Industrial Electrical Power

What is an arc flash boundary?

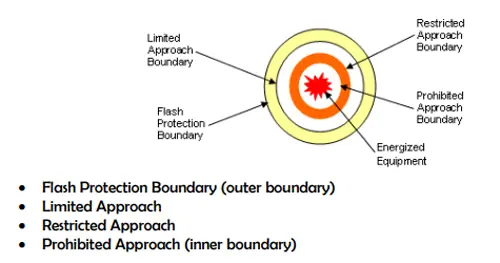

What is an arc flash boundary? It is the NFPA 70E-defined safe working distance where incident energy reaches 1.2 cal/cm², dictating PPE selection, approach limits, arc flash labeling, and electrical safety procedures for energized equipment.

What Is an Arc Flash Boundary?

The arc flash boundary is the NFPA 70E distance where 1.2 cal/cm² incident energy requires PPE and controls.

✅ Defined by NFPA 70E based on incident energy analysis

✅ Requires PPE, signage, and energized work permits inside boundary

✅ Adjusted by fault current, clearing time, and working distance

The term arc flash boundary may sound like technical jargon, but its meaning and evolution have been crucial in shaping modern electrical safety practices. While it’s now a defined safety zone in NFPA 70E and CSA Z462, its origins and significance have a deeper story rooted in the effort to prevent catastrophic workplace injuries. For a plain-language primer on concepts and terminology, the Arc Flash Boundary overview outlines definitions, history, and key safety implications.

Historical Development of the Term

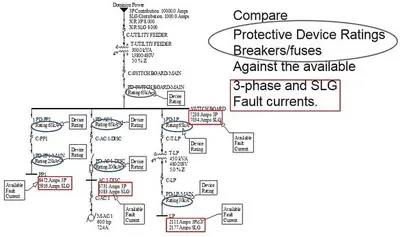

Before the adoption of NFPA 70E, the concept of arc flash hazards received little formal recognition in workplace safety programs. Electrical safety focused primarily on shock hazards, with boundaries defined only in terms of approach distances to energized conductors. To understand how both thermal and shock boundaries are set, see the guide to determining arc flash and electric shock protection boundaries for methodology and examples.

That began to change in the 1990s, as awareness grew around the dangers of arc flash — high-energy explosions caused by electrical faults. Researchers, particularly those involved in IEEE 1584, helped quantify the risks and the amount of incident energy workers could be exposed to during such events. For engineers performing studies, the arc flash boundary calculation resource details equations, assumptions, and data inputs.

With the 2000 publication of NFPA 70E, the arc flash boundary was formally introduced as a critical protection zone — defined as the distance at which a worker could receive 1.2 cal/cm² of incident energy, the threshold for a second-degree burn. In 2015 and later updates, this definition was refined, and emphasis shifted from rigid tables to calculated boundaries based on incident energy analysis, incorporating real-world equipment and system data. When quick lookups are needed, the incident energy boundary table can help verify results and inform PPE selection.

CSA Z462, Canada's parallel standard, adopted similar language and principles, aligning the term across North America and reinforcing its use in both industrial and commercial environments. This alignment also clarifies distinctions from the Limited Approach Boundary, which addresses shock hazards under separate criteria.

Why Does It Matter?

For electrical workers, knowing where the arc flash boundary lies is not theoretical — it’s life-saving. This boundary determines when and where personal protective equipment (PPE) is required and defines safe work distances. It shapes:

-

Job planning and risk assessment

-

The selection of arc-rated clothing and equipment

-

Decisions about energized vs de-energized work

-

Signage, labeling, and physical barriers in the field

In day-to-day tasks like opening panels or performing diagnostics, the arc flash boundary informs whether a worker must don a full arc-rated suit or can proceed with minimal PPE. It also supports supervisors and safety coordinators in enforcing compliant work procedures. For field implementation, the guidance on marking off arc flash boundaries covers labeling, barricades, and temporary controls.

In short, it translates complex hazard calculations into clear, actionable field instructions that protect lives.

Common Misconceptions About Arc Flash Boundaries

Despite its widespread use, the term still carries confusion. Here are a few common misconceptions:

-

“It’s the same as the Limited Approach Boundary.”

False. The Limited Approach Boundary addresses shock hazards. The Arc Flash Boundary relates specifically to thermal energy exposure. -

“All arc flash boundaries are 18 inches.”

Not true. While 18 inches is a common working distance for calculating incident energy, arc flash boundaries vary depending on system voltage, fault current, clearing time, and equipment condition. Practitioners often consult the arc flash boundary chart to visualize how these variables shift distance across equipment types. -

“If I’m outside the arc flash boundary, I don’t need to worry.”

That’s misleading. While PPE may not be required beyond the boundary, awareness and training are still critical. Arc blast pressure, flying debris, and indirect injuries remain possible. -

“Once labeled, a boundary never changes.”

Incorrect. Labels must be updated after system changes, new hazard analyses, or NFPA/CSA standard updates. Assumptions based on outdated data can be dangerous.

The arc flash boundary is more than a technical term — it is a dynamic tool born out of decades of research and tragedy. Its importance continues to grow as electrical systems evolve and safety regulations adapt. By understanding where it came from, what it means, and how to apply it, we can bridge the gap between compliance and true workplace safety.

Would you like a new meta title and description for this updated version?

Visit our Arc Flash Boundary main page for more detailed information on calculating boundaries, protection zones, compliance requirements, and real-world application examples.

Related Articles

Test Your Knowledge About Generators/UPS!

Think you know Generators/UPS? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Latest IEP Content

Electrical Safety Regulations Examined

Electrical safety regulation sets standards and codes for compliance, risk assessment, grounding, arc-flash protection, PPE, lockout-tagout, and inspection, ensuring safe design, installation, operation, and maintenance in electrical engineering through hazard analysis and periodic testing.

What Is Electrical Safety Regulation?

A framework of standards, codes, and practices reducing hazards for safe design and operation.

✅ Defines compliance with NEC, IEC, OSHA, and local electrical codes.

✅ Mandates risk assessment, arc-flash labeling, and PPE selection.

✅ Requires grounding, bonding, protective devices, and lockout-tagout.

Electrical safety regulations are governed by all three levels of government—federal, state/provincial and municipal governments. They set regulations, laws and acts that relate to electrical health and safety and other work-related practices. These electrical safety regulations are founded using the U.S. National Electrical Code and the Canadian Standard Association's Canadian Electrical Code Part 1 (CEC) as a model for regulation. (There are Ontario amendments). In Ontario, compliance guidance is further detailed in the Ontario Electrical Safety Code for jurisdiction-specific practices and inspections.

The National Electrical Code (NEC) is a standard that has been developed by the National Fire Protection Association (NFPA)'s Committee on the National Electrical Code. This committee is comprised of 19 code-making panels, as well as a national ttechnical correlating committee to coordinate between the panels. The NEC is approved as an American national standard by the American National Standards Institute (ANSI). It is formally identified as ANSI/NFPA 70. In federal contexts, OSHA interpretations clarify that OSHA’s electrical standards are based on NFPA 70 and related consensus codes when assessing employer programs and abatement methods.

The Canadian Electrical Code serves as the basis for wiring regulations across Canada. Generally, provincial legislation adopts the CEC by reference, sometimes with provincial changes or amendments that tailor the CEC for local conditions. These amendments may be administrative in nature or may consist of technical content particular to the region. Since the Code is a copyrighted document produced by a private body, it may not be distributed without copyright permission from the CSA group. To support compliant implementation, many organizations distill code obligations into electrical safety manuals that inform training, procedures, and documentation.

Technical requirements of the Canadian Electrical Code are very similar to those of the US National Electrical Code. Specific differences, however, persist and many installations acceptable under one Code may not comply with the other Code. Harmonization of technical requirements between the two Codes is ongoing. For designers and owners, verifying applicable electrical safety requirements early in the project lifecycle helps avoid rework and inspection delays.

Several CEC Part II electrical equipment standards have been harmonized with standards in the USA and Mexico through CANENA, The Council for the Harmonization of Electromechanical Standards of the Nations of the Americas (CANENA) is working to harmonize electrical codes in the western hemisphere.

The technical detail inside the Canadian Electrical Code contains similarities to the National Electrical Code, the electrical safety regulation model used in the United States. The two codes clash on certain technical requirements and installations, however, the correlation of the two codes on meeting a universal set of electrical safety standards is ongoing.

The CEC is divided into four parts. Part I gives electrical safety regulation on electrical maintenance and installation. Part II gives design and construction specifications for electrical equipment. Part III is the electrical safety regulation for transmission and distribution systems. Part IV sets standards for certain institutional and industrial installations, which is not covered in this article. For specialized occupancies, guidance on patient-care spaces is complemented by resources on hospital electrical safety to address risk controls and maintenance practices.

NFPA70e

NFPA 70e establishes the best arc flash practice standards on how to protect electrical workers from arc flash exposure and resulting potential injury and possible death. OSHA has referenced NFPA 70e in a number of cases. Many organizations have now designed an NFPA 70E safety program to help protect their electrical personnel . The 2021 edition is summarized in this overview of NFPA 70E 2021 updates that affect arc-flash risk assessment, PPE, and procedures.

CSA Z462

CSA Z462 is on of the Canadian electrical safety regulations from the Canadian Standards Association that govern workplace electrical safety. CSA Z462 is a "Canadianized" version of the U.S. National Fire Protection Association (NFPA) standard NFPA 70E, Standard for Electrical Safety in the workplace. CSA Z462 was initially developed in conjuntion with the NFPA 70e edition. Attempts have been made to harmonize CSA Z462 with NFPA 70e wherever practical, specifically for Canadian workplaces. CSA Z462 is the worplace electrical standard that deals with strictly electrical safety requirements for employees who perform electrical work such as electrical installation. For Canadian workplaces, a practical synopsis of CSA Z462 requirements can help align hazard assessments, labeling, and energized work permits.

Related Articles

What is a Synchronous Motor? Explained

A synchronous motor is an AC motor that rotates at a constant speed, matching the frequency of the AC power supply. Its rotor locks in step with the stator’s rotating magnetic field, delivering constant speed, high efficiency, and power factor correction.

What is a Synchronous Motor?

A synchronous motor is a type of AC device that operates at a constant speed, which is directly proportional to the frequency of the AC phase supply and the number of poles in the device. Unlike induction motors, which run with slip, synchronous motors maintain perfect synchronism between the rotor and stator fields. To fully understand the role of synchronous motors, it is helpful to explore the basics of electric motors and drives, as well as their function in modern electrical systems.

A synchronous machine is more than just a fixed-speed device. In industrial environments where precision is crucial, this fixed-speed device ensures equipment operates reliably without the slip often seen in induction types. Because it locks exactly with the rotating magnetic field, it is especially valuable in applications requiring accurate timing and consistency, such as compressors, pumps, and high-precision tools.

Another important feature is its ability to act as a power factor correction unit within an electrical system. By operating at either unity power factor or leading power factor, it offsets lagging loads and improves overall system efficiency. Proper rotor and stator alignment is essential in achieving these benefits, since any misalignment can compromise performance. This balance of efficiency, stability, and system support explains why synchronous machines remain a vital choice for engineers seeking both energy savings and grid reliability.

How Does a Synchronous Motor Work?

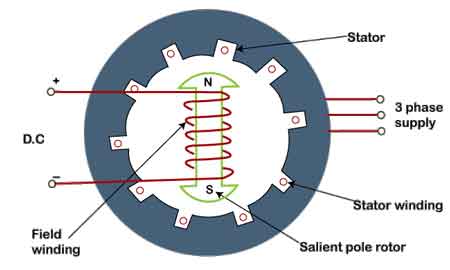

To understand the principle of operation, one must know the roles of the stator and rotor.

-

Stator: The stationary part of the device, consisting of windings that produce a rotating magnetic field when connected to an AC supply.

-

Rotor: The rotating part, which may contain wound field windings or permanent magnets.

When the rotor poles align with the stator’s magnetic field, torque is produced, driving the mechanical load at constant speed. The fundamentals of electric motor design directly influence the construction of synchronous motors and their ability to maintain constant speed.

Advantages of Synchronous Motors

Synchronous motors are widely chosen for their performance benefits:

-

Constant speed operation, regardless of load changes

-

High efficiency and lower energy losses

-

Ability to operate at unity or leading power factor, correcting system lag

Improving electric motor efficiency is often a key reason why engineers choose synchronous motors in industrial applications.

Disadvantages of Synchronous Motors

Despite their advantages, they have some drawbacks:

-

Not self-starting; requires an external starter or VFD

-

More complex construction compared to induction machines

-

Higher initial cost and additional components are needed for starting

How Do Synchronous Motors Differ from Induction Motors?

While both are AC machines, key differences exist:

-

Rotor construction: Synchronous motors utilize wound fields or permanent magnets, while induction motors typically employ squirrel-cage rotors.

-

Starting: Synchronous motors are not self-starting, while induction fixed-speed devices start on their own.

-

Power factor: Synchronous motors can operate at unity or leading power factor, thereby improving efficiency; in contrast, induction devices typically run at a lagging power factor. Comparing synchronous motors with other types, such as the induction motor, highlights their unique ability to maintain exact synchronism with the power supply.

Since many synchronous motors are started or controlled with variable-frequency drives (VFDs), it is essential to understand how a VFD works and its impact on performance.

Applications of Synchronous Motors

Synchronous motors are used wherever constant speed, precision, and efficiency are required:

-

Compressors, pumps, and fans for constant-speed drives

-

Machine tools and robotics for high precision

-

Power plants, where they operate as synchronous motors

-

Industrial settings that benefit from power factor correction

Speed Control of Synchronous Motors

Synchronous Motor speed control can be achieved in two primary ways:

-

Frequency adjustment: Changing the supply frequency alters the constant speed.

-

Pole variation: Adjusting the number of poles in the stator.

Modern systems typically utilize variable frequency drives (VFDs), which provide smooth and efficient speed control by varying the input frequency. Learning how electric motor control works provides context for how synchronous motors achieve precise operation compared to other types.

Contribution to Power Factor Correction

Synchronous motors are valuable in power systems because they can operate at unity or leading power factor. This allows them to offset lagging power factors caused by other loads, lowering energy costs and improving system efficiency.

Frequently Asked Questions

Can a synchronous motor operate without a VFD?

Yes, but they require other starting methods, such as pony devices or damper windings, since they are not self-starting.

Why are they important in robotics?

Their precise, constant-speed operation and ability to maintain synchronism make them ideal for robotics and automation applications requiring accuracy.

Can a synchronous machine generate electricity?

Yes, when driven mechanically, synchronous motors can function as constant-speed generators, converting mechanical energy into electrical energy.

What limits the starting of synchronous motors?

They cannot develop starting torque on their own, which limits direct-on-line starting. This is why auxiliary devices, VFDs, or other methods are used.

Are synchronous machines used in renewable energy?

Yes, constant-speed generators are widely used in hydroelectric and wind power plants, where stable frequency and power factor control are critical.

For a more detailed guide covering design, performance curves, standards, and industrial applications, see our in-depth resource on synchronous motors.

Who's Responsible for Protecting You from Arc Flashes?

Who is responsible for protecting you from arc flashes? Employers, safety managers, and qualified persons under OSHA and NFPA 70E ensure hazard analysis, arc-rated PPE, training, and lockout/tagout through an electrical safety program.

Who Is Responsible for Protecting You from Arc Flashes?

Employers and qualified persons, under OSHA/NFPA 70E, assess hazards, train workers, and provide arc-rated PPE.

✅ Employer implements electrical safety program, training, and procedures.

✅ Qualified person performs arc flash risk assessment and labeling.

✅ Provide arc-rated PPE, boundaries, and LOTO per OSHA/NFPA 70E.

Understanding Responsibilities in Arc Flash Protection

Arc flash hazards pose significant risks to those working in areas with exposed energized parts. Protecting individuals from these dangers involves a comprehensive approach, including proper training, the use of personal protective equipment (PPE), and adherence to safety regulations. But who is ultimately responsible for ensuring safety from arc flash incidents? For context, an arc flash hazard involves extreme heat, pressure, and light that can injure workers.

Responsibility for Arc Flash Protection

The primary responsibility for protecting workers from electric arc flash hazards lies with the employer. Employers must implement safety-related work practices, provide necessary PPE, and ensure compliance with safety standards such as the NFPA 70E and OSHA standards. The Occupational Safety and Health Administration (OSHA) enforces regulations under 29 CFR, which mandates that employers protect employees from electrical hazards, including arc flashes. Detailed interpretations of OSHA arc flash requirements can guide policy development and training updates.

Employers are also responsible for conducting an arc flash hazard analysis to identify potential risks and determine the appropriate protective measures. This includes evaluating incident energy levels and establishing safety protocols, such as lockout/tagout procedures and electrical safe work practices. Understanding the levels of protection helps match PPE categories to anticipated incident energy.

Performing Arc Flash Calculations

Arc flash calculations are essential for determining the incident energy levels at different points within an electrical system. These calculations are typically performed by qualified electrical engineers or safety professionals who have the expertise to analyze electrical systems and assess the associated risks. Employers must ensure that these calculations are accurate and up-to-date, as they form the basis for selecting appropriate PPE and defining safe working boundaries. The latest NFPA 70E arc flash requirements outline methods and boundaries that inform these calculations.

Protecting Yourself from Arc Flash

Individuals working in areas with potential arc flash hazards can protect themselves by following established safety protocols and wearing appropriate PPE. Key steps include:

-

Understanding and Following Safety Procedures: Adhering to safety-related work practices outlined in NFPA 70E and employer-specific protocols is crucial. This includes proper lockout/tagout procedures to de-energize equipment before performing maintenance or repairs. Clarifying who needs arc flash training helps employers prioritize roles and scheduling.

-

Wearing Appropriate PPE: Using arc-rated clothing and gear is essential to reduce the risk of injury. PPE must be selected based on the incident energy level identified during the arc flash hazard analysis. For a broader perspective on selecting and using safeguards, a primer on arc flash protection ties PPE choices to system hazards.

-

Maintaining Safe Working Distances: Keeping a safe distance from exposed energized parts and working within the defined arc flash boundary can significantly reduce the risk of injury.

OSHA Rules for Arc Flash Protection

OSHA enforces several standards to protect workers from electrical hazards, including arc flashes. Under 29 CFR, employers must implement measures to protect employees from electrical hazards. Specific rules related to arc flash protection include:

- Conducting a Hazard Analysis: Employers must perform an arc flash hazard analysis to identify potential risks and determine protective measures.

- Providing PPE: Employers are required to provide appropriate PPE to employees working in areas with potential arc flash hazards.

- Training and Awareness: Employers must ensure that employees are trained in electrical safe work practices and the proper use of PPE.

- Implementing Safety Programs: Employers must develop and enforce comprehensive electrical safety programs, including lockout/tagout procedures and regular equipment maintenance.

Protecting workers from arc flash hazards involves a collaborative effort between employers, safety professionals, and employees. Employers bear the primary responsibility for ensuring safety through hazard analysis, implementation of safety practices, and provision of PPE. Qualified professionals must perform accurate arc flash calculations to inform safety measures. Employees, in turn, must follow established safety protocols and wear protective gear to mitigate risks.

By adhering to OSHA standards and the guidelines set forth in NFPA 70E, workplaces can significantly reduce the dangers associated with electric arc flashes. This comprehensive approach ensures that everyone involved is equipped with the knowledge and tools needed to maintain a safe working environment. For broader context on regulatory oversight, understanding what organizations enforce arc flash standards clarifies how federal, state, and consensus bodies coordinate responsibilities.

4o

Related Articles

EMT Electrical Conduit

EMT electrical conduit, also called thin-wall conduit, is a lightweight metal tubing used to protect and route electrical wiring. Made from galvanized steel or aluminum, EMT conduit offers durability, easy bending, and cost-effective installation for residential, commercial, and industrial applications.

What is EMT Electrical Conduit?

EMT electrical conduit, also known as electrical metallic tubing, is a popular choice for protecting and routing wiring in residential, commercial, and industrial wiring projects. It is:

✅ Lightweight, thin-wall metal tubing made from steel or aluminum

✅ Protects and routes electrical wiring in buildings

✅ Easy to bend, cut, and install for versatile applications

Known for its lightweight, cost-effective design, EMT is often referred to as thin-wall tubing due to its slimmer structure compared to rigid alternatives. Its galvanized steel construction provides corrosion-resistant properties, making it suitable for a variety of environments, including both indoor and outdoor wiring installations. The lightweight design makes it easier to handle during installation, while the galvanized steel helps protect the wiring inside. While commonly used in dry locations, it can also be applied in wet locations with the appropriate fittings, such as compression couplings, to ensure a watertight seal. EMT’s ability to be installed in both exposed and concealed locations adds to its versatility. This article will explore its advantages, compare it to other tubing options, and discuss when it’s best to use.

Frequently Asked Questions

What are the advantages and disadvantages of using EMT electrical conduit?

One of the major advantages of EMT is its easy installation and versatility. Being lightweight, it’s easier to handle and can be bent with standard tools, making it suitable for a range of applications, from residential to industrial wiring. Additionally, EMT is cost-effective, fire-resistant, and non-magnetic, making it a safe and durable choice for many environments. However, it is not as strong as rigid alternatives, which makes it more prone to damage in environments where physical impact is likely. Therefore, it’s not recommended for hazardous locations or areas where heavy wear and tear are expected.

How does EMT compare to other types of EMT conduit?

Compared to rigid metal options, EMT is much more flexible and easier to install. While rigid types offer more durability, they require specialized tools and techniques, making installation more labour-intensive. EMT, on the other hand, is more cost-effective, as it requires fewer specialized tools, which helps reduce overall project costs. While rigid tubing might be preferred for heavy-duty applications, EMT works well for general-purpose commercial and residential wiring. In wet locations, PVC conduits are often preferred, but EMT can be used with the proper watertight fittings.

Is EMT electrical conduit suitable for outdoor use?

Yes, EMT can be used for outdoor wiring if installed with appropriate weatherproof fittings that ensure a watertight seal. While primarily used for indoor wiring, its corrosion-resistant properties allow it to be safely used outdoors in exposed locations. To ensure long-term performance in wet locations, it’s important to install EMT with weatherproof connectors, clamps, and straps. Always follow NEC guidelines for compliant installation.

How do I bend EMT conduit, and what tools are needed?

Bending EMT is relatively simple due to its flexibility. A standard bender can be used to create precise angles, allowing the tubing to navigate around obstacles or fit into tight spaces. When bending EMT, it’s important to ensure the bend doesn’t deform the tubing, as this can damage the wiring inside. Once the bends are made, set-screw or compression couplings are used to securely connect the sections.

EMT is a versatile, cost-effective, and corrosion-resistant option for a variety of installations, from residential to industrial wiring projects. Its lightweight and easy-to-bend properties make it ideal for both exposed and concealed locations. While it may not be as strong as rigid tubing, the balance of advantages makes it a suitable option for many indoor and outdoor wiring applications. By following proper installation techniques and using the right fittings, EMT can provide a durable, long-lasting solution that meets safety standards.

Related Articles

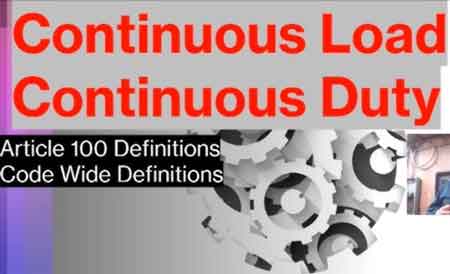

Continuous Load Explained

Continuous load refers to an electrical load expected to run for three hours or more. It requires special consideration in circuit design to prevent overheating and ensure safe, efficient operation.

What is Continuous Load?

Continuous load refers to electrical systems or circuits that are expected to operate at their maximum current for at least three hours, such as lighting, HVAC, and industrial equipment.

✅ Requires derated circuit capacity for safety and code compliance

✅ Affects wire sizing, breaker rating, and load calculation

✅ Defined in NEC for proper electrical system design

Electric Motor Testing Training

Request a Free Training Quotation

In practical terms, a continuous load refers to consistently managing current levels to prevent overloading or overheating, which can damage components and create hazards. Electrical professionals must understand continuous load requirements because they directly affect how they size conductors, choose circuit breakers, and comply with safety codes. By accurately calculating and designing for long-duration loads, electricians can ensure safer, more efficient installations that meet industry standards and prevent costly equipment failures. Understanding electric motor control is essential when designing circuits for constant loads, as precise regulation helps prevent overheating and equipment failure.

Defining Continuous Load

Continuous load, in electrical terms, refers to a situation where the maximum current is expected to remain constant for a minimum of three hours. This definition, specified in various electrical codes, is integral to the design and protection of circuits. For example, according to NEC 210.20(A), circuits that supply these types of loads must be rated to handle at least 125% of the maximum current. This “125 of the continuous” rule is essential to prevent overheating and ensure the durability of electrical systems. In systems running continuously, like HVAC or industrial motors, electric motor protection ensures safe operation by detecting excessive current draw over time.

Key Considerations for Continuous Load Applications

| Aspect | Explanation | Related Code/Standard |

|---|---|---|

| Definition | Load expected to run at maximum current for 3+ hours | NEC 210.20(A) |

| Conductor Sizing Rule | Must be sized to carry 125% of continuous load current | NEC 210.19(A) |

| Breaker Rating Rule | Circuit breakers must also handle 125% of continuous load | NEC 210.20(A) |

| Examples of Applications | HVAC, lighting, industrial machinery, heating systems | Industry-standard usage |

| Derating Practice | Breakers rated for 80% operation must not exceed 80% of ampacity in continuous load scenarios | NEC guidelines and UL 489 |

| Design Implications | Affects wire gauge, breaker selection, and enclosure temperature ratings | NEC, manufacturer specs |

| Common Synonyms | Sustained load, constant load, steady-state load | Used interchangeably in field |

Importance in Circuit Design

Electrical professionals must account for both consistent and non-consistent demands when designing circuits. Branch circuits, for instance, must manage the highest expected current without exceeding the ampacity of the conductors. For sustained load situations, conductor sizing is critical. This calculation involves adding 125% of the demand, ensuring the branch circuit can safely manage all possible conditions. This approach safeguards against conditions where the load is "expected to continue" at high levels for extended periods.

Code Requirements and Safety Standards

Adherence to code requirements, such as those found in NEC 210.19(A), is necessary to maintain system safety. This code requires that branch circuits supplying sustained loads have conductors with an ampacity at least equal to the load they serve, adjusted as necessary to account for any continuous demand. For systems with high ongoing demands, the “maximum current is expected” calculation becomes central to selecting both circuit breakers and conductor sizes, as these must manage not only standard operating conditions but also prolonged current flow.

Continuous vs. Simultaneous Demand

Continuous load differs from a simultaneous demand in several ways. While continuous types focus on duration, simultaneous demands involve multiple electrical needs operating concurrently. Simultaneous loads are essential for understanding peak demand across systems, but continuous loads are about sustained performance over time. This distinction is essential in industrial settings, as both load types contribute to energy demand and system capacity. Choosing the right variable frequency drive is crucial for managing continuous load applications that require steady speed and torque control. VFD sizing directly affects system efficiency and must be matched to expected continuous current to avoid derating or premature failure.

Practical Applications

These considerations are vital in various industrial settings. For instance, steady-state load is common in HVAC systems, lighting, and certain types of industrial machinery. By accurately determining load requirements, electrical professionals can choose appropriate breakers and protect against overloads. This is particularly useful for heating systems, where conductor sizes are calculated based on anticipated continuous demand. Understanding electric motor control is essential when designing circuits for continuous loads, as precise regulation helps prevent overheating and equipment failure.

Another application of constant load is in systems where circuit breakers are rated for continuous operation at up to 80% of their capacity. This rating ensures breakers do not operate beyond safe limits even under prolonged use. Calculating loads to remain within 80% capacity is a proactive step toward energy efficiency, as it balances power usage with system longevity. For facilities operating under long-term demand, proper electric motor maintenance helps extend motor lifespan and ensures stable continuous performance.

Continuous demand calculations form a foundational part of electrical engineering, ensuring the safe, efficient operation of electrical systems. By understanding code requirements and calculating conductor sizes based on maximum loads, electrical professionals can prevent system failures and extend equipment lifespan. Knowledge of constant load empowers electricians to create systems that meet rigorous safety standards, ultimately protecting both workers and equipment. Professionals looking to optimize systems for sustained use can explore efficiency opportunities through motor maintenance to reduce energy waste and enhance reliability.

Related Articles

Control Transformer Explained

A control transformer provides a stable voltage to control circuits in industrial and commercial applications. It ensures reliable performance of contactors, relays, and motor starters by stepping down line voltage for safe, consistent control system operation.

What is a Control Transformer?

A control transformer is a type of transformer used to supply voltage to control devices in electrical systems.

✅ Provides consistent voltage for control circuits and devices

✅ Supports relays, contactors, timers, and PLCs

✅ Ideal for industrial machines and automation systems

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

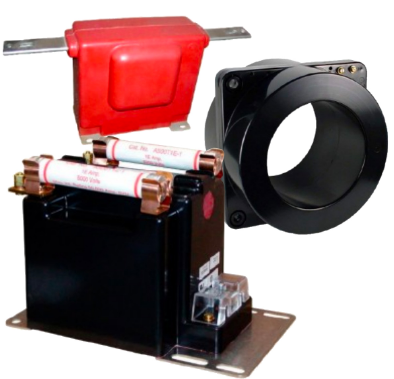

It is designed to provide a stable voltage for control circuits in various applications. This equipment reduces the supply voltage to a lower, more manageable level, suitable for controlling machinery and other electrical devices. Typically, the primary voltage is high, while the secondary voltage is lower, providing the necessary power for systems without compromising safety. Unlike a current transformer, which is used for measurement and protection, a control transformer focuses on delivering reliable voltage for circuits.

The working principle of these units is straightforward. When alternating current flows through the primary winding, it creates a magnetic field that induces a current in the secondary winding. This induced current has a lower voltage, specifically tailored to the needs of control circuits, ensuring consistent and reliable operation of the equipment. For a broader context on energy regulation, see our overview of what is a transformer, which explains how these devices manage voltage in power and systems.

Understanding The Control Transformer

Control transformers are specifically designed to step down the higher voltage from the main power supply to a lower, safer voltage level suitable for control circuits. These circuits are responsible for operating various devices such as relays, contactors, solenoids, and other equipment. Many industrial facilities also pair control transformers with dry type transformers, which offer durability and safety in environments where oil-filled designs are not suitable.

These devices typically operate at lower voltages, usually between 24V and 240V. Control power transformers provide the necessary voltage transformation to ensure the safe and efficient operation of these types of circuits. Discover how step down transformers safely reduce voltage, a principle commonly applied in most control transformer designs for circuit protection.

Construction and Design

Control power transformers are typically constructed with a laminated steel core and two or more windings. The primary winding is connected to the main power supply, while the secondary winding provides the lower voltage output for the circuits.

The design considers various factors, including the required secondary voltage, power rating, and insulation requirements. They are often designed to withstand harsh industrial environments and offer protection against short circuits and overloads.

Key Features and Benefits

They offer several features and benefits that make them indispensable in industrial settings:

-

Safety: The primary function is to provide a safe voltage level for circuits, protecting personnel and equipment from electrical hazards.

-

Reliability: These units are designed to be rugged and reliable, ensuring consistent power delivery to circuits even in demanding conditions.

-

Efficiency: They are engineered to be highly efficient, minimizing energy losses and reducing operating costs.

-

Versatility: They are available in a wide range of voltage and power ratings, making them suitable for various industrial applications.

-

Compact Design: Many units are designed to be compact and space-saving, making them easy to install in confined spaces.

Key Differences Between a Control Transformer and a Power Transformer

While both types serve to transfer electrical energy from one circuit to another, they are distinct in their applications and design. Control power transformers are primarily used to supply power to circuits, whereas power transformers are designed for high-voltage transmission and distribution in electrical grids. Understand different types of devicess to see how they fit into the broader equipment ecosystem, including power, potential, and isolation types.

One key difference lies in the voltage regulation. They offer better voltage regulation, which is crucial for sensitive circuits that require a stable and precise secondary voltage. In contrast, power transformers are optimized for efficiency and capacity, often dealing with much higher power levels.

Additionally, they are designed to handle inrush currents that occur when control devices, such as relays and solenoids, are activated. This ability to manage sudden surges in current makes them ideal for industrial environments where control stability is paramount. If you’re comparing applications, our page on power transformers contrasts with control transformers by focusing on high-voltage transmission and grid distribution.

Typical Applications

Control transformers are widely used in various industrial settings. Some of the typical applications include:

-

Machine Tool: These units provide stable voltage to control circuits in machine tools, ensuring precise operation and safety.

-

HVAC Systems: These systems utilize electrical components to power circuits that regulate temperature and airflow in heating, ventilation, and air conditioning systems.

-

Lighting: In commercial and industrial lighting systems, they help manage the circuits for switching and dimming lights.

-

Motors: They are essential in motor centers, providing the necessary voltage for relays and contactors that start and stop motors.

For comparison, an isolation transformer provides electrical separation and safety, whereas a control transformer specializes in stable voltage regulation for control equipment.

Selecting the Right One

Choosing the appropriate device requires careful consideration of several factors:

-

Voltage Requirements: Determine the primary and secondary voltage levels needed for your application. The secondary voltage should match the requirements of the circuit.

-

Power Rating: Assess the power demand of the circuit and select a unit that can handle the load. The power rating is usually specified in volt-amperes (VA).

-

Inrush Current: Consider the inrush current capacity, especially if the circuit includes components such as relays or solenoids that draw high currents at startup.

-

Environmental Conditions: Ensure the unit is suitable for the operating environment, considering factors such as temperature, humidity, and exposure to dust or chemicals.

-

Regulation and Efficiency: Choose a unit that offers good voltage regulation and efficiency to ensure reliable performance.

For a more detailed look at specialized devices, visit our page on the potential transformer, which also converts voltage but for measurement purposes.

Common Issues and Troubleshooting Steps

Despite their robustness, they can encounter issues. Some common problems include:

-

Overheating: This can occur due to excessive load or poor ventilation. To address this, ensure the device is not overloaded and that it has adequate cooling.

-

Voltage Fluctuations: Inconsistent secondary voltage can result from poor connections or a failing unit. Check all connections and replace the equipment if necessary.

-

Short Circuits: A short circuit in the circuit can cause the unit to fail. Inspect the circuit for faults and repair any damaged components.

-

Noise: Unusual noises often indicate loose laminations or hardware. Tighten any loose parts and ensure the device is securely mounted.

A control transformer is vital in industrial settings, providing stable and reliable voltage to circuits. Understanding their working principles, applications, and differences from power transformers is crucial for selecting the right equipment for your needs. By addressing common issues and following proper troubleshooting steps, you can ensure the longevity and efficiency of your industrial systems, maintaining their smooth operation. Discover how transformer systems operate in real-world applications with our comprehensive resource on what is a transformer, which explains their design, function, and industrial applications.

Related Articles

Surge Protection Devices for Elevators Explained

A surge protection device for elevators safeguards control systems, motors, and electronics from voltage spikes. It ensures reliable performance, minimizes downtime, and extends equipment life by preventing damage from electrical surges caused by lightning or power fluctuations.

What is a Surge Protection Device for Elevators?

✅ Protects elevator motors, control panels, and wiring from damaging voltage spikes

✅ Reduces elevator downtime by preventing surge-related failures

✅ Extends the life of elevator components and improves operational safety

Power Quality Analysis Training

Request a Free Power Quality Training Quotation

Surge protection is crucial for safeguarding elevator systems against electrical damage resulting from voltage spikes and transients. Modern elevators rely on complex electronic controls, making effective system protection essential to prevent failures and ensure passenger safety.

Elevators rely on complex control systems and sensitive electronic components that are vulnerable to electrical surges, which can result in costly downtime, increased maintenance, and equipment failure. By installing the right protection device, you can ensure that your elevator operates efficiently, safely, and with minimal disruptions. In this article, we explore the importance of protection for elevators, how it works, and why choosing the right device is essential for long-term system reliability. For a comprehensive understanding of electrical protection mechanisms, including surge protection, explore our guide on Short Circuit Protection.

Other terms for electrical surges include:

-

Voltage Surge: This is a general term for an unexpected increase in voltage.

-

Transient Voltage: This term highlights that the surge is a brief, temporary event.

-

Overvoltage: This term refers to a voltage level that exceeds the normal operating range.

-

Energy Spike: This term describes the sudden, rapid increase in electrical energy.

-

Voltage Spike: This term specifically refers to a short, sharp peak in voltage.

Electrical surge protection is crucial for ensuring the safe and reliable operation of elevators. Given the complexity of modern elevator systems, which rely on sensitive electronic components, surge protection devices (SPDs) play a crucial role in protecting these components from damage. Frequent spikes, including low-level transient voltage events, can lead to recurring failures, increased maintenance costs, and even complete system shutdowns. This article will examine the importance of surge protection, how to select the right SPD, and the key factors to consider for maintenance and replacement.

Surge protection for elevators is essential to ensure the reliable performance of elevator controls and prevent costly downtime. Modern elevator systems are equipped with sensitive electronic components that can be severely affected by voltage spikes, making a surge protector a critical safeguard. These protective devices help maintain uninterrupted operation, particularly in commercial and high-rise buildings, where safety and efficiency are of paramount importance. Just like elevators, escalators moving continuously throughout the day are also vulnerable to transient surges, which can disrupt control systems and motors. Installing surge protection for elevators and escalators not only protects valuable equipment but also enhances the overall safety and dependability of building transportation systems. To enhance your knowledge on power quality and its impact on electrical systems, consider our insights on Power Quality, which discuss various factors affecting the efficiency and reliability of electrical equipment. In addition to surge suppression, overcurrent protection plays a critical role in safeguarding elevator motors and wiring against excessive currents.

Elevator Surge Protection Quick Guide

| Risk | Impact on Elevators | SPD Solution | Benefit |

|---|---|---|---|

| Voltage spikes | Control system damage | Surge protection device | Prevents downtime |

| Transients from VSDs | Random failures | SPD with transient filtering | Improves reliability |

| Lightning strikes | Motor/electronics burnout | High-capacity SPD | Protects safety & equipment |

Frequently Asked Questions

Why Is Surge Protection Important for Elevators?

Elevators are equipped with advanced control systems that regulate the lift's movement. These systems are vulnerable to voltage spikes caused by various factors, including lightning strikes, switching, or transients from other machinery in the building. A surge protection device can prevent costly damage to critical components, such as human-machine interfaces (HMIs), sensors, and control panels.

Without adequate protection, spikes can lead to downtime, higher maintenance costs, and increased energy usage. Moreover, failure of key components can cause the entire elevator system to malfunction, potentially creating safety hazards for passengers. Surge protection ensures that the safety, robustness, and quality of the elevator system are maintained over time. See: What is Surge Suppression?

What Type of Surge Protection Device Is Best Suited for Elevator Systems?

Choosing the right surge protection device for elevators depends on the system’s specific requirements. Surge protective devices (SPDs) designed for low-level transients are often recommended, as elevators can experience these spikes frequently due to variable speed drives (VSDs). These events may not be strong enough to immediately damage equipment, but can degrade it over time, leading to recurring random failures.

When selecting an SPD, it is essential to consider elevator safety, robustness, and quality. Opting for a sophisticated transient protection system can help eliminate these events, improving the elevator's reliability. The balance direction of the system, rather than just focusing on energy release, should also be a key consideration when choosing an SPD. Reliable surge protection devices must also be paired with proper grounding and bonding to safely divert harmful energy away from sensitive elevator components.

How Does a Surge Protection Device Protect an Elevator's Electrical Components?

An SPD is designed to divert excess electrical energy away from sensitive components by providing an alternate path for the current to flow. This prevents surges from overwhelming control systems, elevator safety features, and other vital components. In the event of a spike, the protector quickly activates, releasing it in the form of heat or diverting it to the ground, thus preserving the integrity of the elevator's systems.

For elevators equipped with variable speed drives, selecting a surge protection device that can handle the increased frequency of low-level spikes is crucial. Such devices can eliminate downtime and reduce energy costs by feeding otherwise wasted energy back into the building's electrical system. Understand the importance of grounding in electrical systems by visiting the page on Grounding and Bonding, which is essential for the safe operation of surge protection devices.

What Are the Common Signs That an Elevator Needs a Surge Protection Device?

Several signs may indicate that an elevator system requires surge protection. These include:

-

Frequent system failures or lockups, often triggered by transients

-

Unexpected downtime, especially in systems using VSDs or sophisticated control panels.

-

Random deprogramming of control settings, such as those experienced in human-machine interfaces (HMIs).

-

Increased maintenance costs, which could be linked to surge-induced damage.

-

Unexplained power fluctuations, especially during storms or heavy electrical use in the building.

These symptoms indicate that the elevator’s electrical components are being affected by voltage spikes, and an SPD should be installed or upgraded to prevent further damage.

How Often Should Surge Protection Devices for Elevators Be Inspected or Replaced?

Routine inspection of surge protection devices is crucial to ensure continued protection for elevators. SPDs should be inspected during regular maintenance checks to assess their condition and ensure they are functioning properly. Factors such as transients or nearby lightning strikes can wear out the SPD over time, thereby reducing its ability to protect the system.

It is generally recommended that SPDs be replaced every five to ten years, or sooner if there are indications of damage or diminished performance. Regular inspections can help identify any issues early, ensuring that surge protection continues to offer the necessary protection.

Surge protection devices are indispensable for maintaining the safety, reliability, and energy efficiency of modern elevator systems. By selecting the right surge protection devices, monitoring their performance, and replacing them as needed, building managers can significantly reduce downtime, prevent costly repairs, and extend the lifespan of elevator equipment. Investing in sophisticated transient protection systems tailored to the specific needs of elevators is essential for ensuring the smooth operation of lift systems and minimizing disruptions.

For information on protecting sensitive electronic equipment from voltage spikes, read our article on Electrical Surge Protection, which complements the discussion on elevator surge protection devices.

Related Articles

IEP News

IEP Media

IEP Articles From ET Magazine

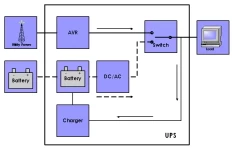

Compatibility Issues with Generator-Backed Power Systems

While both UPS systems and generators serve as safeguards against power disruptions, their integration isn't always seamless. Understanding these compatibility concerns is crucial for ensuring reliable backup power and avoiding damage to sensitive equipment.

Visit Our UPS Systems Study Course

Voltage and Frequency Stability

Generators, particularly smaller portable models, may not provide the same level of voltage and frequency stability as utility power. Line-interactive UPS units are designed to operate within a specific input voltage and frequency range. Wide fluctuations outside these tolerances can trigger the UPS to switch to battery frequently, draining reserves and potentially causing premature battery wear.

Synchronization Issues

When power from a generator is restored, there may be a phase shift or momentary mismatch in frequency compared to the UPS output. This lack of synchronization can lead to a disruptive transfer process, potentially causing a brief outage for the connected equipment.

Harmonic Distortion

Generators, especially lower-quality models or those under non-linear loads, can introduce harmonic distortion into the electrical waveform. This 'noise' in the power supply can affect the operation of sensitive electronics connected to the UPS and degrade overall power quality.

Strategies for Improved Compatibility

UPS Selection: Look for line-interactive UPS models with wider input voltage and frequency tolerance ranges. Some may offer a 'generator mode' that accommodates greater fluctuations.

Generator Quality: Whenever possible, opt for generators with better voltage regulation and lower harmonic distortion. Inverter-based generators generally provide cleaner output than conventional models.

Generator Sizing: Overloading a generator can lead to unstable output. Ensure the generator's capacity comfortably exceeds the anticipated load demand.

Isolation Transformers: In specific cases, an isolation transformer between the generator and UPS can improve compatibility by filtering out some harmonic distortion and stabilizing the voltage.

Double-Conversion UPS: A More Forgiving Solution

While the steps outlined above can improve compatibility, double-conversion online UPS systems are inherently better suited for use with generators. Here's why:

Complete Isolation: Double-conversion UPS units continuously convert incoming AC to DC and back to AC, creating a clean and regulated output regardless of generator power quality.

Wider Tolerance: These UPS systems often have wider acceptable input voltage and frequency windows, handling generator fluctuations without issue.

Considerations When Connecting a Line-Interactive UPS to a Generator

UPS Runtime: If frequent generator power deviations cause the UPS to switch to battery often, runtime will be reduced for longer outages. Assess the stability of your generator to gauge this risk.

Load Sensitivity: Less critical equipment can often tolerate generator-powered line-interactive UPS output. Highly sensitive systems might warrant a double-conversion UPS for cleaner backup power.

Neutral Bonding: Proper grounding practices are vital, especially in a generator-UPS setup. Improper neutral bonding can lead to dangerous stray currents and equipment damage.

Additional Tips

Consult Manufacturer Recommendations: Always refer to the instructions for your specific UPS and generator for guidance on compatibility and best practices.

Regular Testing: Periodically test the switchover between the generator and UPS power under load. This helps identify potential issues and ensures backup systems work as intended when needed.

Integrating line-interactive UPS systems with generators requires attention to power quality and synchronization. While choosing suitable equipment and implementing mitigation strategies improves compatibility, double-conversion UPS systems offer superior inherent resilience against generator power fluctuations. Organizations can design robust power protection schemes that ensure uninterrupted operation even during extended outages by carefully considering backup power needs and equipment sensitivity.

Line-Interactive UPS in Scalable IT Infrastructure

In the evolving landscape of IT infrastructure, reliable and flexible power solutions are paramount. Scalable line-interactive Uninterruptible Power Supply (UPS) systems provide an essential service to growing IT networks by adapting to increasing power demands without the need for complete system overhauls. This adaptability ensures that businesses can expand their IT capabilities while maintaining protection against power interruptions and fluctuations.

Visit Our UPS Systems Study Course

Scalability and Its Importance

Scalability in a UPS context refers to the ability to increase the UPS capacity to handle higher loads as demand grows. This is particularly crucial for businesses experiencing rapid growth or those planning for future expansion. The scalable nature of certain UPS systems allows for the addition of more power modules within the same infrastructure, thereby accommodating growth without significant downtime or large-scale replacements.

Advantages of Scalable UPS Systems

Cost Efficiency: Implementing a scalable UPS system is cost-effective over time. Businesses can invest in what they need today, knowing that the system can grow with their requirements. This staged investment helps manage cash flow better compared to investing in a large system upfront.

Reduced Downtime: The modular design of scalable UPS systems allows for expansions and upgrades to be performed with minimal impact on ongoing operations. This is vital for maintaining high availability and reducing the risk of downtime during upgrades.

Enhanced Flexibility: With scalable systems, IT managers can customize the UPS to meet the exact needs of their network, adjusting for power load, redundancy requirements, and runtime. This flexibility also extends to maintenance and servicing, as individual modules can be serviced or replaced without shutting down the entire system.

Long-term Reliability: Scalable UPS systems are designed to accommodate future technology changes and increases in demand. This foresight ensures that the UPS system remains reliable and effective over a longer period, thereby protecting the IT investment as the business landscape evolves.

Implementation Considerations

When planning to implement a scalable UPS system, several factors need to be considered:

Initial Assessment: Accurately assessing current power needs and future growth projections is crucial to selecting a UPS with appropriate scalability options.

Space Planning: Scalable UPS systems require strategic placement as expansions will necessitate additional space. Planning for this during the initial setup phase is essential.

Budget Allocation: While the initial cost of a scalable UPS may be higher than that of a fixed-capacity system, the long-term savings and benefits often justify the investment.

In the dynamic landscape of IT infrastructure growth, the scalability of line-interactive UPS systems presents a significant advantage. By enabling organizations to match power protection to current needs while retaining expansion capabilities for the future, scalable UPS solutions ensure reliable power, optimized investment, and minimal disruptions during inevitable periods of growth.

Scalable line-interactive UPS systems represent a smart choice for growing IT networks, offering a flexible, reliable, and cost-effective solution that grows alongside business needs. As IT infrastructure becomes increasingly critical, investing in a UPS system that can adapt to changing demands is an essential strategy for future-proofing IT operations and ensuring continuous power protection. This approach not only supports operational continuity but also aligns with the strategic growth objectives of modern businesses.

Securing Critical Infrastructure: The Role of Line-Interactive UPS

UPS (uninterruptible power supply) systems are essential for protecting critical infrastructure in healthcare and finance. They provide backup power in the event of a power outage, ensuring that sensitive equipment and data are protected. Line-interactive UPS systems are a popular choice for these applications, offering a number of advantages over other types of UPS systems.

Visit Our UPS Systems Study Course

Benefits of Line-Interactive UPS Systems

Line-interactive UPS systems offer a number of benefits over other types of UPS systems, including:

Lower cost: Line-interactive UPS systems are typically less expensive than other types of UPS systems, making them a more cost-effective option for businesses on a budget.

Smaller size: Line-interactive UPS systems are also smaller than other types of UPS systems, making them ideal for applications where space is limited.

Lower maintenance: Line-interactive UPS systems require less maintenance than other types of UPS systems, making them a more hassle-free option for businesses.

Types of Line-Interactive UPS Systems

There are two main types of line-interactive UPS systems: standby and online. Standby UPS systems only provide power when the primary power source fails, while online UPS systems provide continuous power, even during power outages.

Standby UPS systems are typically less expensive than online UPS systems, but they also offer less protection. They are a good choice for applications where the risk of a power outage is low.

Online UPS systems are more expensive than standby UPS systems, but they offer more protection. They are a good choice for applications where the risk of a power outage is high, such as hospitals and data centers.

Performance of Line-Interactive UPS Systems

The performance of a line-interactive UPS system is determined by a number of factors, including:

Power output: The power output of a UPS system is measured in VA (volt-amps). It must be sufficient to power the equipment it is protecting.

Runtime: The runtime of a UPS system is the amount of time that it can provide power during a power outage. The runtime of a UPS system is determined by the size of its battery.

Efficiency: The efficiency of a UPS system measures how much power it loses during conversion. A more efficient UPS system will lose less power and be more cost-effective to operate.

Technical Considerations

There are a number of technical considerations that must be taken into account when selecting a line-interactive UPS system, including:

Input voltage: The input voltage of a UPS system is the voltage of the power source that it is connected to. The input voltage of a UPS system must be compatible with the voltage of the power source.

Output voltage: A UPS system's output voltage is the power it supplies to its connected equipment. It must be compatible with the voltage of the equipment it is protecting.

Frequency: The frequency of a UPS system is the rate at which it converts power. The frequency of a UPS system must be compatible with the frequency of the power source.

Across the healthcare and financial sectors, where the consequences of downtime range from inconvenient to life-threatening or financially devastating, line-interactive UPS systems play a silent but vital role. Their ability to provide clean power, instant backup, and facilitate safe shutdown procedures acts as an indispensable insurance policy for critical infrastructure. As power grids evolve and technologies advance, the integration of UPS protection will remain deeply intertwined with maintaining resilience and reliable service delivery in these vital sectors.

Battery Advancements and the Impact on Line-Interactive UPS

Advancements in Battery Technology and Their Impact on Line-Interactive UPS

Line-interactive uninterruptible power supply (UPS) systems play a crucial role in ensuring power continuity for sensitive electronic equipment. Serving as a safeguard against power disruptions, these systems seamlessly switch to battery backup during outages, preventing data loss, equipment damage, and downtime. Recent advancements in battery technology, particularly lithium-ion batteries, have significantly influenced the capabilities and performance of line-interactive UPS systems.

Visit Our UPS Systems Study Course

Lithium-ion: The Emerging Choice

Lithium-ion (Li-ion) batteries, widely known for their use in laptops and electric vehicles, are increasingly finding their way into UPS systems. Here's how they stand out:

Higher Energy Density: Li-ion batteries pack more energy into a smaller and lighter form factor compared to lead-acid counterparts. This translates to space-saving UPS units or more runtime within the same footprint.

Longer Lifespan: Li-ion batteries boast more charge/discharge cycles than lead-acid batteries. This could mean less frequent battery replacements over the lifetime of the UPS system, reducing maintenance costs.

Faster Recharge Times: Li-ion batteries generally recharge faster, contributing to quicker recovery times between outages.

Efficient Operation: Reduced internal resistance leads to greater efficiency in charging and discharging, thus minimizing energy losses.

Considerations and Trade-offs

Cost: Currently, Li-ion-based UPS systems typically carry a higher initial price tag compared to those using lead-acid batteries. However, the total cost of ownership over time may be comparable or even favorable due to their longevity and lower maintenance.

Management Complexity: Li-ion batteries sometimes require more sophisticated battery management systems (BMS) for safe and optimal operation.

Safety: Certain Li-ion chemistries, if mishandled, have greater potential for thermal runaway than traditional lead-acid batteries. Reputable manufacturers prioritize robust design and safety measures in their Li-ion UPS units.

Other Battery Advancements

Enhanced Lead-Acid Batteries: Developments like Thin Plate Pure Lead (TPPL) and Absorbed Glass Mat (AGM) technologies have improved lead-acid battery performance in areas like cycle life, recharge times, and tolerance to temperature fluctuations.

Alternative Chemistries: Flow batteries, sodium-ion batteries, and more offer unique characteristics potentially relevant to specific UPS use cases.

The Impact on Line-Interactive UPS

The integration of advanced battery technologies into line-interactive UPS designs brings about notable implications:

Compact Designs: Smaller batteries open up possibilities for more streamlined and space-efficient line-interactive units, particularly valuable in edge computing and cramped network closets.

Increased Reliability: Longer battery lifespan and resilience towards environmental conditions enhance UPS system reliability overall.

Extended Runtimes: Depending on the application, advanced batteries may unlock longer backup times on smaller line-interactive units.

Eco-Friendliness: Li-ion batteries have the potential for greater recyclability than lead-acid options, minimizing environmental impact at end-of-life.

Choosing the Right Battery Technology

The optimal battery choice for your line-interactive UPS depends on several factors:

Criticality of the Load: For highly critical applications, the added longevity and performance of Li-ion batteries often justify the cost.

Space Constraints: Where installation space is extremely limited, the compactness of Li-ion solutions becomes a major advantage.

Environmental Conditions: If the UPS is in a less temperature-controlled environment, the robustness of newer lead-acid technologies or some advanced options might be preferable.

Budget: If the initial purchase cost is the primary driver, a traditional lead-acid line-interactive UPS may still be the most practical solution.

The advancements in battery technology are transforming the landscape of line-interactive UPS systems, enhancing their efficiency, reliability, and sustainability. As lithium-ion batteries continue to evolve and decrease in cost, they are expected to become the standard choice for new UPS installations, offering significant advantages over traditional battery technologies. Organizations looking to upgrade or install new UPS systems should consider the long-term benefits of lithium-ion batteries, despite the initial higher investment, to ensure reliable and efficient power backup solutions.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Sign Up for Electricity Forum’s Generators/UPS Newsletter

Stay informed with our FREE Generators/UPS Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.