Electrical Safety Testers For Electrical Equipment

CSA Z462 Arc Flash Training - Electrical Safety Essentials

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA 3075 Fact Sheet – Understanding Electrical Hazards in the Workplace

- Learn the effects of electric current on the human body

- Understand OSHA safety standards and protective devices

- Discover essential lockout/tagout and grounding practices

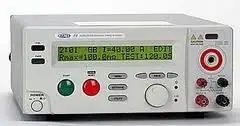

Electrical safety testers verify insulation resistance, hipot (dielectric withstand), ground bond, and leakage current to ensure compliance with IEC standards in R&D, production, and field service, enhancing product safety and quality.

What Are Electrical Safety Testers?

Electrical safety testers assess insulation, ground bond, hipot, and leakage current to meet safety standards.

✅ Hipot and dielectric withstand up to IEC limits

✅ Ground bond and protective earth continuity checks

✅ Leakage current and insulation resistance measurements

Electrical Safety Testers

Electrical equipment receives many of electrical safety tests from manufacturers and standards organizations before consumer usage. Electrical safety testers are used in three different types of electrical safety tests: ground-wire continuity tests, operational and insulation tests.

Electrical Safety Testers – Ground Wire Continuity Test

These kind of electrical safety testers test the quality of three-wire power cords in metal-cased electrical products. No electrical current should pass through this wire during regular operation and, in the case of an electrical fault, the electrical product’s frame should hold at ground potential. If there was no ground wire, an electrical safety hazard could occur. Canadian and U.S. (CSA and UL) standards dictate that the ground-wire continuity must be verified using any indicating electrical safety testers. All electrical safety testers in North America must meet Canadian Standards Association (CSA) and Underwriters Laboratories (UL) standards in Canada and the U.S. respectively. For foundational guidance on regulatory expectations, see the overview at electrical safety requirements for context.

Electrical Safety Testers – Insulation Tests

These kind of electrical safety testers verify the insulation quality of an electrical product. The three kinds of insulation tests performed are:

Additional background on insulation and test methodologies is covered in electrical safety topics for practitioners.

Test Your Knowledge About Arc Flash!

Think you know Arc Flash? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Dielectric Strength (Hi-Pot): Electrical safety testers perform a production test by inspecting the spacing and insulating materials to see if they’re adequate. High-voltage electrical current is applied to the wires holding the electrical device’s case that carry the current at ground potential. If high-fault currents or a disruptive discharge occurs then the product is considered to be faulty. Results are either a PASS or FAIL. Test operators often consult electrical safety manuals to confirm voltage limits and shutdown protocols.

Line-Voltage Leakage Current: Electrical safety testers conduct this test by operating the electrical product at a regular voltage, but keeping the ground-wire open. At that point, a milliampmeter is used to measure the shock that a person would receive during operation. The electrical safety device is connected to exposed metal parts in an area where the product and ground can be measured. When tests involve exposed conductors, adherence to electrical safety work practices reduces risk.

Insulation Resistance (IR): Electrical safety testers measure, record and study the insulating material of large motors and the wiring conditions in buildings for long-term stability, among other uses. Similarities exist between this test and the line-voltage leakage current text, except that the insulation resistance test isn’t ideal for testing the safety of electrical products. Long-term trending of IR results supports broader electrical engineering safety programs within facilities.

Electrical Safety Testers -- Operational Tests

Electrical safety testers that perform operational tests check that the product can perform without drawing excessive current, overheating, or creating a hazard. A measurement of the product’s wattage or current draw will often accomplish this goal. Measurements in temperature and speed can also be performed. Baseline performance checks align with overarching electrical safety principles for equipment commissioning.

For personnel training and awareness, consult general electrical safety resources applicable across industries.