Arc Flash Levels of Protection

By R.W. Hurst, The Electricity Forum

NFPA 70e Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA 3873 Fact Sheet – Minimum Approach Distance and Training Requirements

- Calculate MAD using voltage and overvoltage values

- Ensure proper communication between host and contract employers

- Meet OSHA training requirements for qualified electrical workers

Arc Flash Levels of Protection define PPE categories per NFPA 70E, based on incident energy analysis and approach boundaries. They guide arc-rated clothing selection, shock protection, and safe work practices for electrical systems.

What Are Arc Flash Levels of Protection?

They are NFPA 70E PPE categories based on incident energy, defining arc-rated gear, approach boundaries, and safe work.

✅ Align PPE Category 1–4 with incident energy in cal/cm²

✅ Establish limited, restricted, and arc flash boundaries

✅ Specify arc-rated clothing, gloves, face shields, and tools

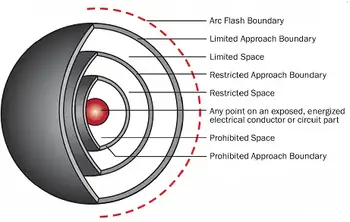

Arc Flash Levels of Protection are best understood as layers or boundaries of protection around and away from hazardous electrical equipment.

Understanding how an arc flash hazard influences boundary selection and PPE choice clarifies why layered protections are necessary in the first place.

Arc flash boundary

The arc flash boundary, or restricted approach boundary, changes depending on the potential arc flash hazard. The arc flash boundary is calculated to 1.2 calories/cm2 of incident energy. That’s the distance where a worker without appropriate PPE would receive second-degree burns. For deeper context, see how NFPA 70E guidance informs boundary calculations in practice.

Sometimes this boundary is the furthest one from the exposed equipment, other times the limited approach boundary is the furthest out. When the arc flash boundary is the furthest away, it becomes the line no one should pass without training and PPE. If the limited approach boundary is further out, then that should be treated as the line no one should pass without training and PPE. This distinction is central to arc flash protection strategies that define who may cross and under what conditions.

Test Your Knowledge About Arc Flash!

Think you know Arc Flash? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Limited approach boundary

Moving toward the energized and exposed equipment, you’ll find the limited approach boundary. Within this boundary, it is still possible to be exposed to a shock hazard. Appropriate PPE should be worn by qualified workers in the limited space (space between the limited approach boundary and the restricted boundary). Non-qualified workers should stay outside of this boundary unless wearing proper PPE and being escorted by a worker with specialized training.

Aligning task categories with arc flash PPE requirements helps ensure non-qualified personnel remain protected when proximity is unavoidable.

Restricted boundary

The area closest to the live, exposed equipment is within the restricted boundary. In order to pass this boundary, you must be a qualified worker with the proper training and PPE. If you need to perform work on the energized equipment, you may also need a work permit and documentation. Selecting appropriate arc flash safety equipment supports permitting decisions and safe work execution.

Arc Flash Protection first became a major area of investigation in the 1980's when in the IEEE published Transactions on "Industry Applications" there happened to appear an article authored by a Ralph Lee entitled: “The Other Electrical Hazard: Electric Arc Blast Burns.” This early investigation led several companies to realize, particularly companies from the petrochemical industry, that too many electrical workers were injured from electrical safety accidents. Consequently, several leading companies acted to create the first known set of work practices that were designed to specifically protect electrical workers who were performing electrical maintenance and service work on energized electrical equipment.

As guidance matured, enforcement through OSHA arc flash requirements accelerated adoption of consistent procedures across sectors.

Visit Our CSA Z462 Arc Flash Training Page

Visit Our NFPA 70E Arc Flash Training Page

In terms of personal protective equipment (ppe), here are the most valuable minimum arc rating levels of protection

- face shield

- required ar

- leather footwear

- hearing protection

- arc flash suit hood

- layer of arc rated ppe

- rubber insulating gloves

While petrochemical facilities were maybe the first to see the need for electrical arc flash protection, it quickly was seen that arc flash hazards apply to all electrical facilities. Although the level of incident energy released in an electrical arc flash explosion may be larger in the higher voltage ranges found in petrochemical and other industrial facilities, it meant that the large volume of medium and especially low voltage electrical equipment in industrial, commercial and institutional facilities would cause the largest number of electrical safety accidents.

Arc Flash Levels of Protection starts with preventing personal protection injuries from occurring is to turn off the electrical equipment before starting work. Standards such as NFPA 70e and CSA Z462 are intended to lay out arc flash guidelines for qualified electrical workers when de-energizing could lead to a greater hazard than leaving the power on. These arc falsh protection standards squarely place the responsibility for electrical worker safety on both employers and facility owners for making sure that safe electrical workplace standards and practices are in place to protect their workers from electrical safety accidents. Organizations can map tasks to NFPA 70E arc flash requirements to justify energized work and select appropriate controls.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

The goal of these electrical arc flash protections standards, such as NFPA 70e, is to keep electrical workers free from the hazards of shock, electrocution, arc flash, and arc blast. It's important, therefore, to understand the requirements set forth in the standards for employee safety, the importance of an electrical safety program, the responsibilities of employer and employee, and the processes and best practices set forth in various industry standards and regulations.

ARC FLASH INDUSTRY STANDARDS

Four separate industry standards establish practices for the prevention of electrical explosion incidents:

OSHA 29 Code of Federal Regulations (CFR) Part 1910, Subpart S

This regulation states, in part, "Safety related work practices shall be employed to prevent electric shock or other injuries resulting from either direct or indirect electrical contacts… ." OSHA also addresses the qualification of workers exposed to electrical shock hazards and the provision for protective equipment appropriate for the work to be performed. OSHA enforces electrical arc flash protection practices and cites the NFPA requirements.

NFPA 70e, National Electrical Code

Section 110.16 requires that companies place a warning label on electrical equipment likely to consitute an electrical safety hazard. This field marking can be generic or very specific, whichever the company selects. Future revisions of the NEC standard may require more detailed information on this label.

NFPA 70e, Standard for Electrical Safety Requirements for Employee Workplaces

NFPA 70E can be considered the “how to” standard behind OSHA enforcement. It provides the detailed actions companies must take to be in federal compliance.

Specifically:

- Arc flash protection program with defined responsibilities

- Calculations for the degree of electrical safety hazard

- Arc rated personal protective equipment (PPE) for workers, such as flame resistant, arc flash suit

- Training for workers

- Tools for safe work

- Warning labels on equipment

IEEE Standard 1584, Guide for Electrical Safety Regulation

In order for the arc flash protection warning labels to carry enough information to show the danger zone for electrical safety conditions, companies must determine that area within which only qualified workers should enter—the protection boundary. IEEE 1584 provides a method to calculate the incident energy in order to specify the level of PPE required for workers.