related Articles

Power Cable Diagnostics - Field Applications and Case Studies

Power cable diagnostics enables condition monitoring through partial discharge testing, VLF and tan delta analysis, insulation resistance measurements, and online fault location to improve reliability, asset health, and predictive maintenance decisions.

What Is Power Cable Diagnostics?

Testing and analysis of MV/HV cable insulation to detect defects, evaluate condition, and optimize maintenance.

✅ Methods: PD, VLF, tan delta, dielectric spectroscopy

✅ Detects insulation aging, water trees, joint/termination faults

✅ Enables risk-based maintenance and outage reduction

Power cable diagnostics are the most advanced ‘tool’ in the ‘toolbox’ of shielded power cable tests. One of the most common questions regarding cable testing tools is how the test will predict the remaining life of the cable. To be clear, a test that will predict remaining cable life does not exist. However, there are cable tests which can help fulfill testing requirements, dramatically improve reliability, and save the cable owner significant cable replacement costs. For a concise overview of modern practices, consult this power cable testing primer to frame the reliability and cost benefits discussed here.

Although standards have offered guidance, cable owners and test providers are largely on their own to determine the best cable test tool for the application. One of the foremost impediments to the decision making process is the lack of clear, credible information. This short paper attempts to provide objective guidance on how to best use the power cable testing toolbox. The paper then gives recommendations on which test is the most effective for different applications and supports this assertion with case studies. Broader context on measurement methods can be found in comprehensive electrical testing resources that help align procedures with emerging standards.

THE TOOLBOX(4)

There are 3 major categories of cable tests: high potential withstand, general condition assessment, and partial discharge (PD). Each of these tests serves a different application. By comparing the strengths and weaknesses of each type of test in practical field application, decision makers can quickly determine the test method best suited for their application. In the following section this paper lists the positive and negative attributes for each of the three categories in light of recently published IEEE standards and exclusive large scale field studies and comparison tests. Although these tests are fundamentally different and cannot be readily compared, some clear distinctions can be made on the basis of practical field application. Even installation details like using properly specified cable cleats can affect stress distribution and influence subsequent test readings.

HIGH POTENTIAL WITHSTAND (HIPOT)

The HIPOT withstand test is the simplest tool in the toolbox. The HIPOT withstand test can be divided by voltage source into three categories: Direct Voltage (DC), Very Low Frequency

(VLF), and Power Frequency. There are positive and negative attributes which pertain to all three types of voltage. Technicians often reference dielectric voltage withstand test criteria when setting HIPOT levels and acceptance thresholds. Documented cable handling and testing procedures also promote safe setup and consistent HIPOT execution.

GENERAL CONDITION ASSESSMENT (GCA)

General Condition Assessment is a term which includes a long list of cable diagnostic test methods and technologies, all of which determine the overall health of the cable insulation. These tests are one of the more sophisticated diagnostic tools in the cable testing toolbox. To name a few of these testing techniques,the following list is provided:

- Dissipation Factor/Tangent Delta/Power Factor

- 50/60 Hz

- 0.1Hz (VLF)

- Dielectric Spectroscopy (Time and Frequency Domain)

- Depolarization -Return Voltage (Recovery Voltage)

- Depolarization -Relaxation Current (Isothermal Relaxation Current)

- Leakage Current

- Total Harmonic Distortion

Each of the technologies has its own advantages and disadvantages which are beyond the scope of this paper. There are, however, generalizations which can be made so reasonable comparison to other cable testing techniques can be made. For material-specific insights, see assessment approaches for XLPE and PILC cables that inform how GCA data should be interpreted.

PARTIAL DISCHARGE DIAGNOSTIC TESTS

PD diagnostics are the most effective tool but also the most sophisticated tool in the cable testing toolbox. There are 3 types of PD diagnostics: on-line PD testing, on-line PD monitoring, and off-line PD testing. Continuous on-line PD monitoring technology for cables, although promising, requires further development to make it attractive. For this reason, this paper focuses on on-line and off-line PD testing. PD diagnostics are the only cable tests which can locate defects in shielded powercable. Coordinating cable diagnostics with power transformer health checks supports holistic grid asset management and outage risk reduction.

Found In: Wire and Cable Wiring Methods Handbook, Vol. 3

Related Articles

Copper Wire Theft

Copper wire theft disrupts electrical infrastructure, targeting utilities, substations, and grounding conductors, risking transformers, power outages, voltage instability, and arc-flash hazards; mitigation includes surveillance, tamper-resistant hardware, asset tracking, and rapid incident response.

What Is Copper Wire Theft?

Unauthorized removal of copper conductors from electrical systems, causing outages, safety risks, and costly repairs.

✅ Targets grounding, feeder, and control conductors at substations.

✅ Impacts reliability: faults, voltage drop, and nuisance tripping.

✅ Mitigation: CPTED, tamper-proof enclosures, fiber alarms, GPS tags.

DANGEROUS, EXPENSIVE, A THREAT TO RELIABILITY

Dangerous

Each and every year, thousands of copper wire thefts occur across North America that not only putting the safety of the thief at risk but emergency responders, utility workers, and local residents.

This ultimately results in power outages, increased costs to utilities that are ultimately passed on to taxpayers, injuries, and in some cases, even deaths.

Expensive

Copper wire theft costs the electricity sector are significant. Estimated by stealthmonitoring.com copper thefts have tripled within the last 5 years.

With copper pricing over $200US, the amount of copper stolen now exceeds $1 billion US annually.

Like all consumer-based sectors, these costs are eventually passed on to the tax payers through higher electricity bills.

The costs are even greater when the downstream impacts on other sectors, including telecommunications and construction, are considered. For additional context on infrastructure targeted by thieves, see underground copper transmission systems and the reliability risks they face.

Copper wire theft also threatens the reliability of the electricity system that the North American public and businesses count on every day. While power outages are inconvenient for families,

they can also jeopardize critical infrastructure, disrupting vital services such as emergency care in hospitals.

The CEA – the voice of electricity in Canada – has release its policy paper on copper wire theft

(SECOND EDITION RELEASED JANUARY 2015). The paper,

Copper Theft from Canada’s Electricity Infrastructure: Dangerous, Expensive and a Threat to Reliability,

highlights the serious impacts of copper theft and outlines four detailed recommendations to deter the theft of copper across the country.

Emerging trends show that renewable assets are not immune, as detailed in this analysis of wind turbine theft affecting remote installations.

Back in Sept. 15/2008 in an Intelligence Assessment prepared by the FBI Criminal Intelligence Section published Copper Thefts Threaten US Critical Infrastructure, https://www.fbi.gov/stats-services/publications/copper-thefts

For communities and responders seeking practical guidance, this overview of electricity safety consolidates best practices for hazard awareness and incident prevention.

About copper wire theft

A rise in scrap metal prices is making copper attractive to thieves. Utilities and contractors can also reduce losses by following rigorous cable handling and testing procedures that improve inventory control and traceability.

- Electric power substations, utility poles and vacant homes and businesses are all targets for thieves.

- Ground wires are routinely target by copper thieves.

Safety concern

Live energized Substations targeted by copper thieves are growing areas of concern, as high-voltage equipment should only be handled by trained professionals. Reinforcing workforce competence with up-to-date electrical safety training further mitigates the risk to personnel and the public.

During repairs and upgrades, identifying wiring that isn't OSHA certified helps prevent code violations and avoid unsafe conditions.

- Thieves often cut holes in fencing to enter a substation. This creates a potential hazard for not only the public, but specifically small animals who already cause problems in many outage situations by entering the substations.

- Electrical personnel who work in substations are a potential injury concern, as they could come into contact with ungrounded equipment.

- When ground wires are removed, usually part of the wire is left hanging. High winds often blow wires around and cause damage to equipment and cause power outages.

- Ultimately, the copper thieves are putting their own lives at risk.

Tips to Help Stop Copper Wire Theft.

- Common targets for copper wire theft are construction sites, farming equipment, and electric utility property. If you notice suspicious activity around one of these copper theft targets, notify authorities. Do not try to intervene yourself.

- If you are responsible for a construction site or farm, properly secure your property. If you have large quantities of copper, you may consider a tracking device that can help locate your copper if it is stolen.

- Store tools and wire cutters in a secure location, and never leave them out while away.

- Help spread the word about the dangers of copper theft.

- If you notice anything unusual with electric facilities, such as an open substation gate, open equipment, hanging wire, etc. contact your electric utility immediately.

- If you see anyone around electric substations or electric facilities other than utility personnel or contractors, call the police.

Facility managers can strengthen controls by adopting industrial electrical safety programs that align security measures with maintenance workflows.

Related Articles

Wire and Cable Media

Wire and Cable Articles From ET Magazine

FERC Complaint Targets Duke, PJM Transmission Planning

A coalition of large energy consumers and ratepayer advocates has filed a complaint with the Federal Energy Regulatory Commission (FERC), urging the agency to prohibit transmission owners from independently planning "local" transmission projects exceeding 100 kilovolts (kV). The coalition argues that such local planning, lacking independent oversight, leads to inefficient and costly transmission development, resulting in unjust and unreasonable rates for consumers.

Background

Transmission planning involves determining the necessary infrastructure to transport electricity from generation sources to consumers. In the United States, this planning is typically conducted by transmission owners, which are often investor-owned utilities. These entities are responsible for identifying and implementing transmission projects to meet local reliability needs. However, the coalition contends that this approach can result in projects that are not cost-effective and may not represent the most efficient solutions for consumers.

The Complaint

The coalition's complaint highlights several concerns:

-

Lack of Independent Review: Local transmission projects often undergo minimal independent scrutiny, leading to potential inefficiencies and higher costs.

-

Incentives for Overinvestment: Transmission owners may be motivated to invest in local projects due to the absence of competitive bidding and the limited review provided by FERC's formula rate process.

-

Regional Planning Deficiencies: The current regulatory framework allows local planning exceptions to override regional planning rules, hindering the development of more efficient regional solutions.

The coalition proposes that FERC mandate regional planning conducted by an independent transmission system planner to ensure that transmission projects are both appropriate and beneficial to consumers. They suggest that regional transmission organizations and independent system operators could serve as independent transmission planners if they meet specific criteria.

Industry Response

Larry Gasteiger, executive director of WIRES—a transmission sector advocacy group—expressed concerns about the potential impact of the complaint. He stated that the complaint could burden FERC and all transmission developers with unnecessary and inefficient new processes, diverting resources from ongoing regional transmission planning and compliance with existing FERC orders.

Regulatory Context

This complaint follows recent developments in transmission planning and oversight:

-

FERC's Order 1920-A: In November 2024, FERC revised its Order 1920 on transmission planning and cost allocation to grant state utility regulators a larger role in the decision-making process. The revised rule requires transmission providers to include state input on the development of future scenarios used in long-term regional transmission planning.

-

FERC's Rejection of PJM's Proposal: In December 2024, FERC rejected proposals that would have given PJM Interconnection transmission owners more control over the grid operator’s transmission planning process. The commission expressed concerns about the potential for undue influence by a single stakeholder group, specifically the PJM transmission owners, over transmission planning and expansion.

Implications

The coalition's complaint underscores ongoing debates about the effectiveness and fairness of transmission planning processes. Proponents of independent planning argue that it can lead to more efficient and cost-effective transmission solutions, ultimately benefiting consumers. Opponents, however, caution that such changes could introduce new complexities and delays into the transmission development process.

As FERC reviews the complaint, stakeholders across the energy sector will be closely monitoring the potential implications for transmission planning and the broader regulatory landscape.

FERC Approves Interconnection for Talen Energy, Amazon Data Center

In a significant move that underscores the growing demand for reliable and sustainable energy to power the expanding digital infrastructure, the Federal Energy Regulatory Commission (FERC) has approved an interconnection agreement between Talen Energy, Amazon Web Services (AWS), and Exelon. This agreement allows for the integration of new energy generation sources to supply a large-scale Amazon data center facility at the Susquehanna nuclear plant in Pennsylvania.

The Growing Need for Data Centers and Renewable Energy

The intersection of energy infrastructure and the rapid growth of data centers is becoming an increasingly important focus for regulators and energy providers. As industries become more reliant on cloud computing, the demand for energy-intensive data centers is surging. These centers host vast amounts of data, supporting services ranging from e-commerce to artificial intelligence, and require substantial electricity to maintain operations around the clock.

AWS, Amazon’s cloud computing division, has emerged as one of the largest consumers of energy in the world, necessitating sustainable energy solutions to meet its ambitious carbon-neutral goals. Talen Energy, an energy company with a mix of traditional and renewable energy assets, is uniquely positioned to help meet this demand. By leveraging the power of its Susquehanna nuclear facility and expanding its generation capacity, Talen aims to ensure a stable, low-carbon energy supply to support these critical infrastructure needs.

Key Elements of the Interconnection Agreement

The interconnection agreement approved by FERC is a crucial component of this effort. It enables Talen Energy to work with Exelon, the operator of the Susquehanna plant, to develop the infrastructure needed to connect new generation resources to the regional power grid. As part of this agreement, Talen will increase the capacity of its existing facilities, including the addition of a battery storage system and the integration of renewable energy sources, which will help meet the energy demands of the AWS data center.

One of the central aspects of the agreement is its focus on ensuring grid reliability and efficient energy distribution. Talen has committed to building out the necessary transmission lines and substations to handle the additional load from the Amazon data center. This infrastructure development is critical not only for meeting the energy needs of Amazon’s facility but also for improving the overall resilience of the grid in the face of growing electricity demands across the region.

Additionally, the project includes provisions for grid modernization, which will enhance the capacity of the power grid to accommodate renewable energy sources and support future electrification efforts in the region. This forward-looking approach aligns with the broader goals of increasing energy efficiency and reducing reliance on fossil fuels, all while meeting the ever-growing demand for cloud computing services.

Impact on Renewable Energy and Sustainability

The agreement represents a significant step forward in the push for renewable energy integration in the U.S. power grid. By incorporating a mix of traditional nuclear power and renewable energy generation, the project stands to reduce the carbon footprint of the data center industry. Amazon has long committed to using 100% renewable energy to power its global operations, and this partnership with Talen Energy is a key element of its strategy to achieve that goal.

The inclusion of battery storage technology also demonstrates a commitment to enhancing grid flexibility and resilience, which are essential as more intermittent renewable energy sources like wind and solar are integrated into the system. Battery storage allows for the balancing of supply and demand, ensuring that power is available even when renewable generation is low or during peak demand periods.

Challenges and Future Implications

While the approval of this interconnection agreement is a major victory for all parties involved, it also highlights the challenges of coordinating large-scale energy projects in the context of increasing demand for power and sustainability goals. The integration of new energy generation sources and the required infrastructure upgrades are complex and costly, and the regulatory process can be lengthy.

Looking ahead, the success of this project could set a precedent for other companies and utilities looking to meet the growing energy demands of the digital economy while adhering to sustainability goals. As the world continues to digitize and the demand for data centers increases, the need for innovative energy solutions will become even more critical.

In conclusion, FERC’s approval of the interconnection agreement between Talen Energy, AWS, and Exelon represents an important step in the integration of renewable energy, nuclear power, and data center infrastructure. It showcases the potential for collaboration between energy providers and tech giants to create sustainable solutions that can power the future of the digital economy while addressing climate change.

FirstEnergy Explores Alternatives to PJM Capacity Market

In a strategic move aimed at enhancing its power supply reliability, FirstEnergy is actively exploring alternatives to the PJM capacity market. This development reflects the company’s proactive approach to addressing challenges within the existing market structure and ensuring a more robust and resilient energy supply for its customers.

Understanding the PJM Capacity Market

The PJM capacity market, administered by PJM Interconnection, is a critical component of the region’s electricity market, which spans parts of the eastern United States. This market is designed to ensure that there is sufficient power generation capacity available to meet future electricity demand. Utilities and power generators participate in the capacity market by offering to provide electricity or reserve capacity during peak demand periods.

Under this system, companies like FirstEnergy commit to having adequate power resources available when needed, receiving compensation for this readiness. While the PJM capacity market has been instrumental in maintaining grid reliability and encouraging investment in new generation resources, it has faced criticism and challenges over the years, including concerns about its effectiveness in supporting new investments and adapting to changing market conditions.

FirstEnergy’s Strategic Shift

FirstEnergy, a major electric utility serving millions of customers across the Midwest and Mid-Atlantic regions, has been evaluating the effectiveness of the PJM capacity market in meeting its needs. The company has raised concerns that the current market structure may not fully address its challenges related to power supply reliability and investment in new resources.

In response, FirstEnergy is seeking alternatives to the PJM capacity market that could better align with its operational goals and the evolving dynamics of the energy sector. These alternatives could include new market mechanisms, partnerships, or regulatory approaches designed to enhance grid reliability and ensure a stable power supply.

Key Motivations Behind the Move

Several factors are driving FirstEnergy’s exploration of alternatives to the PJM capacity market:

-

Reliability and Resilience: FirstEnergy aims to bolster its ability to provide a reliable and resilient power supply. With increasing instances of extreme weather events and other disruptions, the company seeks solutions that enhance its ability to respond to and recover from potential outages.

-

Investment in New Resources: The existing capacity market structure may not provide adequate incentives for investment in new generation resources or upgrades to existing infrastructure. By exploring alternatives, FirstEnergy hopes to create a more favorable environment for attracting new investments in energy technology and infrastructure.

-

Market Adaptability: The energy sector is undergoing significant transformation with the rise of renewable energy sources and evolving regulatory requirements. FirstEnergy’s evaluation of alternative market structures is aimed at ensuring that its power supply strategies are adaptable to these changes.

-

Cost Efficiency: The company is also focused on identifying market mechanisms that offer better cost efficiency. Alternatives to the PJM capacity market may provide more cost-effective solutions for maintaining grid reliability while minimizing the financial burden on consumers.

Potential Alternatives and Their Implications

Several alternative approaches to the PJM capacity market could be considered by FirstEnergy:

-

Custom Capacity Agreements: FirstEnergy could explore the feasibility of custom capacity agreements that are tailored to its specific needs and operational requirements. These agreements could offer more flexibility and alignment with the company’s power supply goals.

-

Integrated Resource Planning: Adopting an integrated resource planning approach could allow FirstEnergy to better coordinate its investments in generation, transmission, and demand response resources. This approach could enhance overall system efficiency and reliability.

-

Regional Collaborations: Collaborating with other utilities or regional stakeholders to develop new market structures or joint investment initiatives could offer opportunities for shared resources and enhanced grid reliability.

-

Regulatory Advocacy: Engaging with regulators and policymakers to advocate for changes in market design or new policy frameworks could help shape a more effective and supportive market environment for power supply.

Looking Ahead

As FirstEnergy continues to explore alternatives to the PJM capacity market, the company’s efforts will be closely watched by industry stakeholders, regulators, and customers. The outcome of this exploration could have broader implications for the regional electricity market and influence future discussions on market design and grid reliability.

In summary, FirstEnergy’s move to seek alternatives to the PJM capacity market reflects a strategic effort to address evolving challenges in power supply reliability and investment. By evaluating new market mechanisms and exploring innovative solutions, the company aims to strengthen its ability to provide dependable electricity while adapting to the dynamic landscape of the energy sector.

Cable Cleats Testing - Crucial to Cable Management

Essentially, cable cleats are devices designed to secure cables and to ensure the retention and support of them, reducing the load that the cable may be exposed to under its own weight. They are also designed to contain the cables under fault conditions, protecting the cables and the cable management system from damage.

The first European cable cleat standard, EN 50368, highlighted the retention and support that cable cleats provided to cables. Most importantly, the standard highlighted the protection of the cable management system and the potential risk to human life that could occur without the use of cable cleats.

It was not until 2003, with the release of standard EN 50368 that any formal standard for cable cleats existed. Prior to this, both cable and cable cleat manufacturers provided their own testing to their own standards for many years all over the world. This standard was then followed up with the publication of IEC 61914:2009, which further focused on the importance of cable cleat products and correct cable cleating. It set the standardized method for testing and certification of cable cleats, to prove they can withstand one or more short circuit tests. IEC 61914:2009: “6.4.3 resistant to electromechanical forces, withstanding one short circuit, 6.4.4 resistant to electromechanical forces, withstanding more than one short circuit.”

The crucial problem causing cable cleats being overlooked is that, at the moment, the implemented standards are advisory. Therefore, at times of cost cutting on cable management systems, reputable cable cleats are compromised for cheaper, lower quality versions, which aren’t certified to these standards.

Read full article in the Electrical Reliability Systems Special Edition 2022

Sign Up for Electricity Forum’s Wire and Cable Newsletter

Stay informed with our FREE Wire and Cable Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue