Electrical Substations

Substation Automation Powers Smart Grids

Substation automation enhances power grid reliability by using intelligent devices and communication protocols for real-time monitoring, control, and protection. It reduces outages, improves efficiency, and enables remote access for smart grid integration.

What is Substation Automation?

Substation automation is a key component of modern electrical grid management that uses digital technologies to monitor, control, and protect substations:

✅ Improves reliability through real-time control and automation systems

✅ Enables remote monitoring and reduced human error

✅ Supports smart grid integration with intelligent electronic devices (IEDs)

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Core Components and Architecture

A typical automated system in electrical infrastructure is organized into three key levels. The process level involves field equipment such as sensors, actuators, and merging units that provide real-time data inputs. The bay level includes intelligent electronic devices, such as protection relays, that analyze data and execute protection control operations. Finally, the station level houses SCADA interfaces, servers, and HMIs that manage the full monitoring system.

To understand how these systems are integrated physically, see our article on electrical substation design.

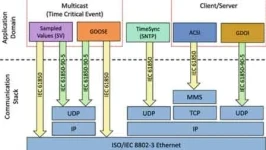

Importance of Communication Protocols

IEC 61850 is the cornerstone protocol that enables fast and reliable communication between smart devices. It ensures interoperability across equipment from different vendors, supports high-speed response for protection applications, and provides a standardized data model that simplifies integration.

You can learn more about how communication technologies are evolving in our detailed overview of the digital substation.

Design, Implementation, and Integration

Successful automation implementation starts with a project-oriented design tailored to site-specific requirements. For legacy facilities, compatibility with existing infrastructure is essential. Most upgrades begin by introducing intelligent IEDs at the bay level before transitioning to full SCADA and communication upgrades.

Testing and commissioning ensure performance, safety, and long-term stability. To understand the equipment's foundational role, see our page on electrical substation components.

Enhancements in Reliability, Efficiency, and Safety

Modern automation offers significant improvements in uptime, safety, and efficiency. Real-time monitoring enables immediate fault detection, while automated control systems minimize response time and reduce human error. Predictive maintenance tools, enabled through data analytics, forecast equipment issues before failure occurs.

Our guide to electrical substation maintenance outlines how condition-based monitoring is transforming maintenance practices.

Integration with Smart Grid and Emerging Technologies

Substation automation is also crucial for integrating distributed energy resources, such as solar and wind. By incorporating IoT sensors and edge computing devices, substations can adapt to real-time fluctuations in load and generation. Artificial intelligence is increasingly being used to forecast energy patterns and manage dynamic system states more effectively.

To learn how these technologies are applied in practice, visit our substation automation training course page.

For background on the overall concept, refer to our general introduction to what is an electrical substation.

Frequently Asked Questions

What is the role of IEC 61850 in substation automation?

IEC 61850 is a communication standard that enables fast, interoperable data exchange between intelligent devices. It supports high-speed control, fault detection, and seamless integration of multi-vendor equipment.

How do protection relays function in a monitoring system?

Protection relays detect electrical faults and send trip signals to disconnect affected circuits. Automated systems respond rapidly and can be configured remotely, improving fault clearing and safety.

Can legacy substations be upgraded to support automation?

Yes, existing substations can be retrofitted with modern IEDs, communication links, and SCADA systems. Gradual upgrades often begin with the bay level and expand upward.

Related Articles

Download Our FREE Electrical Substations Handbook

Electrical Testing And Maintenance Handbook, Vol. 11

The eleventh installment of the Electrical Testing & Maintenance series offers practical information on electrical equipment such as electric motors and electrical transformers. This innovative handbook wraps testing techniques, maintenance tips, and superior work practices into one invaluable resource for on-the-job information.

Properly testing and maintaining electrical equipment—and performing the appropriate procedures safely—ensures that these assets last a long time. The 11th edition of the Electrical Testing & Maintenance handbook maintains this focus throughout its 102 pages. Standard methods of dielectric voltage testing and making the decision to repair or replace electrical equipment are only some of the topics covered in the pages of this updated handbook.

The Electrical Testing and Maintenance Handbook, Vol. 11 is a comprehensive and practical resource designed for engineers, technicians, and maintenance professionals involved in the testing, inspection, and upkeep of electrical systems. This volume focuses on the latest techniques, tools, and best practices to help ensure the safety, reliability, and efficiency of electrical installations across various industries, from power plants and manufacturing facilities to commercial buildings and renewable energy systems.

In this edition, we cover a wide range of topics, including the testing of electrical components such as circuit breakers, transformers, switchgear, cables, and protective relays. Detailed guidance is provided on the selection of testing methods and tools, including insulation resistance tests, continuity tests, and thermal imaging, among others. We also explore condition-based monitoring systems and diagnostic techniques that allow for proactive detection of faults before they lead to system failures.

Volume 11 emphasizes the importance of preventive maintenance strategies and the implementation of effective monitoring systems to track the health of electrical assets. We provide insights into emerging technologies, such as automation in maintenance processes and smart diagnostic tools, which enable more efficient and accurate assessments of electrical system performance.

Latest Electrical Substations Articles

6 Basic Rules to Ensure Substation Safety

6 Basic Rules to Ensure Substation Safety: adhere to lockout/tagout, grounding, PPE, arc-flash boundaries, clearance procedures, and equipment interlocks for switchgear. Ensure OSHA compliance, risk assessments, and preventive maintenance to mitigate electrical hazards.

What Are 6 Basic Rules to Ensure Substation Safety?

They include LOTO, grounding, PPE, arc-flash limits, safe clearances, and interlocks to control electrical risk.

✅ Apply LOTO, verify de-energization, and test before touch

✅ Establish equipotential grounding and bonding conductors

✅ Define arc-flash boundaries; wear rated PPE and face shields

Rule No. 1, CLEARANCE;

Enough clearance from energized parts should be provided to avoid accidental contact with them. If that can’t be met, live parts should be guarded or enclosed.

Rule No. 2, MINIMUM HEIGHT;

A minimum height from the ground to any ungrounded part of an electrical installation should be 8’-6”, so a person staying on the ground can’t touch a substation element or its part which may become energized accidentally. For example, the bottom of a post insulator supporting an energized bus does not normally have any potential. These clearance and height provisions are foundational design criteria addressed in the electrical substation design process to reduce personnel exposure.

For readers new to these facilities, a concise overview of an electrical substation and its functions helps explain why such physical clearances and working spaces matter.

Rule No. 3, ILLUMINATION;

There should be sufficient illumination for personnel to clearly see their surroundings and perform any work safely. Required illumination levels are specified in NESC® [1]. Adequate lighting also supports inspection of critical electrical substation components during routine and emergency work.

Rule No. 4, PASSAGEWAYS;

All passageways and stairs should be wide enough for personnel to navigate them safely, adequate railing should be provided, and floor openings should have guard rails. These provisions align with recognized substation accessibility best practices that facilitate safe movement for workers and responders.

Rule No. 5, EVACUATION ROUTES;

Exits should be clearly marked and evacuation routes should be free from obstructions. Depending on the function of the building (for example, control house), it may require several exits to avoid personnel being trapped during equipment fault, fire, etc. Rapid fault clearing through coordinated substation protection schemes reduces fire and arc-flash hazards along egress paths.

Effective isolation using safe circuit breakers further limits incident energy, supporting orderly evacuation and post-event assessment.

Rule No. 6, GROUNDING;

All substation metallic structures, fences, and equipment tanks should be connected to a station ground grid which should be designed to ensure that step and touch potential values are lower than the ones stipulated in the applicable standards. Detailed guidance on designing and testing the substation grounding system helps ensure touch and step voltages remain within acceptable limits.

Related Articles

Electrical Substation Maintenance: Protecting Assets

Electrical substation maintenance involves testing, inspection, and diagnostics to prevent failures, reduce power outages, and extend equipment life. It enhances system reliability, supports compliance, and uses real-time data to detect early signs of wear or malfunction.

What is Electrical Substation Maintenance?

plays a vital role in ensuring the safety, reliability, and performance of modern power systems. Substations manage voltage levels, regulate power flow, and distribute electricity efficiently. Without proper inspection and servicing, substation equipment is more likely to fail—leading to power outages, equipment damage, and expensive downtime.

✅ Electrical substation maintenance is the routine inspection, testing, and servicing of equipment like transformers, circuit breakers, and protective relays to ensure system reliability and safety.

✅ It detects early signs of wear or failure using tools such as infrared thermography, power factor testing, and data analytics to prevent unplanned outages.

✅ Maintenance supports regulatory compliance, improves power flow and asset performance, and extends the life of critical infrastructure.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

By adopting proactive maintenance strategies supported by real-time monitoring, data analytics, and asset management tools, utilities can reduce the risk of faults, extend the life of high-voltage equipment, and maintain continuous service. Effective inspection and testing practices are best understood in the context of what an electrical substation is, since maintenance directly supports safe and reliable grid operations.

Why Substation Maintenance Matters

Routine substation maintenance is essential for:

-

Preventing equipment failures that can trigger widespread power outages

-

Improving safety and compliance with Department of Energy and utility standards

-

Supporting the reliability of transformers, circuit breakers, and protective relays

-

Enhancing overall grid stability and asset performance

Substations are high-voltage environments with complex systems. Maintenance efforts must target key assets like electrical substation transformer, circuit breaker in substation, and substation protection to ensure safe operation.

Condition Monitoring and Testing

Detecting early signs of equipment degradation is the cornerstone of a successful substation maintenance strategy. Key diagnostic tests include:

-

Power factor testing: Assesses insulation condition on transformers and switchgear

-

Dissolved gas analysis: Detects gases in transformer oil that indicate internal faults

-

Infrared thermography: Locates overheating in conductors and connections

-

Partial discharge testing: Identifies weaknesses in insulation systems

-

Transformer turns ratio (TTR) tests: Validate transformer winding conditions

These tests help identify performance declines early, thereby reducing the risk of failure and allowing for planned maintenance.

Preventive and Predictive Maintenance

There are two core approaches to substation upkeep:

-

Preventive maintenance includes routine inspections and scheduled servicing of equipment, such as substation components, to catch wear before it leads to breakdowns.

-

Predictive maintenance uses advanced tools like SCADA systems, thermal imaging, and load flow analysis to predict failures based on equipment behavior. This strategy relies heavily on real-time data analytics and management software.

Together, they support condition-based interventions that optimize costs and improve system reliability.

Asset Management and Lifecycle Optimization

Substations must be managed as part of a broader asset lifecycle strategy. Through continuous monitoring and diagnostics, utility companies can:

-

Schedule upgrades before critical failures

-

Extend the useful life of aging infrastructure

-

Reduce long-term capital expenditures

Substation automation plays a crucial role in gathering performance data and feeding it into modern asset management systems. This integration allows planners to align maintenance with long-term investment goals.

Safety and Compliance

Substations are inherently hazardous. Maintenance helps enforce substation grounding requirements and ensures fault detection systems operate properly. This protects personnel and ensures compliance with regulatory guidelines, such as those from the Department of Energy and OSHA.

Proper maintenance of protective devices and grounding systems reduces the risk of arc flash events and improves emergency response preparedness.

Role of Technology in Modern Substation Maintenance

Technology is transforming substation maintenance through:

-

Real-time condition monitoring: Sensors and SCADA deliver up-to-the-minute performance data

-

Digital twins: Simulate equipment behaviour to optimize servicing schedules

-

Automated fault alerts: Notify teams of failures before they escalate

-

AI-powered analytics: Enhance decision-making for predictive repairs

These tools enable teams to address failures more quickly and allocate resources more efficiently.

To learn more about how technology supports maintenance strategies, visit our digital substation page.

FAQs

What types of equipment are included in substation maintenance?

Transformers, circuit breakers, protective relays, switches, and grounding systems are key. These components regulate voltage, isolate faults, and protect the grid.

How does maintenance reduce outages?

Maintenance detects faults early, helping avoid unplanned outages. It improves electrical substation reliability and extends equipment life.

How is technology changing maintenance practices?

Digital tools, such as remote sensors, SCADA, and AI, now monitor systems in real-time. This enables faster, more targeted servicing and smarter long-term planning.

What standards apply to substation maintenance?

The Department of Energy and IEEE establish guidelines for inspections, safety testing, and the performance of power assets.

Where can I learn more?

Enroll in our substation maintenance training to build your skills in diagnostics, testing, and compliance.

Related Articles

RTU and HMI Redundancy in Electrical Substations

RTU and HMI redundancy enhances SCADA reliability with failover, hot standby controllers, mirrored databases, dual networks, and fault tolerance, delivering high availability, minimized downtime, and resilient industrial automation for critical process control.

What Is RTU and HMI Redundancy in SCADA Systems?

RTU and HMI redundancy boosts SCADA uptime via failover, hot standby, synced data and dual network paths.

✅ Dual RTUs with hot standby and automatic failover

✅ Redundant HMIs with shared tags and session failover

✅ Diverse networks: ring topologies, VLANs, redundant gateways

As the substation RTU takes on more applications, such as Human-Machine-Interface (HMI), alarm annunciation, math & logic and “relay communication processing”, its need for high availability increases. Anything that takes the RTU out of service – configuration change, firmware update, or component failure – means not only loss of SCADA but also loss of local visibility, loss of non-operational data and, in some applications, loss of local control. Redundancy can address the needs for higher availability. This paper reviews the latest designs for electrical substation RTU redundancy and details required new features, including:

For a broader look at architectures and use cases, see this overview of substation automation concepts and integration strategies.

• Current redundancy designs in substation automation

• Limitations of current implementations

• Suggested design philosophies for substation automation redundancy

• Review of desirable redundancy design features:

o Flexible SCADA interface, including intelligent buffering to prevent Event floods on switchover, selective reporting of Events and acceptance of controls by Standby, and multiple SCADA support

o Ability for the SCADA Master to make a connection to a single IP address shared by both RTUs

o Robust and secure communication link between Active RTU and Standby RTU

o Ability to bi-directionally replicate operator actions on the local HMI such as tagging, alarm acknowledgement and blocking/forcing of point states (to ensure uninterrupted visibility after failure and throwover)

o Ability for both Active RTU and Standby RTU to access SCADA data from IEDs.

o Ability to compare data from Active and Standby RTUs

o Ability to block Standby polling

o Ability to obtain diagnostic data from Standby RTU to confirm health

o Ability to manually force throwover

o Ability for users to select criteria for throwover, and to force auto-throwover

o Ability to test configurations on Standby RTU while Active operates normally

o Auto-transfer of configuration files from Active RTU to Standby RTU

o Design that keeps Active and Standby databases synchronized

o Graphic user interface to indicate redundancy status and health

Definitions

RTU 1 and RTU 2 The redundant pair of RTUs

Active RTU The RTU that is performing the application tasks

Standby RTU The RTU that is ready to take over

Throwover The actions, automatic or forced, that make the Standby RTU Active

Research and Sources

The material in this paper was primarily obtained through direct interviews with engineers and managers at the following utilities: ConEd (NY, USA), Eversource (CT, USA), Entergy (MS, USA), PPL Utilities (PA, USA), BPA (OR, USA), Xcel (MN, USA) and Dairyland Coop (WI, USA)

Other material for this paper was obtained from public web sources for the leading world suppliers of RTUs and substation automation, and from NovaTech internal sources.

Readers newer to the domain may benefit from a primer on what is an electrical substation to frame the redundancy discussion.

Current Redundancy Designs in Substation Automation

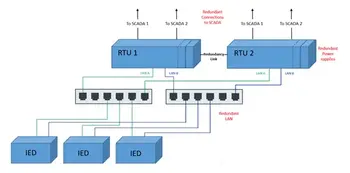

For the substation RTU, designs currently exist for most of the hardware and network redundancy. Figure 1 below shows a modern architecture with redundant SCADA connections, dual RTU power supplies and redundant LANs; Parallel Redundancy Protocol (PRP) in this example.

Figure 1: Modern RTU design with redundant SCADA connections, redundant LANs and dual power supplies

In the most recent redundant RTU designs, powers supplies – arguably the hardware component most likely to fail - are “hot-swappable” from the front. Redundant SCADA connections are supported and some systems will flip-flop Ethernet and protocol addresses, and intelligently clear buffers on the Standby RTU. High-speed standards-based redundant broadband LANs can replace proprietary networks; Parallel Redundancy Protocol (PRP) and High-Availability Seamless Ring (HSR) are gaining favor over other standards as they are sufficiently fast and deterministic for protection applications with 61850 GOOSE. Many modern IEDs are also able to manage independent buffers on multiple sockets on the same physical port, important when both RTUs needs to poll all IEDs for Events. See Figure 2 below:

Modern deployments align with the principles of digital substation design, enabling resilient, time-deterministic communications.

Figure 2: IED supporting multiple sockets with independent event buffers on one physical port

Current implementations improve uptime by eliminating single points of failure, and by enabling failures to be diagnosed and repaired while maintaining operation. These network choices also support substation protection schemes that depend on deterministic messaging.

Limitations of Current Implementations

Looking at the current RTU redundancy state-of-the-art, one may ask why so few redundant RTUs are seen in substations, notably in the US. Reasons include:

1) RTUs in the larger and more critical substations – where redundancy is most often considered – are now taking on non-traditional RTU tasks such as Human-Machine-Interface (HMI), alarm annunciation, math & logic processing and “relay communication processing” (passthrough relay access), Each of these tasks imposes specific and complicating requirements on the redundancy design, such as bi-directionally replicating user-initiated actions from one HMI to another, or enabling predictable hand-off of control on switchover.

2) Interface to legacy SCADA requires more flexibility in the redundancy design, notably where multiple SCADA connections from different organizations are required. Each may have different needs; one serial, one broadband. One may want Events from both RTUs; the other may not. One may want certain controls issued from both RTUs, others will not. Etc.

3) Not all IEDs are able to accommodate connection to both RTUs, and a substation may have some IEDs than can and some that can’t. Accommodating mixed vintage IEDs becomes a redundancy design and operational challenge. A clear inventory of electrical substation components helps evaluate which devices support dual connections.

4) Living with complicated redundant RTUs can be challenging, and the hand-off from engineering to operations may never be quite complete. Few designs provide clear diagnostics and status data, intuitive throwover controls, simple methods to keep programs in sync, or simple methods to test new configuration before going online.

Suggested Design Philosophies for Substation Automation Redundancy

An important step in designing improved substation RTU and HMI redundancy is to define design philosophies. Suggestions:

1) The system design will continue to meet user performance requirements* with the failure of any one system component.

2) The failure of one portion of the system should not cause a failure in another portion of the system.

3) Any failure should be automatically detected, specifically identified, and annunciated.

4) Any failure should be able to be fixed without rendering the system inoperable.

5) Changes should be able to be made to the system while continuing to meet user systems performance requirements*.

6) A technician-level employee should be able to operate, maintain and repair the system.

*presenting data to SCADA, solving logic, refreshing HMI screens with fresh data, logging alarms and SOE, etc

Many of these philosophies echo best practices found in electrical substation design guidance and standards.

Review of Desirable Design Features

o Flexible SCADA interface, including intelligent buffering to prevent Event floods on switchover, selective reporting of Events and acceptance of controls by Standby, and multiple SCADA support.

Basic clearing of event buffers when Standby to prevent event flood on switchover is straightforward, but increased complexity is introduced when the Standby RTU is also required to respond to event polls, or to accept controls. See scenarios in Figure 3 below.

Figure 3: Standby RTU responses to SCADA, with or without Events and controls

Further complication is added when multiple SCADA Masters impose varying requirements. See Figure 4 below.

Figure 4: Standby RTU response to multiple SCADA Masters, each with or without Events and controls

o Ability for the SCADA Master to make a connection to a single IP address shared by both RTUs

Needed here is a standards-based approach. Low-level custom coding in the RTU can force the Ethernet address to the one that SCADA polls, but custom approaches may not gracefully make and release connections, may not make other fixed addresses available and may not be easy to maintain. A standard such as Common Address Redundancy Protocol (CARP) may serve well here (pending how this may affect cyber security) where the RTU that is “Active” takes on a virtual common address, and a fixed address remains for user interface. See Figure 5 below.

Figure 5: Ethernet address management with Common Address Redundancy Protocol (CARP)

o Robust and secure communication link between Active RTU and Standby RTU

The link between the two RTUs should be redundant and monitored in order to eliminate a single point of failure. The link should also offer an encryption option to enable the two RTUs (or SCADA Masters) to be placed in geographically separate locations.

o Ability to bi-directionally replicate operator actions on the local HMI such as tagging, alarm acknowledgement and blocking/forcing of point states

The substation HMI integral to the RTU typically will include alarming, tagging, and “blocking” functions for maintenance. For safety reasons, operator actions on the one RTU should be replicated on the other RTU to ensure consistent awareness. When an alarm is acknowledged by an operator on the Active RTU, it should appear as acknowledged on the Standby RTU. Similarly, when a tag is placed or removed on a controllable element on the Active HMI, it should appear, or disappear from the HMI on the Standby RTU. These real-time operator actions must be retained through power cycles, and preferably, should be bi-directional; e.g. tags placed on the Standby RTU HMI should appear on the Active RTU HMI. Coordinating these operator workflows with robust substation grounding practices further mitigates risk during maintenance.

o Ability for both Active RTU and Standby RTU to access SCADA data from attached IEDs

It is important, where possible, to have both the Active RTU and the Standby RTU poll data from IEDs, or accept data reports from IEDs. This enables operators to confirm network health to the Standby RTU before throwover occurs.

o Ability to compare data from Active and Standby RTUs

When both RTUs poll the same sets of data from IEDs, or when data is reported to both RTUs from IEDs, data comparison, and dual data reporting should be possible. Comparison of data accessed by Active and Standby RTU may be useful to confirm proper scaling and time synchronization in IEDs and RTUs. When a critical piece of data is used in control algorithms, confirming it as the same from Active RTU and Standby RTU increases assurance of proper control.

o Ability to block Standby polling

In some applications with polled architecture, and with mixed version IEDs, not all IEDs may be able to accept connections from both RTUs at the same time. In other applications, such as where the RTU is performing an extended role as a small SCADA Master, polling of the substation RTUs by the Standby SCADA system may be impractical or impossible. In both these cases, selective blocking of the polling by the Standby is important.

Figure 6: RTU in extended role as a small SCADA Master. The “Block Polling” feature may be important in this application.

o Ability to obtain diagnostic data from Standby RTU to confirm health prior to throwover

The health and status data from the Standby RTU should be accessible, including temperature, power supply status, time sync accuracy and comm integrity. Security status should also be accessible: names of users attached, how they are attached, syslog data, etc. Access of these data enables users to address problems prior to throwover, and to respond to security events quickly.

o Ability to manually force throwover

Situations will occur during operation and maintenance where it will be necessary to force the Active RTU into Standby (which will make the Standby RTU go Active). Examples: when the Standby RTU is healthier than the Active RTU, and where hardware in the Active RTU must be upgraded.

o Ability for users to select criteria for throwover, and to force auto-throwover

Situations will occur where the Standby RTU is healthier than the Active RTU. Examples:

-One power supply failed in the Active RTU, both healthy in the Standby;

-Active RTU lost time sync. Standby RTU synced up fine;

-Points from IEDs coming in offline at Active RTU, but online at Standby.

-SCADA polling the Standby fine, but not polling the Active

The user may want to select these criteria and conditions to force auto-throwover.

o Ability to test configurations on Standby RTU while Active operates normally

The Standby RTU should be able to be forced into a special mode where it is functionally isolated from the redundancy application. In this mode, configurations should be able to be tested safely without any impact on the Active RTU. This mode is also useful for firmware upgrades.

o Auto-transfer of configuration files from Active RTU to Standby RTU

Complicated RTUs with integral HMI may include multiple configuration files for logic, graphics pages and RTU point mapping. In redundancy designs that require configurations to be identical, an automatic mechanism to move configuration files from Active RTU to Standby RTU reduces setup steps and reduces errors.

o Design that keeps Active and Standby databases synchronized

Keeping Events from being double-reported, or lost on throwover, is minimized when the Active RTU database is replicated to the Standby RTU. Real-time control algorithms are also able to be executed more reliably on throwover when databases are synchronized.

o Graphic user interface to indicate redundancy status and health

Text-based diagnostic, status and control screens work fine, but some users prefer a more intuitive and simple graphic to indicate redundancy system health, including which RTU is which, connection status, health and controls. Design concept in Figure 7 below.

Figure 7: Design concept for redundancy diagnostics, status and control

Conclusion

As the substation RTU takes on new tasks, redundancy and the higher availability it brings will increase in importance. Although current redundancy solutions are sufficient for the basic substation RTU function, RTUs that serve broader roles in the substation will require new features, expanded flexibility and simplified operation.

Related Articles

Substation Explosion

A substation explosion can trigger a major power outage, release plumes of smoke, and damage transformers. Learn what causes these incidents and how utilities can prevent them.

It is one of the electrical power grid's most dangerous and disruptive events. When an incident occurs at a power substation, it can produce plumes of smoke, result in a widespread power outage, and damage the utility infrastructure. Although these events are rare, the consequences are often severe. Understanding a substation explosion's root causes and impacts is critical for preventing future incidents and enhancing grid reliability.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Causes of Substation Explosion

A substation explosion usually begins with a technical fault that escalates into a catastrophic failure. One of the most common causes is equipment failure in substation components, especially transformers. An aging transformer can overheat, and if its oil-based insulation ignites due to an internal arc or electrical fault incident, a violent transformer explosion can occur. Understanding the role of a substation transformer is essential when analyzing how internal failures can escalate into a full substation explosion.

Common causes include:

-

Transformer explosion due to overheating or arcing in oil-filled units

-

Insulation failure that leads to electrical arcing and combustion

-

Lightning strikes or storms that introduce surges and trigger faults

-

Tree contact or debris falling onto live equipment during weather events

-

Human interference, such as vandalism, theft, or sabotage

-

Neglected maintenance, allowing small faults to grow into major failures

Similarly, poor insulation on switchgear, loose connections, or deteriorated breakers can initiate arcing, rapidly escalating into fire or blast conditions. If an electrical substation transformer malfunctions, the result can be catastrophic due to the large volumes of insulating oil and high voltage.

Environmental conditions also play a significant role. Lightning strikes can inject massive overvoltages into the system, damaging components and triggering chain-reaction failures. High winds and fallen tree branches may cause short circuits or mechanical impacts, increasing the likelihood of a substation accident. In some cases, sabotage or vandalism has been documented as the root cause of damage, further complicating prevention efforts.

Consequences and Impacts

The fallout from a substation explosion can be immediate and far-reaching. The most noticeable consequence is a power outage, affecting entire communities or industrial zones. This disruption halts daily routines and paralyzes critical services such as hospitals, emergency communications, and transportation systems.

Major impacts include:

-

Power outage across critical sectors like hospitals, transit, and communication

-

Utility infrastructure damage requiring costly and time-consuming repairs

-

Service interruptions for thousands of customers and business operations

-

Plumes of smoke spreading across neighborhoods, triggering evacuations

-

Public safety risks, particularly to untrained responders or bystanders

In addition to service disruption, the explosion itself often causes extensive utility infrastructure damage. Electrical fires spread quickly among tightly packed equipment, often producing plumes of smoke that pose serious health risks to nearby populations. Many substation explosions begin with faulty electrical substation components that go undetected until it's too late. First responders face hazardous conditions, including live electrical systems, burning oil, and limited access. Cleanup and repairs can take days or weeks, depending on the destruction scope and replacement components' availability.

The economic impact is also considerable. Businesses experience downtime, repair costs strain utility budgets, and the public may lose confidence in grid reliability if incidents are frequent or mishandled.

Fire Suppression and Protection Measures

Preventing or containing a substation explosion requires proactive fire suppression strategies tailored to the unique risks of electrical environments. A modern fire suppression system may include inert gas technologies that can suppress flames without conducting electricity, making them safe around energized equipment. Water mist systems are another option, providing localized cooling and flame reduction without flooding the facility.

Physical layout is also a crucial factor. Proper electrical substation design helps isolate fault zones and minimize the spread of fire or blast damage. Fire-rated partitions and blast-resistant enclosures can compartmentalize damage, limiting the spread of fire or explosions to nearby components. Proper ventilation and oil containment systems further reduce ignition risk. All of these systems must be regularly inspected and maintained to be effective. Deferred maintenance is one of the leading contributors to substation accident escalation.

Developing a structured maintenance plan is essential, and the methodology for electrical substation maintenance programs offers a proven framework for reducing the risk of failure-related incidents.

Safety Protocols and Emergency Response

Rapid and coordinated emergency response is essential in the event of a substation explosion. Utilities must establish clear emergency action plans that include procedures for shutting down equipment, isolating affected areas, and notifying first responders. Substation personnel should receive regular safety training to ensure they recognize early warning signs and know how to evacuate safely.

Best practices include:

-

Comprehensive emergency plans outlining shutdown and communication steps

-

Personnel training on hazard recognition and evacuation procedures

-

Clear signage and access routes for first responders

-

Joint drills with local fire departments to build coordinated response readiness

-

Real-time alerts and SCADA systems to assist in remote monitoring during events

Coordination with local emergency services is equally important. Firefighters and hazmat teams must be familiar with the layout and potential hazards of the substation to respond effectively. Joint training exercises and pre-incident planning help reduce confusion during real emergencies and increase the chance of containing a fire or blast before it spreads.

A broad understanding of power system infrastructure is critical, and foundational substation training helps personnel recognize risks and apply safety procedures effectively during emergencies.

Infrastructure Resilience and Modernization

One of the most effective ways to reduce the likelihood of a substation explosion is to modernize the infrastructure. Replacing outdated or failure-prone components with arc-resistant equipment significantly lowers the risk of a catastrophic event. Our detailed overview of substation protection explores proper protection strategies.

Smart grid integration plays a pivotal role in modern reliability efforts. Real-time monitoring systems can detect abnormal temperature, current, or voltage conditions, allowing utilities to intervene before a fault evolves into a serious problem. Predictive analytics, condition-based maintenance, and remote diagnostics all contribute to a safer and more reliable power substation environment.

Gas-insulated systems can offer higher fault tolerance, and a gas insulated substation may reduce the risk of arc fault propagation compared to air-insulated configurations. As part of prevention strategies, utilities should consider enrolling technical teams in substation automation training to understand digital monitoring and fault isolation systems better. In addition, monitoring systems in a digital substation can detect early warning signs of failure and prevent incidents before they become explosive.

Compliance with established standards, such as NFPA 850 for fire protection and IEEE guidelines for substation design, ensures that critical safety measures are built into the system. When combined with strategic investment and proper oversight, these efforts dramatically improve grid reliability and reduce the risk of explosion-related failure.

Frequently Asked Questions

What is the main cause of a substation explosion?

The primary cause is usually equipment failure in substation transformers or switchgear. This can result in a transformer explosion or electrical fault incident that ignites insulating materials and leads to fire.

How does a substation explosion affect the community?

It often causes a major power outage, disrupts essential services, and produces plumes of smoke. Cleanup and repair can take days, impacting both public safety and the economy.

What can utilities do to prevent a substation explosion?

Prevention includes upgrading aging infrastructure, implementing an advanced fire suppression system, conducting regular inspections, and using real-time monitoring to detect early warning signs.

Related Articles

Construction Drones

Construction drone enables RTK surveying, LiDAR mapping, photogrammetry, and thermal inspection for electrical infrastructure, substations, and transmission lines, supporting BIM updates, progress tracking, orthomosaic planning, and safe, remote condition monitoring.

What Is a Construction Drone?

A construction drone is an unmanned aerial system for RTK surveying, LiDAR, and thermal inspection of electrical assets.

✅ RTK/GNSS mapping enhances substation as-built accuracy

✅ Thermal imaging detects faults in switchgear and busbars

✅ LiDAR/photogrammetry supports BIM updates and clash checks

Fingertip Cost Savings for T&D Industry Infrastructure

The surge of interest in construction drones to be used in the T&D infrastructure construction process is growing and advancing in leaps and bounds as the North American utilities companies realize the multi-potential uses of this technology. Not since the introduction of the mobile computer devices to the utilities sector has there been so much recognizable potential for this technology, in so many different capacities. The drone world has begun to turn its eye to the electrical construction industry regarding the building of power plants to electrical substations to distribution systems, and the potential for savings and improvements is staggering. The drone technology for surveying, safety, security and even resource tracking is now available, literally at ones fingertips.

T&D Construction Booms

In 2015 North American Electric T&D industry exceeded $49 billion on T&D construction projects from power plants to electrical substations to distribution systems. That is higher than any of the previous years since the 2009; To ensure these investments translate into reliable assets, many teams reference an electrical substation design roadmap when scoping upgrades and new builds.

Regulatory requirements and incentives, fueled by the need to improve the reliability and capacity of the North American T&D network, provides an opportunity for utilities and developers to make substantial investments to replace, upgrade, and expand new and existing T&D infrastructure. Modern reliability goals are increasingly met through substation automation that integrates protection, control, and monitoring.

T&D Infrastructure Overview

- Power Plant - Electricity is generated at the power plant at a relatively low voltage

- High Voltage Transformer – Voltage is increased by transformers from hundreds to hundreds of thousands of volts for transportation over long distances.

- Transmission Lines – High voltage transmission lines carry power from the power plant to the substations.

- Transmission Substations – Contain high voltage switches allowing the connection, isolation or maintenance of high-power lines.

- Distribution Substations – Contain transformers that “step-down” reduce the high voltage power to a lower level for distribution to the end user.

- Distribution Systems – Main/primary power lines and low voltage secondary power lines deliver electricity via overhead or underground wires/cables to the end user.

- Service Connection – Power line that connects the electricity to a meter at the end users location.

For readers new to the topic, this flow is anchored by understanding what an electrical substation is and how it fits between generation and load.

Construction Drones

Companies like 3D Robotics, DroneDeploy and Kespry to name a few, offer “smart construction drones”. As an example of the seemingly endless technology, Kespry’s drone the Kespry 2.0 can fly over 150 acres in 30 minutes providing aerial data. Even self-built and off the shelf drones have the capability to provide an astounding range of information with the use of basic attachments and software. Drone imagery can directly support 3D substation design utilizing AutoCAD by validating clearances and as-built conditions.

Listed below are a few of the technically advanced attributes which the new “smart drones” are capable of producing.

Site Mapping with Drones

- completing accurate 3D models of existing and new structures

- overlays of the original plans with the recorded data

- accurate topographical maps

- temporary roads and structures can be planned in advance and plotted into the 3D maps

These models become foundational data for planning a digital substation where systems are engineered around accurate geospatial context.

Materials & Inventory Controls

- determine the size of stockpiles like gravel, lumber, and rebar

- identify equipment and machinery on site

- inventory updates, useable materials automatically assessed and equipment requirements calculated

- provides accurate data for the project manager

- eliminate unnecessary spending

- real time information

- real time and forecasted business decisions.

Further Features

- cloud connectivity

- monitor progress (on more than one project if necessary)

- show progress to clients

- keep extensive 3D records of the changes on a day by day basis

- structural inspection

- authenticate work done from office or home

- security service; perform automated patrols of a defined area, recording security footage (even utilizing infrared cameras)

Routine visual patrols also help prioritize maintenance on critical components like the substation breaker so outages can be prevented proactively.

There are many construction industry security services and construction industry management services which are now realizing the advantages of employing the use of drones in the building of power plants to electrical substations to distribution systems. Basically one construction drone can perform most of the features mentioned above without the requirement of specialist equipment. Their software handles the raw data and translates it into meaningful and actionable information throughout all aspects of a T&D infrastructure construction project and post project. The cost savings and time savings compared to traditional methods will be staggering and very hard for an electrical utilities company to ignore. Upskilling project teams through focused electrical substation training ensures drone-derived insights are translated into safe, compliant decisions.

Related Articles

Substation Protection Explained

Substation protection safeguards transformers, breakers, and switchgear from faults, overloads, and short circuits. Using relays, grounding, and surge protection ensures electrical safety, reliable power distribution, and stable operation in utility and industrial systems.

What is Substation Protection?

Substation protection is the coordinated system of devices and practices that detect, isolate, and mitigate electrical faults to ensure safety and reliability.

✅ Protects transformers, breakers, and switchgear

✅ Prevents outages, overloads, and equipment damage

✅ Ensures safe, stable, and efficient power delivery

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Electrical substations are the backbone of modern power systems, playing a critical role in transmitting and distributing electricity efficiently and reliably. However, without proper protection mechanisms, these vital installations are vulnerable to faults, equipment failures, and external threats that can lead to costly outages and compromised grid stability. Substation protection is the specialized field dedicated to safeguarding substations from such risks. By employing advanced protective relays, sensors, and control systems, the power safety system ensures the safe operation of electrical networks, minimizes downtime and enhances overall system resilience. Let's explore the principles of the power safety system, its key components, and why it is indispensable for maintaining the reliability and safety of power systems worldwide. Effective substation grounding is a cornerstone of substation protection, ensuring fault currents are safely dispersed to protect equipment and personnel.

The Importance of Substation Protection in Power Systems

Substation protection is essential to modern electrical power systems, ensuring the reliable transmission and distribution of electricity across vast networks. Electrical devices serve as critical nodes in this infrastructure, transforming high voltages to levels suitable for end-users and managing the flow of power through transmission and distribution networks. However, the complex nature of these systems means that faults can occur, posing risks to both the equipment and the continuity of service. Robust systems are vital for maintaining stability, minimizing disruptions, and safeguarding assets in the event of a fault.

Protective Relays: The First Line of Defense

At the heart of an effective power safety system are protective relays. These intelligent devices continuously monitor the power system, detecting abnormalities such as overcurrent, undervoltage, or frequency deviations. When a fault is detected, protective relays initiate swift actions, often engaging circuit breakers to isolate the affected section of the network. This coordinated response not only prevents extensive damage to critical infrastructure but also enhances safety for maintenance crews and the surrounding community.

Circuit Breakers: Protecting Equipment and Ensuring Safety

Circuit breakers play a pivotal role in substation protection by physically interrupting the flow of electricity in faulted circuits. These components are engineered to handle immense electrical loads, ensuring that even the most severe faults are swiftly contained. Without their ability to manage high voltages and currents during a fault, the reliability of transmission and distribution networks would be severely compromised.

The Role of Current and Potential Transformers and Substation Protection

Current and potential transformers also play an indispensable role in power safety systems. These specialized transformers provide accurate measurements of electrical quantities, such as current and voltage, ensuring that control systems operate with precision and accuracy. By stepping down high voltages to levels manageable by control equipment, they enable protective relays to function effectively and support accurate fault detection and isolation.

Substation Automation: Enhancing Protection and Efficiency

Modern substations are increasingly adopting advanced automation systems to enhance their operational efficiency and reliability. Device automation integrates protective relays, control systems, and monitoring technologies into a cohesive network that can respond dynamically to changing conditions. This level of automation not only improves fault response times but also provides operators with real-time data on the power system's health. Such insights are invaluable for maintaining the stability of the broader power system. Proper electrical substation maintenance ensures that protective devices remain fully operational, reducing the risk of costly outages.

Frequently Asked Questions

What is the primary purpose of substation protection?

The primary purpose of a power safety system is to safeguard critical equipment within electrical substations and ensure the reliable operation of the broader power system. Power safety system minimizes the impact of electrical faults, such as short circuits or equipment failures, by detecting issues and isolating the affected area to prevent further damage or disruptions. This is vital for maintaining the continuity of power supply, ensuring personnel safety, and protecting expensive infrastructure from catastrophic failures. Without an effective power safety system, the stability and reliability of power transmission and distribution networks would be at significant risk. Specialized electrical substation training equips engineers and technicians with the knowledge to design, operate, and troubleshoot protection systems effectively.

What are the key components of a substation protection system?

A substation protection system comprises several interconnected components that work in harmony to monitor, detect, and respond to faults. Key components include:

-

Protective relays analyze electrical parameters and initiate corrective actions during abnormalities.

-

Circuit breakers isolate faulted sections by interrupting electrical current flow.

-

Current transformers (CTs) and potential transformers (PTs), provide accurate current and voltage measurements to the relays.

- Control systems and automation technologies, which integrate data and coordinate responses across the substation.

Together, these components create a cohesive system that ensures timely fault isolation and prevents damage to other parts of the power network.

How do protective relays detect and respond to faults in electrical substations?

Protective relays are the heart of a power safety system, designed to detect anomalies in electrical conditions such as overcurrent, under-voltage, and frequency deviations. They continuously monitor input data from CTs and PTs to compare against pre-set thresholds. If the relays identify a deviation indicative of a fault, they send a signal to circuit breakers to open and isolate the faulted section. Advanced protective relays can also communicate with control systems to log events, perform diagnostics, and coordinate responses for complex faults, ensuring quick restoration of normal operations. Using a circuit breaker in substation applications is critical for isolating faults and maintaining reliable power distribution.

What are the challenges and emerging technologies in substation protection?

Power safety system faces several challenges, including:

-

Integration with renewable energy sources introduces variability and requires advanced adaptive systems.

-

Cybersecurity threats, as modern protection systems rely heavily on digital communication and automation.

-

Aging infrastructure may struggle to support modern technologies.

Emerging technologies in substation protection are addressing these challenges. For instance, digital substations equipped with IEC 61850 communication standards enable faster and more reliable data exchange. Artificial intelligence (AI) and machine learning (ML) are also being used for predictive maintenance and enhanced fault detection. These advancements ensure that power safety systems remain robust in the face of evolving complexities in the power grid. Modern digital substations enhance protection by integrating intelligent relays, monitoring systems, and automation for faster fault detection and response.

How does device protection contribute to the reliability of distribution networks?

Power safety systems play a critical role in ensuring the reliability and safety of transmission and distribution networks by minimizing the impact of electrical faults. When a fault occurs, rapid detection and isolation prevent cascading failures, maintaining the stability of the power grid. Moreover, the system safeguards equipment and personnel, reducing the risk of prolonged outages and costly repairs. By maintaining operational continuity and enhancing fault tolerance, the power safety system supports the efficient delivery of electricity to consumers and the overall resilience of the power system.

Substation protection is a critical aspect of modern electrical infrastructure, designed to safeguard substations and ensure the reliable flow of electricity across transmission and distribution networks. It involves advanced systems and technologies, including protective relays, circuit breakers, and transformers, that work together to detect, isolate, and mitigate electrical faults. By preventing equipment damage, minimizing downtime, and ensuring safety, the power safety system plays a vital role in maintaining the stability of the power grid. As power systems evolve with the integration of renewable energy and digital automation, power safety systems continue to advance, addressing emerging challenges and reinforcing the resilience of our energy networks. Implementing the 6 basic rules to ensure substation safety is essential for protecting workers, preventing accidents, and reinforcing overall substation protection strategies.

Related Articles

Electrical Substations News

Electrical Substations Media

Electrical Substations Articles From ET Magazine

Understanding the IEC 61850 Protocol in Substation Automation

Why Net-Zero is Cheaper for the UK

The United Kingdom has set an ambitious target to achieve net-zero greenhouse gas emissions by 2050. This goal necessitates a comprehensive transformation of various sectors, including energy, transportation, and agriculture. While the environmental imperatives are clear, there is growing evidence that this transition could also yield significant economic advantages for the nation.

Energy Sector Transformation

A pivotal component of the UK's net-zero strategy involves a substantial shift towards renewable energy sources. By 2040, projections suggest that wind and solar power will supply approximately 80% of the country's electricity needs. This transition is expected to reduce energy imports, enhancing national energy security and potentially lowering energy costs for consumers.

The adoption of technologies such as heat pumps for home heating is another crucial step. Heat pumps, which extract heat from the environment to warm homes, offer efficiencies of up to 400%. Their widespread adoption could lead to reduced reliance on fossil fuels and lower household energy bills.

Transportation Sector Overhaul

The automotive landscape is also undergoing significant changes. The Climate Change Committee (CCC) recommends that by 2040, 80% of cars on UK roads should be fully electric. This shift would decrease the demand for imported oil, enhance air quality, and align with global trends towards sustainable transportation.

Agricultural Adjustments

Agriculture plays a role in the nation's carbon footprint, particularly concerning meat consumption. The CCC advises that reducing meat consumption by approximately 260 grams per week per person could significantly lower emissions. This dietary shift would not only contribute to climate goals but also improve public health outcomes.

Economic Growth and Job Creation

The transition to a low-carbon economy is poised to stimulate economic growth through job creation and innovation. Investments in renewable energy infrastructure, such as solar panels and wind turbines, are expected to generate employment opportunities across various regions. For instance, in 2024, the installation of certified heat pumps, solar panels, and battery storage systems reached a record high, indicating a burgeoning green jobs sector.

Moreover, enhancing building insulation and adopting energy-efficient technologies can lead to substantial energy savings. These improvements not only reduce carbon emissions but also lower heating costs for households, thereby increasing disposable income and economic well-being.

Health and Social Benefits

Beyond economic and environmental gains, the net-zero transition offers significant health benefits. Upgrading homes with advanced insulation and modern heating systems can improve indoor air quality, reducing respiratory ailments and other health issues. Additionally, promoting active transportation methods, such as walking and cycling, can lead to healthier lifestyles and reduced public health expenditures.

Ensuring a Just Transition

To maintain public support for net-zero initiatives, it is crucial to distribute the costs and benefits equitably. Government policies should focus on making green technologies accessible and affordable, particularly for lower-income households. This approach ensures that the transition does not disproportionately burden vulnerable communities and that the economic benefits are widely shared.

Achieving net-zero emissions by 2050 presents both challenges and opportunities for the UK. The transition to renewable energy, sustainable transportation, and dietary changes offers the potential for economic growth, job creation, and improved public health. By implementing inclusive and forward-thinking policies, the UK can lead the way in demonstrating that environmental sustainability and economic prosperity are not mutually exclusive but mutually reinforcing

FERC Complaint Targets Duke, PJM Transmission Planning

A coalition of large energy consumers and ratepayer advocates has filed a complaint with the Federal Energy Regulatory Commission (FERC), urging the agency to prohibit transmission owners from independently planning "local" transmission projects exceeding 100 kilovolts (kV). The coalition argues that such local planning, lacking independent oversight, leads to inefficient and costly transmission development, resulting in unjust and unreasonable rates for consumers.

Background

Transmission planning involves determining the necessary infrastructure to transport electricity from generation sources to consumers. In the United States, this planning is typically conducted by transmission owners, which are often investor-owned utilities. These entities are responsible for identifying and implementing transmission projects to meet local reliability needs. However, the coalition contends that this approach can result in projects that are not cost-effective and may not represent the most efficient solutions for consumers.

The Complaint

The coalition's complaint highlights several concerns:

-

Lack of Independent Review: Local transmission projects often undergo minimal independent scrutiny, leading to potential inefficiencies and higher costs.

-

Incentives for Overinvestment: Transmission owners may be motivated to invest in local projects due to the absence of competitive bidding and the limited review provided by FERC's formula rate process.

-

Regional Planning Deficiencies: The current regulatory framework allows local planning exceptions to override regional planning rules, hindering the development of more efficient regional solutions.

The coalition proposes that FERC mandate regional planning conducted by an independent transmission system planner to ensure that transmission projects are both appropriate and beneficial to consumers. They suggest that regional transmission organizations and independent system operators could serve as independent transmission planners if they meet specific criteria.

Industry Response

Larry Gasteiger, executive director of WIRES—a transmission sector advocacy group—expressed concerns about the potential impact of the complaint. He stated that the complaint could burden FERC and all transmission developers with unnecessary and inefficient new processes, diverting resources from ongoing regional transmission planning and compliance with existing FERC orders.

Regulatory Context

This complaint follows recent developments in transmission planning and oversight:

-

FERC's Order 1920-A: In November 2024, FERC revised its Order 1920 on transmission planning and cost allocation to grant state utility regulators a larger role in the decision-making process. The revised rule requires transmission providers to include state input on the development of future scenarios used in long-term regional transmission planning.

-

FERC's Rejection of PJM's Proposal: In December 2024, FERC rejected proposals that would have given PJM Interconnection transmission owners more control over the grid operator’s transmission planning process. The commission expressed concerns about the potential for undue influence by a single stakeholder group, specifically the PJM transmission owners, over transmission planning and expansion.

Implications

The coalition's complaint underscores ongoing debates about the effectiveness and fairness of transmission planning processes. Proponents of independent planning argue that it can lead to more efficient and cost-effective transmission solutions, ultimately benefiting consumers. Opponents, however, caution that such changes could introduce new complexities and delays into the transmission development process.

As FERC reviews the complaint, stakeholders across the energy sector will be closely monitoring the potential implications for transmission planning and the broader regulatory landscape.

12 Tips to Protect Against Common Lineworker Safety Hazards

Lineworkers face numerous risks daily, from respiratory ailments to electrical hazards. These dangers can result in severe injuries, low blood pressure, bleeding, and vomiting. However, by adhering to established safety protocols, contractors and employers can significantly reduce the likelihood of accidents. Below are 12 practical tips to protect lineworkers from common safety hazards.

1. Identifying Job Hazards

The first step to mitigating risks is recognizing them. Conduct regular inspections of the worksite to identify potential hazards. Evaluate equipment and work conditions to detect safety threats that may be difficult to eliminate. Interview workers and managers to understand their concerns and observations. Use this feedback to create a detailed hazard map, marking both existing and potential hazards.

Involving workers in this process fosters a culture of safety and boosts morale. It’s crucial to maintain electrical installations, repair faulty appliances, and ensure the proper use of high-quality footwear. By addressing these concerns, employers create a safer working environment.

2. Using personal protective equipment

PPE is essential for protecting workers from injuries, infections, and other workplace hazards. Lineworkers should wear safety goggles, face shields, gas masks, and self-contained breathing apparatuses to guard against chemical splashes, burns, and respiratory diseases.

Ensure that all PPE complies with safety standards. Goggles and face shields should be free of cracks, and hard hats must be dent-free and stored away from high heat to maintain shell integrity. Workers should also wear high-visibility, heat-resistant overalls and gloves to protect against extreme temperatures and toxic substances.

3. Properly using cover-up equipment

Cover-up equipment shields lineworkers from energized machines and electrical currents. Items like line hoses and conductor covers prevent accidental contact with live conductors, thereby reducing the risk of electric shocks and arc flash hazards.

To maximize protection, ensure that workers have access to appropriate cover-up equipment. Regularly inspect and maintain these tools to ensure they remain in optimal working condition.

4. Protecting against currents in grounded systems

Grounded systems are often perceived as safe, but they can still pose risks due to electromagnetic fields. Under extreme conditions, these fields may create currents that endanger lineworkers.

To prevent such hazards, regularly inspect all equipment before use. Conduct safety training to educate workers about these hidden dangers and establish protocols for handling grounded systems safely.

Sign Up for Electricity Forum’s Electrical Substations Newsletter

Stay informed with our FREE Electrical Substations Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue