IABC benefits from consumer demand for batteries

By PR Newswire

Protective Relay Training - Basic

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

"Consumers are, to some extent, spending (money) out of need rather than desire," said Scott Hoyt, Director of Consumer Economics at Moody's Economy.com in a June article.

"The strength of our business is based solidly on the fact that consumer demand for batteries continues to rise despite our economic state," said Interstate Batteries Franchise and Development Director Justin Darland. "Replacement batteries for automobiles and forklifts to road signs and heart defibrillators meet critical consumer needs and remain unaffected by recession."

Experts agree. Analysts project the retail battery category will reach $50 billion by 2010 and IABC's record sales reflect these consumer trends.

This year, IABC's total revenue is up seven percent versus the same time last year and the company, who recently celebrated a franchise signing for its 100th store location, continues to expand throughout the nation.

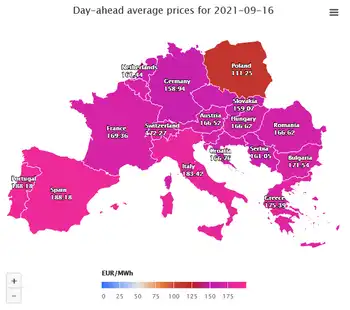

While items like watches, laptops, alarm systems, cordless tools, radios, iPods, cell phones and flashlights will always rely on IABC battery solutions, the company's business model allows stores to continually expand product offerings to adjust to changing consumer needs. Gadgets run by battery and solar-power or cost-savings tools combat the rising costs of electricity and gas prices and invaluable energy savings to IABC customers.

Electricity usage monitors that connect to household appliances can assess efficiency by displaying energy consumption and calculating electrical expenses. Specialized power strips protect valuable electronics while calculating their costs. Solar outdoor spotlights offer powerful light without crashing the electric bill. Even electric bicycles offer alternatives to rising gas prices and make local commutes affordable.

"The energy efficient devices we recently introduced in our stores are flying off the shelves," said Darland. "Coupled with the ever-growing demand for battery-powered products, IABC has found a solution to satisfy consumer needs for years to come."