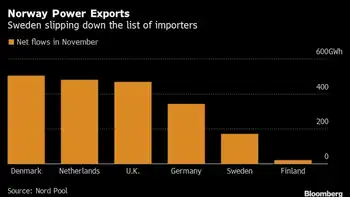

Natural gas crisis looms, study warns

By Financial Post

Substation Relay Protection Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

U.S.-based Cambridge Energy Research Associates says in the study released at the weekend that even the prospect of new finds in Western Canada will not be enough to head off the looming crunch.

"Western Canada has growth potential left, but it won't be enough to balance the North American market," Daniel Collins, CERA's associate director in Calgary, said in an interview.

He told the Financial Post the study was done to alert people to the expected gas crisis in which prices will hover between US$6 and US$7 per thousand British thermal unit at least until 2008 or 2009.

"We wanted to let everyone know its coming," he said, adding that prices could go even higher if there is unusual weather patterns. Current gas prices are between US$4 and US$5 per MMBtu.

The energy research institute based in Cambridge, Mass., found that despite near record levels of new onshore drilling in the United States, gas production in the country continues to fall. Even exports from Canada, the U.S.'s largest foreign supplier, cannot make up the difference.

Supplies of gas from Canada's Mackenzie Delta and eventually Alaska will not come into the U.S. market in time to head off the inevitable price crunch, said Mr. Collins.

"North America's natural gas supply shortfall -- the clear inability of domestic supply from available lands to keep pace with demand -- will challenge the North American natural gas market for the next several years," the study says.

"If no measures are taken to boost supply or dampen demand, North America is set to experience the highest sustained prices in the industry's history," it concludes.

Natural gas became more in demand several years ago when gas prices were relatively cheap, hovering about US$2 per MMBtu. Since no new nuclear plants were being built and coal-powered plants were considered polluting, many power generators built cheap gas-driven plants.

In fact, North America added 200,000 megawatts of new power capacity -- twice that of nuclear power -- in recent years with 94% of that gas driven, the study finds.

However, the run-up in gas prices over the past several years has prompted some electricity producers to consider shutting down those newer plants.

"Residential and commercial customers will see higher bills, impacting pocketbooks and the overall economy," CERA says.

The study warns that U.S. politicians should resist the temptation to accuse energy companies of price gouging and instead encourage the development of new sources of gas, especially liquefied gas.

"The finger-pointing and charged investigation that can be generated by an energy market suddenly out of balance will not result in an easing of high and volatile prices," it said.

CERA said there are some encouraging signs, including the moves recently in the United States toward building more LNG plants with more than 35 being proposed compared to 13 just a year ago. That could represent about 11 billion cubic feet a day compared to 1.4 billion cubic feet currently. North America uses about 68.3 billion cf a day.

Besides encouraging new LNG plants, CERA says the United States in particular should allow more exploration on lands considered taboo, such as offshore or in the Rockies.

As well, the United States should ease some of its restrictions on coal-fired capacity.

The CERA study, sponsored by the global consulting company Accenture, suggests there should be ways of discouraging the current trend toward short-term or spot gas buying among utilities since it tends to make gas prices more volatile.

Congress is struggling to push through a new energy bill that would, among other things, encourage the development of the Alaska gas pipeline through guarantees and other incentives.

"New North American frontier resources will become an important part of the supply mix if allowed or encouraged to proceed," CERA says.