Smart Grid

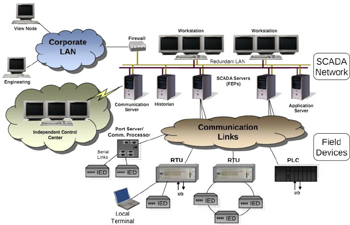

SCADA Architecture

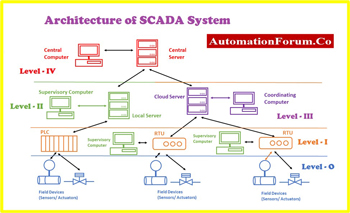

SCADA architecture defines how supervisory control and data acquisition systems are structured across field devices, control servers, and operator interfaces to ensure efficient monitoring, automation, and communication across electrical and industrial utility networks.

What is SCADA Architecture?

SCADA Architecture refers to the layered structure of hardware and software that enables data collection, control, and monitoring in real-time utility operations.

✅ Clearly separates field, control, and user interface layers

✅ Supports scalable and distributed system integration

✅ Enhances real-time visibility, reliability, and fault response

SCADA Architecture – System Design

Supervisory control and data acquisition (SCADA) architecture forms the structural backbone of modern industrial automation. It connects field-level devices with centralized software systems to control and monitor processes across wide geographic areas. A robust SCADA design framework ensures reliable data acquisitions, timely system responses, and actionable visibility into remote operations.

SCADA architecture refers to the design and layout of components that enable real-time supervisory control and data acquisition. It includes the physical devices, software platforms, communication networks, and user interfaces that work together to collect data and execute control actions.

This architecture is critical to electrical utilities, water systems, oil and gas pipelines, and other sectors where infrastructure must be controlled from a central location.

-

Organizes sensors, controllers, and software into defined system layers

-

Enables automation and human oversight across remote sites

-

Integrates field data into centralized SCADA software for decision-making

If you want more information about What is SCADA, read the full article.

Core Layers of SCADA Architecture

A typical supervisory control design includes four primary functional layers: field instrumentation, control equipment, communication networks, and supervisory software. Each plays a role in the seamless operation of the entire system.

At the field level, sensors measure process variables like voltage, temperature, or flow. These readings are transmitted to remote terminal units (RTUs) or programmable logic controllers (PLCs) for processing. These control devices perform localized automation and send data upstream.

-

Sensors: Capture physical values (e.g., voltage, pressure, flow)

-

PLCs and RTUs: Execute control logic and transmit data

-

Control equipment: Responds to automated or manual operator commands

This structure ensures that real-world operations are constantly observed, interpreted, and acted upon as needed. Read How Does SCADA Work, for a complete description of how this technology is used.

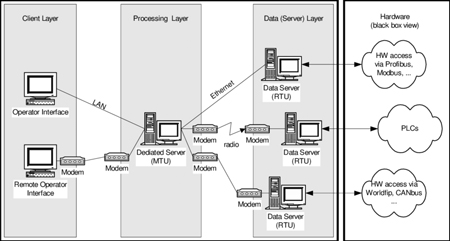

Communication and Data Flow

The effectiveness of SCADA design framework relies heavily on the communication network that links all devices. This network carries data from remote sites to central control rooms using secure, often redundant communication protocols.

Common standards such as Modbus, DNP3, and IEC 60870 ensure data integrity and compatibility across systems. Both wired (Ethernet, fiber) and wireless (radio, cellular) technologies may be used.

-

Protocols: Enable interoperability between diverse equipment

-

Networks: Ensure real-time connectivity across long distances

-

Cybersecurity: Protects control and data acquisition pathways from intrusion

Reliable communication is essential not only for remote control but also for storing and retrieving historical data, which supports trend analysis and maintenance planning.

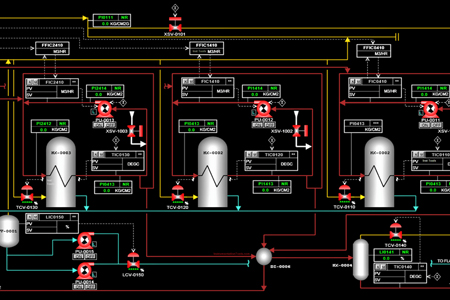

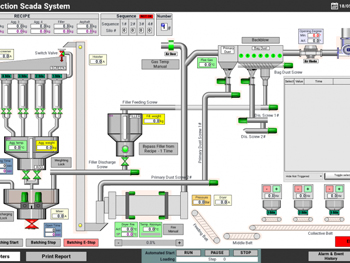

SCADA Software and User Interfaces

Once data reaches the central system, SCADA software processes it. This software layer applies logic, triggers alarms, and archives operational records. Operators interact with the system through human machine interface (HMI) screens that provide real-time visualizations of process conditions.

A well-designed user interface enhances safety and decision-making. It displays alarms, trending data, equipment status, and control options in an intuitive layout.

-

SCADA software: Executes automation logic, stores data, manages alarms

-

HMI: Allows operators to monitor and control systems through graphic displays

-

User interfaces: Provide access to live and historical data

Operators can manually adjust setpoints, acknowledge alerts, or trigger system overrides as needed.

Types of SCADA System Architecture

Over the years, several architectural models have evolved to meet growing industrial needs. Each model represents a step toward greater connectivity, reliability, and scalability.

-

Monolithic SCADA systems – Early centralized systems with limited external communication. Rarely used today.

-

Distributed systems – Introduced modularity by spreading tasks across separate computers. Increased reliability.

-

Networked SCADA systems – Today’s standard, connecting all components through integrated networks.

-

Modern SCADA systems – Incorporate cloud platforms, mobile access, and advanced analytics for greater flexibility.

These types of SCADA system architectures reflect the increasing demand for system integration, remote access, and real-time automation.

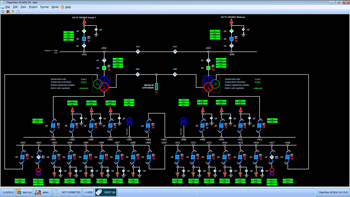

Applications in Electrical Automation

In electrical engineering, SCADA system layout plays a central role in industrial automation and grid management. It enables power utilities to control transmission lines, substations, and switchgear from a distance.

Control equipment, such as circuit breakers and transformers, is operated via PLCs and monitored through HMI terminals. Data is logged for performance evaluation, fault detection, and preventive maintenance.

-

Coordinates voltage regulation and load balancing

-

Reduces manual intervention and improves response time

-

Ensures safe, reliable operation across high-voltage infrastructure

As smart grid initiatives grow, SCADA serves as the command center for distributed energy resources and grid-wide optimization.

The Role of System Integrators

Designing and deploying a modern SCADA framework requires the expertise of system integrators. These professionals configure communication links, program PLCs, set up RTUs, and develop custom HMI layouts tailored to the application.

They also ensure that all components—from field sensors to control software—function together as a cohesive system.

-

Build and program automation systems

-

Configure user interfaces and alarm management

-

Optimize system architecture for reliability and scalability

Their work is essential in creating solutions that meet industry-specific standards for safety and performance.

SCADA system layout is more than just a technical blueprint—it’s the operational foundation for critical infrastructure. By combining programmable logic controllers and remote terminal units, reliable networks, powerful SCADA software, and intuitive HMIs, this architecture enables seamless control and data acquisition across diverse applications.

It supports real-time decisions, minimizes downtime, and offers centralized visibility for complex systems. As demands grow and technologies evolve, supervisory system design remains a cornerstone of connected, intelligent, and automated operations.

Related Articles

Download Our FREE Smart Grid Handbook

T&D Automation and AMR/AMI Systems Handbook Vol. 2

Volume 2 of our T&D Automation and AMR/AMI handbook series provides detailed information on the automation of the transmission and distribution networks, coupled with the widespread use of new metering technologies. Distributed generation, the cost benefit of modern substation automation, advanced metering infrastructure, intelligent switchgear and wireless technologies are a sampling of the articles included in this more than 104 page handbook.

The T&D Automation and AMR/AMI Systems Handbook, Vol. 2 is a comprehensive resource that explores the latest advancements, methodologies, and best practices in T&D automation and metering systems. Designed for electrical engineers, system operators, and utility professionals, this handbook provides a deep dive into the integration, implementation, and management of automation systems and smart metering solutions within modern power grids.

In this volume, we examine the key components of T&D automation, including SCADA systems, distribution automation, fault detection, isolation and restoration (FDIR), and the role of sensors and actuators in enhancing system performance and reliability. We also explore the integration of advanced communication technologies that enable utilities to remotely monitor, control, and optimize their distribution networks.

Additionally, Volume 2 focuses on the importance and functionality of AMR/AMI systems, which enable utilities to collect and analyze detailed data on energy consumption. We cover the architecture, design, installation, and maintenance of AMR and AMI systems, with a focus on how these technologies improve operational efficiency, billing accuracy, and customer service.

Latest Smart Grid Articles

SCADA HMI

SCADA HMI integrates Supervisory Control and Data Acquisition (SCADA) with Human-Machine Interface (HMI), providing operators with real-time system visibility, data visualization, and equipment control to enhance monitoring, decision-making, and performance.

What is SCADA HMI?

SCADA HMI refers to the interface that enables operators to visually monitor and control SCADA systems. It plays a key role in real-time control, efficiency, and safety.

✅ Enables real-time system control for remote and local operations

✅ Visualizes equipment and process data through intuitive dashboards

✅ Improves operator decision-making with alerts, trends, and diagnostics

Supervisory control and data acquisition (SCADA) is essential to modern industrial automation. Its Human Machine Interface (HMI) empowers operators to monitor and control complex systems, integrating control and data acquisition into a unified supervisory framework. This article examines control system architecture, hardware components, software layers, and operational benefits while limiting the term “SCADA” to 14 uses. For a deeper understanding of how data flows through a control system, see our guide on how does SCADA work.

SCADA HMI System Components and Functions

| Component | Function | Location in System Architecture |

|---|---|---|

| Field Devices | Measure and transmit process variables (e.g., pressure, temperature, flow) | On-site at the equipment/process level |

| Programmable Logic Controllers (PLCs) | Execute control logic, manage I/O, and interface with sensors and actuators | Local panels or near-field equipment |

| Remote Terminal Units (RTUs) | Collect remote data, perform basic control, relay info to SCADA master | Remote or distributed field locations |

| SCADA Software | Perform supervisory control, log data, generate alarms and trends | Centralized server or control center |

| HMI Software | Provide a graphical user interface for operator interaction | Control room displays, local or remote |

| Human Machine Interface (HMI) | Visualize process data, alarms, and system status in real time | Operator terminals or mobile access points |

| Communication Network | Transmit data between devices, controllers, and servers | Throughout the facility and remote sites |

| Data Historian | Archive process data for trend analysis and reporting | SCADA server or cloud environment |

| Cybersecurity Layer | Protect the system from unauthorized access and cyber threats | Across the entire control system |

Control System Architecture and Field Devices

A reliable control system architecture integrates multiple hardware layers. Field devices such as sensors, actuators, and meters collect real-time data from operational environments. These signals are sent to programmable logic controllers (PLCs) and remote terminal units (RTUs), which perform local control and transmit data upstream. If you're new to the subject or need a refresher, start with this overview on what is SCADA, including its role in industrial automation and remote system control.

At the supervisory level, SCADA software running on host computers executes control logic, stores historical data, and manages alarms. The HMI SCADA system offers a graphical user interface that enables operators to visualize process conditions, receive alerts, and interact with the system through HMI software.

Key architectural elements include:

-

Field devices for sensing and actuation

-

PLCs for high-speed local logic

-

RTUs for wide-area communication

-

Central servers for supervisory functions

-

HMI for user interaction and process feedback

Data Acquisition and Visualization

Data acquisition SCADA systems gather real-time analog and digital inputs from multiple sources. These inputs are processed and displayed through the human machine interface HMI, which converts raw values into visual formats such as graphs, status indicators, and alarm panels. To explore the core layers and logic behind supervisory control systems, visit our detailed explanation of SCADA architecture.

Operators use the HMI to oversee system status, detect anomalies, and initiate process control adjustments. In addition to live data, most systems offer historical trend analysis, allowing teams to track performance and investigate past events.

HMI visualization typically includes:

-

Real-time data meters and digital indicators

-

Process flow diagrams and mimic panels

-

Historical trend charts for performance evaluation

-

Alarm dashboards and status logs

Supervisory Control and Remote Monitoring

One of the greatest strengths of SCADA HMI systems is their ability to facilitate remote monitoring. RTUs and PLCs located across extensive infrastructure transmit data to central servers, enabling the supervision and control of industrial processes from a control room or even a mobile device. Substations are a critical part of many SCADA deployments; learn more about how SCADA is used in electric utilities through our article on substation SCADA.

Benefits of remote monitoring:

-

Reduced need for on-site personnel

-

Faster response to system faults

-

Centralized oversight of geographically dispersed assets

-

Enhanced worker safety and operational efficiency

HMI Software and Operator Interaction

The role of HMI software is to present complex process data in an intuitive and manageable format. It allows operators to adjust setpoints, acknowledge alarms, and issue manual commands using touchscreen displays, keypads, or workstations. A key benefit of SCADA HMI is continuous oversight of operations—see how SCADA monitoring supports real-time visibility and incident response.

By simplifying the interaction between people and machines, the human machine interface HMI improves situational awareness and reduces the risk of operator error. It also allows multiple operators to manage different parts of the system simultaneously, supporting greater operational scale and flexibility.

Typical operator functions include:

-

Start/stop of motors and pumps

-

Adjustment of process setpoints

-

Acknowledgment of system alarms

-

Review of operational logs and reports

Integration and Interoperability

Modern systems must operate in heterogeneous environments with diverse devices and protocols. Standards such as Modbus, OPC UA, and IEC 61850 ensure that SCADA HMI platforms can communicate with third-party controllers, sensors, and enterprise systems. Effective systems must integrate hardware, software, and protocols seamlessly—our article on SCADA integration explains how this is achieved across platforms.

This interoperability allows organizations to:

-

Upgrade legacy systems with minimal disruption

-

Combine multi-vendor equipment into a unified platform

-

Support digital transformation and enterprise integration

-

Scale operations without redesigning core systems

Real-Time Data, Alarms, and Process Control

Real-time visibility is a core function of any SCADA HMI platform. By accessing real-time data through the HMI, operators can detect out-of-range conditions, act on alarms, and engage in immediate troubleshooting.

The graphical user interface not only displays alarms but also records them in chronological logs for post-event analysis. These features form the backbone of effective process control, providing insight into every stage of operation and enabling predictive maintenance and continuous improvement.

Effective alarm systems should include:

-

Prioritized alert levels (critical, warning, info)

-

Time-stamped event logs

-

Audible/visual signals for attention

-

Escalation rules for safety compliance

Applications Across Industry Sectors

SCADA HMI systems are used in virtually every sector of the industrial economy. In power utilities, they manage substation control and distribution grids. In the oil and gas industry, they control pipeline pressure and operate remote pumping stations. In water and wastewater, they oversee filtration systems, chemical dosing, and reservoir levels.

In manufacturing, these systems track assembly lines, batch processes, and machine utilization. Across all these applications, the integration of SCADA software and HMI enables high-efficiency, scalable, and safe control of complex operations.

Controllers, RTUs, and Field-Level Integration

Programmable logic controllers PLCs and remote terminal units RTUs are essential components of data acquisition SCADA systems. PLCs are optimized for high-speed local control, whereas RTUs are often used in remote or harsh environments.

Both devices serve as bridges between field devices and higher-level supervisory control. The HMI visualizes their activity, translating electrical signals into user-friendly graphics and alarms.

Advanced Features and Cybersecurity

New-generation SCADA HMI platforms support edge computing, cloud connectivity, and AI-enhanced analytics. These features enable predictive maintenance, reduce manual effort, and support continuous optimization.

Security is also critical. As part of the broader industrial control system, HMI platforms must be able to resist cyber threats. Encryption, role-based access, firewalls, and network segmentation are now standard to protect systems from intrusion and maintain operational integrity.

SCADA HMI systems provide the foundation for modern control and data acquisition. They empower operators to visualize conditions, monitor and control processes, and respond to events in real time. By integrating HMI software, graphical user interfaces, and a robust control system architecture, organizations can achieve operational efficiency, enhanced safety, and long-term reliability.

This tightly integrated solution supports dynamic operations across energy, manufacturing, water, and infrastructure sectors, where visibility, control, and action must align at all times. As connectivity expands, protecting control systems is more critical than ever. Read how SCADA cybersecurity strategies help defend industrial infrastructure from modern threats.

Related Articles

Role of Data Analytics in Operational Efficiencies and as Sustainable Future

Data analytics in electrical engineering leverages machine learning, time-series modeling, and anomaly detection on SCADA and IoT big data to optimize power systems, signal processing, predictive maintenance, and real-time grid reliability.

What Is Data Analytics?

Data analytics applies statistical, ML, and signal processing to power data for optimization, diagnostics, and reliability.

✅ Time-series analysis of SCADA and PMU signals

✅ Predictive maintenance via anomaly detection models

✅ Load forecasting and grid optimization with ML

Mobile, social, cloud, analytics and Internet of Things (IoT) technologies are driving the digital transformation in utilities creating new opportunities to optimize operations, and integrate the utility customer into the energy and water value chain. With the global focus on sustainability, these technologies are becoming increasingly central to achieving the energy efficiency and water conservation goals.

Dawn of a New ‘Data’ Age

Across all industries, Gartner forecasts that 6.4 billion connected devices will be in use worldwide in 2016 – up 30 percent from 2015 – with the number reaching 20.8 billion by 2020. In 2016 alone, 5.5 million new devices will be connected each day. IoT is at the center of all of this. IoT makes it possible to connect people, products and services to empower people to make decisions, and utilize assets efficiently. By investing in IoT, utilities are already seeing tremendous opportunity to transform their business practices and eventually will have the touch points in all operations and customer engagement. What goes hand in hand with this is the data that all these devices generate and the analyses of such data, to allow for better decision making. For many utilities, understanding the evolution from traditional networks to the smart grid helps frame investments and workforce planning.

The largest volumes of data and its use has been mostly in intelligent assets and metering and meter data management. In the near future all customers will have smart meters to monitor power, gas and water consumption in real time. At present, the use of smart meters is frankly rudimentary, as they are primarily utilized for customer billing. However, there is a treasure trove of information in this data that utilities can use to help themselves and their customers in many ways. For example, the enormous amount of data and its analytics could help in changing consumer behavior by becoming a communication link between the meter and other devices, thus allowing the consumer to see usage in real time. There is also the smart grid investments and intelligent assets, which are connecting to each other and communicating. As machine learning becomes more prevalent in this communication loop, these assets will become more intelligent where they will be able to self-diagnose and allow the utility to become more efficient in the relevant operations. This large amount of data that the utility will collect and analyze through software analytics platforms will also allow utilities to improve efficiencies and customer engagement. To reduce unplanned outages and extend asset life, operators are deploying transformer condition monitoring that feeds analytics with continuous health indicators and alarms.

As much as IoT will benefit a utility’s day-to-day operation, the biggest growth area is customer engagement. Using data from smart meters and other grid connected devices, a number of use cases have emerged for the utility customers in the areas of energy consumption profiling, connected home, smart appliances, and electric vehicle management. Mobile apps and web portals have been the most effective way to deliver analytics to customers. The major benefit of adopting a mobile strategy is the access to real time data by consumers. Mobility allows consumers to become aware of how much energy they are actually using in near real time, rather than waiting to get their bill weeks later. With the adoption of mobile software applications, the consumption patterns can be made readily available to them through mobile applications to instigate lifestyle and behavioral changes (an average consumer in the U.S. picks up his mobile devices up to 150 to 200 times a day, i.e. nearly 30 billion mobile moments each day). These experiences are powered by data streaming from modern electricity meters that report interval usage and event notifications to the utility.

As distributed energy grows, pairing customer analytics with critical energy storage helps smooth peaks and maintain resilience during local disruptions.

This type of engagement can further be made increasingly effective using big data analytics for customer segmentation. Using micro-segmentation, the customer interactions can be much more personalized, thereby increasing the engagement and response. For example, including income and demographics can help personalize the program and efficiency recommendations across residential, commercial and low-income groups, since customer preferences and needs can vary across each segment.

Because personalization relies on sensitive operational and customer data, a comprehensive grid cybersecurity strategy is essential to protect services and sustain consumer trust.

Even water agencies see great potential in data analytics to reduce leaks and avoid losing billions of gallons of water annually. The only way to ensure water is available to our future generations is to have a conservation plan and make the utility customers a part of that plan. According to the United States Environmental Protection Agency, an average household in the US leaks more than 10,000 gallons of water every year. This instance extends a direct opportunity for the utilities to identify, prioritize, and resolve revenue-losing functions and fix them with the help of third-party cloud/software vendors, if they are unable to themselves.

The EPA also confirms, an irrigation system that has a leak 1/32nd of an inch in diameter (about the thickness of a dime) can waste about 6,300 gallons of water per month. With data emanating from smart meters, IoT devices and other related devices, it can be collated and processed using analytics and the insights; thus, this generated data can be used in the practical world to take corrective and preventative measures. Accuracy improves further as utilities adopt improved sensor technology that expands coverage and delivers higher-resolution insights for field teams.

It is thus becoming evident how IoT, data and analytics are impacting day-to-day key operations of a utility, affecting their ROI on infrastructure, enabling revenue realization, and increased customer loyalty, through engagement from customer intelligence derived from data analytics. Having said that, technology would evolve and more opportunities would present themselves for utilities to further use data from Social, Mobile, Cloud and IoT. As these platforms become more apparent in the utility landscape, it will only bring the customer, intelligent assets and the utility into a real-time 360-degree relationship. In parallel, reliability planning guided by practices on how utilities can keep the lights on will maximize the value of these digital investments over time.

Related Articles

How does SCADA work?

SCADA systems gather data from sensors and RTUs, transmit it via secure networks, and display it through HMI software. Operators monitor and control remote equipment in real time using SCADA software and programmable logic controllers.

How Does SCADA Work?

✅ SCADA collects data from sensors and remote terminal units (RTUs) in real time.

✅ Transmits signals using wired or wireless communication networks to control centers.

✅ Displays system data through SCADA software and HMI user interfaces for operator action.

Supervisory Control and Data Acquisition systems are essential tools in modern electrical and industrial infrastructure. These platforms are designed to monitor, gather data from, and control equipment distributed across multiple locations. A SCADA system acts as a bridge between field operations and centralized oversight, enabling operators to make informed decisions based on real-time data.

At its core, a solution consists of sensors and control equipment installed in the field, which feed data into devices such as remote terminal units (RTUs) and programmable logic controllers (PLCs). These devices transmit collected data through a network using standard communications protocols, such as Modbus or DNP3, to centralized SCADA software. Operators interact with this software through a human-machine interface (HMI), where they can observe system status and execute control actions. If you want more information about What is SCADA, read the full article.

SCADA in Electrical Engineering

In the field of electrical engineering, this platform plays a critical role in ensuring stability, reliability, and efficiency across power generation, transmission, and distribution networks. Through automated control and remote visibility, SCADA systems help utility operators reduce system losses, detect faults early, and maintain safe voltage levels across a wide range of equipment.

Electrical substations, for example, often rely on SCADA to manage switching operations, breaker statuses, and transformer data. PLCs provide local intelligence for local control, while SCADA manages supervisory oversight through centralized user interfaces. With a growing focus on smart grid modernization, SCADA has become the foundation for grid-wide automation and real-time coordination.

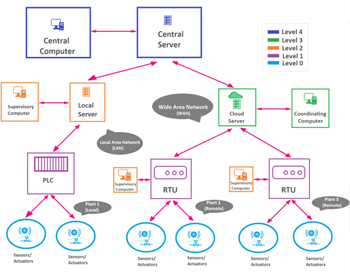

SCADA System Architecture Diagram

This diagram illustrates the core components of SCADA in electrical power systems, including sensors, RTUs, communications, and HMI interfaces.

SCADA Working Principle

The working principle of a control architecture involves four essential processes: data acquisition, communication, control, and interface. These processes work together to provide a comprehensive control system for remote infrastructure.

-

Data Acquisition:

The process begins with gathering data from field devices such as sensors that measure voltage, temperature, flow, and other parameters. RTUs or PLCs collect and digitize this information. -

Communications Protocols:

The RTUs send the collected data to a central control center over wired or wireless communication networks using robust and secure communications protocols. This ensures the reliable transfer of real-time data across long distances. -

Processing and Control:

At the master station, software processes this incoming data and applies automation logic. Operators can respond to events, trigger alarms, or change setpoints, often using built-in intelligence within the system. -

Human-Machine Interface (HMI):

All monitored values and controls are presented through the HMI SCADA screen — the most interactive part of the system. These interfaces allow human operators to visualize trends, respond to faults, and monitor and control the entire network efficiently.

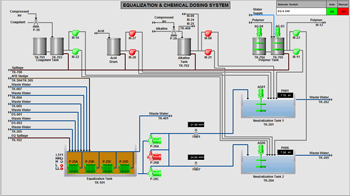

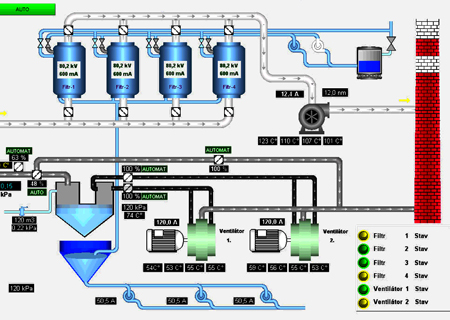

Operator HMI Interface Example

A sample HMI screen showing real-time system status, alarms, and operational controls.

Components of a SCADA System

A well-designed SCADA architecture contains multiple system components that interact seamlessly:

-

Field Sensors: Capture physical values like pressure, current, or temperature.

-

RTUs and PLCs: Process and transmit data from field devices.

-

SCADA Network: Connects remote sites to the control center using secure protocols.

-

SCADA Software: Manages data flow, logic, and visualization.

-

User Interface (HMI): Allows human operators to control and oversee operations.

These components provide operators with actionable insights, whether they are managing a power plant, substation, or pipeline.

Key Components and Functions of a SCADA System

| Component | Function | Keyword(s) Included |

|---|---|---|

| Field Sensors | Measure real-world values (e.g., voltage, pressure, flow) | collected data, gathering data |

| Remote Terminal Unit (RTU) | Acquires data from sensors and transmits it to the control center | remote terminal unit, communications protocols |

| Programmable Logic Controller (PLC) | Executes control logic and performs localized automation | programmable logic controllers plcs, local control |

| Network | Enables communication between field devices and central servers | network, communications protocols |

| Software | Processes real-time data, manages automation logic | software, automation solution |

| Human Machine Interface (HMI) | Displays data visually and allows operators to interact with the system | human machine interface hmi, hmi scada, user interface |

| Control Equipment | Responds to commands (e.g., switchgear, breakers, valves) | control system, monitor and control |

Why SCADA Matters

Despite advancements in AI and cloud computing, SCADA remains foundational for mission-critical infrastructure. A robust SCADA solution delivers reliability, operational efficiency, and centralized oversight. Its ability to collect, analyze, and respond to real-time data from a wide range of devices across long distances makes it indispensable for industries ranging from power generation to manufacturing.

Operators depend on SCADA to maintain high levels of uptime, minimize manual intervention, and ensure safe and coordinated field operations. As new technologies integrate into existing control systems, SCADA remains adaptable, scalable, and central to the evolution of industrial automation.

Related Articles

Cost of Different Storage Systems for Smart Grids

The cost of different storage systems for smart grids varies depending on the technology, efficiency, and scalability. Understanding battery, thermal, and pumped storage expenses helps utilities plan reliable, sustainable, and cost-effective energy solutions.

What is the cost of different storage systems for smart grids?

It refers to the economic evaluation of technologies, batteries, thermal storage, and pumped hydro, used to balance energy supply, demand, and reliability in smart grids.

✅ Compares capital, operational, and lifecycle costs

✅ Guides utilities, grid operators, and policymakers

✅ Informs energy planning for sustainability and resilience

Cost of Different Storage Systems for Smart Grids

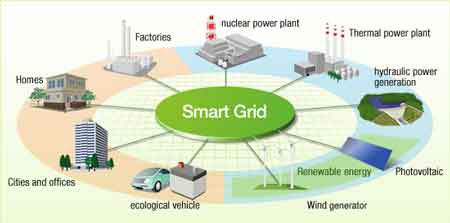

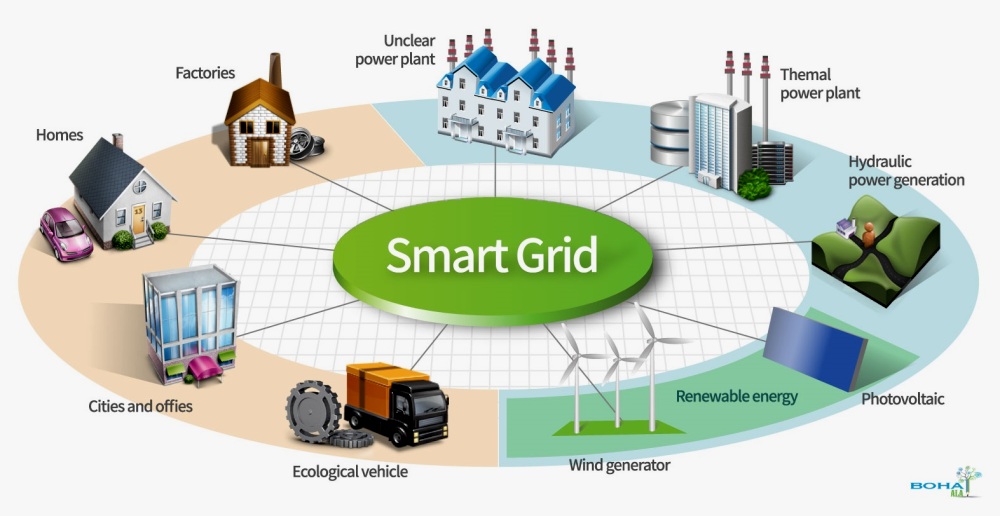

Smart grids are reshaping modern electricity networks by combining automation, digital intelligence, and advanced energy storage technologies. The cost of different storage systems for smart grids depends on capital expense, efficiency, and long-term performance. Evaluating these costs is crucial to ensure the reliable integration of renewable energy sources, particularly as grids face increasing peak demand and the need for grid stability. To better understand this transition, see what is smart grid.

Lithium Ion Batteries: The Market Benchmark

Lithium-ion batteries dominate today’s storage market because they are efficient, compact, and increasingly affordable. These ion batteries are widely used for solar shifting and frequency regulation. In smart grids, they work alongside coordinated automation schemes, enabling utilities to balance distributed energy resources and reduce curtailment.

Despite declining prices, planners must also consider cycle life, augmentation, and maintenance costs when comparing lithium-ion to other systems.

Flow Batteries for Long-Duration Applications

Flow batteries offer a flexible design that separates energy capacity from power output, making them well-suited for longer discharge times. They play a vital role in optimizing energy by storing excess renewable output for evening peaks. When combined with smart grid communication and advanced analytics, they enhance visibility into performance.

Although initial costs are higher than those of lithium-ion batteries, their long lifespan and ability to discharge deeply without degradation can provide greater value over time.

Lead Acid Batteries in Niche Roles

Lead-acid batteries, one of the oldest storage technologies, are still deployed for backup and localized applications. While less efficient and durable, they remain attractive for low-cost installations. In modern grids, their usefulness increases when integrated with improved sensor technology, which helps monitor performance and extend service life in microgrids or emergency systems.

Pumped Hydro and Bulk Storage Options

Beyond batteries, pumped-storage hydropower continues to provide some of the lowest lifetime storage costs where geography allows. With multi-decade lifespans, pumped hydro supports bulk balancing for days at a time. Emerging options such as compressed air and thermal storage are also relevant, especially when combined with SCADA architecture and supervisory control for dispatching stored energy effectively.

Cybersecurity and System Protection

The integration of storage also introduces risks that must be addressed. Cyber threats can disrupt operations, making grid cybersecurity strategy and government notices, such as DHS/FBI alerts, crucial for securing assets. Protecting storage systems connected to SCADA monitoring and SCADA HMI interfaces helps ensure that both cost savings and system reliability are not compromised.

Data Analytics and Utility Reliability

True cost comparisons must go beyond installation to include lifecycle value. Data analytics tools enable operators to forecast degradation, plan augmentation, and calculate the levelized cost of storage (LCOS). Pairing this with how utilities can keep the lights on highlights the role of storage in reliability planning. Utilities that integrate analytics with SCADA integration and SCADA cybersecurity can better manage both cost and risk.

Smart substations are also critical. A smart substation links storage to the broader grid, ensuring energy is dispatched where needed. Similarly, substation SCADA supports local monitoring and automation for cost-effective operation.

Finally, understanding the basics—such as what is SCADA and how does SCADA work—provides the foundation for linking storage costs to control systems.

The cost of different storage systems for smart grids must be evaluated across various technologies and their respective lifecycles. Lithium ion leads the market, flow batteries grow in long-duration roles, lead acid remains for backup, and pumped hydro anchors bulk storage. Supporting systems—ranging from SCADA integration to smart grid monitoring-ensure these investments improve reliability, meet peak demand, and expand the use of renewable energy sources.

Related Articles

Developing a Cybersecurity Strategy for the Grid

Grid cybersecurity strategy fortifies OT networks with SCADA risk assessments, NERC CIP compliance, IEC 61850 segmentation, zero-trust access, intrusion detection, encryption, and anomaly monitoring to safeguard substations, DERs, and control centers.

What Is a Grid Cybersecurity Strategy?

A structured method to secure power systems and OT assets using standards, segmentation, and continuous monitoring.

✅ Aligns with NERC CIP, IEC 62443, and ISO/IEC 27019 controls

✅ Segments SCADA/IEC 61850 networks; enforces zero-trust access

✅ Detects anomalies with IDS, SIEM, and synchronized logging

Understanding the vulnerabilities associated with communication protocols is a critical first step

To compete in today’s dynamic markets, power utilities are increasingly deploying IoT-based technologies and integrating their IT and operational technology (OT) networks. While these advances enable predictive maintenance, improve efficiency, and reduce downtime, they also expose grid infrastructures to a much wider attack surface. For example, initiatives in condition monitoring modernization can improve asset reliability while expanding telemetry pathways that must be secured.

The attacks that took down portions of the Ukrainian grid in 2015 and 2016 are proof that hackers have the ability to breach utility networks and disrupt operations. Subsequent DHS/FBI joint advisories have detailed tactics targeting energy networks that utilities should incorporate into threat models.

In fact, the threat of a cyber attack was cited as a major concern by 41 percent of senior power executives in a recent Deloitte survey.

Given these new threats, integrating cybersecurity into a utility’s overall safety and business continuity strategy is no longer optional. This process begins by understanding the primary vulnerabilities.

The Communication Protocol Risk

The use of remote control and connectivity to substations in order to streamline efficiency requires relaying critical information back to Energy Management Systems (EMS) and SCADA Centers for analysis. As utilities migrate toward digital substation architectures they gain flexibility but must also harden communications paths.

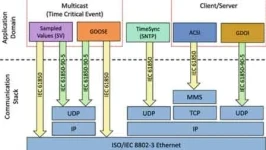

Many modern grids use a variety of documented protocols and standards alongside proprietary vendor protocols. These include IEC-61850, IEC-60870-5, DNP3 and others. Using documented standards and protocols yield the advantage of interoperability between systems from different vendors. This is the foundation of the smart grid. Along with these advantages, however, there are also risks. These same protocols can be leveraged by an attacker in the reconnaissance and last mile stages of cyber-attacks. This interoperability underpins smart grid capabilities that depend on trustworthy data flows.

Adopting principles of open network architecture can simplify integration yet requires rigorous segmentation and access control.

In the 2016 campaign against the Ukraine grid, legitimate protocol commands were exploited by the Industroyer malware. What made this attack so effective was its four payload components:

IEC 60870-5-101 (IEC101) - Designed to scan the IOA range of the IED and execute single and double commands. These can switch breakers on or off or cause other changes in the process that rely on this protocol.

IEC 60870-5-104 (IEC104) - The same capabilities of the IEC101 payload with the added ability to stop all communication to and from a device.

IEC 61850 - Designed to scan the logical model of the IED and find all Logical Nodes (LNs). It then searched for all nodes related to switch or circuit breaker and can change their state upon command.

OLE for Process Control Data Access (OPC DA) – Similar to the other components, this module attempts to enumerate over OPC servers and to change the position state of the discovered OPC items.

The documentation on how to issue those commands is freely available on the IEC website. Software used to execute these commands, often labeled as “test tools,” is available in open source formats and accessible to anyone.

These payload or protocol components are common in most power networks. Robust substation protection schemes should be validated against misuse of legitimate commands to prevent unintended switching operations.

Detecting Protocol Attacks

Historically, network managers deployed security measures at the control center. Today, however, data must be gathered from each component of the network - from the bay level to the EMS level. This requires the ability to understand the protocols used in the EMS and substation.

To identify attacks that are unique to power distribution networks, utilities should deploy deep packet inspection (DPI) engines for documented protocols commonly used in power grid networks. These include IEC-61850, IEC-104 and DNP3 as well as proprietary vendor protocols, such as Siprotec, S7 and Sicam used by Siemens. In parallel, modern substation automation initiatives require visibility down to IED messaging to maintain deterministic behavior.

DPI engines can identify last mile attacks and reconnaissance activities, such as those used by Industroyer and other malware. These engines extract the relevant information from these protocols and identify the exact action taken with them.

The events are then presented with deep context on the source, destination and the nature of the event and include suggested remediation steps. This allows security managers to understand exactly what happened and determine if further action is required.

Other Threats

Since power networks are typically distributed across a large area, with assets are often located outdoors and in remote areas, they are hard to monitor. By physically accessing a device (e.g., via serial cable), an attacker can infiltrate the station network and change the logic of the bay and station controllers, change process parameters or leave backdoors for future remote access.

To identify cases of physical tampering, utilities should periodically query individual devices to identify whether any changes have been performed. It is especially important to be able to query all IEDs in the network, as these devices control the regular grid operations. It is also important to query servers, workstations, networking equipment, gateways, and any other devices that are critical to the regular network operations.

As networks evolve, older devices are upgraded or replaced. This typically results in a mix of newer and older devices with various patch levels. Maintaining an up-to-date patch management program for the entire inventory is a difficult task and requires a significant amount of manual work and planning.

Some of these legacy devices were not designed with cybersecurity in mind. Over time, many vulnerabilities have been discovered in many types of electrical equipment. The ICS-CERT and other organizations issue alerts on vulnerabilities, but without a way to query devices for their exact state and details, mapping vulnerabilities to network devices is challenging.

Patch management should be based on deep awareness of the state and characteristics of every device. This requires the ability to accurately match between each device’s specific condition and the vulnerabilities knowledge base to eliminate false positives and false negatives. This inventory base should be updated automatically and regularly so that they can be kept in sync with newly discovered vulnerabilities.

Utilities that maintain an accurate asset inventory have access to device details such as the exact model, firmware, patch levels, installed software, serial number and others. These details allow users to identify devices that should be patched or completely upgraded .

The complex and interconnected nature of power grids contributes to making them more challenging to protect from cyber threats. Gaining a full situational awareness and understanding of where the weaknesses lie, however, provides a roadmap for developing an effective cybersecurity strategy.

About the Author: Mille Gandelsman is CTO of Indegy, where he leads the company’s technology research and product development. Prior to Indegy, he led engineering efforts for Stratoscale and spent several years managing cybersecurity research for the elite 8200 intelligence unit of the Israel Defense Forces. Mille has more than 15 years of experience in ICS and cybersecurity.

Related Articles

Smart Grid Monitoring and SCADA

Smart grid monitoring uses sensors, SCADA, and analytics to track energy flow in real time, improve reliability, enable predictive maintenance, and integrate DERs across substations and the distribution grid.

What is Smart Grid Monitoring?

Smart grid monitoring is the real-time observation and control of electrical networks using digital sensors, SCADA, and analytics to enhance reliability and efficiency.

? Real-time visibility for substations, feeders, and smart meters

? Predictive maintenance and faster fault detection/restoration

? Better DER integration, load management, and grid reliability

As electric power systems grow in complexity, it has become essential. At the heart of this capability is SCADA—Supervisory Control and Data Acquisition—a foundational technology that allows utilities to collect, analyze, and act on data from remote devices across the network. SCADA is a key enabler of smart grid performance and resilience. For a detailed look at the technology behind SCADA systems, visit our guide to What is SCADA and its role in grid modernization.

From high-voltage substations to distributed energy resources (DERs), SCADA systems play a central role in smart grid monitoring by improving visibility, supporting automation, and enabling fast fault detection and response. As demand rises for decentralized control and integration of renewables, SCADA’s importance in smart grid operations continues to expand. To explore the broader context of this topic, see our Smart Grid Channel, which explains how digital technologies are transforming utility operations.

SCADA Architecture

A modern SCADA system supports monitoring through three critical layers:

Field Devices:

Remote Terminal Units (RTUs) and Programmable Logic Controllers (PLCs) collect real-time data from substations, transformers, and switchgear. These devices serve as the sensors of the smart grid.

Communication Infrastructure:

Telemetry protocols such as DNP3, Modbus, and IEC 60870-5-104 transmit data across fiber, Ethernet, or wireless networks.

Central Control System:

Human-Machine Interfaces (HMIs), historian databases, alarms, and control logic allow operators to supervise energy flow, manage voltages, and issue commands in real time.

This layered architecture ensures reliable and secure monitoring of smart grid assets across vast geographic areas. For insights on how automation enhances real-time control, read about coordinated automation schemes used in smart grid environments.

SCADA vs. DMS vs. EMS

Smart grid monitoring is often supported by three integrated systems:

-

SCADA provides real-time supervisory control and data acquisition.

-

DMS (Distribution Management System) adds automation, outage management, and volt/VAR control for medium- and low-voltage networks.

-

EMS (Energy Management System) operates at the transmission level, optimizing generation, forecasting loads, and managing market participation.

These systems often work together in a unified platform to enable end-to-end control. The success of depends heavily on data analytics, which drive performance improvements and predictive maintenance.

Integrating DERs

Distributed energy resources (DERs) such as solar panels, wind turbines, and battery storage require modern SCADA platforms to manage bidirectional power flow and ensure power quality.

With DER Management Systems (DERMS) integration, monitoring enables utilities to:

-

Track generation from rooftop and distributed assets

-

Control inverter output for voltage regulation

-

Coordinate dispatch and network balancing

-

Maintain synchronization and stability

It must support real-time communication, open protocols, and dynamic data modeling to handle the variability of DERs effectively.

Real-Time Analytics

Modern intelligent monitoring leverages data analytics to move beyond simple control and toward predictive maintenance, performance optimization, and cost reduction.

Advanced SCADA platforms now feature:

-

Edge computing for faster, localized data analysis

-

Cloud integration for scalability and remote access

-

AI and machine learning to forecast failures and detect anomalies

-

Visual dashboards for real-time decision support

These enhancements enable utilities to shift from reactive to proactive grid operations. Effective monitoring systems must also consider grid cybersecurity strategies to defend against growing threats to critical infrastructure.

Challenges

Despite its benefits, many utilities face barriers when modernizing SCADA for smart grid applications:

-

Interoperability issues due to proprietary protocols

-

Cybersecurity concerns require compliance with NERC CIP standards

-

Limited bandwidth in remote areas

-

Integration challenges with GIS, asset management, and mobile systems

Future-ready SCADA systems must be secure, modular, and designed to scale with evolving smart grid technologies.

Conclusion

Smart grid monitoring, powered by modern SCADA systems, is the backbone of today’s intelligent electric network. It ensures real-time visibility, automation, and control—enabling utilities to enhance reliability, optimize energy distribution, and support the integration of renewable energy.

As grid infrastructure evolves, so too must the technologies that monitor and manage it. Investing in SCADA modernization is not just about upgrading old systems—it’s about preparing for a smarter, more resilient, and data-driven future.

Related Articles

Smart Grid News

Smart Grid Media

Smart Grid Articles From ET Magazine

Understanding the IEC 61850 Protocol in Substation Automation

Why Net-Zero is Cheaper for the UK

The United Kingdom has set an ambitious target to achieve net-zero greenhouse gas emissions by 2050. This goal necessitates a comprehensive transformation of various sectors, including energy, transportation, and agriculture. While the environmental imperatives are clear, there is growing evidence that this transition could also yield significant economic advantages for the nation.

Energy Sector Transformation

A pivotal component of the UK's net-zero strategy involves a substantial shift towards renewable energy sources. By 2040, projections suggest that wind and solar power will supply approximately 80% of the country's electricity needs. This transition is expected to reduce energy imports, enhancing national energy security and potentially lowering energy costs for consumers.

The adoption of technologies such as heat pumps for home heating is another crucial step. Heat pumps, which extract heat from the environment to warm homes, offer efficiencies of up to 400%. Their widespread adoption could lead to reduced reliance on fossil fuels and lower household energy bills.

Transportation Sector Overhaul

The automotive landscape is also undergoing significant changes. The Climate Change Committee (CCC) recommends that by 2040, 80% of cars on UK roads should be fully electric. This shift would decrease the demand for imported oil, enhance air quality, and align with global trends towards sustainable transportation.

Agricultural Adjustments

Agriculture plays a role in the nation's carbon footprint, particularly concerning meat consumption. The CCC advises that reducing meat consumption by approximately 260 grams per week per person could significantly lower emissions. This dietary shift would not only contribute to climate goals but also improve public health outcomes.

Economic Growth and Job Creation

The transition to a low-carbon economy is poised to stimulate economic growth through job creation and innovation. Investments in renewable energy infrastructure, such as solar panels and wind turbines, are expected to generate employment opportunities across various regions. For instance, in 2024, the installation of certified heat pumps, solar panels, and battery storage systems reached a record high, indicating a burgeoning green jobs sector.

Moreover, enhancing building insulation and adopting energy-efficient technologies can lead to substantial energy savings. These improvements not only reduce carbon emissions but also lower heating costs for households, thereby increasing disposable income and economic well-being.

Health and Social Benefits

Beyond economic and environmental gains, the net-zero transition offers significant health benefits. Upgrading homes with advanced insulation and modern heating systems can improve indoor air quality, reducing respiratory ailments and other health issues. Additionally, promoting active transportation methods, such as walking and cycling, can lead to healthier lifestyles and reduced public health expenditures.

Ensuring a Just Transition

To maintain public support for net-zero initiatives, it is crucial to distribute the costs and benefits equitably. Government policies should focus on making green technologies accessible and affordable, particularly for lower-income households. This approach ensures that the transition does not disproportionately burden vulnerable communities and that the economic benefits are widely shared.

Achieving net-zero emissions by 2050 presents both challenges and opportunities for the UK. The transition to renewable energy, sustainable transportation, and dietary changes offers the potential for economic growth, job creation, and improved public health. By implementing inclusive and forward-thinking policies, the UK can lead the way in demonstrating that environmental sustainability and economic prosperity are not mutually exclusive but mutually reinforcing

New York's Path to 8.5 GW of Grid Flexibility by 2040

New York State's transition to a clean, zero-emissions energy grid could include up to 8.5 gigawatts (GW) of grid flexibility by 2040, according to a new report from the Brattle Group. This projection, while contingent on achieving ambitious decarbonization goals, illustrates how the state could harness a variety of advanced technologies to meet its clean energy objectives while managing peak demand and lowering grid costs. New York's goal of achieving a fully zero-emissions power sector by 2040, coupled with the electrification of several key sectors, offers a potential pathway to significant grid flexibility and cost savings.

The concept of "grid flexibility" refers to the ability of the grid to adapt to fluctuations in demand or supply, helping to integrate renewable energy sources, manage peak loads, and ensure grid stability. This flexibility is especially important as New York shifts away from fossil fuels and aims to incorporate more intermittent renewable energy sources like wind and solar power. The key to unlocking this flexibility lies in technologies that allow for dynamic, real-time responses to electricity demand, thereby reducing strain on the grid.

The Role of Electrification in Achieving Flexibility

The Brattle Group’s report emphasizes how electrifying key sectors, particularly transportation and heating, can drive grid flexibility. The study predicts that by 2040, New York could see 60% of its heating systems electrified, alongside over 6 million electric vehicles (EVs) on the road. In addition, over 2 GW of behind-the-meter storage—such as residential and commercial batteries—could be deployed across the state, contributing further to grid flexibility.

Electric vehicles play a particularly important role in enhancing grid flexibility. Through vehicle-to-grid (V2G) technology, EVs can not only consume electricity but also return it to the grid during times of peak demand. This "demand-side" flexibility could help balance fluctuations caused by renewable energy generation, particularly on days when wind and solar output is lower than expected.

Similarly, the deployment of heat pumps is expected to play a crucial role in decarbonizing the heating sector. Heat pumps, which are more efficient than traditional heating methods, can be easily integrated with renewable electricity. By using electricity to either heat or cool buildings, heat pumps can provide significant energy savings and, if coordinated smartly, contribute to grid flexibility.

On top of this, residential and commercial energy storage systems are gaining traction in New York. With the right incentives and regulatory support, these distributed energy resources can store surplus renewable power generated during off-peak hours and discharge it when demand is high, thereby stabilizing the grid and reducing reliance on fossil-fueled backup plants.

Brattle Group’s Findings on Potential Flexibility

According to the Brattle Group, these advancements could combine to yield a total of 8.5 GW of grid flexibility by 2040 in a scenario where New York meets its clean energy targets. This figure represents a nearly six-fold increase over the state’s current capacity for grid flexibility, which stands at around 1.4 GW. Achieving this level of flexibility could significantly reduce the cost of maintaining the grid, particularly during peak demand periods.

One of the most intriguing findings in the Brattle report is the potential cost savings associated with increased grid flexibility. The study estimates that, by 2040, the marginal cost of generation could exceed $200 per kilowatt per year if hydrogen turbines were to be used for backup power generation. In contrast, flexible grid resources—such as those powered by electric vehicles, heat pumps, and distributed storage—could offer more affordable alternatives, potentially lowering the cost of managing the grid during high-demand periods.

Brattle’s analysis goes beyond focusing on just one or two technologies. While previous studies, such as those conducted by the New York State Energy Research and Development Authority (NYSERDA) and the PEAK Coalition, have primarily focused on EVs and electric heating, Brattle’s report includes a more comprehensive range of flexible resources. This broader approach provides a more optimistic view of the potential for grid flexibility in New York, suggesting that integrating a mix of technologies can help reduce generation costs and improve grid resilience.

Challenges and Uncertainties

Despite the promising outlook, Brattle acknowledges that there are uncertainties surrounding the actual deployment of these technologies. The flexibility potential outlined in the report depends heavily on the rate at which key technologies, such as electric vehicles, heat pumps, and energy storage, are adopted by consumers and businesses. Delays in the widespread adoption of these technologies could reduce the state’s overall flexibility potential.

Moreover, scaling up these technologies requires overcoming several barriers, including the need for supportive policies, investments in infrastructure, and consumer incentives. A key part of making this vision a reality is ensuring that the necessary regulatory frameworks and market structures are in place to enable these resources to be integrated into the grid efficiently.

New York’s Path to a Clean Energy Future

The transition to a zero-emissions grid and the pursuit of increased grid flexibility is a critical aspect of New York’s broader clean energy strategy. As the state works toward its goal of achieving 100% zero-emissions electricity by 2040, integrating flexible grid resources will be essential to managing the variability inherent in renewable energy sources. These resources not only help maintain grid stability but also offer potential cost savings, helping to make clean energy more affordable for all New Yorkers.

Ultimately, while there are challenges ahead, the Brattle Group’s report illustrates the tremendous potential of grid flexibility in New York’s clean energy future. By leveraging advanced technologies, such as electric vehicles, heat pumps, and energy storage, the state can build a more resilient, cost-effective, and sustainable power grid that supports a fully decarbonized economy. As New York moves closer to its 2040 targets, the findings in this report will likely help guide policymakers, utilities, and consumers in making informed decisions about the future of energy in the state.

PG&E Secures $15B Loan for Energy Upgrades

Pacific Gas and Electric Company (PG&E), a major utility serving Northern and Central California, has secured a conditional $15 billion loan guarantee from the U.S. Department of Energy's (DOE) Loan Programs Office. This funding aims to enhance PG&E's hydropower generation, battery storage capabilities, and transmission infrastructure, marking a significant investment in the region's energy future.

Project Overview

The loan is designated for several key initiatives:

-

Hydropower Expansion: Refurbishing and upgrading existing hydroelectric facilities to increase capacity and efficiency.

-

Battery Storage Development: Establishing large-scale battery storage systems to store renewable energy, thereby enhancing grid stability and reliability.

-

Transmission System Enhancement: Upgrading transmission lines and infrastructure to support the integration of renewable energy sources and meet growing electricity demand.

These projects are expected to bolster PG&E's ability to provide reliable and clean energy to its service areas, aligning with California's ambitious climate goals.

Financial Implications

The loan is structured to offer PG&E favorable terms, including a lower interest rate compared to traditional financing options. CEO Patti Poppe highlighted that this arrangement would result in approximately $100 million in annual savings for customers, totaling over $1 billion in savings over the loan's lifespan.

Community and Economic Impact

PG&E plans to collaborate with the local chapter of the International Brotherhood of Electrical Workers to provide training and employment opportunities for members of underserved communities. Additionally, the company intends to expand outreach programs to engage Native American tribes, community organizations, and low- to middle-income communities, ensuring that the benefits of these infrastructure investments are widely distributed.

Political Context

The loan agreement is anticipated to be finalized before President-elect Donald Trump assumes office in January 2025. While the incoming administration has expressed intentions to review and potentially alter existing energy policies, PG&E remains optimistic about the alignment of these projects with the new administration's priorities, particularly concerning the enhancement of U.S. energy capacity to support emerging technologies like artificial intelligence.

Broader Implications

This substantial investment underscores the federal government's commitment to modernizing the nation's energy infrastructure and supporting the transition to renewable energy sources. By facilitating the development of hydropower, battery storage, and transmission systems, the DOE aims to enhance grid resilience, reduce greenhouse gas emissions, and promote economic growth through job creation in the clean energy sector.

In summary, PG&E's receipt of a $15 billion loan guarantee from the DOE represents a significant step toward modernizing California's energy infrastructure. The initiative promises to deliver environmental, economic, and community benefits, reinforcing the state's leadership in clean energy innovation.

Sign Up for Electricity Forum’s Smart Grid Newsletter

Stay informed with our FREE Smart Grid Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue