Utility Transformers

Transformer Wiring Diagram Explained

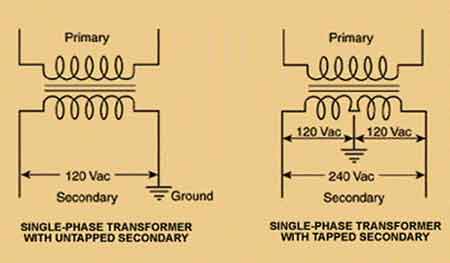

A transformer wiring diagram illustrates the correct connection of primary and secondary windings for effective voltage transformation. It ensures correct electrical connections, aids in troubleshooting, and supports safe installation of power, distribution, or control transformers.

What is a Transformer Wiring Diagram?

A transformer wiring diagram is fundamental for electrical engineering and maintenance professionals.

✅ Shows electrical connections for primary and secondary windings

✅ Helps in installing, troubleshooting, and maintaining transformers

✅ Ensures proper voltage transformation and safety compliance

This visual representation depicts how the windings are interconnected, significantly impacting their operation and performance. A thorough understanding of this diagram is crucial for several reasons: it facilitates proper installation, troubleshooting, and maintenance; it ensures safe and efficient power distribution; and it enables the selection of the most suitable transformer configuration for specific applications.

To grasp these diagrams, it's important first to understand what is a transformer, including its function of increasing or decreasing voltage. This foundational knowledge helps interpret wiring for both control transformers and measurement-class devices, such as current transformers.

The intricacies of a transformer wiring diagram reveal more than just lines and labels; they encapsulate the heart of electrical systems. A well-constructed wiring diagram not only aids in understanding transformer connections but also ensures the safety, reliability, and efficiency of power distribution systems. These diagrams provide indispensable guidance, whether dealing with single-phase transformer connections or more complex three-phase transformers.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

The intricacies of a transformer wiring diagram reveal more than just lines and labels; they encapsulate the heart of electrical systems. A well-constructed wiring diagram not only aids in understanding transformer connections but also ensures the safety, reliability, and efficiency of power distribution systems. These diagrams provide indispensable guidance, whether dealing with three-phase configurations or single-phase transformers.

Three-Phase Connections

Transformer connections vary widely depending on their purpose, and three-phase configurations form the backbone of modern electrical grids. Diagrams illustrating Delta-Delta (Δ-Δ), Star-Star (Y-Y), Delta-Star (Δ-Y), and Star-Delta (Y-Δ) arrangements are particularly common. For example, understanding delta-to-wye conversion is crucial when modifying system configurations to meet specific voltage requirements.

Each configuration has unique attributes that suit specific applications. For instance, the Delta-Delta connection offers robustness for high-load environments, while Delta-Star is valued for its ability to step down voltage efficiently, providing a stable secondary connection. These wiring configurations are indispensable in industrial and commercial setups, where detailed diagrams ensure proper implementation.

Open Delta (V-V) Connection

One noteworthy arrangement often encountered in diagrams is the open delta (V-V) connection. This innovative design proves invaluable when one transformer in a Delta-Delta system fails. By rearranging the wiring to form an open delta, the system can continue operating, albeit at a reduced capacity. Such versatility underscores the importance of wiring diagrams in troubleshooting and maintaining system resilience. Including precise depictions of open delta arrangements allows technicians to make informed decisions during unexpected outages.

Scott-T Transformer Connection

Another fascinating aspect of wiring is the Scott-T connection, used to convert three-phase power into two-phase power or vice versa. These diagrams are particularly relevant in niche industrial applications where legacy equipment requires two-phase input. By clearly outlining the interconnection of windings, Scott-T wiring diagrams ensure that even complex transitions between power systems are executed seamlessly. Understanding these diagrams can bridge the gap between old and new electrical infrastructures.

Wiring Color Codes and Standards

Beyond connection configurations, adherence to wiring color codes and standards is crucial for safety and compliance. Every diagram should reflect established guidelines, especially in three-phase systems. Clear identification of phases through standardized colors prevents miswiring, which could lead to hazardous situations. For example, secondary connections in single-phase units must be distinctly marked to avoid confusion during installation or maintenance. Wiring diagrams that incorporate these standards promote safer practices and easier troubleshooting.

Voltage Transformer Connections

Voltage transformer connections, often included in wiring diagrams, are essential for protective applications in power systems. These connections enable accurate measurement and relay functionality, critical for maintaining system integrity. For example, capacitor voltage transformers are used to isolate metering equipment while stepping down voltage for monitoring.

Protective relaying systems rely on precise voltage readings to identify and isolate faults, minimizing potential damage. Wiring diagrams play a pivotal role in safeguarding infrastructure and ensuring uninterrupted power delivery by detailing these connections.

The comprehensive nature of a diagram extends beyond technicalities, offering a visual guide that simplifies complex systems. A 3-phase to single-phase transformer diagram, for instance, illustrates the interaction between the primary and secondary windings, ensuring that the voltage ratios align with operational requirements. In larger systems, these diagrams facilitate the integration of multiple transformers, helping engineers visualize how components interconnect to meet demand. Diagrams transform abstract electrical concepts into actionable insights by mapping out these connections.

Wiring diagrams also highlight the evolution of electrical systems. Technological advances have introduced innovations such as automation and smart grids, requiring updated approaches to transformer wiring. Modern diagrams incorporate additional components, such as sensors and communication modules, reflecting the evolving landscape of power systems. These enhancements improve monitoring and control, making connections more efficient and adaptive to dynamic load conditions.

It is an indispensable tool in the electrical industry, bridging the gap between theory and application. These diagrams enable precise implementation and maintenance by illustrating configurations such as Delta-Delta, Scott-T, and open delta. They also reinforce the importance of standards like wiring color codes, ensuring safety and compliance. From single-phase units to advanced protective applications, wiring diagrams provide clarity and reliability, fostering a deeper understanding of electrical systems. As the industry continues to evolve, electrical transformers will remain central to the energy infrastructure, and wiring diagrams will continue to be a cornerstone of effective power distribution.

Related Articles

Download Our FREE Utility Transformers Handbook

Electrical Transformer Testing Handbook Vol. 4

This 130 page handbook examines many of the crucial steps needed to test and maintain transformers.

Volume 4 of this handbook explores a wide range of testing methodologies, from routine diagnostic tests to more advanced techniques aimed at detecting subtle faults and signs of wear. It covers essential topics such as insulation resistance testing, power factor testing, load testing, oil quality analysis, and partial discharge testing, providing detailed explanations of each procedure and its importance in identifying potential issues early. The handbook also highlights the latest advancements in testing technology and tools that enhance testing accuracy and efficiency.

This volume is designed for engineers, technicians, and maintenance professionals who are directly involved in the testing and upkeep of electrical transformers across various sectors, including power generation, transmission, and industrial applications. By combining theoretical knowledge with practical, hands-on advice, Volume 4 ensures that professionals are equipped with the necessary expertise to perform comprehensive transformer assessments and diagnose issues that could impact system performance and safety.

With a focus on best practices, safety standards, and industry trends, the Electrical Transformer Testing Handbook, Volume 4 is a critical resource for anyone seeking to maintain optimal transformer performance, reduce risk, and safeguard the integrity of electrical networks.

Latest Utility Transformers Articles

Transformer Design Principles

Transformer design ensures efficient voltage regulation, insulation, cooling, and magnetic flux control. By optimizing windings and core materials, engineers improve energy efficiency, reliability, and safety in electrical power systems.

What is Transformer Design?

Transformer design is a complex and critical aspect of electrical engineering that demands a deep understanding of various factors, including the magnetic core, winding configurations, voltage regulation, and cooling methods.

✅ Balances core materials, windings, and insulation

✅ Optimizes cooling systems and magnetic circuits

✅ Ensures energy efficiency, reliability, and compliance

By addressing these aspects and answering key questions, engineers can design devices that effectively transmit and distribute electrical power, ensuring the efficient operation of various systems and technologies. A solid grasp of design begins with understanding the broader utility transformers category, which covers applications from power distribution to industrial systems.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Core Architectures and Materials

At the heart of thedesign is the magnetic core, which transfers energy between circuits through the phenomenon of electromagnetic induction. Cores can be shell-type or core-type. Shell-type designs enclose the windings, offering better leakage control, while core-type designs surround the core with windings, making them more economical and widely used in power applications. A detailed construction of transformer guide highlights how core, windings, and insulation come together in the design process.

Materials are equally important. Silicon steel laminations dominate traditional designs due to low core loss and high efficiency, while ferrites are preferred at high frequencies because of reduced eddy currents. Engineers also optimize stacking factor (lamination efficiency) and window space factor (copper fill) to balance performance and cost. The role of 3-phase transformers in balancing loads and ensuring stable power supply is central to effective design.

Core Types Comparison

| Core Type | Structure & Design | Advantages | Applications |

|---|---|---|---|

| Core-Type | Windings surround the core limbs | Economical, widely used, simple to build | Power and distribution transformers |

| Shell-Type | Core surrounds windings | Lower leakage flux, better short-circuit strength | Large power units, specialized designs |

Windings, Turns Ratio, and Voltage Regulation

Winding configurations define the input and output voltage levels. Copper is typically used due to its high conductivity and low resistance. The turns ratio directly determines voltage transformation, while the number of turns, conductor size, and arrangement influence efficiency and losses.

Losses fall into two categories: core losses (from magnetic hysteresis and eddy currents) and copper losses (from winding resistance). Careful balance of wire size, number of turns, and core design minimizes these losses. Typical transformer efficiencies can reach 97–99%, with voltage regulation generally in the ±1–5% range, depending on size and type.

When engineers calculate the cross-sectional area of the core, they must also carefully design the magnetic flux to achieve the correct magnetic flux density for efficient operation. Excessive flux density increases power losses and heating, thereby reducing the transformer's lifespan. The primary and secondary coil arrangement, including the number of turns in the primary winding and the primary and secondary windings as a whole, directly determines voltage transformation. Matching the primary voltage to the intended application ensures that the transformer delivers reliable performance across varying load conditions. In transmission systems, design engineers often compare distribution transformers with larger substation transformers to meet unique performance and installation requirements.

Cooling Methods

Efficient cooling prevents overheating, which can reduce lifespan or lead to failure. Methods range from natural air (AN) to forced air (AF), oil-immersed systems (ONAN/ONAF), and even forced circulation in large power units. Cooling design is tailored to match the load and environmental conditions, with performance evaluated against temperature rise standards.

Transformer Types and Installations

Transformers come in many types depending on the application:

-

Power transformers: used in transmission networks, designed for high efficiency and durability.

-

Distribution transformers: supply local loads, often pad-mount or pole-mount installations.

-

Step-up and step-down transformers: adjust voltage levels between generation and utilization.

-

Specialty designs: audio, pulse, and instrument transformers optimized for unique performance needs.

Pad-mount transformers serve neighborhoods and campuses, pole-mount transformers provide rural distribution, and substation transformers integrate with high-voltage systems.

Sizing and Nameplate Essentials

Proper sizing ensures performance and safety. Transformers are rated in kVA, calculated by:

kVA = (Volts × Amps) ÷ 1000

Nameplate data includes primary and secondary voltages, frequency (50 or 60 Hz), kVA rating, impedance, cooling class, and connection diagrams. These specifications help engineers match the transformer to the intended load and conditions.

Advanced Insulation Design

Insulation systems separate conductive parts, prevent breakdown, and protect against thermal stress. Materials may include resin, paper, or ceramic, chosen for dielectric strength and thermal endurance. Designers also account for the stacking factor and the window space factor to optimize copper fill, flux density, and mechanical clearances.

Environmental factors such as humidity, altitude, and pollution also influence insulation choices. Effective design also considers protective features, such as transformer insulation and transformer overcurrent protection, to enhance safety and reliability.

Tap-Changer Mechanisms

Voltage regulation is enhanced through tap changers, which adjust winding turns to maintain a stable output.

-

No-load tap changers (NLTCs): adjusted manually when de-energized.

-

On-load tap changers (OLTCs): adjust automatically under load, essential in transmission and industrial applications.

Tap changers enhance flexibility, efficiency, and resilience in response to fluctuating supply conditions.

Tap Changer Mechanisms

| Tap Changer Type | Adjustment Method | Advantages | Common Uses |

|---|---|---|---|

| NLTC (No-Load) | Manual, only when de-energized | Simple, lower cost | Distribution and fixed-load transformers |

| OLTC (On-Load) | Automatic, adjusts under load | Continuous regulation, high flexibility | Transmission and industrial systems |

Fire Safety Measures

High-voltage, oil-cooled transformers pose fire risks. Safety codes such as NFPA 850 require firewalls and barriers to limit damage in substations. Design measures may include fire-resistant fluids, containment pits, and protective spacing to minimize the risk of explosions and cascading failures.

Transformer Design Standards

Standards from the IEEE, IEC, and ANSI provide guidelines for design methodologies, testing, and performance metrics. Routine factory tests include insulation resistance, winding resistance, and no-load/copper loss checks. Type tests, on the other hand, validate performance under short-circuit or lightning-impulse conditions.

Condition Monitoring and Maintenance

Modern transformers increasingly integrate condition monitoring systems. Sensors track parameters such as temperature, dissolved gas in oil, partial discharge, and load profiles. Predictive analytics help detect insulation breakdowns, overheating, or winding deformation before failure occurs. Combined with protective relays, these systems extend lifespan and reduce downtime.

A well-rounded design approach combines robust core and winding design, advanced insulation strategies, efficient cooling, and proper voltage regulation through tap changers. By following international standards, incorporating fire safety measures, and adopting real-time condition monitoring, engineers ensure that transformers operate at peak efficiency, reliability, and safety—serving applications ranging from household distribution to massive power networks. With modernization, advanced condition monitoring has become a vital design element, enabling predictive maintenance and extending the lifespan of transformers.

Related Articles

Electric Pole Transformer Explained

Electric pole transformer delivers step-down voltage from medium-voltage overhead lines on a utility pole, supplying distribution transformer functions for residential power, grid reliability, and safe service drops to homes and small businesses.

What Is an Electric Pole Transformer?

An overhead distribution unit that steps medium voltage down to service-level power for homes and commercial loads.

✅ Steps 4-35 kV to 120/240 V for end users

✅ Mounted on utility poles near overhead feeders

✅ Oil-filled or dry-type, protected by fuses and arresters

An electric pole transformer is a critical component of power distribution systems, ensuring that power generated at high voltage in power plants is safely reduced to usable levels for homes and businesses. Mounted on power lines, these utility equipment play a vital role in stepping down voltage through electromagnetic induction, minimizing energy loss and ensuring efficient power delivery. Understanding how equipment work is essential for maintaining grid stability, reducing operational costs, and improving energy efficiency. As demand for reliable power continues to rise, utility pole transformers remain indispensable in modern infrastructure, safeguarding power distribution across urban and rural landscapes. For a concise overview of components and ratings, the power pole transformer guide outlines typical construction, insulation choices, and common kVA ranges for field use.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Voltage Transformation

The primary function of an electric pole transformer is voltage transformation. Power plants generate pwer at extremely high voltage levels, as this minimizes energy loss during long-distance transmission. However, such high voltage cannot be directly supplied to homes and businesses. Instead, equipment work by stepping down this voltage through electromagnetic induction, making it suitable for local consumption. The winding of the equipment and the magnetic fields it generates are key to this process, allowing power to be efficiently adjusted to the required voltage levels. Further background on step-down principles is covered in the electrical power distribution transformer overview, including winding arrangements and core materials.

Types and Configurations

Electric pole transformers are available in various types and configurations to accommodate different distribution needs. Some systems use single-phase equipment, which are commonly found in residential areas where energy demand is lower. In contrast, three-phase equipment are used in commercial and industrial settings, where higher energy loads are necessary. The versatility of these equipment ensures that power distribution remains stable and efficient, regardless of the specific demands of the connected infrastructure. For residential feeders and light commercial loads, families of pole-mounted transformers offer standardized ratings, enclosure options, and bushing configurations to match service requirements.

Installation and Mounting

Installation and mounting of utility pole transformers require careful planning and expertise. Typically, these equipment are mounted on wooden or concrete utility poles, strategically positioned along power lines to ensure optimal power distribution. Their placement depends on factors such as load demand, terrain, and accessibility for maintenance. Proper installation is essential to ensure efficiency, prevent power disruptions, and reduce energy losses as power moves from substations to end users. Placement along feeders is influenced by conductor size and clearances, and resources on the powerline transformer explain typical mounting hardware, drip loops, and service drop practices.

Safety Features

Safety is a fundamental concern in the design and operation of utility pole transformers. Given their exposure to harsh weather conditions and surges, these devices are equipped with various protective features. Surge arresters and fuses are commonly integrated into their design to safeguard against lightning strikes, overvoltage, and short circuits. Additionally, equipment must be properly insulated to prevent hazards to both utility workers and the general public. Routine safety checks and monitoring systems help ensure that these critical components function effectively and reduce the risk of power failures. Modern monitoring borrowed from the power transformer domain, such as dissolved gas analysis and temperature alarms, is increasingly adapted to distribution-class units for earlier fault detection.

Maintenance and Lifespan

The lifespan of an electric pole transformer depends on several factors, including environmental conditions, usage patterns, and maintenance schedules. Regular inspections and servicing are necessary to identify potential issues such as overheating, oil leaks, or insulation degradation. If properly maintained, these equipment can operate efficiently for decades, providing consistent voltage transformation and ensuring the smooth operation of networks. Utility companies invest in predictive maintenance strategies to extend the longevity of equipment and minimize costly replacements. Maintenance programs tailored to the distribution transformer fleet often combine periodic oil sampling with infrared inspections to prioritize replacements and reduce outage risk.

Role in the Power Infrastructure

The operation of utility pole transformers is intricately linked to the broader power infrastructure, including power lines and power plants. These equipment act as key nodes within the distribution network, enabling the transfer of power from high-voltage systems to local circuits. Their efficiency directly affects energy consumption, grid stability, and overall power quality. By optimizing equipment performance, utility providers can enhance energy distribution and reduce strain on grids. Their coordination with reclosers and feeders originates upstream at the electrical substation transformer, where voltage levels and protection settings are established for downstream reliability.

Understanding How Device Work

Understanding how tequipment work is essential for both industry professionals and consumers. At the core of their functionality is the principle of electromagnetic induction, where energy is transferred between coils of wire through a magnetic field. This process allows for the precise adjustment of voltage levels, ensuring that devices receive the appropriate power supply. Advances in equipment technology continue to improve efficiency, reliability, and environmental sustainability.

Frequently Asked Questions

How does an electric pole transformer work?

An electric pole transformer operates on the principle of electromagnetic induction to step down high voltage from power lines to a lower, safer voltage suitable for residential and commercial use. Inside the equipment, primary and secondary windings wrapped around a magnetic core transfer energy between circuits without direct contact. When high-voltage power enters the primary coil, it creates a magnetic field, which induces a lower voltage in the secondary coil. This process ensures that homes and businesses receive the appropriate voltage needed to safely power appliances and equipment.

What are the common types of electric pole transformers?

Electric pole transformers come in single-phase and three-phase configurations. Single-phase equipment are typically used in residential areas, supplying power to homes and small businesses where the demand is relatively low. Three-phase equipment, on the other hand, are used in commercial and industrial applications where higher power loads are required. They provide more efficient energy distribution, reducing losses and ensuring stable voltage supply for large equipment and heavy machinery.

What safety features are included in pole-mounted transformers?

To ensure safe operation, pole-mounted equipment are equipped with various protective features. These include surge arresters, which prevent damage from lightning strikes and voltage spikes, and fuses, which disconnect the equipment in case of power fault or overload. Additionally, the equipmentare oil-insulated, which helps in cooling and insulation. Proper grounding and weatherproof enclosures further protect the equipment from environmental hazards, preventing hazards to both utility workers and the public.

How are utility pole transformers maintained and how long do they last?

Regular maintenance is essential to ensure the longevity and efficiency of utility pole transformers. Utility companies conduct inspections to check for issues such as oil leaks, overheating, and corrosion. Infrared scanning is often used to detect early signs of failure. Proper cooling and insulation management can significantly extend equipment's lifespan, which typically ranges from 25 to 40 years, depending on environmental conditions, load demands, and maintenance quality.

Why are electric pole transformers essential in power distribution?

Electric pole transformers are crucial for ensuring efficient and reliable power distribution. Without them, the high voltage power generated at power plants would be unsuitable for direct use in homes and businesses. These equipment reduce voltage to safe levels, preventing damage to appliances while maintaining a steady and efficient power supply. Their strategic placement on power lines ensures that power is distributed effectively, minimizing power loss over long distances and supporting the growing demand for energy in urban and rural areas alike.

An electric pole transformer is a crucial component of the power distribution system, mounted on utility poles to step down high-voltage power from distribution lines to a lower voltage suitable for residential and commercial use. These equipment help ensure safe and efficient power delivery by reducing voltage levels before power reaches homes and businesses. Typically oil-filled for cooling and insulation, pole-mounted equipment play a vital role in maintaining a stable and reliable power supply in urban and rural areas. Their compact design and overhead placement make them cost-effective and easy to maintain.

Related Articles

Is The Power Supply And The Transformer The Same Thing

Is the power supply and the transformer the same thing? No; a power supply rectifies, filters, and regulates AC/DC, while a transformer provides voltage conversion and isolation, stepping up or step-down without rectification or regulation.

Is the Power Supply and the Transformer the Same Thing?

No. A power supply regulates DC; a transformer only changes AC voltage and isolates.

✅ Power supply: rectifier, filter, regulator; DC output for electronics.

✅ Transformer: AC voltage conversion and galvanic isolation.

✅ Not interchangeable; PSUs may include a transformer inside.

In the world of electrical engineering, understanding the relationship between power supply and transformers is essential, especially in utility transformers. While these terms are often used interchangeably, they serve distinct functions in the electrical grid. A power supply refers to the source of electrical energy, while a transformer is a crucial component that alters voltage levels for efficient distribution and safe consumption. Recognizing the differences between these two elements is vital for ensuring the optimal operation of utility transformers, which play a critical role in maintaining a stable and reliable power supply. Let's explore what power supply and transformers are, their roles in the electrical grid, and why understanding their functions is key to the efficiency and safety of utility transformers. For a deeper overview of power transformer applications in utility grids, see this guide for context.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Understanding the Functional Differences

The relationship between a power supply and a transformer is often misunderstood. Although both components are essential to the functioning of electrical systems, they serve distinct purposes and operate in different ways. A power supply is responsible for converting and regulating electrical energy to meet the needs of electronic devices. It takes raw electricity from an external source and transforms it into a form that is usable by the device, such as DC voltage. In contrast, a transformer’s primary role is to adjust the voltage levels within the electrical system. While transformers work in conjunction with power supplies, they do not alter the type of current; instead, they focus on modifying voltage levels, whether stepping it up or stepping it down, depending on the system’s requirements. To clarify the distinct role of voltage adaptation, consult an explanation of transformer functions for further detail.

Component Integration: How Transformers Fit Into Power Supplies

The integration of transformers within power supplies is a common feature in systems such as switched-mode power supplies (SMPS). These power supplies utilize transformers to achieve a variety of important functions, including converting AC voltage to DC voltage and ensuring that the device receives a steady, regulated power flow. In these systems, the transformer is crucial for voltage transformation, as it adjusts the AC input voltage to a level that is appropriate for the specific electronic device or system. Additionally, transformers provide electrical isolation, which helps prevent electrical faults from causing damage to sensitive equipment or posing a risk to users. Without transformers, power supplies would not be able to function efficiently, especially in high-voltage applications, where the ability to modify voltage levels is critical. If you need a refresher on coil coupling and isolation, review how transformers work to connect these concepts.

Power Conversion: The Role of Transformers in Voltage Adjustment

Power conversion is another key area where transformers play a vital role. Various types of power conversion processes, including converting AC to DC, DC to DC, and even AC to AC, rely on transformers to adjust voltage levels as needed. For example, when converting AC voltage to DC voltage, the transformer steps down or steps up the voltage to ensure that it is at an optimal level for rectification and smoothing processes. This is important because different devices require specific voltage levels to operate properly, and transformers enable power supplies to meet those needs. Similarly, in high-voltage applications, transformers are used to step down the voltage to a safer, more manageable level for specific devices or systems. In rectified and regulated supplies, DC power transformer considerations influence size, losses, and isolation.

Design Considerations: How Transformer Construction Impacts Power Supply Performance

The design of a transformer is an important factor that influences its performance within a power supply. Transformer designs vary based on the materials used in their construction, including the core materials and the configuration of the windings. High-quality materials and precise design contribute to the efficiency and performance of both the transformer and the power supply system as a whole. For example, a transformer with a well-designed core and optimized winding configuration will have lower losses and greater efficiency, which is particularly important when dealing with high-voltage applications. The size and design of a transformer must also match the requirements of the power supply, ensuring that the voltage is regulated and that the system can handle the required power levels without overheating or suffering from energy loss. Core geometry and flux density limits are discussed in power transformers explained for designers optimizing efficiency.

Safety and Isolation: Protecting Equipment and Users

Safety is another critical consideration when discussing power supplies and transformers. Electrical isolation, provided by transformers, is one of the key ways that power supplies protect both equipment and users from electrical hazards. High-voltage systems, in particular, can be dangerous if not properly isolated. Transformers act as a barrier between the high-voltage input and the lower-voltage output that reaches sensitive equipment, ensuring that users are protected from electrical shocks and that devices are not damaged by surges or spikes in voltage. This isolation is particularly important in industrial and residential applications, where electrical safety is paramount. It is important to distinguish isolation transformers from autotransformers, as outlined in this comparison to avoid safety misconceptions.

Frequently Asked Questions

What is the primary difference between a power supply and a transformer?

- A power supply is an electronic device that converts electrical energy from a source (like the main AC power grid) into the required voltage and current for a specific load (such as an electronic device). It can include multiple components like rectifiers, filters, regulators, and transformers.

- A transformer is a passive electrical device that changes the voltage of alternating current (AC) through electromagnetic induction. It does not convert AC to DC or regulate voltage; it only steps up or steps down voltage levels.

How do transformers work within power supplies?

In a power supply, a transformer is typically used to step up or down the input voltage to a level suitable for the device. For example, if the input voltage is 120V AC and the device requires 12V, the transformer reduces the voltage. It works by creating a magnetic field in the primary coil, which induces a corresponding current in the secondary coil, thus transferring energy. For typical line-frequency applications, AC transformer fundamentals provide a useful baseline.

Can a power supply function without a transformer?

Yes, a power supply can function without a transformer if it operates with a switching regulator or DC-DC converter. These designs directly convert one DC voltage to another or use high-frequency switching techniques that don't rely on the physical characteristics of transformers. For instance, a power supply using a buck converter or boost converter may not have a traditional transformer but still adjust voltage effectively.

What are the advantages of using transformers in high-voltage power supplies?

The main advantages of using transformers in high-voltage power supplies are:

- Voltage Step-up or Step-down: Transformers can easily increase or decrease voltage for transmission or to meet specific needs, ensuring safe and efficient operation.

- Electrical Isolation: They provide electrical isolation between the high-voltage input and low-voltage output, enhancing safety by preventing direct electrical contact.

- Improved Efficiency: At certain frequencies, transformers are highly efficient in transmitting power over long distances or for high-power applications.

- Reliability: Transformers are robust and reliable components, offering long service life in high-voltage power systems.

How does the design of a transformer impact the efficiency of a power supply?

The efficiency of a transformer is influenced by several factors:

- Core Material: The choice of core material, like silicon steel or ferrite, affects energy losses due to eddy currents and hysteresis, which impact efficiency.

- Windings: The quality of the windings, including wire gauge and insulation, affects the resistance and, therefore, energy losses.

- Leakage Inductance: The transformer design should minimize leakage inductance to reduce energy losses during the energy transfer process.

- Frequency: The operating frequency can impact the transformer’s efficiency, as high frequencies may lead to higher core losses but also allow for smaller, more compact designs. Proper frequency selection balances efficiency and size.

A power supply and a transformer are not the same thing, though they are related in many electrical systems. A power supply is a device that converts electrical energy from a source into the necessary voltage and current for a specific load, often including multiple components such as rectifiers, regulators, and transformers. A transformer, on the other hand, is a passive component that changes the voltage of alternating current (AC) by stepping it up or down through electromagnetic induction. While a power supply can function without a transformer in some cases, especially with advanced switching regulators, transformers are essential in many power supplies to adjust voltage levels and provide electrical isolation. Therefore, while a transformer is an important part of many power supplies, they are distinct components with different roles in electrical systems.

Related Articles

Powerline Transformer Explained

A powerline transformer reduces high voltage from distribution lines to usable service levels. Installed on poles or ground units, they ensure safe electricity delivery, stable voltage regulation, and reliable power flow for residential, commercial, and rural networks across the electric grid.

What is a powerline transformer?

A powerline transformer is a distribution device that converts high-voltage electricity into lower, usable levels for safe and reliable delivery. It:

✅ Reduces high-voltage electricity from distribution lines to safe, usable levels.

✅ Ensures reliable voltage regulation and efficient power delivery to end users.

✅ They are mounted on poles or ground units in residential and rural networks.

The primary function of a powerline transformer is to step down the high voltage transmitted through power lines to a lower voltage suitable for distribution to end-users. This voltage transformation is essential for maintaining the efficiency and safety of the electrical grid. For a broader overview of grid equipment, see our detailed utility transformers guide, which explains their role in large-scale power distribution.

High voltage is used for long-distance transmission to minimize energy losses due to resistance in the wires. However, this high voltage is far too dangerous for direct use in homes and businesses. Power line transformers act as intermediaries, converting the high transmission voltage to lower distribution voltages, typically 120/240 volts for residential customers and higher voltages for commercial and industrial applications. Discover how 3 phase transformers supply commercial and industrial loads with efficient, balanced power.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Power Line Transformer Technical Overview

| Feature | Description |

|---|---|

| Function | Steps down high-voltage electricity from distribution lines to safe service levels |

| Installation | Commonly pole-mounted in residential areas or ground-mounted in rural networks |

| Typical Primary Voltage | 2.4 kV – 34.5 kV (distribution line input) |

| Typical Secondary Voltage | 120/240 V single-phase or 208/120 V three-phase for end users |

| Capacity (kVA Range) | 10 kVA – 500 kVA depending on load requirements |

| Voltage Regulation | Provides stable and efficient voltage for continuous electricity supply |

| Applications | Power homes, small businesses, farms, and light commercial loads |

| Safety Role | Prevents dangerous high voltage from reaching consumer systems |

Frequently Asked Questions

How Does a Powerline Transformer Work?

A powerline transformer operates on the principle of electromagnetic induction. It consists of two or more coils of wire (windings) wrapped around a common magnetic core. The high-voltage electricity from the power lines flows through the primary winding, creating a magnetic field in the core. This changing magnetic field induces a lower voltage in the secondary winding, which is then distributed to consumers.

The ratio of turns in the primary and secondary windings determines the voltage transformation ratio. For instance, a distribution device like this with 1000 turns in the primary winding and 100 turns in the secondary winding will step down the voltage by a factor of 10. Our article on high-voltage transformers explains how bulk power is transmitted across transmission networks before being stepped down.

What are the Different Types?

There are several types of powerline transformers, each designed for specific applications:

-

Distribution: These are used to step down high voltage from power lines to the voltage levels required for residential and commercial use. They are typically mounted on poles or placed on pads. Learn how a distribution transformer steps voltage down for everyday use, similar to how electrical grid transformers serve local networks.

-

Substation: These are used in electrical substations to step down the voltage from transmission levels to distribution levels. They handle very high voltage and are critical for the intermediate stages of power distribution.

-

Pole-Mounted: Installed on utility poles, these transformers serve residential neighborhoods by converting high voltage from distribution lines to lower voltages. Compare the differences between pole mounted transformers and pad-mounted units to understand installation options available in both rural and urban areas.

-

Pad-Mounted: These are enclosed in secure, ground-level cabinets and used in residential, commercial, and industrial areas where underground power lines are preferred. For a deeper look at design fundamentals, see our resource on transformer components, covering cores, windings, and insulation.

What Safety Features are Incorporated?

Power line transformers include several safety features to ensure reliable operation and protect against potential hazards:

-

Surge Protectors: These devices protect the step-down unit from voltage spikes caused by lightning or other transient events.

-

Pressure Relief Devices: These safety valves release excess pressure within the step-down unit, preventing explosions and ensuring safe operation.

-

Fuses and Circuit Breakers: These components protect the distribution device and connected circuits from overcurrent conditions, isolating faults to prevent damage.

-

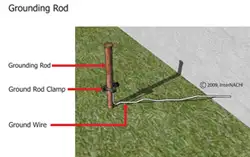

Grounding: Proper grounding ensures that any fault currents are safely directed to the ground, reducing the risk of electric shock and equipment damage.

What Maintenance is Required?

Regular maintenance is crucial to ensure the longevity and reliability of power line transformers. This includes visual inspections to check for leaks, corrosion, or physical damage, as well as periodic oil analysis for liquid-filled units. To understand performance and reliability, review condition monitoring in transformers, which details modern diagnostic tools. Additionally, infrared thermography can be used to detect hot spots that may indicate potential problems.

-

Inspection: Routine visual inspections to check for physical damage, oil leaks, and other visible signs of wear.

-

Oil Testing: Insulating oil should be regularly tested for moisture, acidity, and other contaminants to ensure proper insulation and cooling.

-

Electrical Testing: Periodic testing of the windings and insulation resistance to detect potential faults before they lead to failures.

-

Cleaning: Keeping the distribution device and its surroundings free from dust, dirt, and debris ensures proper cooling and prevents overheating.

A power line transformer is vital to the electrical grid, enabling the safe and efficient distribution of electricity from high-voltage power lines to end-users. By understanding its function, type, safety features, and maintenance requirements, we can ensure the reliable operation of this essential device. Regular maintenance and adherence to safety protocols are crucial for maximizing the lifespan and performance of pole-mounted transformers.

Related Articles

3 Phase Transformers

3 phase transformers step voltage up or down using delta or wye connections. Built with laminated cores and robust insulation, they balance loads, improve efficiency, and serve industrial, utility, and pad-mounted distribution applications.

What are 3 Phase Transformers?

3 phase transformers are electrical devices that convert voltage efficiently across three phases, ensuring stable, balanced power for utility, industrial, and commercial systems.

✅ Convert voltage levels with shared laminated cores and windings

✅ Use delta or wye connections for load balancing and flexibility

✅ Applied in substations, pad-mounted units, and industrial facilities

Although three single-phase transformers can be connected to form a bank, purpose-built three-phase units are more efficient. They require less material, are more compact, and are lighter for the same kVA rating. For these reasons, they are the standard choice for large-scale applications. This makes them a preferred choice for large-scale applications. For a broader understanding of how these units fit into the grid, see our overview of power transformers.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Construction and Insulation

A typical 3 phase transformer is built by winding three single-phase windings onto a shared laminated steel core. The unit is enclosed and often filled with dielectric oil, which insulates the windings, provides cooling, and prevents moisture damage. Dry-type transformers, by contrast, utilize air or resin insulation and are typically chosen for indoor settings where fire safety is a critical concern.

Core designs vary:

-

Laminated cores minimize eddy current losses.

-

Toroidal cores reduce magnetic leakage, lower noise, and improve efficiency.

The winding design and insulation determine load handling and voltage regulation. In step-down units, the primary windings are connected to a higher supply voltage, while the secondary windings deliver a reduced voltage for distribution or equipment. For a deeper background, see Construction of a Transformer. For a look at how electrical energy is transferred between circuits, read our explainer on how transformers work.

Transformer Windings and Connections

The way windings are arranged — Delta (Δ) or Wye/Star (Y) — defines how a transformer behaves in a system:

-

Delta–Delta (Δ/Δ): No phase shift, handles unbalanced loads, continues operation if one winding fails.

-

Delta–Wye (Δ/Y): Common for stepping down voltage, provides both three-phase and single-phase outputs.

-

Wye–Delta (Y/Δ): Often used to step up generator voltages for transmission.

-

Wye–Wye (Y/Y): Provides grounding on both sides, useful for harmonics control.

Specialized designs include:

-

Open Delta: Supplies three-phase loads with only two transformers (reduced capacity).

-

Zigzag grounding transformers: Create a neutral point and manage zero-sequence currents for stability.

These connections determine phase shift, vector group classification, and compatibility when paralleling transformers.

Some designs utilize open-delta configurations to supply three-phase loads with only two transformers, or employ zigzag grounding transformers to create a neutral and manage zero-sequence currents, thereby improving system stability under unbalanced load conditions. In distribution systems, a 3 phase pad-mounted transformer provides safe, ground-level voltage conversion for residential and commercial customers.

Vector Groups and Phase Shift

Every three-phase transformer has a vector group designation (e.g., Yd11, Dy1). This indicates the winding connections and the phase angle difference between primary and secondary voltages. Correct vector group selection is critical when transformers operate in parallel, ensuring phase alignment and preventing circulating currents.

Comparison of 3 Phase Transformers vs. Single-Phase Transformers

| Feature | Three Phase Transformers | Single-Phase Transformers |

|---|---|---|

| Efficiency | Higher efficiency due to continuous balanced power delivery | Lower efficiency, especially for high-capacity applications |

| Material Usage | Requires less conductor material for the same power output | Requires more material for equivalent output |

| Size and Weight | More compact and lighter for the same kVA rating | Larger and heavier for equivalent capacity |

| Load Handling | Handles heavy industrial loads with better voltage regulation | Best suited for smaller, lighter loads |

| Installation | Requires specialized equipment for transport and installation as one unit | Easier to transport and install individually |

| Redundancy | Failure of one coil may require removal of the entire unit | If one unit fails, others can still operate in a bank |

| Cost | Lower cost per kVA in large-scale applications | Higher cost per kVA for the same output |

Why the Three-Phase System Matters

With voltages spaced 120 degrees apart, three-phase power delivers continuous energy with less conductor material. This efficiency makes it the global standard for long-distance transmission, industrial equipment, and large commercial facilities. Three-phase transformers adapt these systems to match generation output, transmission requirements, and load needs.

Advantages and Disadvantages

Compared to single-phase transformer banks, three-phase units offer higher efficiency, lower cost per kVA, lighter weight, and reduced space requirements. However, single-phase units can be easier to transport, install, and replace if one fails, whereas repairing an integrated three-phase transformer may require removing the entire unit.

Advantages:

-

Higher efficiency than single-phase banks

-

Lower cost per kVA

-

Smaller size and lighter weight

-

Better load balancing and reduced losses

Disadvantages:

-

More challenging to transport and install as one unit

-

A single coil failure can require removing the entire transformer

Application Examples

3 phase transformers are found in substation installations, pad-mounted units for underground distribution, and renewable energy systems connecting wind or solar farms to the grid. They are also used in industrial plants, large commercial facilities, and regional utility networks to ensure consistent, efficient power delivery.

Three-phase transformers are critical components in today’s electrical networks. They offer high efficiency, compact construction, and flexibility in voltage transformation. With various winding configurations, robust insulation systems, and precise vector group classifications, they deliver reliable and efficient power for industrial, commercial, and utility-scale applications. Distribution networks often rely on electrical substation transformers to step voltages up or down for efficient transmission.

3 phase transformers are used across the utility and industrial sectors:

-

-

Substations: Stepping voltage up or down for transmission and distribution

-

Pad-mounted units: Providing safe, ground-level service in urban or suburban areas (Pad-Mounted Transformers)

-

Renewable energy systems: Connecting wind farms and solar plants to the grid

-

Industrial facilities: Supplying motors, drives, and heavy loads

-

Regional networks: Enabling long-distance bulk power transfer

-

Pad-Mounted Three-Phase Transformers

A special application is the 3 phase pad-mounted transformer, which steps down medium voltage (2.4–35 kV) to lower levels suitable for end-use. Installed outdoors on concrete pads, these enclosed units are common in underground distribution systems.

Advantages include:

-

Compact, visually unobtrusive design

-

Enhanced safety with dead-front construction

-

Use of biodegradable insulating fluids for environmental safety

-

High reliability for critical loads like data centers

-

Simplified installation and maintenance

Maintenance and Reliability

Routine inspections are crucial for preventing overheating, insulation breakdown, and mechanical wear. Oil-filled units require periodic oil analysis to assess dielectric quality and detect moisture ingress. Thermal imaging is often used to locate hot spots in windings and cores, allowing early repairs and extending service life. When grounding is required for system stability, grounding transformers are used to create a neutral and manage unbalanced loads.

Frequently Asked Questions

Delta vs. Star – what’s the difference?

Delta (Δ) windings form a closed triangle, providing higher line-to-line voltage and excellent load balancing for heavy loads. Star (Wye, Y) windings connect to a neutral point, resulting in lower phase voltages and allowing for grounded neutrals, which enhances safety.

Why are 3 phase transformers more efficient?

They deliver continuous, balanced power with reduced fluctuation, utilizing a single integrated core instead of three separate units, which in turn reduces losses, costs, and size.

Where are they used?

They power industrial motors, commercial buildings, substations, renewable energy connections, and utility grids.

How do I choose the right core type?

Core-type is cost-effective for lower ratings. Shell-type offers greater strength and efficiency at high currents or voltages. Space, cooling, and load demand determine the choice.

How do windings affect voltage regulation?

The turns ratio sets the voltage output. Balanced, well-designed windings enhance regulation, prevent overheating, and ensure stability under varying load conditions.

What is a vector group?

It identifies winding connections and phase shift. Matching vector groups ensures compatibility and prevents circulating currents in parallel systems.

Dry-type vs. oil-filled – what’s the difference?

Dry-type uses air cooling, is safer indoors, and has lower maintenance. Oil-filled units utilize insulating oil for enhanced efficiency and capacity, but they require specific safety precautions.

Three-phase transformers are critical for the global power system. With diverse winding connections, robust insulation systems, and efficient core designs, they provide reliable voltage transformation for every part of the grid. From substations and renewable energy systems to pad-mounted transformers, these units ensure that electricity is delivered safely and efficiently to industries, businesses, and communities.

Related Articles

3 Phase Pad Mounted Transformers

3 Phase Pad Mounted Transformer delivers reliable medium-voltage distribution for underground utility networks, with oil-filled, tamper-resistant, compartmental designs, loop or radial feed, ANSI/IEEE compliance, and kVA ratings stepping primary to low-voltage secondary.

What Is a 3 Phase Pad Mounted Transformer?

A sealed distribution transformer that steps medium-voltage primaries down to low-voltage three-phase service.

✅ Oil-filled, tamper-resistant, compartmental enclosure

✅ Radial or loop feed; dead-front bushings

✅ kVA sizes, impedance, and taps per ANSI/IEEE

In the realm of electrical power distribution, 3 phase pad mounted transformers play a crucial role in delivering electricity to commercial and industrial facilities. These self-contained units are designed for outdoor installation on concrete pads and offer numerous advantages over traditional overhead transformers. For broader context on distribution equipment, resources like the electrical power distribution transformer overview explain how pad-mounted units interface with feeders and protective devices.

What is a 3 Phase Pad Mounted Transformer?

A 3 phase pad mounted transformer is an electrical device that steps down medium voltage (typically ranging from 2.4 kV to 35 kV) to lower voltages suitable for end-use applications. It consists of three individual transformers, each handling one phase of the electrical power, housed within a protective enclosure. These units are commonly used in underground distribution systems, providing a compact and aesthetically pleasing solution for delivering power to various establishments.

For an overview of three-phase operation, the three-phase transformer guide outlines phase displacement, winding connections, and typical applications.

A 3 phase pad mounted transformer is an electrical device designed to transform high-voltage electrical power to lower voltages suitable for end-use applications. These transformers are installed on a concrete pad at ground level and are fully enclosed, providing a safe and secure solution for various environments. They are typically used in commercial and industrial applications, including data centers, where reliable power supply is crucial. Industry guides on the padmount transformer detail enclosure ratings, tamper resistance, and grounding practices for these settings.

Advantages of Using a 3 Phase Pad Mounted Transformer

3 phase pad mounted transformers offer several compelling advantages:

- Compact Design: These transformers offer a compact and aesthetically pleasing design, making them suitable for urban and suburban areas where space is limited.

- Enhanced Safety: The dead front design of pad mounted transformers ensures that all high-voltage components are enclosed, minimizing the risk of accidental contact and improving safety for maintenance personnel.

- Environmentally Friendly: Modern pad mounted transformers are designed to be environmentally friendly, often using biodegradable fluids with a high fire point to reduce the risk of fire hazards.

- Reliability: These transformers provide a reliable power supply, which is essential for critical applications such as data centers.

- Ease of Installation: The pad-mounted design simplifies installation, reducing the time and cost associated with setting up high-voltage equipment.

A comprehensive primer on the pad-mounted transformer also reviews environmental considerations and utility coordination during project planning.

Key Components of a 3 Phase Pad Mounted Transformer

These transformers consist of several key components working together to ensure efficient and safe operation:

- Transformer Core and Windings: The core, typically made of laminated steel, provides a path for the magnetic flux, while the primary and secondary windings facilitate the voltage transformation process.

- Insulation: High-quality insulation materials, such as mineral oil or epoxy resin, protect the windings and ensure electrical isolation.

- Cooling System: A cooling system, often utilizing oil or air, dissipates heat generated during operation to prevent overheating and maintain optimal performance.

- Enclosure: A sturdy metal enclosure houses the internal components, protecting them from environmental factors and unauthorized access.

- Bushings: These insulated conductors allow for safe connection of high voltage and low voltage cables to the transformer.

Technical references on 3-phase transformers delve into core steel grades, loss calculations, and cooling class selection for durability.

Factors to Consider When Selecting a 3 Phase Pad Mounted Transformer

Choosing the right 3 phase pad mounted transformer requires careful consideration of several factors:

- Voltage and kVA Rating: It is crucial to select a unit with voltage and power ratings that match the specific requirements of the application.

- Insulation Type: Depending on the installation environment and safety considerations, you can choose between liquid-filled (mineral oil or other fluids) and dry-type transformers.

- Enclosure Type: Standard or tamper-resistant enclosures are available to cater to varying security needs.

- Accessories: Options like load break switches, lightning arrestors, and temperature monitoring devices can enhance functionality and safety.

- Customer Specifications: Reputable manufacturers like Eaton with their Cooper Power series offer customizable transformers to meet unique customer specifications.

When planning civil works, consult guidance on the transformer mounting pad to ensure proper clearances, drainage, and cable routing.

Safety Precautions

Working with 3 phase pad mounted transformers requires strict adherence to safety guidelines:

- Proper Training: Ensure that all personnel working with these transformers are adequately trained and knowledgeable about electrical safety practices.

- Personal Protective Equipment (PPE): Use appropriate PPE, such as insulated gloves, safety goggles, and protective clothing, to reduce the risk of electrical shock and injury.

- Regular Maintenance: Perform routine inspections and maintenance to identify and address potential issues before they lead to failures or hazards.

- Clear Signage and Barriers: Install clear warning signs and physical barriers around the transformer to prevent unauthorized access and accidental contact.

- Emergency Procedures: Establish and communicate clear emergency procedures for responding to electrical incidents, including shutdown protocols and first aid measures.

Understanding differences with the pole-mounted transformers can inform hazard assessments, work methods, and switching procedures.

By prioritizing safety and selecting the right transformer for the specific application, you can ensure reliable and efficient power distribution for your commercial or industrial facility.

Three-phase pad mounted transformers are indispensable in modern electrical distribution systems, offering a range of advantages from compact design and enhanced safety to environmental friendliness and reliability. Understanding their key components, the factors to consider when selecting them, and the necessary safety precautions can ensure their optimal performance and longevity. Whether in data centers, commercial complexes, or industrial applications, these transformers play a pivotal role in delivering stable and efficient power tailored to customer specifications. By adhering to best practices and industry standards, you can maximize the benefits and ensure the safe operation of three-phase pad mounted transformers.

Related Articles

Utility Transformers News

Utility Transformers Media

Utility Transformers Articles From ET Magazine

The Role of Transformer Oil Alternatives in Improving Safety and Environmental Sustainability

The Growing Need for Safer and Greener Transformer Oils

Transformer oil plays a vital role in the operation and longevity of power transformers, providing insulation, cooling, and arc suppression. Traditionally, mineral oil has been the industry standard due to its effective dielectric properties and cost-efficiency. However, growing concerns about fire safety, environmental impact, and sustainability have driven the search for alternative transformer oils. Synthetic esters, natural esters (vegetable-based oils), and silicone fluids are emerging as viable substitutes, offering enhanced fire resistance and biodegradability while maintaining reliable performance. As utilities transition to greener and safer solutions, the role of transformer oil alternatives is becoming increasingly important in ensuring a more resilient and sustainable energy infrastructure.

Limitations of Traditional Mineral Oil

While mineral oil has been widely used for decades, it presents several significant drawbacks. One of the primary concerns is its flammability. Mineral oil has a relatively low fire point, making transformers susceptible to fire hazards, particularly in densely populated areas or critical infrastructure locations. Additionally, in the event of a spill or leakage, mineral oil poses environmental risks due to its slow biodegradation and potential for soil and water contamination. Regulatory agencies and environmental organizations are tightening restrictions on the disposal and handling of mineral oil, pushing utilities to explore safer alternatives.

Another challenge associated with mineral oil is its inability to handle high thermal stress over long periods. As transformers operate under increased loads due to rising energy demands, the thermal stability of insulation fluids becomes a key factor in extending equipment lifespan. Given these limitations, the industry is gradually shifting toward synthetic and natural ester-based alternatives that provide superior fire safety and environmental benefits.

Read the full article in the Transformer Technologies Special Edition

Enhancing Transformer Resilience: Fire Barriers and Safety Measures in Modern Substations

The Growing Concern of Transformer Fire Risks

An Electrical Substation Transformer is a critical component of modern substations, playing a vital role in the transmission and distribution of electricity. However, due to the high-voltage operations, flammable insulation materials, and exposure to extreme weather conditions, transformers are at significant risk of fire and explosions. A solid foundation for transformer safety starts with thoughtful electrical substation design, ensuring layout and equipment placement mitigate fire risk. The consequences of transformer fires can be severe, leading to equipment damage, power outages, environmental hazards, and, in some cases, loss of life. As utilities expand their grids and integrate renewable energy sources, the need to enhance transformer resilience against fire hazards has become more pressing than ever. Proper substation grounding protocols protect transformers and personnel from electrical faults and fire-related events.

Implementing fire barriers and adopting advanced safety measures are crucial to mitigating risks and ensuring an uninterrupted power supply. Understanding the causes and impacts of a substation explosion is essential to improving overall infrastructure resilience.

Causes of Transformer Fires and Explosions

Transformer fires are typically caused by insulation failure, short circuits, overheating, or external environmental factors such as lightning strikes. One of the primary causes is the degradation of transformer insulating oil, which can break down under high temperatures, producing flammable gases that increase the risk of ignition. Electrical arcing, caused by insulation breakdown or mechanical faults, generates extreme heat that can lead to explosions. Robust substation protection systems are critical in isolating faults and minimizing fire propagation.

Overloading transformers beyond their design capacity also contributes to excessive heating, accelerating insulation failure and increasing fire risks. External impacts, such as earthquakes, vandalism, or accidental collisions, can sometimes trigger catastrophic failures.

Read our What is a Substation article for a deeper understanding of substation technology. Consistent electrical substation maintenance is the key to identifying potential hazards before they lead to costly failures.

You can also visit our Substation Maintenance training course.

Visit our Electricity Forum Electrical Substation Channel Page.

Read the full article in the Transformer Technologies Special Edition

Navigating the Transformer Supply Crunch: Strategies for Utilities Amidst Global Shortages

The Growing Transformer Supply Crisis

The global transformer supply chain is facing unprecedented challenges, with utilities worldwide struggling to procure essential equipment due to material shortages, manufacturing delays, and logistical constraints. Transformers are the backbone of electrical transmission and distribution networks, and their scarcity poses significant risks to grid reliability, infrastructure expansion, and system resilience. As demand continues to outpace supply, utilities must adopt strategic approaches to mitigate risks, ensure the timely acquisition of transformers, and maintain operational stability.

Factors Driving the Transformer Shortage

Several factors contribute to the current transformer supply crunch. Raw material shortages, particularly of electrical steel, copper, aluminum, and insulating oils, have led to significant procurement challenges. Electrical steel, essential for transformer cores, has experienced price volatility due to rising global demand and production limitations. Manufacturing bottlenecks have further exacerbated the issue, with many transformer manufacturers operating at full capacity, constrained by workforce shortages and aging production facilities. Lead times for large power transformers, which once averaged 12 to 18 months, have now extended well beyond two years in some cases.

Geopolitical tensions and trade challenges have also played a role in disrupting supply chains. Tariffs, export restrictions, and geopolitical conflicts have made it difficult for utilities to source transformers from traditional suppliers, leading to increased costs and uncertainty. Meanwhile, the global push for electrification, renewable energy integration, and grid modernization has driven demand to unprecedented levels, placing additional strain on an already fragile supply chain. Logistical constraints, including shipping delays, container shortages, and port congestion, have further hindered the timely delivery of transformers, compounding the issue.

Read the full article in the Transformer Technologies Special Edition

MITIGATING TRANSFORMER FAILURES: ADVANCED MONITORING AND MAINTENANCE STRATEGIES

Power transformers are critical assets in electrical transmission and distribution networks. Their failure can lead to widespread outages, costly downtime, and potential safety hazards. As transformers age and operate under varying electrical and environmental stresses, degradation becomes inevitable. However, through advanced monitoring techniques like Dissolved Gas Analysis (DGA) and Frequency Response Analysis (FRA), utilities can proactively identify early signs of failure, enabling preventive maintenance and extending transformer service life.

Dissolved Gas Analysis (DGA): A Window into Transformer Health

DGA is a well-established diagnostic method used to detect transformer insulation and oil degradation by analyzing the gases dissolved in transformer oil. When internal faults occur, electrical and thermal stresses break down the oil and solid insulation materials, generating gases that dissolve in the oil. By examining the composition and concentration of these gases, engineers can infer the nature and severity of the developing faults.

The primary gases analyzed in DGA provide insights into different fault conditions:

- Hydrogen (H₂) indicates low-energy partial discharge activity

Methane (CH₄) suggests overheating of oil at moderate temperatures. - Ethane (C₂H₆) and Ethylene (C₂H₄) signify thermal degradation of oil at high temperatures.

- Acetylene (C₂H₂) is strongly associated with arcing and electrical breakdowns.

- Carbon Monoxide (CO) and Carbon Dioxide (CO₂) indicate degradation of cellulose-based insulation, such as paper and pressboard.

Read the full article in the Transformer Technologies Special Edition

Sign Up for Electricity Forum’s Utility Transformers Newsletter

Stay informed with our FREE Utility Transformers Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue