Circuit Protection Devices Explained

By Howard Williams, Assocaite Editor

Substation Relay Protection Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

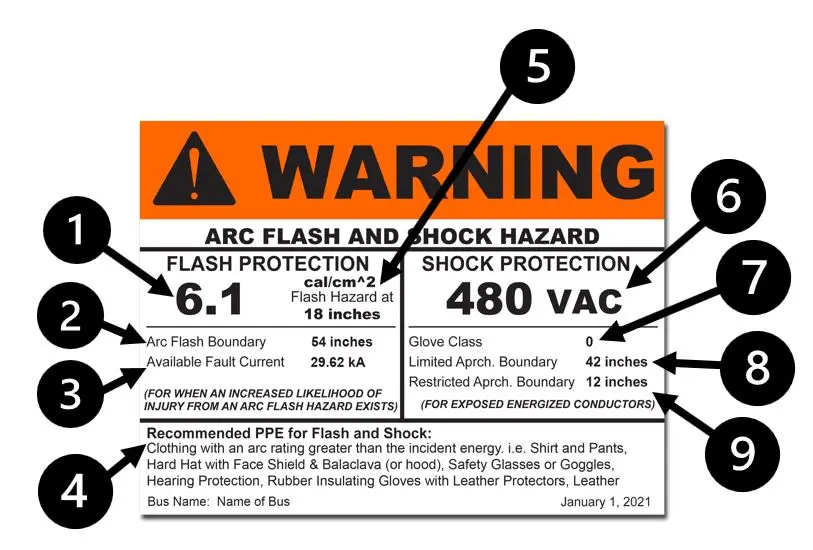

Download Our OSHA 3873 Fact Sheet – Minimum Approach Distance and Training Requirements

- Calculate MAD using voltage and overvoltage values

- Ensure proper communication between host and contract employers

- Meet OSHA training requirements for qualified electrical workers

Circuit protection devices safeguard electrical systems by interrupting overloads, short circuits, and faults. Essential in residential, commercial, and industrial applications, they enhance safety, improve reliability, and ensure compliance with electrical codes and standards.

What are Circuit Protection Devices?

Circuit protection devices are components designed to safeguard electrical systems and equipment from damage resulting from overloads, short circuits, and other electrical faults.

✅ Prevent equipment damage by interrupting excessive current

✅ Improve electrical safety in homes, industry, and utilities

✅ Ensure compliance with electrical codes and reliability standards

A strong foundation in what is electrical protection helps explain the principles that guide the design and use of all devices.

Basic Protection Relay Training

Request a Free Training Quotation

Perhaps the most serious electrical problem is a direct short. This occurs when a conductor at full system voltage comes into contact with ground or the return side of the path, creating a nearly resistance-free flow. The wires, which have limited capacity, can overheat rapidly. Left unchecked, this heat can cause conductors to melt or damage equipment. Protection devices, often working with overcurrent protection, interrupt the fault before it escalates.

In aircraft and other specialized systems, wires are usually small-gauge and sensitive to excessive current. That is why fuses, relays, and breakers are carefully coordinated to ensure faults are isolated quickly without causing further damage.

Other forms of protection include the residual current device, which detects leakage currents that may pose shock hazards, and solid-state solutions that provide fast and reliable switching. While circuit breakers and fuses handle larger systems, small devices such as thermal protectors and miniature breakers extend the same safety principles to individual appliances and sensitive electronics. Together, these devices form an essential safety network designed to protect both equipment and people from electrical hazards.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Protective Devices in Action

To protect electrical systems, several devices are installed: fuses, circuit breakers, thermal protectors, and arc fault interrupters.

These protective devices all share the same purpose — to safeguard wiring and connected equipment. Some are designed primarily to protect conductors, while others isolate specific components in the event of overheating. Basic Protective Relay Training provides professionals with the skills to apply and test these solutions effectively.

Other options include the residual current device, which detects leakage currents that may pose shock hazards, and solid-state technologies that deliver fast, reliable switching. While fuses and breakers cover large networks, small devices such as thermal protectors extend safety principles to appliances and sensitive electronics.

Fuse

Figure 1 shows the schematic symbol for the fuse. Fuses are used to protect the circuit from overcurrent conditions. The fuse is installed in the circuit so that all the current in the circuit passes through it. In most fuses, the strip of metal is made of an alloy of tin and bismuth, which will melt and open the circuit when the current exceeds the rated capacity of the fuse. For example, if a 5-amp fuse is placed into a circuit, the fuse will allow currents up to 5 amps to pass. Because the fuse is intended to protect the circuit, it is crucial that its capacity matches the circuit's needs.

When replacing a fuse, consult the manufacturer’s instructions to ensure a fuse of the correct type and capacity is installed. Fuses are installed in two types of fuse holders in aircraft. “Plug-in holders” or in-line holders are used for small and low-capacity fuses. “Clip” type holders are used for heavy, high-capacity fuses and current limiters.

Fig. 1 - Schematic symbol for fuse.

Current Limiter

Similar to a fuse, a current limiter uses a copper link that tolerates short-term overloads but opens under sustained excess current. They are often used to sectionalize high-current systems, such as aircraft buses. Once opened, they must be replaced.

Circuit Breaker

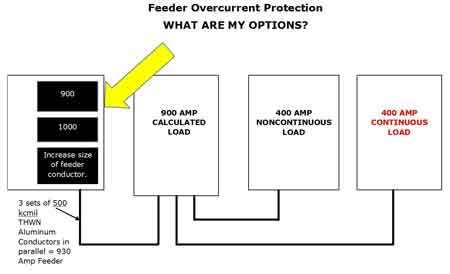

The circuit breaker is commonly used in place of a fuse and is designed to break the loop and stop the current flow when the current exceeds a predetermined value. Unlike the fuse, the breaker can be reset; whereas the fuse or current limiter must be replaced. Figure 10-67 shows the schematic symbol for a breaker. In many applications, transformer protection relies on fuses, relays, and breakers to safeguard expensive utility equipment from electrical damage.

Fig. 2 - Schematic symbol for breaker

There are several types of breakers commonly used in aircraft systems. One is a magnetic type. When excessive current flows in the circuit, it makes an electromagnet strong enough to move a small armature, which trips the breaker. Another type is the thermal overload switch or breaker. This consists of a bimetallic strip, which, when overheated by excessive current, bends away from a catch on the switch lever, permitting the switch to trip open.

Most circuit breakers must be reset by hand. If the overload condition still exists, the breaker will trip again to prevent damage to the circuit. At this point, it is usually not advisable to continue resetting the breaker; instead, initiate troubleshooting to determine the cause. Repeatedly resetting a breaker can lead to damage to the circuit or its components, which may then cause the breaker to trip again. Another type is the thermal overload switch or breaker. This consists of a bimetallic strip, which, when overheated by excessive current, bends away from a catch on the switch lever, permitting the switch to trip open.

Sign Up for Electricity Forum’s Electrical Protection Newsletter

Stay informed with our FREE Electrical Protection Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

An breaker can be reset after it trips, unlike a fuse, which must be replaced. This makes it one of the most common devices used to protect an electrical circuit from damage caused by overloads or faults. In large-scale power distribution systems, breakers safeguard high voltage circuits, while in homes, they are used to protect every household appliance from dangerous currents. Depending on the design, breakers can be reset manually or automatically, offering flexibility in how they respond to faults.

Arc Fault Circuit Breaker

In recent years, the arc fault breaker has begun to provide an additional layer of protection beyond that already provided by conventional breakers. The arc fault breaker monitors the circuit for an electrical arcing signature, which can indicate possible wiring faults and unsafe conditions. These conditions can lead to fires or loss of power to critical systems. The arc fault breaker is only beginning to make an appearance in the aircraft industry and is not yet widely used, unlike the thermal-type breaker. Modern arc fault interrupter breakers extend the role of circuit protection by detecting dangerous arcing conditions that traditional breakers may not identify.

Frequently Asked Questions

What are circuit protection devices?

Protection devices, such as fuses, circuit breakers, and relays, are components that prevent overloads, shorts, and faults to protect electrical systems.

Why are these devices important?

They prevent equipment damage, reduce fire hazards, improve system reliability, and ensure compliance with electrical safety codes.

What are common types of circuit protection devices?

The most common types include fuses, breakers, current limiters, thermal fuses, and arc fault circuit interrupters (AFCIs). Specialized applications, such as surge protection devices for elevators, demonstrate how circuit protection technology is tailored to safeguard both equipment and passengers.

How do they work?

They monitor current flow and interrupt the circuit when excessive current, faults, or unsafe conditions occur, protecting both wiring and connected equipment.

Related Pages