Arc Flash Protection Explained

By R.W. Hurst, Editor

NFPA 70e Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA 4475 Fact Sheet – Being Aware of Arc Flash Hazards

- Identify root causes of arc flash incidents and contributing conditions

- Apply prevention strategies including LOTO, PPE, and testing protocols

- Understand OSHA requirements for training and equipment maintenance

Arc flash protection mitigates electrical hazards through NFPA 70E compliance, IEEE 1584 arc flash studies, PPE selection, incident energy analysis, boundaries, and safe work practices for switchgear, MCCs, and energized maintenance.

What Is Arc Flash Protection?

Arc flash protection uses standards, PPE, and engineering controls to limit incident energy and protect workers.

✅ Perform IEEE 1584 arc flash study and incident energy calculations

✅ Apply NFPA 70E boundaries, PPE categories, and safe work practices

✅ Implement engineering controls: current limiting and arc-resistant gear

Arc flash protection is a critical safety measure designed to protect workers from the hazards of uncontrolled electrical explosions. An arc flash (AF) occurs when an electric arc creates a high-temperature explosion, releasing significant energy, which can cause severe injuries, including third-degree burns, electric shocks, and even death. Arc blast, a related phenomenon, involves the intense pressure wave from the explosion, which can cause additional injuries. The primary goal is to minimize the risk of arc flash occurring and ensure the safety of personnel working on or near electrical equipment. For additional context, resources explaining the circumstances that trigger an arc flash can help teams tailor hazard controls effectively.

Request a Free Training Quotation

Protecting Workers from Electrical Hazards: Key Strategies for Safety

Electrical hazards are a significant concern in any workplace that involves energized equipment. Among these, the risk of high-energy incidents from an electric arc presents serious dangers, including severe burns, electric shock, and physical injuries caused by the intense heat and pressure of an arc blast. To mitigate these risks, employers must develop comprehensive safety strategies, following industry standards like the NFPA 70E Standard for Electrical Safety in the Workplace. For a concise overview, see guidance on NFPA 70E arc flash principles to align training, procedures, and documentation.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Key Steps for Worker Protection from Electrical Hazards

To protect workers from potential incidents, the first step is a thorough risk assessment of the electrical system. This involves identifying potential dangers, such as unintentional contact with energized circuit parts, and determining the likelihood of an electric arc incident. The assessment must include a review of electrical equipment, ensuring that protective devices are functioning properly and the system is adequately maintained. Reviewing the fundamentals of the arc flash hazard supports accurate system studies, labeling, and mitigation planning.

A critical part of the assessment is determining the approach boundaries, which are zones of varying risk levels. The limited approach boundary restricts how close unqualified personnel can get to energized parts, while the restricted approach boundary limits access to qualified workers wearing appropriate personal protective equipment (PPE). Beyond these boundaries, proper signage and training are essential for maintaining a safe distance from the hazard. Additional clarification on NFPA 70E approach boundaries helps supervisors brief both qualified and unqualified personnel effectively.

In addition to PPE, workers must follow established safe work practices, including lockout/tagout procedures, to avoid exposure to energized systems. Organizations should verify that procedures meet NFPA 70E arc flash requirements for establishing and maintaining an electrically safe work condition.

What Personal Protective Equipment (PPE) is Required?

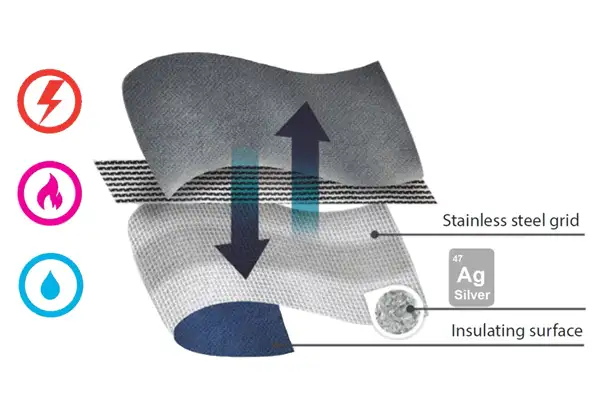

Selecting the right PPE is vital for minimizing the risk of injury from electrical incidents. The NFPA 70E standard outlines various levels of PPE based on the incident energy levels workers may face. For lower risk situations, basic flame-resistant clothing, safety gloves, and face shields may suffice. However, higher-risk environments, particularly those where an arc blast is possible, require more advanced PPE, such as insulated gloves, arc-rated suits, and helmets with protective shields. Reference materials describing arc flash levels of protection can aid in selecting garments and face protection appropriate to incident energy.

The type of PPE selected depends on the specific working distance from the energized parts and the calculated energy exposure. Proper PPE is crucial for keeping workers safe, particularly within the AF boundary, where the risk of severe injury is highest. A catalog of arc flash safety equipment can also assist in specifying accessories such as hoods, balaclavas, and voltage-rated tools.

How Do You Determine the Arc Flash Boundary and Incident Energy Levels?

The AF boundary defines the distance from an energized part where the heat energy is high enough to cause a second-degree burn. This boundary is determined through calculations based on factors such as the system's voltage, available fault current, and the protective device's clearing time. Tools like IEEE 1584 are used to calculate these boundaries accurately.

Additionally, the working distance — the space between the worker and the equipment during operation — plays a significant role in minimizing risk. The further the worker is from the energized part, the lower the energy they are exposed to, reducing the likelihood of severe injury.

A well-documented risk assessment is essential for establishing these boundaries and determining which controls, both administrative and engineering-based, are needed to protect workers.

NFPA 70E Standards for Electrical Safety

The National Fire Protection Association (NFPA) developed the NFPA 70E Standard for Electrical Safety in the Workplace to provide guidelines for minimizing the dangers associated with energized work. This standard requires employers to identify potential hazards, establish approach boundaries, and ensure the proper selection and use of PPE.

Training is a major component of compliance with NFPA 70E. Workers must be educated on recognizing electrical hazards, understanding approach boundaries, and knowing how to safely interact with electrical equipment. The standard also mandates regular audits of electrical safety programs to ensure they are current and effective.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

The NFPA 70E emphasizes that no one should work within the restricted approach boundary without the appropriate qualifications and protections, underscoring the importance of maintaining proper distance from energized parts.

How Do Engineering Controls Impact Worker Safety?

While PPE and administrative controls play a critical role, engineering controls offer another layer of protection. One effective method is designing an electrical system to minimize the risk of high-energy incidents. For example, circuit breakers, fuses, and protective relays can be installed to detect faults and interrupt the flow of electricity, reducing the likelihood of dangerous events.

Additional measures include installing barriers and insulation around live electrical parts to prevent accidental contact and using remote racking devices to allow operators to work at a safer distance. These engineering controls are critical for reducing the need for workers to come into close proximity with energized equipment.

Proper maintenance of the electrical system is also crucial to ensuring that protective devices operate as intended. Faulty or poorly maintained equipment increases the chance of an electric arc incident, which can have catastrophic consequences for workers.

Worker safety in environments involving energized electrical equipment requires a combination of risk assessment, PPE, and engineering controls. Following the NFPA 70E Standard for Electrical Safety in the Workplace, organizations can create a safe work environment by establishing approach boundaries, providing the correct PPE, and implementing engineering solutions to limit the danger of electrical incidents.

By remaining vigilant and adhering to safety standards, employers can significantly reduce the risk of injury or death from electric arc events and ensure that workers are protected in hazardous conditions.