Overhead T&D

Reliability & Protection in Utility Distribution

Reliability and protection in utility distribution are safeguarded through breakers, relays, automation, and fault isolation, ensuring grid stability, preventing outages, and providing safe, resilient power for residential, commercial, and industrial users.

What is Reliability & Protection in Utility Distribution?

Reliability and protection in utility distribution ensure safe, continuous electricity delivery by detecting faults, isolating affected areas, and restoring service efficiently.

✅ Uses relays, reclosers, and breakers to clear faults quickly

✅ Improves outage performance with automation and fault isolation

✅ Adapts to DER integration for stronger grid reliability

Part of enhancing reliability and protection in Utility Distribution involves harmonizing protection strategies with the overall network design, as discussed in our overview of electrical distribution systems.

Utility distribution is where electricity meets the customer, and its reliability depends on strong protection strategies. Faults, equipment failures, and severe weather are inevitable — but with coordinated protection, utilities can minimize outages and restore service quickly. Reliability and protection are not just technical concerns; they define the customer experience and the resilience of the modern grid. One of the key challenges to reliability in utility distribution is dealing with costly interconnection delays, which can slow down system upgrades and impact protection planning.

The Role of Protection in Reliability

In utility networks, reliability is measured through indices such as SAIDI, SAIFI, and CAIDI, which track outage frequency and duration. Behind those numbers lies a simple principle: protection devices must respond fast enough to clear faults but selective enough to avoid cutting off more customers than necessary.

Consider a radial feeder serving a rural community. A single fault along the line can interrupt service for everyone downstream. With the right combination of breakers, reclosers, and fuses, that same fault could be confined to a small segment, keeping most customers supplied while crews make repairs.

Layers of Protection in Utility Distribution

Protection in utility distribution relies on multiple devices working together:

-

Breakers at substations interrupt large fault currents.

-

Reclosers attempt to clear temporary faults and restore service automatically.

-

Sectionalizers detect passing fault current and open to isolate problem areas.

-

Fuses protect lateral branches and small loads.

The effectiveness of these devices comes from careful coordination. Each must operate in the right sequence so that the smallest possible section is taken out of service. Poor coordination risks unnecessary outages, while proper design ensures reliability. Understanding electric power distribution provides the foundation for evaluating how protection devices interact within the broader utility grid.

Comparative Roles of Protection Devices in Utility Distribution

| Device | Typical Fault Response Time | Coverage Area | Reliability Impact |

|---|---|---|---|

| Breaker | Instant to a few cycles | Entire feeder circuit | Prevents catastrophic faults from spreading upstream. |

| Recloser | Less than 1 second, with reclosing attempts | Feeder segments | Clears temporary faults, reducing unnecessary outages. |

| Sectionalizer | Opens after fault current passes | Branch or loop section | Isolates smaller faulted areas, keeping most customers online. |

| Fuse | Seconds (melts under sustained fault) | Small branches, taps | Protects localized loads, acts as final safeguard. |

Effective protection depends on critical components like the electrical insulator, which maintains safety and stability by preventing leakage currents and supporting conductors. To minimize downtime and improve service reliability, utilities often rely on monitoring devices, such as fault indicators, to pinpoint disturbances quickly.

Protection Coordination in Action

Protection is effective only when devices operate in harmony. Two common strategies are:

-

Fuse-saving: a recloser operates first, giving temporary faults a chance to clear before a fuse blows.

-

Fuse-blowing: the fuse operates on sustained faults, preventing upstream devices from unnecessarily tripping.

Modern adaptive relays now adjust thresholds dynamically. For example, when distributed energy is producing heavily, relay settings shift to account for reverse power flow.

Did you know? FLISR (Fault Location, Isolation, and Service Restoration) can reconfigure feeders in under 60 seconds. One Midwestern utility reported a 25% reduction in SAIDI after installing automated reclosers and FLISR software across its suburban service territory.

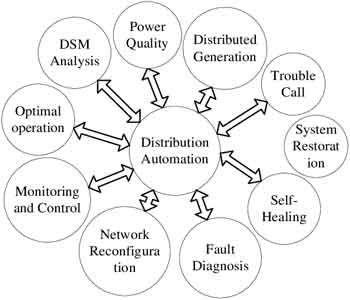

Smart Protection and Automation

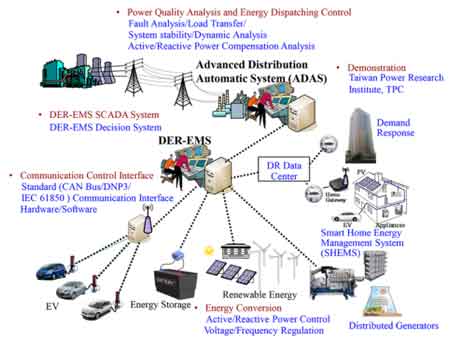

Utilities are increasingly adopting automated protection schemes. Fault Location, Isolation, and Service Restoration (FLISR) technology uses sensors, communications, and smart switches to reroute power in seconds. Instead of dispatching crews to manually isolate a fault, the system reconfigures itself, reducing both outage duration and the number of affected customers.

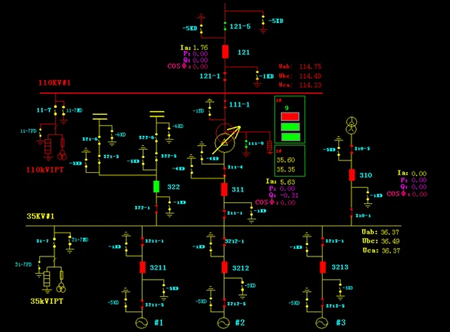

Automation turns protection from a reactive safeguard into a proactive reliability tool. Utilities that deploy digital relays, SCADA integration, and smart switching see measurable improvements in performance, with lower SAIFI and CAIDI values across their service areas. Advances in distribution automation enable utilities to detect faults, isolate problem areas, and restore service more quickly, directly improving reliability indices such as SAIDI and SAIFI.

Impact of Protection and Automation on Reliability Indices

| Reliability Index | Definition | Effect of Protection & Automation |

|---|---|---|

| SAIDI | Average outage duration per customer (minutes/year) | Automation reduces restoration time by rerouting power quickly. |

| SAIFI | Average number of outages per customer (interruptions/year) | Coordinated reclosers and sectionalizers lower outage frequency. |

| CAIDI | Average outage duration per interruption | Faster fault isolation and service restoration shorten each outage. |

Challenges in a Distributed Era

Distributed energy resources (DERs) such as solar, wind, and storage are transforming how protection operates. Power no longer flows one way from the substation to the customer. Reverse flows can confuse traditional protection settings, while inverter-based resources may not produce fault currents large enough to trigger older devices.

To address this, utilities are deploying directional relays, adaptive settings, and advanced digital relays capable of handling bidirectional power. Protection strategies must evolve in tandem with the grid to maintain reliability as more distributed resources connect at the distribution level. The rapid growth of distributed energy resources has reshaped how utilities design protection schemes, necessitating adaptive relays and more sophisticated coordination strategies.

Barriers to Stronger Protection

Despite technological progress, several barriers remain:

-

Interoperability between legacy and digital equipment is often limited.

-

Communication networks must be robust enough to support widespread automation.

-

Cybersecurity is critical, as protection devices are now part of utility control systems.

-

Workforce skills must expand, with protection engineers learning networking and analytics alongside relay coordination.

Utilities that overcome these barriers position themselves to deliver safer and more reliable services in the decades ahead. Long-term resilience in distribution systems also depends on strong links with electricity transmission, which supplies the bulk power that distribution networks deliver safely to end users.

Reliability and protection in utility distribution are inseparable. Protection devices detect, isolate, and clear faults; reliability is the result of how well those devices are coordinated. With automation, adaptive relays, and smarter strategies, utilities can minimize outages and keep customers connected even as the grid grows more complex. In an era of distributed resources and rising expectations, robust protection is the foundation of reliable utility distribution.

Related Articles

Download Our FREE Overhead T&D Handbook

As utilities are faced with replacing rapidly aging transmission and distribution infrastructures, it is essential to be aware of the latest techniques, products and applications available on the market. Volume 1 of our Overhead & Underground T&D handbook series provides detailed information on testing and maintenance methods, the practical and theoretical applications of overhead transmission, and the unique challenges and opportunities presented by underground distribution networks. These topics and more are covered in detail in the 100-page first-volume handbook.

In this first volume, we explore the core principles and practices related to overhead and underground power transmission and distribution. We examine the key components of these systems, such as transmission lines, substations, transformers, cables, and switches, while delving into the design, installation, and maintenance of both overhead and underground configurations. Special attention is given to the unique challenges and considerations associated with each type of system—highlighting factors such as environmental conditions, reliability, safety standards, and operational efficiency.

This handbook is designed to assist engineers, utilities, technicians, and planners by providing practical insights and technical expertise for optimizing T&D systems. We cover essential topics such as grid infrastructure, fault detection, protection schemes, and the integration of emerging technologies like smart grids and renewable energy solutions. Whether you are involved in the planning of new installations or maintaining existing systems, Volume 1 offers the tools and guidance necessary for ensuring the safe and efficient delivery of power.

With a blend of theoretical concepts, industry best practices, and real-world applications, Overhead & Underground T&D Handbook, Volume 1 aims to be an indispensable reference for professionals seeking to deepen their understanding of transmission and distribution systems, and to navigate the evolving challenges of modern electrical networks.

Latest Overhead T&D Articles

Electrical Distribution System

An electrical distribution system delivers electricity from substations to homes and businesses. It includes transformers, feeders, and circuit breakers that ensure a safe and reliable power flow. Learn how these systems support energy efficiency, grid stability, and electrical load management.

What is an Electrical Distribution System?

An electrical distribution system safely delivers power from transmission lines to end users through a network of interconnected components:

✅ Ensures reliable power delivery through feeders, transformers, and switches

✅ Manages voltage levels for safe residential, commercial, and industrial use

✅ Supports energy efficiency, fault protection, and load balancing

The backbone of reliable supply depends on electricity transmission seamlessly connecting with local distribution systems to deliver power where it’s needed.

Electrical Distribution System Topologies

The structure of an electrical distribution system greatly influences its reliability, fault tolerance, and maintenance flexibility. The three primary system topologies used in power distribution are radial, loop, and network configurations. Each has its benefits and applications depending on the load density, geographic area, and service reliability requirements. Understanding electric power distribution helps explain how energy moves from substations to end-use facilities.

Radial Distribution System

A radial system delivers power from a single substation outward through individual feeders to end users. This single-source distribution model is widely used in rural power systems and smaller suburban developments due to its simplicity and lower installation cost.

While easy to design and maintain, radial feeders offer limited fault tolerance. If a fault occurs along the line, all customers downstream lose power until repairs are made. Service interruption risk is therefore higher compared to more complex topologies.

-

Advantages: Cost-effective, simple to design and maintain.

-

Disadvantages: Limited reliability — a fault on a single feeder can interrupt service to all downstream customers.

Loop Distribution System

Loop, or ring-type, distribution systems are designed with feeders arranged in a closed path. Although only one segment of the loop is normally energized, alternate supply paths can be quickly activated in the event of a fault. This configuration improves fault isolation and enhances service continuity without significantly increasing system complexity.

Ring main units (RMUs) are commonly used in these systems to control flow and protection at various nodes in the loop. Loop distribution is ideal for commercial zones and medium-density residential areas where uninterrupted service is a priority.

-

Advantages: Improved reliability and fault isolation.

-

Disadvantages: More complex control and slightly higher installation costs.

Network Distribution System

In high-demand environments such as city centers, hospitals, airports, and industrial parks, network distribution systems are used to ensure maximum reliability. These systems consist of interconnected transformers and multiple power sources, allowing electricity to flow through various routes to the same load center.

The urban electrical grid often relies on such interconnected networks to avoid single points of failure. Even during equipment outages or scheduled maintenance, power remains available through redundant paths. This level of fault-tolerant distribution is essential for critical load centers and high-reliability applications.

-

Advantages: Extremely reliable; service is maintained even during multiple failures.

-

Disadvantages: High initial cost and complex protection coordination.

Typical Voltage Levels in an Electrical Distribution System

| System Segment | Voltage Range (Volts) | Purpose |

|---|---|---|

| Generation | 11,000 – 33,000 V | Power generated at medium voltage before step-up for transmission. |

| High-Voltage Transmission | 69,000 – 765,000 V | Bulk power transferred over long distances via transmission lines. |

| Primary Distribution | 4,160 – 35,000 V | Power delivered from substations to local distribution transformers. |

| Secondary Distribution | 120 – 600 V | Final voltage supplied to residential, commercial, or light industrial users. |

| Utilization Voltage (Residential) | 120/240 V (single-phase) | Standard voltage for home appliances and lighting. |

| Utilization Voltage (Commercial/Industrial) | 208Y/120 V, 480Y/277 V (three-phase) | Common voltages for commercial buildings, factories, and heavy equipment. |

The integration of distributed energy resources is transforming traditional distribution systems into more dynamic, flexible grids.

Choosing the Right Topology

Choosing the appropriate topology requires a careful analysis of current and projected load requirements, voltage level optimization, and consideration of geographic constraints. In many modern systems, a combination of radial and loop structures is employed to strike a balance between cost efficiency and fault protection. Smart technologies, such as distribution automation, improve reliability by enabling operators to remotely monitor and reconfigure feeders.

As the grid evolves with the integration of distributed energy resources, electric vehicles, and smart monitoring systems, future-ready distribution networks must be adaptable to meet these changes. Building flexible infrastructure now ensures resilience, reduces the impact of outages, and supports long-term power reliability across diverse service areas.

Transformers in the Electrical Distribution System

The role of power transformers is central to the operation of an AC system. Without these devices, the step-up and step-down voltage functions necessary for power transmission and distribution would not be possible. Transformers enable the efficient delivery of electrical energy from generators to end users by adjusting voltage levels to match transmission, distribution, and utilization requirements. Understanding electric power distribution helps explain how energy moves from substations to end-use facilities.

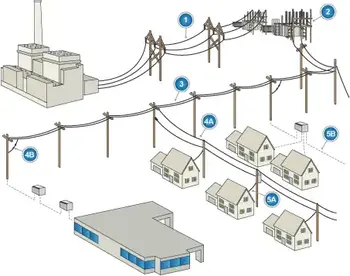

In its broadest sense, the electrical distribution includes generation, high-voltage transmission, and local distribution infrastructure. As shown in Figure 1, the transition from long-distance transmission to localized distribution typically occurs at a substation, where step-down transformers reduce voltage to medium levels suitable for primary distribution circuits.

Distribution substations are increasingly equipped with remote control, monitoring, and automation capabilities, allowing operators to manage switchgear, breakers, and auxiliary systems from centralized control rooms. These technologies improve grid responsiveness, load balancing, and fault isolation.

Fig. 1. Typical electrical distribution system.

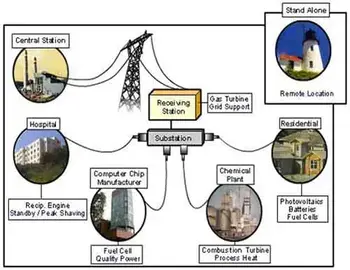

A significant amount of protection, voltage regulation, and power flow control takes place within the distribution system, particularly in industrial and commercial applications. Figure 2 illustrates the various stages in the delivery of electrical power to an industrial facility, from substation input to final utilization equipment.

Fig. 2. Stages in the delivery of power to an industrial user

Primary and Secondary Distribution

The distribution system is commonly divided into primary and secondary segments, distinguished by their voltage levels and function:

-

Primary distribution refers to the medium-voltage circuits (typically 4.16 kV to 35 kV) that carry electricity from substations to localized areas or service transformers.

-

Secondary distribution delivers power at lower voltages (120 V to 600 V) to homes, businesses, and smaller industrial users.

-

The distribution transformer acts as the interface between these two segments, stepping down the voltage for end-use applications. Voltages connected to the transformer’s primary side are referred to as distribution voltages, while the secondary side supplies utilization voltages.

Interpreting Single-Line Diagrams

In industrial and commercial settings, single-line diagrams are widely used to represent power distribution layouts. These simplified schematics use a single line to indicate multi-phase conductors and identify all major components such as transformers, feeders, breakers, and grounding systems.

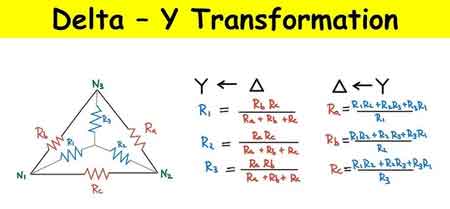

Wye and Delta transformer connections can be displayed in a single-line diagram. Each transformer symbol indicates whether the primary and secondary windings are configured in a Wye (Y) or Delta (Δ) arrangement, which affects phase relationships, load balancing, and grounding practices. Operators use devices such as the fault indicator to quickly pinpoint and isolate issues within distribution feeders.

Key Design Considerations

A well-designed distribution system must be able to serve all customers, from single-family residences to large industrial complexes, safely, efficiently, and economically. Effective design involves planning for both current and future energy needs. Major considerations include:

-

Structure type: Choice of radial, loop, or network topology based on load size and reliability needs

-

Present and future utilization: Load forecasting, energy growth projections, and planned system upgrades

-

System lifespan: Design based on the projected life of the facility or infrastructure

-

Flexibility: Capacity to expand, reconfigure, or isolate faults as needed

-

Service entrance and equipment location: Optimization of switchgear, panels, and wiring routes

-

Installation method: Overhead lines vs. underground cabling, based on terrain, aesthetics, and risk factors

Essential components, such as electrical insulators, maintain safety and system integrity by supporting conductors on overhead lines.

Related Articles

Electrical Insulator

An electrical insulator prevents the unwanted flow of current by providing high resistance between conductive parts. Essential in power transmission systems, these materials ensure isolation, enhance safety, and protect equipment from arcing and short circuits.

What is an Electrical Insulator?

An electrical insulator is a vital component in T&D systems, ensuring safety and reliability. However, it comes in various materials and types, each with advantages and disadvantages.

✅ Provides electrical isolation in high-voltage systems

✅ Made from dielectric materials like porcelain or polymer

✅ Prevents arcing and protects conductors from short circuits

Understanding the insulating properties of dielectric materials, resistance, and breakdown voltage is essential for selecting the most suitable non-conductive material for a specific application. By making informed choices, engineers can ensure the longevity and safety of transmission and distribution (T&D) installations and equipment.

An electrical insulator is a material that restricts the flow of electric current, ensuring that electric charge does not easily pass through it. They are essential components in power systems, as they help protect equipment, structures, and people from electric shocks and short circuits. A high-quality electrical insulator possesses high resistivity, which means it can withstand high voltages without allowing current to flow unimpeded.

High Voltage Transmission Uses

High-voltage power transmission insulating devices are typically made from materials such as glass, porcelain, or composite polymers. Porcelain types consist of clay, quartz or alumina, and feldspar and feature a smooth glaze that allows water to run off easily. When high mechanical strength is required, porcelain rich in alumina is utilized. Porcelain ones have a dielectric strength of around 4–10 kV/mm. Glass types possess a higher dielectric strength; however, they tend to attract condensation, which can result in thick, irregular shapes that are necessary for non-conductive insulating devices. These shapes can lead to internal strains.

Consequently, some manufacturers ceased producing glass ones in the late 1960s, opting instead for ceramic materials.

Electric utilities sometimes use polymer composite materials for certain types of insulators. These typically consist of a central rod of fibre-reinforced plastic and an outer weather shield made of silicone rubber or ethylene propylene diene monomer (EPDM) rubber. Composite non-conductive materials are more cost-effective and lightweight, exhibiting exceptional hydrophobic properties. This combination makes them ideal for use in areas with high pollution levels. However, these materials have not demonstrated the same long-term service life as their glass and porcelain counterparts.

Different Materials

Different types of electrical insulator are designed to cater to various applications and environments. They are classified based on the material used, such as ceramic, glass, and polymer insulators. Each type has specific insulating properties that make it suitable for certain uses.

Dielectric materials are a crucial component of any electrical insulator. They function by inhibiting the electric field within their structure, preventing the flow of a charge. A dielectric material's insulating properties are primarily determined by its dielectric constant, which measures its ability to store energy without conducting it.

Ceramic ones, such as porcelain, have been used for many years due to their excellent insulating properties, mechanical strength, and resistance to high temperatures. They are typically used in high-voltage applications, including power transmission and distribution systems. However, they can be heavy and brittle, which reduces durability and increases maintenance costs.

Materials such as glass paper, on the other hand, offer excellent transparency and a smooth surface that helps prevent dirt accumulation. They also have high dielectric strength, meaning they can withstand high voltage without breaking down. However, like ceramic ones, they are fragile and prone to breakage.

Polymer insulators are a recent innovation made from silicone rubber or epoxy resins. They are lightweight, durable, and have good insulating properties. Additionally, polymer devices exhibit increased resistance to environmental factors, including UV radiation and pollution. However, their long-term performance still needs to be studied, and they may be more expensive than traditional ceramic or glass insulators.

Performance is affected by its resistance and breakdown voltage. Resistance measures a material's ability to prevent the flow of electric current. A higher resistance means that the insulating device is more effective at blocking the flow of electricity. On the other hand, the breakdown voltage is the maximum voltage an insulator can withstand before it fails and allows electric current to flow through it. Therefore, a higher breakdown voltage indicates better insulating capabilities.

Electrical insulators play a crucial role in power transmission and distribution systems. They support and separate conductors, ensuring that the electric field and current remain confined within the conductors. They also help maintain the integrity of the wiring and prevent short circuits or leakage currents that may cause equipment damage or pose safety risks.

Several factors should be considered when selecting an electrical insulator for a specific application, including the operating voltage, environmental conditions, and mechanical stresses. The non-conductive material should possess a high dielectric constant, good resistance to temperature changes, and adequate mechanical strength. Additionally, it should resist environmental factors such as moisture, pollution, and UV radiation.

Various Types

Pin Insulator - This type is attached to a pin mounted on the cross-arm of a utility pole. It features a groove near its top, just below the crown, through which the conductor runs and is fastened using an annealed wire made of the same material as the conductor. Pin insulators are commonly used to transmit communication signals and electric power at voltages of up to 33 kV. However, they can become bulky and uneconomical for operating voltages between 33 kV and 69 kV.

Post Insulator - Introduced in the 1930s, they are more compact than traditional pin-types. They have rapidly replaced many pin-types in lines with voltages up to 69 kV and, in some configurations, can be designed for operation at up to 115 kV.

Suspension Insulator - Suspension devices are typically utilized for voltages exceeding 33 kV. They consist of a series of glass or porcelain discs linked together with metal connectors, forming a string. The conductor is suspended from the bottom of this string, while the top is secured to the tower's cross-arm. The number of disc units required depends on the voltage.

Strain Insulator - When a straight section of a transmission line ends or changes direction, a dead-end or anchor pole or tower is employed. These structures must withstand the lateral (horizontal) tension from the long straight section of wire. Strain devices are used to support this load. For low-voltage lines (under 11 kV), shackle ones are strain insulators. For high-voltage transmission lines, cap-and-pin (suspension) insulator strings are used, mounted horizontally to the crossarm. In cases of extremely high tension, such as long river spans, two or more parallel strings may be necessary.

Shackle Insulator - Initially, shackle types were employed as strain insulators. Nowadays, they are predominantly used for low-voltage distribution lines. These can be installed in horizontal or vertical orientation and can be directly fastened to the pole with a bolt or to the crossarm.

Related Articles

Fault Indicator Explained

A fault indicator is an electrical device that detects and displays fault conditions in power systems. Used in distribution networks and switchgear, it improves fault detection, outage response, and grid reliability while supporting predictive maintenance.

What is a fault indicator?

A fault indicator is a monitoring device used in electrical distribution systems to quickly locate fault conditions and improve service reliability.

✅ Detects and displays fault conditions in power lines

✅ Enhances outage response and reduces downtime

✅ Supports predictive maintenance and grid efficiency

Understanding how this device functions and its role in maintaining a reliable power system is crucial for any electrician working in an industrial setting. Let’s explore the core concepts, their various applications, and the benefits they offer in terms of issue location, outage reduction, and overall system reliability. By reading this article, an industrial electrician will gain valuable insights into how a fault indicator contributes to safer, more efficient, and more resilient electrical infrastructure. Fault indicators play a crucial role in distribution automation, where remote monitoring and SCADA integration are essential for enhancing grid resilience.

They play a critical role in modern power systems by providing a rapid and reliable means of detecting and locating disturbances. These devices are essential for minimizing downtime, improving safety, and ensuring the efficient operation of electrical networks. In modern electrical distribution systems, fault indicators provide real-time fault location that speeds up troubleshooting and repair.

A faulted circuit indicator (FCI) is more than a simple signal device; it functions as a reliable circuit monitoring device that helps utilities quickly identify abnormal conditions. Whether used as an overhead line indicator on distribution networks or integrated into underground systems, these tools improve outage response and reduce downtime. When connected to SCADA fault detection platforms, they provide real-time data that supports proactive maintenance and rapid dispatch of crews. As utilities transition toward smart grid monitoring, advanced FCIs play a key role in creating safer, more resilient, and efficient power systems.

Fault Location/Detection

A primary function of these devices is to pinpoint the exact location of a circuit problem. This capability is crucial in complex networks with extensive overhead lines and underground cables. Overhead indicators are strategically placed along power lines to visually signal the presence of an issue. When a disturbance occurs, the indicator activates, providing a clear cue to line crews that enables them to quickly identify the affected section and commence repairs. Underground indicators are installed in cable systems and vaults to detect conditions beneath the surface. This precise location capability reduces the time and effort required to identify and address problems, resulting in faster restoration of service. Utilities that depend on reliable electric power distribution benefit from fault indicators to quickly identify and isolate problem areas.

Technology/Functionality

Modern FCIs sense both magnetic and electric fields to distinguish between normal load surges and true electrical events, enabling directional detection and avoiding false trips. With detection speeds measured in milliseconds, they provide real-time pinpointing. Current sensing remains a common approach, but advanced models also utilize digital signal processing (DSP) to minimize false alarms. Some units feature inrush restraint to prevent tripping during temporary surges. Remote indication capability enables the wireless transmission of data to SCADA systems or control centers, providing operators with immediate insight and facilitating the faster dispatch of crews.

Standards & Features

Leading designs include variable trip thresholds, multiple reset types, and low-pass filtering to minimize misoperations. Many models are hotstick-installable for safety and conform to IEEE compliance standards, ensuring reliability across diverse applications. These features not only enhance accuracy but also reduce maintenance requirements, enabling efficient long-term operation.

Historical Evolution

Since their introduction in the 1940s, these devices have evolved from simple manually reset flags to sophisticated electronic equipment. Early versions required crews to manually reset them after repairs. Over time, automatic reset functionality, LED indicators, and remote communication were added. Today’s smart indicators integrate programmable logic, data logging, and seamless communication with grid monitoring systems, reflecting decades of advancement in line sensor evolution. As electricity transmission networks expand, indicators become increasingly critical in maintaining safety and reducing large-scale outages.

Benefits

The benefits of using these monitors are numerous and far-reaching. By quickly identifying the affected circuit, they significantly reduce outage time, minimizing disruption to customers and businesses. This rapid location capability also enhances the overall reliability of the power system, as it enables faster repairs and restoration of service. They improve safety by enabling quick isolation of the affected section, preventing escalation and hazards to personnel. In wildfire-prone areas, indicators support rapid response strategies that reduce risks associated with downed lines and delayed detection.

Smart Grid Integration

Today’s FCIs are part of broader smart grid monitoring strategies. Integrated with SCADA systems, they provide operators with real-time situational awareness. Some advanced designs incorporate wireless transmitters and receivers that signal directly to protective relays, allowing for rapid and coordinated isolation. This integration improves grid resilience, reduces downtime, and supports predictive maintenance by identifying intermittent or developing issues before they escalate. With the rise of smart grid technologies, fault indicators are evolving into intelligent sensors that enhance monitoring and predictive maintenance.

Comparison of Indicator Types

| Type | Features | Typical Application |

|---|---|---|

| Basic Visual | Manual reset, flag or LED indication | Overhead distribution lines |

| Automatic Reset | Resets after fault clears, simple indication | Overhead and underground |

| Electronic | Current/voltage sensing, inrush restraint, low-pass filtering | Substations, industrial systems |

| Smart/SCADA Integrated | DSP filtering, wireless communication, remote reset, programmable logic | Utilities, smart grid monitoring |

Analysis

The strong emphasis on line location highlights its critical importance in power system management. Accurately pinpointing the source of a disturbance is paramount for efficient troubleshooting and timely restoration. The increasing adoption of real-time monitoring, inrush restraint, and remote indication demonstrates a trend toward more sophisticated management systems. This technological diversity enables greater flexibility and customization, meeting the specific needs of utilities, industrial facilities, and smart grid operators. In overhead T&D, fault indicators complement devices like the electrical insulator by improving protection against system faults.

Frequently Asked Questions

What is a fault indicator, and how does it work?

It’s a device that detects and signals the presence of an abnormal condition in an electrical power system. It works by monitoring parameters such as current and voltage, triggering an alert when unusual activity is detected. This alert may be visual (flag or LED) or transmitted remotely to a control center.

What are the different types available?

They are categorized based on their application and functionality. Common types include:

-

Overhead: Used on overhead lines, typically visual.

-

Underground: Designed for cable vaults, often audible or remote.

-

Electronic: Offer advanced features like DSP filtering, inrush restraint, and communication.

-

Smart/SCADA: Fully integrated into monitoring and relay systems.

How do fault indicators improve power system reliability?

They reduce outage times, support immediate response through remote signaling, and enhance preventive maintenance by identifying intermittent problems before escalation.

What factors should be considered when selecting?

Consider factors such as application (overhead or underground), environmental conditions, functionality (visual vs. remote), accuracy, standards compliance, and installation requirements.

How are they installed and maintained?

Overhead indicators are typically pole-mounted, while underground versions are installed in vaults or directly on cables. Maintenance involves inspections, testing, and cleaning. Electronic units may require battery changes or firmware updates.

Do they ever give false alarms?

Advanced models use DSP filtering, inrush restraint, and directional detection to minimize false indications. Proper placement and settings further improve accuracy.

A fault indicator is an indispensable tool for maintaining the reliability and safety of modern power systems. From their origins in simple visual devices to today’s smart, SCADA-integrated models, their ability to quickly and accurately locate circuit issues significantly reduces outage times and improves overall grid resilience. By understanding their functions, standards, and benefits, electricians and system operators can make informed decisions that strengthen electrical infrastructure and support the transition to smarter, safer, and more efficient networks.

Related Articles

T&D Asset Operators Look to Critical Energy Storage

Critical energy storage ensures uptime with UPS systems, battery backup, and microgrids, stabilizing renewables and grid resilience through frequency regulation, peak shaving, and long-duration solutions for hospitals, data centers, and industrial facilities.

What Is Critical Energy Storage?

Systems that provide guaranteed power continuity and grid support using UPS, batteries, and microgrids.

✅ Ensures uptime for critical loads during outages

✅ Stabilizes grids via frequency regulation, peak shaving

✅ Integrates renewables with storage, UPS, and microgrids

Upgrading and deferring existing wires and substations may be the most common application of battery storage utilized for transmission and distribution. However, batteries also provide a range of solutions designed to maximize the lifetime of T&D infrastructure. Also referred to as T&D asset optimization, these energy storage systems (ESSs) are designed to enhance the efficiency and effectiveness of existing T&D assets to provide electricity in a given service territory. Ensuring that these systems are reliable is critical to the effective operation of electricity throughout a given service territory.

Navigant Research anticipates that a cumulative 35.5 GW of new energy storage will be built for critical infrastructure through 2027. Approximately 25% of this storage capacity is expected to directly address T&D issues. Mission critical installations require systems that deliver continuous electrical service with high power quality to the grid. Such installations also require facilities like large data centers, telecom operations, financial services centers, hospitals and complex manufacturing operations. This market segment is growing and can be addressed by a variety of system design topologies that can deliver high-fidelity electricity.

There exist a variety of specific drivers that have led utilities around the world to deploy ESSs to improve operations in T&D infrastructure. Local grid conditions and utility preference have a significant impact on the likelihood that storage systems will be developed to defer T&D upgrades. Specifically, there are three key issues that ESS help mitigate in this market. For readers new to system architecture, the fundamentals of power distribution help explain how storage eases bottlenecks across feeders.

Reliability

The primary driver for utilities pursuing reliability improvements—with or without energy storage—is the need to enhance the reliability of energy supply for their customers. ESSs enable this by either avoiding local outages that may originate on the feeder where an ESS is deployed or islanding the feeder and maintaining power supply for customers. Improving reliability is a concern for commercial and industrial (C&I) customers, who often place a premium on reliability as they risk significant financial losses from an outage. To understand the impact of grid outages for customers, analysts and utilities calculate the value of lost load (VOLL), which represents the cost of going without power for a certain period. For a homeowner this cost is minimal, more of an inconvenience than a major economic impact. However, for C&I buildings, the VOLL in the United States is estimated to average around US$20,000/MWh, according to a 2014 study from The Brattle Group. With the increasing cost-effectiveness of distributed energy resources and independent energy procurements allowing large companies to defect from their local utilities, maintaining reliable service is a critical concern for grid operators. In outage-prone zones, deploying a microgrid can maintain service while upstream faults are cleared.

Congestion and Curtailment

Transmission line congestion is a frequent issue faced by grid operators around the world. Transmission congestion issues can occur in both urban and rural areas and may be driven by either renewable or conventional energy generation. Congestion is caused when increased demand for electricity during peak periods outpaces the available transmission capacity. This issue is frequently the result of generation facilities being located far from load centers, with limited bandwidth to transfer energy from generation to load centers. During peak demand periods (that is, when wires heat up), congestion on transmission lines can result in insufficient energy to serve load, instability on the transmission network and increased costs for load-serving utilities. Although congestion issues on the transmission network receive the most attention, congestion can also occur on the electricity distribution system when existing infrastructure is unable to serve peak demand in each area. This situation is often exacerbated by high penetrations of variable distributed generation, such as solar PV, wherein fluctuating output leads to rapid changes in demand for electricity at the grid edge. As utilities integrate more distributed energy resources, storage can buffer variability at the grid edge.

Load Growth

Overall load growth rates have decreased or remained flat in the US and other developed economies in recent years; however, the dynamics of peak demand periods on the grid continue to evolve. Some utilities are experiencing decreasing overall load growth rates yet have increasing growth in their peak demand. Furthermore, the duration of peak demand is growing in many areas, moving from the traditional two to four-hour peak period to well over four or even eight hours in some locations. This trend is being exacerbated by the rising penetration of solar generation, particularly in hot climates. According to utility Arizona Public Service, hot summer temperatures above 100°F combined with decreasing solar generation in the evening result in six to seven-hour peaks across their system to cover air conditioning usage. Advanced smart grid controls can stretch capacity during extended peaks without immediate wire upgrades.

What Types of Technologies Fit?

There are key advanced battery technologies that have the optimal characteristics to serve critical loads in high fidelity settings. These technologies are judged by metrics including the following:

- Power and Energy Density

- Lifespan

- Cost

- Operation and Maintenance Requirements

- Physical Size/Housing Requirements

While there are several technologies that have attractive profiles across the above criteria, there are three key technologies that are poised to have a substantial impact on the backup power market.

Li-ion

Lithium ion (Li-ion) batteries have good energy and power densities, round-trip efficiency and life cycle expectations, making them particularly well-suited for power-intensive critical infrastructure applications. Li-ion batteries have emerged as the leading technology for both utility-scale and C&I energy storage applications because of their flexibility and availability through mass production, pushing them further down the experience curve than other advanced batteries. Several leading vendors—including LG Chem, Samsung SDI, Panasonic and BYD—have rapidly expanded manufacturing capabilities in recent years, contributing to the falling costs of the technology. For project timelines, anticipating costly interconnection delays helps developers align procurement and commissioning.

Flow

Flow batteries are advantageous because they can store chemical energy for long periods of time by simply adding more tanks of liquid electrolyte. This makes them favorable for low cost, long-duration applications that require shifting of multiple hours’ worth of energy from one time of day to another. They are generally safer than Li-ion batteries as thermal management is not required. They also have little to no depletion of active materials over time, giving them greater life cycle expectancies than other battery types. This benefit is magnified by the fact that many flow batteries use inexpensive materials, vanadium being the primary exception.

Hybrid Battery/Fossil Generator

Hybrid battery-fossil fuel technology can be especially flexible as a grid or building asset and is increasingly being recognized as a tool to improve the efficiency, flexibility, and resiliency of existing fossil fueled power systems. In the same way a hybrid car uses battery storage to improve efficiency and reduce fuel consumption, an ESS integrated with conventional power can result in significant fuel savings while improving the system’s overall resiliency. Additionally, critical facilities with the need for long-duration guaranteed power (for example, 12-, 24-, or 72-hour needs) often are required by legislature to have diesel generators onsite. Pairing storage with improved overhead switchgear can further enhance fault isolation and reduce restoration times.

What Should Stakeholders Do to Prepare?

Utilities should work with vendors and project developers to offer solutions tailored to their customers’ specific needs. The most viable early projects may be smaller in capacity and specifically target a T&D issue a utility is experiencing. Smaller problems are more likely to be accepted by utilities and regulators due to the lower risk involved. Additionally, vendors should focus on providing standardized, modular systems that can be scaled to meet the required capacity for projects now and in the future. By starting small with modular systems, additional capacity can always be added as needed. Once utilities and regulators become comfortable with ESSs for T&D deferral, small modular systems will be easier to replicate in new locations and with new customers.

Storage providers need to determine how to structure their business models to take advantage of additional revenue streams while ensuring the reliability of core T&D optimization benefits. This challenge will require input and collaboration between project developers and integrators, software providers, utilities and market regulators to determine the best-fitting solutions. Storage industry stakeholders should be actively involved in ongoing regulatory processes to ensure that the full benefits of the technology are well understood.

Related Articles

High Voltage AC Transmission Lines

Ac transmission lines deliver alternating current across the power grid using high voltage, overhead conductors, and insulators, controlling reactive power, impedance, and corona effects to minimize losses, improve efficiency, and ensure reliable long-distance electricity transmission.

What Are AC Transmission Lines?

Ac transmission lines carry high-voltage AC power long distances with minimal losses.

✅ Typical voltages: 69 kV to 765 kV; higher reduces I2R losses

✅ Requires reactive power compensation: shunt capacitors, SVC, STATCOM

✅ Design factors: conductor bundling, corona control, insulation coordination

Three-phase electric power systems are used for high and extra-high voltage AC transmission lines (50kV and above). The pylons must therefore be designed to carry three (or multiples of three) conductors. The towers are usually steel lattices or trusses (wooden structures are used in Germany in exceptional cases) and the insulators are generally glass discs assembled in strings whose length is dependent on the line voltage and environmental conditions. One or two earth conductors (alternative term: ground conductors) for lightning protection are often added to the top of each pylon. For background on material properties, the electrical insulator overview provides relevant design considerations.

Detail of the insulators (the vertical string of discs) and conductor vibration dampers (the weights attached directly to the cables) on a 275,000 volt suspension pylon near Thornbury, South Gloucestershire, England. In some countries, pylons for high and extra-high voltage are usually designed to carry two or more electric circuits. For double circuit lines in Germany, the “Danube” towers or more rarely, the “fir tree” towers, are usually used. If a line is constructed using pylons designed to carry several circuits, it is not necessary to install all the circuits at the time of construction. Medium voltage circuits are often erected on the same pylons as 110 kV lines. Paralleling circuits of 380 kV, 220 kV and 110 kV-lines on the same pylons is common. Sometimes, especially with 110 kV-circuits, a parallel circuit carries traction lines for railway electrification. Additional context on span lengths, conductor bundles, and right of way is covered in this transmission lines reference for practitioners.

High Voltage DC Transmission Pylons

High voltage direct current (HVDC) transmission lines are either monopolar or bipolar systems. With bipolar systems a conductor arrangement with one conductor on each side of the pylon is used. For single-pole HVDC transmission with ground return, pylons with only one conductor cable can be used. In many cases, however, the pylons are designed for later conversion to a two-pole system. In these cases, conductor cables are installed on both sides of the pylon for mechanical reasons. Until the second pole is needed, it is either grounded, or joined in parallel with the pole in use. In the latter case, the line from the converter station to the earthing (grounding) electrode is built as underground cable. Engineers can review converter topologies, pole configurations, and control methods in the direct current technology guide to inform design choices.

Guidance on electrode placement, resistivity, and corrosion protection is summarized in the grounding electrodes overview relevant to HVDC return paths.

Raliway Traction Line Pylons

Pylons used for single-phase AC railway traction lines are similar in construction to pylons used for 110 kV-three phase lines. Steel tube or concrete poles are also often used for these lines. However, railway traction current systems are two-pole AC systems, so traction lines are designed for two conductors (or multiples of two, usually four, eight, or twelve). As a rule, the pylons of railway traction lines carry two electric circuits, so they have four conductors. These are usually arranged on one level, whereby each circuit occupies one half of the crossarm. For four traction circuits the arrangement of the conductors is in two-levels and for six electric circuits the arrangement of the conductors is in three levels. With limited space conditions, it is possible to arrange the conductors of one traction circuit in two levels. Running a traction power line parallel to high-voltage transmission lines for threephase AC on a separate crossarm of the same pylons is possible. If traction lines are led parallel to 380 kV-lines, the insulation must be designed for 220 kV because, in the event of a fault, dangerous overvoltages to the three-phase alternating current line can occur. Traction lines are usually equipped with one earth conductor. In Austria, on some traction circuits, two earth conductors are used. Integration with substation feeders and sectioning posts must align with the power distribution practices used along the route.

Types Of Pylons

Specific Functions:

- anchor pylons (or strainer pylons) utilize horizontal insulators and occur at the endpoints of conductors.

- pine pylon – an electricity pylon for two circuits of three-phase AC current, at which the conductors are arranged in three levels. In pine pylons, the lowest crossbar has a wider span than that in the middle and this one a larger span than that on the top.

- Twisting pylons are anchor pylons at which the conductors are “twisted” so that they exchange sides of the pylon.

- long distance anchor pylon

A long distance anchor pylon is an anchor pylon at the end of a line section with a long span. Large gaps between pylons reduces the restraints on the movement of the attached conductors. In such situations, conductors may be able to swing into contact with each during high wind, potentially creating a short circuit. Long distance anchor pylons must be very stably built due to the large weight of the exceptionally long cables. They are implemented occasionally as portal pylons. In extreme cases, long distance anchor pylons are constructed in pairs, each supporting only a single cable, in an effort to reduce the strain of large spans.

Branch Pylon: In the layout of an overhead electrical transmission system, a branch pylon denotes a pylon which is used to start a line branch. The branch pylon is responsible for holding up both the main-line and the start of the branch line, and must be structured so as to resist forces from both lines. Branch pylons frequently, but not always, have one or more cross beams transverse to the direction of travel of the line for the admission of the branching electric circuits. There are also branch pylons where the cross beams of the branching electric circuits lie in the direction of travel of the main line. Branch pylons without additional cross beams are occasionally constructed. Branch pylons are nearly always anchor pylons (as they normally must ground the forces from the branch line). Branch pylons are often constructed similarly to final pylons; however, at a branch pylon the overhead line resumes in both directions, as opposed to only one direction as with a final pylon.

Anchor Portal: An anchor portal is a support structure for overhead electrical power transmission lines in the form of a portal for the installation of the lines in a switchyard. Anchor portals are almost always steel-tube or steel-framework constructions.

Termination Pylon: Anchor pylons or strainer pylons utilize horizontal insulators and occur at the endpoints of conductors. Such endpoints are necessary when interfacing with other modes of power transmission (see image) and, due to the inflexibility of the conductors, when significantly altering the direction of the pylon chain. Anchor pylons are also employed at branch points as branch pylons and must occur at a maximum interval of 5 km, due to technical limitations on conductor length. Conductors are connected at such pylons by a short conductor cable “strained” between both ends. They often require anchor cables to compensate for the asymmetric attachment of the conductors. Therefore, anchor pylons tend to be more stably built than a support pylon and are often used, particularly in older construction, when the power line must cross a large gap, such as a railway line, river, or valley. A special kind of an anchor pylon is a termination pylon. It is used for the transition of an overhead powerline to an underground cable. A termination pylon at which the powerline runs further as well as overhead line and as underground cable is a branch pylon for a cable branch. For voltages below 30kV, pylon transformers are also used. Twisted pylons are anchor pylons at which the conductors are “twisted” so that they exchange sides of the pylon. Anchor pylons may also have a circuit breaker attached to their crossbeam. These so called switch pylons are operated from the ground by the use of long sticks. The attachment of circuit breakers to pylons is only practical when voltages are less than 50kV. Where sectionalizing or protection is required aloft, utilities are adopting overhead switchgear innovations to reduce footprint and maintenance.

Materials Used

- Wood Pylon

- Concrete Pylon

- Steel Tube Pylon

- Lattice Steel Pylon

Conductor Arrangements

Portal Pylon: In electricity distribution, a portal pylon is a type of pylon with which the cross beams on the conductor cables rest on at least two towers. Portal pylons can be made of wood, concrete, steel tubing or steel lattice. They are used in German railroad wiring because of their enormous space requirement as a rule only for anchor pylons, which have to resist high traction power and as bases for lines in switchgears as anchor portals. Their application and clearances are coordinated with prevailing electrical distribution systems standards for safe operation.

Delta Pylon: A delta pylon is a type of support structure for high-voltage electric power transmission lines. The pylon has a V-shapedtop for the admission of the cross beam. Delta pylons are usually established only for one electric circuit, occasionally for two electric circuits. They are used for voltages up to 765 kV. Delta pylons are far more common in the USA, France, Spain, Italy and formerYugoslavia, while in Germany on delta pylons shifted high voltage transmission lines are very rare.

Single-level Pylon: A single-level pylon is an electricity pylon for an arrangement of all conductor cables on a pylon in one level. The singlelevel pylon leads to a low height of the pylons, connected with the requirement for a large right of way. It is nearly always used for overhead lines for high-voltage direct current transmissions and traction current lines. If three-phase current is used, if the height of pylons may not exceed a certain value.

Two-level Pylon: A two-level pylon is a pylon at which the circuits are arranged in two levels on two crossbars. Two-level pylons are usually designed to carry four conductors on the lowest crossbar and two conductors at the upper crossbar, but there are also other variants, e.g. carrying six conductors in each level or two conductors on the lowest and four on the upper crossbar. Two-level pylons are commonplace in former West-Germany, and are also called Donau pylons after the river Danube.

Three-level Pylon: A three-level pylon is a pylon designed to arrange conductor cables on three crossbars in three levels. For two three-phase circuits (6 conductor cables), it is usual to use fir tree pylons and barrel pylons. Three-level pylons are taller than other pylon types, but require only a small right-of-way. They are very popular in a number of countries.

Three-level Pylon: A three-level pylon is a pylon designed to arrange conductor cables on three crossbars in three levels. For two three-phase circuits (6 conductor cables), it is usual to use fir tree pylons and barrel pylons. Three-level pylons are taller than other pylon types, but require only a small right-of-way. They are very popular in a number of countries.

From: Overhead and Underground T&D Handbook, Volume 1, The Electricity Forum

Related Articles

Distributed Energy Resources - Small Scale Power

Distributed energy resources integrate rooftop solar, battery storage, EV charging, and demand response within microgrids and virtual power plants to optimize load, enhance grid resilience, lower costs, and enable real-time, bidirectional power flows.

What Are Distributed Energy Resources?

Distributed energy resources are small-scale, grid-connected assets that generate, store, or manage electricity locally.

✅ Integrates solar PV, batteries, EVs, and demand response

✅ Enhances grid reliability, resilience, and peak-load flexibility

✅ Enables microgrids and virtual power plants for local balancing

Distributed energy resources (DERs) can benefit the power system and individual homes and businesses. DERs can increase the resiliency and reliability of the power grid, reduce greenhouse gas emissions, reduce the overall power cost, and provide power at the point of use. Several types of DERs can be used to generate electricity, including renewable energy sources like solar photovoltaic, wind power, and fuel cells, as well as energy storage systems like battery storage and combined heat and power (CHP) systems. DERs can also be used to power electric vehicles (EVs) and help to reduce greenhouse gas emissions in the transportation sector.

One of the most significant benefits of DERs is their ability to increase the resiliency and reliability of the power grid. When traditional power plants experience outages, DERs can continue to provide power to homes and businesses, reducing the impact of the outage. DERs can also help to reduce the strain on the power grid during peak demand periods, which can help to prevent blackouts and brownouts. Advanced distribution automation can coordinate DER dispatch for reliability gains.

Another benefit of DERs is their ability to reduce greenhouse gas emissions. Renewable energy sources such as solar photovoltaic and wind power do not produce carbon emissions, which can help reduce the amount of greenhouse gases released into the atmosphere. In addition, CHP systems can use natural gas to generate electricity while using waste heat to provide heating or cooling to homes or businesses. This can help reduce overall power consumption and lower carbon emissions.

Electric vehicles (EVs) are another type of DER that can help to reduce greenhouse gas emissions. EVs can be charged using renewable energy sources, which means that they can help to reduce the use of fossil fuels in transportation. In addition, EVs can also provide energy storage, which can help balance the power grid during periods of high demand.

DERs can also help to reduce the overall cost of power. Because DERs are typically small-scale, they can be less expensive to install and maintain than large-scale power plants. In addition, DERs can provide power at the point of use, which can help reduce the amount of power lost during transmission and distribution. For context, understanding power distribution helps explain how localized generation reduces network losses.

Several types of DERs can be used to generate electricity. Solar photovoltaic (PV) systems use solar panels to generate electricity from the sun's energy. Wind power systems use wind turbines to generate electricity from the wind. Fuel cells use hydrogen and oxygen to generate electricity, with water as the only byproduct.

In addition to renewable energy sources, DERs can include energy storage systems such as battery storage. Battery storage systems can store energy generated by renewable energy sources, which can be used during periods of high demand or when the renewable energy source is unavailable. Utilities often rely on critical energy storage to maintain service continuity during contingencies.

DERs can also include CHP systems, which use natural gas to generate electricity and waste heat to provide heating or cooling to homes or businesses. In addition, CHP systems can provide power at the point of use, which can help reduce the amount of power lost during transmission and distribution.

DERs can be connected to the power grid through a smart grid, which can help to monitor and manage the flow of energy. A smart grid can also help to balance the power grid during periods of high demand by using DERs to provide additional power. To learn more about the enabling technologies, see what a smart grid is and how it orchestrates DERs.

One of the most significant advantages of DERs is their small-scale nature, which allows them to be located close to where the electricity is needed, reducing transmission and distribution losses. DERs can also provide power during peak demand periods, helping to avoid the need for additional power plants or transmission lines. These local benefits accrue within electrical distribution systems where congestion and voltage constraints are most acute.

Another advantage of DERs is their ability to operate independently or in concert with other DERs as part of a microgrid. Microgrids are small-scale power systems that can work independently of the primary power grid, allowing for increased resiliency and reliability in the event of a power outage or other disruption to the power grid. Microgrids can also help to integrate DERs into the power system, providing a more flexible and efficient power system. If you are unfamiliar with the concept, explore what a microgrid is and how its islanded operations support resilience.

DERs can also help reduce the overall power cost by reducing the need for expensive transmission and distribution infrastructure. DERs can be installed and operated by individual homes and businesses, reducing the need for large-scale power plants and transmission lines. This can help reduce the overall power cost and provide more affordable power options for consumers.

However, there are also some challenges associated with DERs. One of the biggest challenges is the integration of DERs into the power grid. DERs can generate electricity intermittently, making it challenging to balance the power grid and ensure a consistent electricity supply. In addition, DERs can be located in areas where the power grid may not be able to accommodate additional power generation. This can require upgrades to the power grid and further investment in infrastructure. Projects may also face costly interconnection delays that extend timelines and budgets.

Another challenge is the need for energy storage systems to balance the power grid during high-demand or low-renewable power availability periods. Energy storage systems can be expensive, and their efficiency and reliability can vary depending on the type of technology used.

Despite these challenges, DERs have the potential to play a significant role in the transition to a more sustainable and resilient power system. By leveraging renewable energy sources and energy storage systems, DERs can help reduce greenhouse gas emissions, increase power resiliency and reliability, and reduce the overall energy cost.

What are the characteristics of distributed energy resources?

DERs are small-scale power sources that can be located close to the electricity needed. Renewable energy sources often power them, and they can be connected to the power grid or operate independently as part of a microgrid. They can also provide power during peak demand periods and help reduce the overall energy cost.

What are the benefits of distributed energy resources?

The advantages of using distributed energy resources include increased resiliency and reliability of the power grid, reduced greenhouse gas emissions, and decreased overall power cost. Disadvantages include challenges related to integration into the power grid and the need for energy storage systems to balance the power grid during periods of high demand or low renewable poweravailability.

How do distributed energy resources impact the existing power grid?

DERs can impact the existing power grid by providing additional sources of electricity during peak demand periods and reducing the strain on the power grid. However, the intermittent nature of some DERs can also create challenges in balancing the power grid and ensuring a consistent electricity supply.

What is the role of energy storage in distributed energy systems?

Energy storage plays a critical role in distributed energy systems by allowing excess energy generated by renewable power sources to be stored and used during periods of high demand or low renewable energy availability. Energy storage can also help balance the power grid and ensure a consistent electricity supply.

How are regulations and policies impacting the adoption of distributed energy resources?

Regulations and policies can impact the adoption of DERs by creating incentives for investment in DERs and promoting the integration of DERs into the power system. However, regulations and policies can also create barriers to entry for new technologies or increase the cost of implementation.

What is the future outlook for distributed energy resources, and what trends are emerging in this field?

The future outlook for DERs is promising as the demand for renewable sources and increased resiliency and reliability continue to grow. Emerging trends in this field include the use of blockchain technology to create peer-to-peer markets and the increased use of artificial intelligence and machine learning to optimize the performance of DERs.

Related Articles

Overhead T&D News

Overhead T&D Media

Overhead T&D Articles From ET Magazine

Transmission Construction Industry Leader Retires and Sells at Absolute Auction!

S.E., Inc. has been providing the very best in Transmission Powerline Construction for over (40) years throughout the Western United States. Brothers Mark, Steve, David, and Craig Sorenson have decided to retire and pursue other interests. Everything in the auction is owned by S.E., Inc. and will positively sell to the highest bidder without minimum or reserve!

S.E., Inc. has hired Hunyady Auction Company to conduct their liquidation. Hunyady Auction Company is celebrating their 35th year in business and specializes in liquidation auctions of electrical construction companies plus many other industries.

Transmission and Distribution (T&D) professionals have a unique opportunity to acquire high-quality equipment at the upcoming auction hosted by Hunyady Auction Company. Scheduled for June 10th, 11th, and 12th, 2025, this comprehensive event will take place across three locations: Deaver, Wyoming; Nunn, Colorado; and Quartzsite, Arizona.

Why T&D Professionals Should Be Interested

This auction represents a significant opportunity for T&D professionals to enhance their operational capabilities. With a wide array of specialized equipment available, attendees can expect to find assets that align with their specific needs, potentially at more competitive prices than purchasing new. The variety and quality of equipment on offer make this event particularly appealing for those looking to expand or update their resources.

Benefits of Participating

One of the key benefits of participating in this auction is S.E., Inc.’s decades long, exemplary reputation for well maintained equipment, up to date fleet, and work ethic. Auctions often provide equipment at prices lower than retail, allowing companies to maximize their budgets and acquire high-quality machinery without overspending. Another advantage is immediate availability. Unlike ordering new equipment, which can involve long lead times, purchasing at an auction enables businesses to integrate their acquisitions into ongoing projects right away, minimizing downtime and delays. Additionally, the auction offers a diverse selection of equipment, giving attendees the opportunity to find multiple assets in one setting, making it a convenient and efficient way to source specialized T&D equipment.

Who Should Attend

The auction is ideal for:

-

Utility Companies: Seeking to upgrade or expand their T&D infrastructure.

-

Contractors: Specializing in power line construction and maintenance.

-

Equipment Rental Firms: Looking to diversify their inventory with specialized T&D machinery.

-

Maintenance Teams: In need of reliable equipment for routine operations.

Featured T&D Equipment Up for Auction

The auction boasts an extensive inventory tailored to the needs of T&D professionals. Notable items include:

-

Boom/Aerial Lifts: Such as the 2010 NATIONAL 9103A, a 26-ton boom mounted on a 2010 PETERBILT 365 T/A

-

Hydraulic Cranes: Including the 2008 TADANO GR300XL-1, a 30-ton rough terrain crane

-

Wire Pullers and Rewind Machines: For instance, the 2014 (Rebuilt) PENGO TRCP30-3, a three-drum hydraulic puller mounted on a 1958 Fruehauf T/A Rigid Neck Lowboy Trailer

-

Wire Tensioners: Such as the UTAH SPROCKET 60”, a four-bundle bull wheel tensioner mounted on a 1988 Mack CH612 T/A Carrier

-

Stringing Blocks: A variety of sizes, including 32” helicopter bundle blocks and 28” bundle blocks

-

Sagging Tractors: For example, the 1974 CAT D7F Crawler Tractor equipped with three PLECCO 30,000# winches

-

Aerial Line Guard Towers: Including the HI-RANGER 10-90I, a 90’ aerial "Line Guard" tower mounted on a 1974 Dorsey T/A Flatbed Trailer

-

Reel and Pole Trailers: Such as the 1977 LOAD KING Tri-Axle Step Deck Reel Trailer

-

Bucket Trucks: For instance, the 2007 LIFT-ALL LAN/HD-75-2E, a 75’ bucket truck mounted on a 2007 FREIGHTLINER Business Class M2, 4x4 Flatbed Truck

-

Digger Derricks and Production Diggers: Including the 2000 ALTEC D4060TR Digger Derrick mounted on a 2001 FREIGHTLINER T/A Flatbed Truck

-

Skid Steer Loaders and Backhoes: Such as the 2019 KUBOTA SVL95-2S Crawler Skid Steer Loader

-

Aerial Lifts and Scissor Lifts: For example, the 2007 AICHI SR18AJ/ISR60J, a 60’ crawler aerial lift

-

Track and Riding Dumpers: Including the 1991 MOROOKA MST2200 Crawler Dumper

-

Utility and Trencher Tractors: Such as the 2005 NEW HOLLAND TC45DH, a 4x4 utility tractor

-

Truck Tractors and Lowboy Trailers: For instance, the 2006 KENWORTH T800 T/A Truck Tractor

-

Step Deck and Flatbed Trailers: Including the 2005 FONTAINE EDFT-6-8048WSAWK Spread Axle Step Deck Trailer

-

Dump Trucks, Water Trucks, and Log/Pole Loader Trucks: Such as the 2000 STERLING T/A Dump Truck

-

Flatbed, Utility, and Service Trucks: For example, the 2022 FORD F-450 Lariat, a 4x4 Crew Cab Flatbed/Utility Truck

-

4x4 Crew Cab Pickup Trucks: Including the 2022 FORD F-250 Lariat Super Duty

-

Gooseneck, Dump, Tag-A-Long, and Cargo Trailers: Such as the 2021 LOAD TRAIL T/A Dump Trailer

-

Miscellaneous Equipment: Including air compressors, generators, and a large quantity of power line and contractor tools

How the Auction Works

Hunyady Auction Company ensures a seamless experience for all participants. All items will be sold at public, absolute auction without minimums or reserves via both virtual, live-broadcast and timed online platforms. Items will be available for inspection, at each location, for approximately (1) week prior to auction dates. Interested buyers can register through Proxibid. Additional information can be found at www.Hunyady.com The Hunyady team is available to answer any questions, feel free to call (800) BID-N-BUY, (215) 361-9099, or email sales@hunyady.com

Why Net-Zero is Cheaper for the UK

The United Kingdom has set an ambitious target to achieve net-zero greenhouse gas emissions by 2050. This goal necessitates a comprehensive transformation of various sectors, including energy, transportation, and agriculture. While the environmental imperatives are clear, there is growing evidence that this transition could also yield significant economic advantages for the nation.

Energy Sector Transformation

A pivotal component of the UK's net-zero strategy involves a substantial shift towards renewable energy sources. By 2040, projections suggest that wind and solar power will supply approximately 80% of the country's electricity needs. This transition is expected to reduce energy imports, enhancing national energy security and potentially lowering energy costs for consumers.

The adoption of technologies such as heat pumps for home heating is another crucial step. Heat pumps, which extract heat from the environment to warm homes, offer efficiencies of up to 400%. Their widespread adoption could lead to reduced reliance on fossil fuels and lower household energy bills.

Transportation Sector Overhaul

The automotive landscape is also undergoing significant changes. The Climate Change Committee (CCC) recommends that by 2040, 80% of cars on UK roads should be fully electric. This shift would decrease the demand for imported oil, enhance air quality, and align with global trends towards sustainable transportation.

Agricultural Adjustments

Agriculture plays a role in the nation's carbon footprint, particularly concerning meat consumption. The CCC advises that reducing meat consumption by approximately 260 grams per week per person could significantly lower emissions. This dietary shift would not only contribute to climate goals but also improve public health outcomes.

Economic Growth and Job Creation