Transmission & Distribution

Coordinated Protection, Control Automation Schemes

Coordinated automation schemes optimize grid operations with substation automation, SCADA, IEC 61850 interoperability, protective relays, and load shedding, enabling real-time control, fault isolation, and DER integration for resilient, efficient power system performance.

What Are Coordinated Automation Schemes?

Schemes aligning relays, SCADA, and IEC 61850 to coordinate protection, control, and optimization across power systems.

✅ Integrates relays, PLCs, DCS, and SCADA via IEC 61850/GOOSE

✅ Coordinates protection, load shedding, and remedial action schemes

✅ Enhances reliability, selectivity, and grid resilience under faults

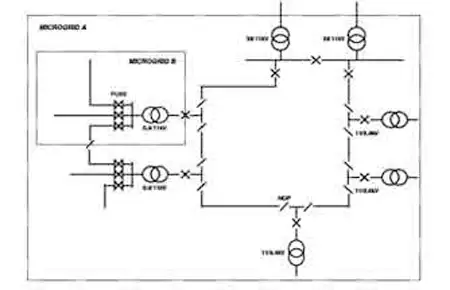

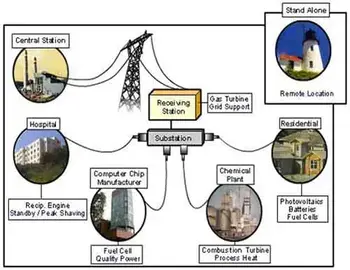

Widespread concerns over the environmental impact of traditional transmission connected thermal generating units are driving the installation of a significant level of generation within distribution networks. The term microgrid refers to the coordinated integration of small-scale distributed or microgeneration within the lower voltage levels of the distribution network, facilitated through the formation of semi-autonomous zones covering a relatively small geographical area. For foundational context, see the overview of microgrid fundamentals that clarifies scope, components, and typical operating modes.

Such a paradigm shift raises important issues surrounding the operation and protection of a potentially fragmented active network. The need to accommodate significantly varying primary network conditions, minimize customer interruptions, and harness the ancillary benefits of distributed or microgeneration are all fundamental to solving the aforementioned issues. This paper presents the results of research aimed at developing practical protection, control and automation schemes for microgrids. The key issues for protecting low-voltage networks operating with the microgrid paradigm will be given, and will draw strongly on representative examples from distribution systems found within the United Kingdom. Several schemes will be outlined and demonstrated covering both urban and rural applications. The major functional elements of the schemes will be shown in detail, including: the interface, network and microgenerator protection. In addition to illustrating the core protection functionality, attention will be directed towards the benefits obtainable from closely coordinating these functions with that of network automation. These objectives align with ongoing grid modernization initiatives that emphasize interoperability, situational awareness, and adaptive protection.

#google#

INTRODUCTION

The electricity supply industry is under pressure to move away from relying principally on large transmission connected thermal power stations, and to accommodate smaller, more environmentally sustainable forms of generation connected to distribution networks. This is exemplified in the United Kingdom (UK) by the recent Energy Review. This transition is integral to broader smart grid concepts that prioritize flexibility, resilience, and customer participation.

The drivers for these changes arise from growing concerns surrounding the negative environmental impact of greenhouse gases emitted by the combustion of fossil fuels, and are strongly supported by regulatory incentives within liberalized energy markets. One particular facet of this change in the generation portfolio relates to the changes that may occur at the lowest level of the distribution network, where individual consumers could be incentivised to install microgeneration within residential or commercial premises. The potential capacity available - if fully harnessed - could make a significant contribution towards meeting localized network demand in the future. At the consumer level, widespread adoption of distributed generation can reshape demand profiles, reverse power flows, and influence tariff design.

However, the ability to facilitate the connection of high levels of generation at low voltages will need careful technical consideration as barriers are thought to exist which may hinder the adoption of these technologies: the potential for voltage rise and the need to install additional protection are often cited as issues [3]. One major avenue of current investigation is to create areas of the network that are identified as microgrids where specific supportive measures have been taken to support the connection of high levels of generation and energy storage. Mitigating voltage rise, coordination, and fault performance requires adapting established power distribution practices to accommodate high DER density and dynamic operating states.

The term microgrid refers to the coordinated integration of small-scale distributed and microgeneration within the lower levels of the distribution network, facilitated through the formation of semi-autonomous zones covering a relatively small geographical area. In doing so, important issues are raised surrounding the management, operation and protection of a potentially fragmented active network. The provision of an effective, yet affordable protection scheme for microgrid networks represents a challenging objective for research within the field of power system protection. Significantly varying network conditions, a potentially large number of installations, and a relatively low level of engineering capability for those installing and operating equipment are just some of the issues to be addressed. Viewed within the broader architecture of electric power systems, microgrids function as controllable subsystems capable of both islanded and grid-connected operation.

The results of research aimed at developing practical protection schemes for microgrid networks, and specifically provides:

By aligning detection, control, and restoration logic with the behavior of the electricity grid, the schemes aim to maintain stability and service quality during disturbances.

• A brief overview of the microgrid concept and discussion of key assumptions made about their size and scope.

• The key issues for protecting networks operating with the microgrid paradigm, drawing strongly on representative examples from distribution systems.

• A potential scheme that is functionally outlined and demonstrated conceptually using both rural and urban application examples – the impact of network specific issues such as transitory faults and the radial topology are stressed as applicable.

• In addition to illustrating the core protection functionality, the paper outlines the benefits obtainable from closely coordinating these functions with these of network automation controllers.

MICROGRIDS

Microgrids offer the potential to maximize the level of generation that can be connected at the lower voltage levels of the distribution network and at the same time provide consumers with improved levels of supply security. A microgrid can be temporarily operated in an intentional islanded mode in response to significant disturbances within the upstream grid system (e.g. outage of circuits or power quality disturbances). The adoption of such a strategy effectively creates a cellular structure within the distribution network. This will break down the conventional hierarchical approach to control and raises issues surrounding the operation and management of a potentially fragmented active network.

Related Articles

Test Your Knowledge About Dielectric Fluids!

Think you know Dielectric Fluids? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Latest T&D Content

Power Pole Transformer And T&D

A power pole transformer steps down high-voltage electricity from distribution lines to usable levels for homes and businesses. Mounted on utility poles, these transformers play a key role in electrical power distribution, ensuring safe, efficient energy delivery.

What is a Power Pole Transformer?

A power pole transformer is a distribution transformer mounted on a utility pole. It converts high-voltage electricity to lower voltages for safe residential and commercial use.

✅ Steps down utility line voltage for household use

✅ Mounted on power poles for efficient distribution

✅ Ensures safe, reliable electricity delivery

It is a vital piece of equipment in distribution transformer networks, responsible for stepping down high-voltage electricity into lower, manageable voltages for safe and effective use in various systems. Understanding how electrical pole equipment operates is crucial for safety, performance, and system reliability. Let’s explore the components and applications of these devices to support maintenance, installation, and troubleshooting for industrial electricians.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Mounting and Installation

Mounted on utility poles, often wood or concrete, these devices are elevated to improve safety and delivery efficiency. The pole-mounted transformer setup is ideal for outdoor distribution, reducing contact risks while providing easy access to power lines in both urban and rural environments. Positioned high above ground, they not only enhance accessibility for power lines but also minimize risks associated with tampering or accidental contact. This design makes them a cornerstone of outdoor primary and secondary local distribution systems, where reliability and durability are paramount.

Types and Configurations

Power pole transformers are available in single-phase and three-phase configurations. Single-phase power transformers are commonly used in rural areas, whereas three-phase transformer types predominate in industrial and urban zones, where higher power demands are typically found.These variations highlight the versatility of this electrical equipment in adapting to the unique demands of the grid.

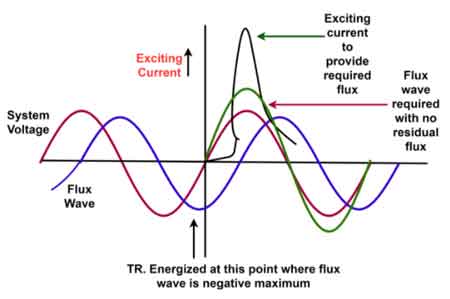

Voltage Step-Down Process

These transformers use a magnetic core and primary and secondary windings to reduce voltage. High-voltage input enters the primary winding, inducing a lower voltage in the secondary winding. The principles of step-down transformers follow standard transformer operation, enhanced by materials such as silicon steel to reduce energy loss.

One of the critical functions of the grid device is stepping down the voltage for safe and efficient use. This process involves the primary windings, which receive high-voltage electricity, and the secondary windings, which output the lower, usable voltage. By incorporating materials like silicon steel into their cores, these devices optimize magnetic fields, thereby minimizing energy losses during the transformation process. This focus on efficiency is especially important, given that these devices are continuously energized, demanding a design that prioritizes both performance and longevity.

Applications in Power Distribution

In the broader context of electricity distribution, these devices play a crucial role in delivering electricity to end-users. They form an essential link in the power grid, enabling the seamless flow of electricity from generation stations through the distribution network to homes, offices, and small industries. Without grid devices, the high voltage carried by transmission lines would be incompatible with the needs of everyday electrical devices, underscoring their importance in the modern world. To understand how these components fit into the broader network, explore our page on electrical power transformers.

Efficiency and Design Considerations

Transformer cores must be designed for continuous use and minimal loss. Transformer losses due to heat and magnetic field fluctuation are reduced through the use of specialized materials and advanced construction techniques. Additionally, these devices are engineered to perform optimally under varying loads, ensuring consistent delivery even during fluctuations in demand. This reliability is critical in maintaining the stability of the grid.

Frequently Asked Questions

What does a power pole transformer do?

A power pole transformer is a crucial component of the electrical distribution system, reducing the high voltage of electricity carried by lines to a lower, usable voltage suitable for homes, businesses, and other facilities. For example, it typically steps down the voltage from several thousand volts to the standard 120/240 volts used in residential areas.

How does a power pole transformer work?

The core and coil design allows magnetic induction between windings, creating a lower output voltage. This process follows the principles described in our guide on how transformers work.

What are the common types of power pole transformer?

These include single-phase and three-phase models, oil-filled transformer or dry-type transformers, each suited to different environments and load needs.

Single-phase transformers are used in residential areas or small businesses and step down the voltage for single-phase distribution systems. Three-phase devices are commonly used in industrial and commercial settings and are specifically designed for three-phase electrical distribution. They are installed directly on utility poles for overhead distribution systems, while pad-mounted transformers are often used in areas where power lines are underground but can serve the same function as pole-mounted transformers. Oil-filled devices utilize insulating oil for both cooling and insulation, making them more durable for high-voltage applications. In contrast, dry-type devices use air for cooling and are typically employed in lower-voltage or indoor settings.

What are the signs of failure?

Signs of a failing power pole transformer include overheating, which may be indicated by visible smoke or signs of melting insulation. Unusual noises, such as humming, buzzing, or clicking sounds that are louder or different from normal operation, can also be a warning. Physical damage, such as cracks, bulges, or oil leaks on the device casing, along with electrical interruptions, frequent outages, or irregular voltage delivery, are clear indicators. A burning smell or fluctuating voltage, such as lights dimming or flickering in nearby buildings, may signal internal failure or overheating.

What is the lifespan and maintenance?

Typically lasting 25–40 years, these devices require regular inspections, transformer testing, oil analysis, and load checks for optimal performance.

Maintenance includes routine inspections for physical damage, leaks, and corrosion, as well as oil testing for oil-filled devices to detect contamination, moisture, or breakdown products. Cleaning to remove debris, dirt, or bird nests from the device and its surroundings is important. Thermal scanning can identify hotspots that may indicate overloading or internal faults, while load monitoring ensures the device is not overloaded beyond its rated capacity. Preventive repairs should address minor issues promptly to prevent larger failures. Regular maintenance and monitoring maximize the lifespan and reliability of grid devices.

Related Articles

Electrical Insulator

An electrical insulator prevents the unwanted flow of current by providing high resistance between conductive parts. Essential in power transmission systems, these materials ensure isolation, enhance safety, and protect equipment from arcing and short circuits.

What is an Electrical Insulator?

An electrical insulator is a vital component in T&D systems, ensuring safety and reliability. However, it comes in various materials and types, each with advantages and disadvantages.

✅ Provides electrical isolation in high-voltage systems

✅ Made from dielectric materials like porcelain or polymer

✅ Prevents arcing and protects conductors from short circuits

Understanding the insulating properties of dielectric materials, resistance, and breakdown voltage is essential for selecting the most suitable non-conductive material for a specific application. By making informed choices, engineers can ensure the longevity and safety of transmission and distribution (T&D) installations and equipment.

An electrical insulator is a material that restricts the flow of electric current, ensuring that electric charge does not easily pass through it. They are essential components in power systems, as they help protect equipment, structures, and people from electric shocks and short circuits. A high-quality electrical insulator possesses high resistivity, which means it can withstand high voltages without allowing current to flow unimpeded.

High Voltage Transmission Uses

High-voltage power transmission insulating devices are typically made from materials such as glass, porcelain, or composite polymers. Porcelain types consist of clay, quartz or alumina, and feldspar and feature a smooth glaze that allows water to run off easily. When high mechanical strength is required, porcelain rich in alumina is utilized. Porcelain ones have a dielectric strength of around 4–10 kV/mm. Glass types possess a higher dielectric strength; however, they tend to attract condensation, which can result in thick, irregular shapes that are necessary for non-conductive insulating devices. These shapes can lead to internal strains.

Consequently, some manufacturers ceased producing glass ones in the late 1960s, opting instead for ceramic materials.

Electric utilities sometimes use polymer composite materials for certain types of insulators. These typically consist of a central rod of fibre-reinforced plastic and an outer weather shield made of silicone rubber or ethylene propylene diene monomer (EPDM) rubber. Composite non-conductive materials are more cost-effective and lightweight, exhibiting exceptional hydrophobic properties. This combination makes them ideal for use in areas with high pollution levels. However, these materials have not demonstrated the same long-term service life as their glass and porcelain counterparts.

Different Materials

Different types of electrical insulator are designed to cater to various applications and environments. They are classified based on the material used, such as ceramic, glass, and polymer insulators. Each type has specific insulating properties that make it suitable for certain uses.

Dielectric materials are a crucial component of any electrical insulator. They function by inhibiting the electric field within their structure, preventing the flow of a charge. A dielectric material's insulating properties are primarily determined by its dielectric constant, which measures its ability to store energy without conducting it.

Ceramic ones, such as porcelain, have been used for many years due to their excellent insulating properties, mechanical strength, and resistance to high temperatures. They are typically used in high-voltage applications, including power transmission and distribution systems. However, they can be heavy and brittle, which reduces durability and increases maintenance costs.

Materials such as glass paper, on the other hand, offer excellent transparency and a smooth surface that helps prevent dirt accumulation. They also have high dielectric strength, meaning they can withstand high voltage without breaking down. However, like ceramic ones, they are fragile and prone to breakage.

Polymer insulators are a recent innovation made from silicone rubber or epoxy resins. They are lightweight, durable, and have good insulating properties. Additionally, polymer devices exhibit increased resistance to environmental factors, including UV radiation and pollution. However, their long-term performance still needs to be studied, and they may be more expensive than traditional ceramic or glass insulators.

Performance is affected by its resistance and breakdown voltage. Resistance measures a material's ability to prevent the flow of electric current. A higher resistance means that the insulating device is more effective at blocking the flow of electricity. On the other hand, the breakdown voltage is the maximum voltage an insulator can withstand before it fails and allows electric current to flow through it. Therefore, a higher breakdown voltage indicates better insulating capabilities.

Electrical insulators play a crucial role in power transmission and distribution systems. They support and separate conductors, ensuring that the electric field and current remain confined within the conductors. They also help maintain the integrity of the wiring and prevent short circuits or leakage currents that may cause equipment damage or pose safety risks.

Several factors should be considered when selecting an electrical insulator for a specific application, including the operating voltage, environmental conditions, and mechanical stresses. The non-conductive material should possess a high dielectric constant, good resistance to temperature changes, and adequate mechanical strength. Additionally, it should resist environmental factors such as moisture, pollution, and UV radiation.

Various Types

Pin Insulator - This type is attached to a pin mounted on the cross-arm of a utility pole. It features a groove near its top, just below the crown, through which the conductor runs and is fastened using an annealed wire made of the same material as the conductor. Pin insulators are commonly used to transmit communication signals and electric power at voltages of up to 33 kV. However, they can become bulky and uneconomical for operating voltages between 33 kV and 69 kV.

Post Insulator - Introduced in the 1930s, they are more compact than traditional pin-types. They have rapidly replaced many pin-types in lines with voltages up to 69 kV and, in some configurations, can be designed for operation at up to 115 kV.

Suspension Insulator - Suspension devices are typically utilized for voltages exceeding 33 kV. They consist of a series of glass or porcelain discs linked together with metal connectors, forming a string. The conductor is suspended from the bottom of this string, while the top is secured to the tower's cross-arm. The number of disc units required depends on the voltage.

Strain Insulator - When a straight section of a transmission line ends or changes direction, a dead-end or anchor pole or tower is employed. These structures must withstand the lateral (horizontal) tension from the long straight section of wire. Strain devices are used to support this load. For low-voltage lines (under 11 kV), shackle ones are strain insulators. For high-voltage transmission lines, cap-and-pin (suspension) insulator strings are used, mounted horizontally to the crossarm. In cases of extremely high tension, such as long river spans, two or more parallel strings may be necessary.

Shackle Insulator - Initially, shackle types were employed as strain insulators. Nowadays, they are predominantly used for low-voltage distribution lines. These can be installed in horizontal or vertical orientation and can be directly fastened to the pole with a bolt or to the crossarm.

Related Articles

Power Transformer Market Research Report 2019 Predicts Global Power Transformer Market of $34 Billion by 2023

Power Transformer Market Research Report delivers industry analysis, market size, CAGR forecasts, technology trends, competitive landscape, regional segmentation, grid modernization, HV/MV applications, and demand drivers across transmission and distribution, worldwide utility procurement insights.

What Is a Power Transformer Market Research Report?

A technical study of demand, specs, trends, and forecasts for power transformers in transmission and distribution.

✅ Market sizing by voltage class (HV/MV/LV) and application

✅ Technology trends: amorphous cores, OLTC, digital monitoring

✅ Standards, losses, efficiency, grid code and T&D investments

Report provides comprehensive information on Global Power Transformer Market size, share, industry trends, growth, with regional forecast to 2023. Report analyses Power Transformer Market Upcoming Opportunities, challenges, Key Country Analysis, with business development strategies, And key players insights. For readers seeking foundational context, see the power transformers explained resource to understand terminology and scope.

Global Power Transformer Market – Overview

A resent research report about the global power transformer market that adumbrates aggrandizement for this market at 8.64% CAGR between 2018 and 2023. By value, the market has been figured to be worth the US $ 34 billion by the end of forecast period. With global electrification and power backup rapidly becoming a reality, the demand, as well as market for transformers, is growing in countries where cities and villages are being electrified now or where arrangements are needed for power backup.

The distinctive factor supporting the global power transformer market growth is the investments in the energy sector due to the infrastructural developments. Other market drivers include growth in the renewable energy sector and growing demand for electricity for the consumer as well as commercial purposes. Power transformers are a reliable source of energy backup for power and utility sectors. It can contribute to reduction of energy emissions in several sectors. Furthermore, they can support the use of generators and grids. In particular, clarifying what constitutes a modern power transformer helps unpack these growth drivers.

Key Players

The key players in the global power transformer market include ABB Ltd., (Switzerland), Bharat Heavy Electricals Limited (India), Crompton Greaves Ltd. (India), Hyosung Power & Industrial Solutions (South Korea), Hyundai Electric & Energy Systems Co. Ltd. (South Korea), Mitsubishi Electric Corporation (Japan), Schneider Electric (France), SGB-SMIT Group (Germany), Siemens AG (Germany), SPX Transformer Solutions Inc. (USA), and Toshiba Corporation (Japan). Market concentration can also be gauged by surveying prominent transformer manufacturers operating across regions today.

Segmental Analysis

The global power transformer market has been segmented on the basis of cooling type, power rating, and by region. By cooling type, this market has been segmented into oil-cooled transformers and power-cooled transformers. Both of these kinds of transformers can transmit power over large distances. Based on power rating, the market has been segmented into small power, medium power, and large power. Small power range has the capacity in the range of 100-500 mega volt-amps (MVA). The medium range power transformers have a capacity between the ranges of 500-800 MVA. The large range power transformers have the potential of above 800 MVA. These classifications align with how a typical electrical power distribution transformer is specified for grid integration and planning.

Industry Trend

Research and development are inspiring installation of the latest techniques that are taking the market forward and is assisting in the maintenance of social compliances. For instance, in April 2018, ABB Ltd. launched ABB Ability Power Transformer, which is first of its kind integrated solution

for digitally enabled power transformers.

In March 2017, Siemens AG supplied power transformers of 405/20-kV 570- MVA capacity to EDF for promoting power generated from the high capacity nuclear power plants. Alongside digitalization, routine power transformer health checks are enabling condition-based maintenance across fleets.

Utilities are increasingly adopting asset management using health index methodologies to prioritize refurbishment and replacement programs.

Detailed Regional Analysis

The regional segmentation of the global power transformer market segments the global market into regional markets known as North America, Europe, Asia Pacific, and rest of the world (RoW). The North America market is due to the presence of well-established market players, and rapid technological advancements. Important country-specific markets in this region are USA and Canada. During the forecast period, the market in Europe is set to surge at a striking rate due to the replacement of aging infrastructure along with the increasing rate of installation of eco-friendly transformers. There are several small and medium power transformer projects that present a positive outlook of the market growth in this region. Important country-specific markets in Europe are France, Germany, Russia, and the UK, followed by the remaining countries of Europe.

During the forecast period, the Asia Pacific region is likely to emerge as the fastest growing market. In this region, updates and upgrades of existing transmission and distribution infrastructure to serve the growing demand for electricity are regular. The market growth is being contributed by emerging economies like China, India, and Japan, due to the need for improving access to electricity and steady economic growth. Many countries in this region have poor economies and infrastructure. Therefore, many foreign firms are investing in the infrastructural expansion of the Asia Pacific region. The RoW segment covers the countries of Latin America and the Middle East & Africa (MEA). In Latin America, Argentina and Brazil are two strong economies that can be suitable markets in the future. The MEA region is the small regional market due to poor countries, lack of awareness, lack of infrastructure, lack of advanced technology, and lack of education. Procurement teams in both mature and emerging markets benefit from structured evaluation of transformers to standardize specs and reduce lifecycle risk.

Related Articles

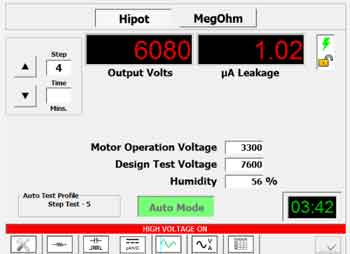

Hipot Testing Explained

Hipot testing checks electrical insulation strength by applying high voltage to confirm there are no current leaks. It is essential for ensuring safety, detecting faults, and preventing electrical failures in power equipment, cables, transformers, and other high-voltage systems.

What is Hipot Testing?

Hipot testing is a critical procedure for evaluating the dielectric strength and insulation integrity of electrical systems.

✅ Detects insulation breakdowns and leakage currents.

✅ Ensures equipment safety and compliance with standards.

✅ Prevents electrical hazards in high-voltage systems.

Also known as dielectric withstand, hipot testing applies high voltage to confirm that insulation can endure operating and surge conditions without breaking down. This test is crucial across various industries, including medical devices, automotive electronics, and aerospace systems, where insulation failure can pose life-threatening hazards. Companies that fail to conduct a proper dielectric strength test risk product recalls, lawsuits, and reputational damage, while effective analysis ensures reliability and safety.

A comprehensive dielectric strength evaluation is essential to ensure electrical insulation can withstand high voltages without failure. During hipot evaluations, engineers closely monitor the leakage current limit to detect any early signs of insulation breakdown. Complementary procedures like the insulation resistance inspection verify the long-term reliability of insulating materials, while partial discharge measurement helps identify microscopic defects that may develop into serious faults under stress. Additionally, performing a ground bond measurement ensures that all conductive paths can safely carry fault currents, completing a robust safety and quality assurance process.

Hipot Testing and Dielectric Withstand Test

Hipot testing, also known as a dielectric withstand test, is a method used to verify the electrical insulation strength of a device or component. The term “dielectric” refers to an insulating material’s ability to resist the flow of electric current, while “withstand” indicates the material’s capacity to endure high voltage without breaking down. During this test, a voltage much higher than the device’s normal operating level is applied between the conductive parts and the insulation. The goal is to ensure that the insulation can safely block current flow, preventing electrical shock, equipment damage, or catastrophic failures.

In practice, the dielectric withstand test checks for:

-

Leakage current: Measuring if any unwanted current flows through insulation when exposed to high voltage.

-

Breakdown point: Identifying the voltage level at which insulation fails or starts conducting.

-

Safety margins: Confirming the insulation can withstand voltage spikes far above normal operating conditions.

This test is essential in industries like medical, automotive, and aerospace, where insulation integrity directly impacts safety and reliability.

The Importance of Hipot Testing

Hipot testing is a cornerstone of electrical safety, particularly in industries where failure is not an option. In medical devices, patient safety is paramount—any breakdown in insulation resistance could lead to electrical shock or malfunctions during critical procedures. The same applies to automotive and aerospace systems, which must perform reliably under extreme conditions. High-voltage tests conducted during production ensure that every device meets rigorous safety standards before it reaches the field. Neglecting this step can result in product recalls, lawsuits, or catastrophic failures, both financially and ethically.

There are three primary hypot test methods:

-

AC test applies alternating current, which can expose insulation weaknesses that occur under dynamic voltage conditions.

-

DC test uses direct current and is effective for identifying leakage currents and insulation resistance over time.

-

Impulse test simulates sudden, transient voltage spikes to assess how components withstand extreme surges.

The examination process consists of three stages: preparation, examination, and analysis. It starts with ground bond tests to verify that the grounding path can safely handle fault currents. Once verified, the device under test is connected to a hipot tester, and the required voltage is applied for a set duration. During this period, leakage current is closely monitored, and any readings above acceptable limits indicate insulation failure or degradation.

Modern automated hipot testers have transformed the process, enabling the simultaneous examination of multiple devices, reducing human error, and accelerating production lines. These systems can store data for analysis, enabling trend monitoring and preventive maintenance. Equally important is the regular calibration and maintenance of the test equipment itself, as inaccurate or poorly maintained testers can lead to false pass/fail results, compromising both product quality and safety.

Hipot Test Types – Comparison Table

| Test Type | Description | Applications | Advantages/Limitations |

|---|---|---|---|

| AC Hipot Test | Applies alternating current at high voltage to the DUT | Common for transformers, cables, and general devices | Detects weaknesses under dynamic voltage but can stress capacitive loads |

| DC Hipot Test | Uses direct current to check insulation integrity | Ideal for capacitive loads like cables and motors | Easier leakage measurement but may not reveal AC-related weaknesses |

| Impulse Test | Simulates transient high-voltage spikes (surges) | Aerospace, automotive, and lightning surge test | Closest to real surge conditions but highly specialized |

Voltage Levels and Test Duration

Determining the correct test voltage and duration is crucial for accurate dielectric withstand.

Standard Formula:

Test Voltage ≈ 2 × Operating Voltage + 1,000 V

For instance, a product rated at 480 V would typically be tested at:

(2 × 480) + 1,000 = 1,960 V.

Typical test durations:

-

Design tests (prototype/certification): ~1 minute for thorough insulation verification.

-

Production tests (quality checks): ~1 second for efficient, large-scale assessment while maintaining safety.

These parameters ensure that insulation can endure unexpected surges without damaging the device or compromising user safety.

Safety Considerations and Leakage Current Thresholds

Hipot testing involves high voltages, making the safety of both operators and equipment a top priority. Test setups must minimize the risk of electric shock or equipment damage.

Key safety practices:

-

Grounding design: Properly ground all exposed conductive parts to divert fault current.

-

Current limits: Keep total current limits as low as possible, typically between 0.1 mA and 20 mA, depending on the standard.

-

Safe fixtures: Use enclosures, interlocks, and warning indicators to prevent accidental contact.

-

Tester maintenance: Regular calibration ensures accurate readings and avoids false results.

In addition to dielectric strength tests, engineers often conduct insulation resistance tests and ground bond tests to confirm the existence of safe conductive paths. For high-voltage applications, partial discharge measurement is used to detect microscopic insulation defects that standard hipot testing may not reveal.

Interpreting Hipot Test Results

Interpreting the results of a high-potential test requires technical insight, as even minor deviations can have significant implications. A common challenge is understanding the measurements of leakage current. While some leakage is acceptable, excessive current indicates insulation breakdown, which can compromise electrical safety. Accurate analysis of these results requires experience and technical expertise. Production lines often use statistical process control (SPC) to monitor these results over time, ensuring consistency and identifying trends that may signal a developing problem. A clear interpretation of these test reports enables timely corrective action, minimizing disruptions to the production line.

Standards and Regulatory Compliance in Hipot Testing

Hipot testing must align with global standards to guarantee product safety and certification.

Key standards include:

-

IEC 60950: High-voltage evaluation for IT and communication equipment.

-

IEC 61010: Safety protocols for industrial, laboratory, and control equipment.

-

UL and CSA: North American standards that require a dielectric strength test for certification.

-

Partial discharge test: Used alongside hipot tests in power systems and transformer industries for detecting latent insulation weaknesses.

Adhering to these standards ensures compliance with legal requirements, enhances market acceptance, and protects manufacturers from liability.

The Future of Hipot Testing: Automation, AI & Predictive Maintenance

Emerging technologies are transforming dielectric strength test (hipot testing), making it more efficient, accurate, and safe. Automated test systems now reduce human error, streamline production line integration, and provide real-time data analytics for improved fault detection. The next wave of innovation includes integrating AI and machine learning to analyze large test datasets and predict insulation failures before they occur, enabling predictive maintenance and continuous quality assurance. Remote measurement capabilities—such as PLC-controlled testers and even drone-equipped systems—are expanding access to examination in hazardous or remote environments while minimizing operator exposure to high voltage. Companies adopting these modern approaches stay ahead of evolving safety mandates and deliver reliable, future-ready inspection solutions.

Frequently Asked Questions

What is the meaning of hipot?

Hipot, short for “high potential,” is a high-voltage safety test that verifies the insulation strength of electrical devices, ensuring they can withstand surges and prevent leakage current.

How is a hipot test done?

A device under test is connected to a tester that applies AC, DC, or impulse voltage between conductive parts and insulation. Leakage current is measured, and any excessive value indicates a failure.

What is a hipot failure?

A failure occurs when insulation cannot withstand the applied voltage, resulting in high leakage current or breakdown, which could lead to electrical shocks or equipment malfunctions.

Is the hipot test AC or DC?

Hipot testing can be performed with either AC or DC voltage. AC tests reveal weaknesses under fluctuating conditions, while DC tests are preferred for stable, capacitive loads.

Related Articles

Core Current Transformer Explained

A core current transformer measures alternating current by producing a scaled secondary current that is proportional to the primary current. It ensures accurate metering, protection, and monitoring in electrical systems, commonly used in power distribution and industrial applications.

What is a Core Current Transformer?

A core current transformer (CCT) is a crucial component in the field of electrical systems, commonly used for monitoring and controlling electrical circuits.

✅ Converts high primary currents into safe, measurable secondary currents.

✅ Enhances accuracy for metering and protective relays.

✅ Used in electrical substations, industrial control systems, and power distribution networks.

To understand the basic function of transformers, see our guide on what is a transformer.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

The core current equipment works by measuring the current flowing through conductors and ensuring the' safe and efficient operation of electrical networks. It generates a proportional secondary current in response to the magnetic field induced by the primary current. Electricians will learn the importance of core CTs in industrial applications, the various types available, and how to properly install and maintain them for optimal performance. With this knowledge, professionals can enhance their troubleshooting skills, prevent costly downtime, and improve overall electrical safety in industrial settings. A current transformer plays a vital role in scaling down high primary currents to safe, measurable levels for monitoring and protection.

Types of Core Current Transformer: Solid Core vs. Split Core

The types of CTs vary based on their configurations and intended applications. In particular, the two most common types are the solid-core and split-core current transformer. The solid core design is typically preferred for fixed installations where the wiring configuration does not need to be altered after installation. The core is a single, continuous piece of material that provides a stable and durable structure for the equipment. On the other hand, the split core current equipment allows for easy installation around existing conductors. The ability to "split" the core open makes this configuration ideal for retrofit applications, where adding new wiring or modifying existing circuits would be impractical. Comparing designs such as delta and wye connections, our delta vs wye article explains key differences in configuration and performance.

Comparison of Core Current Transformers: Solid Core vs. Split Core

| Feature | Solid Core Current Transformer | Split Core Current Transformer | Best Applications |

|---|---|---|---|

| Design | Single, continuous magnetic core | Core opens/closes for easy placement | Solid core for fixed installs, split core for retrofits |

| Installation | Requires disconnecting conductors during setup | Installs without removing existing wiring | Split core preferred in existing systems |

| Durability | More robust and stable structure | Slightly less durable due to openable core | Solid core for high-durability needs |

| Accuracy | High measurement accuracy | Slightly lower accuracy compared to solid core | Solid core in precision metering |

| Cost | Generally lower cost | Typically higher cost due to design flexibility | Split core for convenience-focused projects |

| Maintenance | Minimal maintenance required | Also low, but hinges may need periodic check | Both for industrial and commercial use |

Applications

CCTs are widely used in different sectors, particularly in environments where safety and reliability are paramount. Their applications span commercial, industrial, and residential settings, where they serve to protect circuits and ensure the proper functioning of control systems. In commercial buildings, a CCT is often integrated into power distribution panels, enabling the monitoring and control of energy usage. They also find applications in industrial environments, such as factories, where accurate current measurement is critical for optimizing machinery operation and preventing equipment failures. Industrial applications often pair core CTs with instrument transformers to enhance precision in electrical metering systems.

Fire Safety and Environmental Protection

The use of CCTs extends to areas where fire safety and environmental protection are significant concerns. In settings such as hospitals, schools, and chemical plants, where maintaining operational safety is crucial, the design of dry-type equipment becomes particularly important. Dry-type equipment, including CT equipment, is often used in these environments due to its lower risk of fire. Since they don't rely on liquid insulation materials, they present fewer fire hazards compared to liquid-filled transformers. This makes them a preferred choice for sensitive applications that require both reliable current measurement and safe operation. For installations needing both current and voltage measurement, a potential transformer works alongside CTs to step down voltages safely.

Advantages and Disadvantages of Core Current Equipment

While a CCT offers various advantages, it is also essential to consider the limitations it may present. One of the primary benefits of this equipment is its minimal maintenance requirements. The absence of liquid insulation and the use of robust materials in the core and enclosure design ensure that the equipment requires less frequent maintenance than other types. Moreover, dry-type core current equipment is environmentally friendly as it avoids the use of toxic substances, contributing to a greener, more sustainable energy system.

However, this equipment may experience higher operational temperatures when compared to liquid-filled types, which could potentially affect their longevity if not properly managed. While effective in many situations, the air-cooled design may not always be sufficient for very high-load applications. Therefore, engineers must carefully assess the operating environment to ensure that the transformer can perform optimally under the expected conditions.

Standards and Compliance for CT

Moreover, CTs must comply with established industry standards to ensure their performance and safety. Standards set by organizations such as ANSI, NEMA, and IEEE help manufacturers produce equipment that meets the requirements of modern electrical systems. Compliance with these standards is critical in maintaining the reliability of control systems that depend on this equipment. For instance, ensuring that the equipment meets the required accuracy class is crucial in applications where precise current measurement is essential for system protection or load balancing. Learn about step-down transformers, which reduce high voltages for safe operation in electrical equipment.

Frequently Asked Questions

What is a core current transformer?

A CCT is the central component of current equipment, typically made of a magnetic material, such as iron or silicon steel. The core serves as the pathway for the magnetic flux generated by the current passing through the primary conductor. The core's main purpose is to produce a proportional output current in the secondary winding, which can then be measured for monitoring or protection purposes in electrical systems. See how autotransformers offer cost-effective voltage regulation for industrial applications.

What is the difference between CCT and PT?

The main difference between a CCT and a Potential Transformer (PT) lies in their function and application:

-

CCT: A CT is used to measure the current flowing through a conductor by producing a reduced, proportional current in its secondary coil, which is easily measured and monitored.

-

PT: A PT, also known as a voltage transformer (VT), is used to step down high voltage levels in electrical systems to a lower, safer level for measurement and monitoring purposes. It provides a proportional voltage to its secondary winding.

In short, CCTs measure current, while PTs measure voltage.

What are the 3 types of transformer cores?

The three primary types of transformer cores are:

-

Shell-type: In this type, the windings are placed around the central core, which is a continuous structure. This configuration provides enhanced magnetic coupling and minimizes leakage flux.

-

Core-type: The windings are placed around the legs of the core, which is typically rectangular. This design is commonly used for power equipment.

-

Toroidal: This type of core is ring-shaped, allowing the windings to be placed around it. The toroidal design offers low core losses and is used in applications where compactness and efficiency are crucial. For a more comprehensive overview of various transformer designs, visit our page on different types of transformers.

A core current transformer is an electrical device used to measure the current flowing through a conductor by producing a proportional output current or voltage. It typically consists of a magnetic core around which the primary conductor passes, with the secondary winding placed around the core. When current flows through the primary, it generates a magnetic field that induces a current in the secondary winding. Core CTs are widely used in power systems for protection, measurement, and monitoring purposes, offering benefits such as electrical isolation, accuracy, and the ability to safely measure high currents without direct contact. Dive into detailed transformer types in our section on electrical power transformers.

Related Articles

Distributed Energy Resources - Small Scale Power

Distributed energy resources integrate rooftop solar, battery storage, EV charging, and demand response within microgrids and virtual power plants to optimize load, enhance grid resilience, lower costs, and enable real-time, bidirectional power flows.

What Are Distributed Energy Resources?

Distributed energy resources are small-scale, grid-connected assets that generate, store, or manage electricity locally.

✅ Integrates solar PV, batteries, EVs, and demand response

✅ Enhances grid reliability, resilience, and peak-load flexibility

✅ Enables microgrids and virtual power plants for local balancing

Distributed energy resources (DERs) can benefit the power system and individual homes and businesses. DERs can increase the resiliency and reliability of the power grid, reduce greenhouse gas emissions, reduce the overall power cost, and provide power at the point of use. Several types of DERs can be used to generate electricity, including renewable energy sources like solar photovoltaic, wind power, and fuel cells, as well as energy storage systems like battery storage and combined heat and power (CHP) systems. DERs can also be used to power electric vehicles (EVs) and help to reduce greenhouse gas emissions in the transportation sector.

One of the most significant benefits of DERs is their ability to increase the resiliency and reliability of the power grid. When traditional power plants experience outages, DERs can continue to provide power to homes and businesses, reducing the impact of the outage. DERs can also help to reduce the strain on the power grid during peak demand periods, which can help to prevent blackouts and brownouts. Advanced distribution automation can coordinate DER dispatch for reliability gains.

Another benefit of DERs is their ability to reduce greenhouse gas emissions. Renewable energy sources such as solar photovoltaic and wind power do not produce carbon emissions, which can help reduce the amount of greenhouse gases released into the atmosphere. In addition, CHP systems can use natural gas to generate electricity while using waste heat to provide heating or cooling to homes or businesses. This can help reduce overall power consumption and lower carbon emissions.

Electric vehicles (EVs) are another type of DER that can help to reduce greenhouse gas emissions. EVs can be charged using renewable energy sources, which means that they can help to reduce the use of fossil fuels in transportation. In addition, EVs can also provide energy storage, which can help balance the power grid during periods of high demand.

DERs can also help to reduce the overall cost of power. Because DERs are typically small-scale, they can be less expensive to install and maintain than large-scale power plants. In addition, DERs can provide power at the point of use, which can help reduce the amount of power lost during transmission and distribution. For context, understanding power distribution helps explain how localized generation reduces network losses.

Several types of DERs can be used to generate electricity. Solar photovoltaic (PV) systems use solar panels to generate electricity from the sun's energy. Wind power systems use wind turbines to generate electricity from the wind. Fuel cells use hydrogen and oxygen to generate electricity, with water as the only byproduct.

In addition to renewable energy sources, DERs can include energy storage systems such as battery storage. Battery storage systems can store energy generated by renewable energy sources, which can be used during periods of high demand or when the renewable energy source is unavailable. Utilities often rely on critical energy storage to maintain service continuity during contingencies.

DERs can also include CHP systems, which use natural gas to generate electricity and waste heat to provide heating or cooling to homes or businesses. In addition, CHP systems can provide power at the point of use, which can help reduce the amount of power lost during transmission and distribution.

DERs can be connected to the power grid through a smart grid, which can help to monitor and manage the flow of energy. A smart grid can also help to balance the power grid during periods of high demand by using DERs to provide additional power. To learn more about the enabling technologies, see what a smart grid is and how it orchestrates DERs.

One of the most significant advantages of DERs is their small-scale nature, which allows them to be located close to where the electricity is needed, reducing transmission and distribution losses. DERs can also provide power during peak demand periods, helping to avoid the need for additional power plants or transmission lines. These local benefits accrue within electrical distribution systems where congestion and voltage constraints are most acute.

Another advantage of DERs is their ability to operate independently or in concert with other DERs as part of a microgrid. Microgrids are small-scale power systems that can work independently of the primary power grid, allowing for increased resiliency and reliability in the event of a power outage or other disruption to the power grid. Microgrids can also help to integrate DERs into the power system, providing a more flexible and efficient power system. If you are unfamiliar with the concept, explore what a microgrid is and how its islanded operations support resilience.

DERs can also help reduce the overall power cost by reducing the need for expensive transmission and distribution infrastructure. DERs can be installed and operated by individual homes and businesses, reducing the need for large-scale power plants and transmission lines. This can help reduce the overall power cost and provide more affordable power options for consumers.

However, there are also some challenges associated with DERs. One of the biggest challenges is the integration of DERs into the power grid. DERs can generate electricity intermittently, making it challenging to balance the power grid and ensure a consistent electricity supply. In addition, DERs can be located in areas where the power grid may not be able to accommodate additional power generation. This can require upgrades to the power grid and further investment in infrastructure. Projects may also face costly interconnection delays that extend timelines and budgets.

Another challenge is the need for energy storage systems to balance the power grid during high-demand or low-renewable power availability periods. Energy storage systems can be expensive, and their efficiency and reliability can vary depending on the type of technology used.

Despite these challenges, DERs have the potential to play a significant role in the transition to a more sustainable and resilient power system. By leveraging renewable energy sources and energy storage systems, DERs can help reduce greenhouse gas emissions, increase power resiliency and reliability, and reduce the overall energy cost.

What are the characteristics of distributed energy resources?

DERs are small-scale power sources that can be located close to the electricity needed. Renewable energy sources often power them, and they can be connected to the power grid or operate independently as part of a microgrid. They can also provide power during peak demand periods and help reduce the overall energy cost.

What are the benefits of distributed energy resources?

The advantages of using distributed energy resources include increased resiliency and reliability of the power grid, reduced greenhouse gas emissions, and decreased overall power cost. Disadvantages include challenges related to integration into the power grid and the need for energy storage systems to balance the power grid during periods of high demand or low renewable poweravailability.

How do distributed energy resources impact the existing power grid?

DERs can impact the existing power grid by providing additional sources of electricity during peak demand periods and reducing the strain on the power grid. However, the intermittent nature of some DERs can also create challenges in balancing the power grid and ensuring a consistent electricity supply.

What is the role of energy storage in distributed energy systems?

Energy storage plays a critical role in distributed energy systems by allowing excess energy generated by renewable power sources to be stored and used during periods of high demand or low renewable energy availability. Energy storage can also help balance the power grid and ensure a consistent electricity supply.

How are regulations and policies impacting the adoption of distributed energy resources?

Regulations and policies can impact the adoption of DERs by creating incentives for investment in DERs and promoting the integration of DERs into the power system. However, regulations and policies can also create barriers to entry for new technologies or increase the cost of implementation.

What is the future outlook for distributed energy resources, and what trends are emerging in this field?

The future outlook for DERs is promising as the demand for renewable sources and increased resiliency and reliability continue to grow. Emerging trends in this field include the use of blockchain technology to create peer-to-peer markets and the increased use of artificial intelligence and machine learning to optimize the performance of DERs.

Related Articles

Understand How To Test a Transformer

Learn how to test a transformer: insulation resistance, TTR, winding resistance, polarity, continuity, and dielectric checks. Confirm condition, find faults, and keep safe with a multimeter, megohmmeter, and clear procedures for field work on site.

How to Test a Transformer?

How to test a transformer is the practical process of verifying a unit’s health and safety with standard electrical tests—insulation resistance, turns ratio, winding resistance, polarity—and documenting results against nameplate and manufacturer limits.

✅ Safety first: de-energize, lockout/tagout, discharge capacitors, verify absence of voltage

✅ Perform IR (megohmmeter), TTR, winding resistance, polarity/phase, basic functional checks

✅ Record readings, compare with specs and trends; decide repair, drying, or replacement

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

How to test a transformer is a crucial step in ensuring reliability, safety, and compliance with electrical standards. Whether in the field or at the shop, routine checks help identify faults, extend service life, and prevent costly failures. A thorough procedure involves a combination of visual inspection, standard electrical measurements, advanced diagnostic tests, and careful interpretation of the results. Proper testing procedures often depend on transformer design, so reviewing the construction of a transformer can provide valuable context.

Visual Inspection and Pre-Check Steps

Before applying any test instrument, always begin with a close inspection. Look for oil leaks, bulges, burn marks, corrosion, or cracked bushings. Dirt, dust, and moisture on terminals can compromise insulation and give false readings. Confirm that nameplates are intact and legible. These steps cost little time but often reveal issues long before instruments are connected. Field testing often reveals issues with insulation and winding integrity, which makes knowledge of transformer insulation essential for interpreting results.

How to test a transformer: Safety and Preparation

Safety comes first. De-energize the transformer, lock out/tag out all sources, and verify the absence of voltage. Discharge stored energy in capacitors and ground the windings. Use personal protective equipment (PPE) appropriate to the transformer’s voltage class. Ensure your test instruments—megohmmeters, multimeters, or resistance bridges—are calibrated and leads are intact. Skipping these basics risks inaccurate data or dangerous accidents. Testing steps vary for dry-type, oil-filled, and distribution units, which is why knowledge of the distribution transformer is essential for field technicians.

Standards and Specifications

Accurate testing means knowing what values are acceptable. IEEE, IEC, and national codes outline limits for insulation resistance, turns ratio, and dielectric strength. For example, insulation resistance values are corrected to 20 °C to ensure proper comparison with manufacturer data. Turns ratio should not deviate more than about ±0.5% from the nameplate, depending on class. Always record ambient conditions, as results depend heavily on temperature and humidity.

How to Test a Transformer: Comparison of Test Methods

| Test Name | Purpose | Procedure | Key Indicators / Results |

|---|---|---|---|

| Insulation Resistance (IR) | Checks insulation health between windings and ground | Apply DC voltage with a megohmmeter, record values at 15s, 1m, 10m | High resistance (MΩ) = good; low values or downward trend = moisture or insulation failure |

| Turns Ratio Test (TTR) | Verifies correct ratio between primary and secondary windings | Apply test voltage across primary and measure secondary | Ratio should match nameplate within ±0.5% (varies by standard) |

| Winding Resistance | Detects shorted turns, loose connections, or poor joints | Measure resistance with DC bridge or micro-ohmmeter | Balanced values across phases; high or unequal readings suggest defects |

| Polarity & Phase Check | Ensures windings are correctly oriented for parallel operation | Apply low AC voltage, observe phasing or use test set | Proper polarity and phase alignment; incorrect results prevent safe paralleling |

| Continuity | Confirms windings are continuous and not open-circuited | Use multimeter to measure continuity across windings | Continuous reading = intact winding; open = fault present |

| No-Load & Load Loss Tests | Evaluates efficiency, core and copper losses | Energize at rated voltage (no-load) or rated current (load) | Acceptable loss values within manufacturer limits |

| Dielectric Withstand (Hipot) | Proves insulation can handle overvoltage | Apply test voltage above operating level for set duration | No breakdown or flashover during test = pass |

| Short-Circuit Test | Determines impedance and short-circuit strength | Apply reduced voltage until rated current flows | Impedance matches design; abnormal = winding issues |

| Oil/Fluid Analysis | Assesses liquid insulation condition in oil-filled units | Sample oil, test for gases, moisture, acidity, dielectric strength | High gas/moisture/acidity = aging or fault; strong dielectric = healthy oil |

| Partial Discharge Test | Detects early-stage insulation defects | Apply AC voltage and monitor discharge signals | Low or no discharge = good; high activity = insulation breakdown risk |

Core Electrical Tests

Once the visual checks and safety steps are complete, the next stage involves conducting the standard tests that provide a baseline assessment of the transformer's condition. When performing load and no-load loss tests, it is helpful to understand the transformer core, as its design directly impacts efficiency and measurement accuracy. These are the essential diagnostic methods most technicians rely on:

-

Insulation Resistance (IR): Measured with a megohmmeter at voltages matched to the winding class. Record readings at 15 seconds, 1 minute, and 10 minutes to calculate polarization index (PI) or dielectric absorption ratio (DAR).

-

Turns Ratio Test (TTR): Confirms that the primary-to-secondary voltage ratio matches design. Significant deviation may indicate shortened turns.

-

Winding Resistance: Performed with DC bridges or micro-ohmmeters, corrected for temperature, and compared across phases and tap positions.

-

Polarity and Phase Check: Ensures correct connection orientation, critical when paralleling units.

-

Continuity: Confirms that windings and tap changers are intact and not open-circuited.

Advanced and Supplemental Tests

For a more complete picture of transformer health, advanced tests go beyond the basics and can uncover hidden problems. These are typically carried out during factory acceptance or major maintenance intervals:

-

No-Load and Load Loss Tests: Measure excitation current, core losses, impedance, and copper losses.

-

Dielectric Withstand (Hipot): Applies a voltage higher than the operating voltage to verify insulation integrity.

-

Short-Circuit Tests: Determine impedance and identify weak points.

-

Oil or Fluid Analysis: For liquid-filled transformers, dissolved gas analysis or dielectric fluid testing reveals insulation breakdown.

-

Partial Discharge Tests: Detect microscopic insulation defects before they escalate.

Measurement Techniques and Best Practices

The accuracy of results depends heavily on how tests are conducted. Following consistent methods ensures readings are comparable over time:

-

Connect the megger leads with proper grounding, ensuring the other windings are shorted and grounded during IR tests.

-

Allow time for the transformer to stabilize after de-energization before resistance checks.

-

Record temperature with every test, since winding resistance and insulation behaviour vary with heat.

-

When measuring IR, note time-based values for PI or DAR analysis; a PI below 2 typically signals deteriorating insulation.

Interpretation of Results

Numbers alone mean little without proper context. Once results are collected, the following principles help interpret them effectively:

-

Compare results with manufacturer data, industry standards, and previous test records.

-

Watch for declining insulation resistance trends, even within acceptable limits, as they may point to moisture ingress.

-

Check for unbalanced winding resistance, which could indicate loose connections or partial shorts.

-

Evaluate deviations in TTR: small shifts may be tolerable, but large errors signal winding problems.

Many failures detected during transformer testing are related to overheating, so combining tests with preventive practices like maintenance inspection windows on transformers improves long-term reliability.

Next Steps When Tests Fail

If a transformer fails to meet the expected standards, corrective action is necessary. Depending on the results, steps may include:

-

Drying out moisture with heaters or using a vacuum dryer.

-

Repairing bushings, gaskets, or connections.

-

Replacing or filtering insulating oil.

-

Rewinding or replacing the unit in cases of major internal faults.

Context Matters

Not all transformers are tested the same way. Distribution transformers, small dry types, and large power transformers each require different approaches and acceptance values. Match your testing plan to the transformer’s design, voltage class, and service environment. Oil-filled units require specialized fluid checks, making transformer oil analysis a critical extension of electrical testing. To fully verify safety margins, testing should be combined with knowledge of transformer overcurrent protection, which determines how protective devices respond under fault conditions.

How to test a transformer is more than connecting a megger or multimeter. It is a structured process of inspection, safety, measurement, interpretation, and corrective action. By including both standard checks and advanced diagnostic methods, and by aligning results with industry standards, electrical professionals can safeguard assets, protect personnel, and ensure system reliability.

Related Articles

T&D News

T&D Media

T&D Articles From ET Magazine

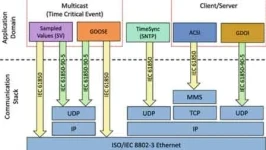

Understanding the IEC 61850 Protocol in Substation Automation

Climate Change Fuels Spread of Deadly Fungal Infections in the UK

As global temperatures rise, scientists warn that the UK faces an increasing threat from deadly fungal infections, particularly those caused by the Aspergillus species. These fungi, which can lead to severe respiratory illnesses and brain infections, are projected to expand their range into northern Europe, including the UK, due to climate change.

The Aspergillus Threat

Aspergillus fumigatus and Aspergillus flavus are the primary culprits behind invasive aspergillosis, a life-threatening disease that affects the lungs and can spread to other organs, including the brain. These fungi produce airborne spores that can be inhaled, posing significant risks to individuals with weakened immune systems, such as those undergoing chemotherapy or organ transplants. In the UK, the incidence of aspergillosis is expected to rise as the climate warms, potentially leading to increased hospital admissions and mortality rates.

Climate Change and Fungal Expansion

Research indicates that rising global temperatures are creating more favorable conditions for the proliferation of Aspergillus species. A study led by Norman van Rhijn at the University of Manchester suggests that by 2100, A. fumigatus could expand its range by 77%, potentially exposing an additional 9 million Europeans to infection. Similarly, A. flavus is expected to spread into new regions, including parts of the UK. These projections underscore the urgent need for enhanced surveillance and preparedness to mitigate the impact of these fungal pathogens.

Challenges in Detection and Treatment

Diagnosing fungal infections can be challenging, as symptoms often overlap with other respiratory illnesses. Moreover, antifungal treatments are limited, and resistance is becoming more prevalent. The World Health Organization lists A. fumigatus as one of the most critical fungal pathogens, highlighting the need for improved diagnostic tools and treatment options.

Impact on Agriculture and Food Security

Beyond human health, Aspergillus species pose a significant threat to agriculture. A. flavus produces aflatoxins, potent carcinogens that can contaminate crops such as maize, peanuts, and cotton. Climate change is expected to exacerbate the spread of these toxins, affecting food safety and security. Increased temperatures and humidity levels can enhance the growth of A. flavus, leading to higher aflatoxin contamination in crops.

Urgent Need for Action

Experts emphasize the importance of addressing the dual threats of climate change and fungal infections. Investing in fungal research, improving diagnostic capabilities, and developing effective treatments are critical steps in mitigating the impact of these pathogens. Public health systems must be equipped to recognize and respond to emerging fungal threats, particularly as climate change continues to alter the distribution of infectious diseases.

In conclusion, the spread of deadly fungal infections in the UK, driven by climate change, presents a multifaceted challenge to public health and agriculture. Proactive measures are essential to prevent widespread outbreaks and safeguard the well-being of populations at risk.

Climate Change Impacts and Adaptation Efforts in British Columbia

As of early May 2025, British Columbia is experiencing significant climate-related challenges, including rising temperatures, increased wildfire risks, and ecological disruptions. These developments underscore the urgency for comprehensive adaptation strategies to safeguard communities and ecosystems.

Escalating Wildfire Risks

The province is witnessing an early onset of wildfire season, with 107 active fires reported. Experts attribute the heightened risk to a combination of warmer temperatures and prolonged drought conditions. The BC Wildfire Service has indicated a "high potential for an active spring wildfire season," emphasizing the need for preparedness and swift response measures.

Ecological Disruptions in Urban Forests

In Vancouver's Stanley Park, climate change is manifesting through the proliferation of the western hemlock looper moth, which has led to the death of approximately 160,000 trees. These moths thrive in warmer winters, facilitated by climate change, and have caused significant ecological damage to the park's century-old trees.

Urban Heat and Infrastructure Challenges

Projections indicate that by 2050, Vancouver's climate could resemble that of San Diego, with average summer temperatures rising and increased occurrences of "tropical nights." This shift necessitates urgent adaptations in urban planning and infrastructure to mitigate heat-related health risks and manage water resources effectively.

Strategic Adaptation Initiatives

In response to these challenges, Vancouver has updated its Climate Change Adaptation Strategy, focusing on enhancing resilience against extreme heat, poor air quality, drought, extreme rainfall, and sea level rise. Key initiatives include:

-

Urban Greening: Expanding tree canopy coverage to 30% by 2050 to provide natural cooling and improve air quality.

-

Building Retrofits: Upgrading 30 buildings to enhance cooling and reduce emissions.

-

Green Infrastructure: Implementing green rainwater infrastructure across three hectares of city streets to manage stormwater and mitigate urban heat island effects.

-

Coastal Adaptation: Developing a city-wide coastal adaptation policy to address sea level rise and coastal flooding.

Community Engagement and Equity

The strategy emphasizes equity, recognizing that climate change disproportionately affects vulnerable populations. Each action plan incorporates equity outcomes, ensuring that adaptation measures benefit all residents, particularly those most at risk.

British Columbia's proactive approach to climate adaptation, exemplified by Vancouver's updated strategy, sets a precedent for other regions facing similar challenges. By integrating climate resilience into urban planning and community development, the province aims to safeguard its residents and ecosystems against the escalating impacts of climate change.

Canada Files 200 Fisheries Act Charges Against ArcelorMittal for Alleged Environmental Violations

In a significant enforcement action, Environment and Climate Change Canada (ECCC) has laid 200 charges against ArcelorMittal Canada, alleging violations of the Fisheries Act. The charges pertain to the unlawful deposit of harmful substances into fish-bearing waters in Quebec between 2014 and 2022. These alleged infractions occurred at the Fire Lake Mine and the Mont-Wright mining complex, the latter being the largest open-pit iron mine in Canada. The affected waterways flow into the Moisie River, a provincially administered aquatic reserve and one of North America's major salmon rivers.

Background of the Allegations

The Fisheries Act prohibits the deposit of deleterious substances into waters frequented by fish or in places where such substances may enter these waters. ECCC's enforcement officers initiated investigations into ArcelorMittal Canada's operations at the Fire Lake and Mont-Wright sites after receiving reports of potential environmental violations. The subsequent investigations led to the filing of 200 charges against the company for allegedly permitting or causing the deposit of harmful substances into the aforementioned waterways.

Environmental Significance of the Moisie River

The Moisie River holds ecological importance due to its role as a habitat for Atlantic salmon, a species of significant conservation concern. The river's designation as a provincial aquatic reserve underscores its environmental value and the necessity for stringent protection measures. Alleged contamination of its tributaries could have detrimental effects on local biodiversity and water quality, highlighting the gravity of the charges against ArcelorMittal Canada.

Previous Environmental Infractions