Students develop arc protection device

Their prototype, built at the request of a local utility company, consists of a lightweight aluminum frame that uses rope and a lever-and-pulley system to enable the worker to detach a transformerÂ’s power connector, known as a load break elbow. This operation sometimes triggers an explosive arc that can cause serious skin burns and eye injuries.

Such arcs can travel as far as 8 feet from the transformer, but the studentsÂ’ device would enable workers to disconnect the line from 10 to 12 feet away.

“We’re very pleased with the outcome of this project,” said Bruce R. Hirsch, a Baltimore Gas & Electric Co. representative who worked with the students. “What they’ve given us is a good start.

It’s a very simple design, and they’ve suggested some further refinements. This device was made to enhance the safety of our people, and that’s BGE’s top priority.”

To acquire the new safety tool, the utility last year turned to Johns Hopkins undergraduates enrolled in the two-semester Engineering Design Project course, offered by the Department of Mechanical Engineering. BGEÂ’s project was aimed at protecting technicians who work in the above-ground, pad-mounted transformer boxes commonly found in residential neighborhoods.

Currently, because of the risk of an electrical arc, such workers must wear safety goggles, flame retardant clothing, protective gloves and a hard hat, and must use an 8-foot-long “hot stick” to disconnect lines that typically carry 7,600 volts. BGE asked the students to devise a system that would allow the workers to remove such lines from 10 to 12 feet away, beyond the reach of an explosive arc.

The utilityÂ’s challenge was assigned to a team consisting of seniors Kyle Azevedo of Bridgewater, Conn.; Julie Blumreiter of Muskego, Wis.; and Doo Hyun Lee of Seoul, Korea. BGE provided an unpowered out-of-service residential transformer box for the team members to use in developing their tool.

The students initially considered complex designs that would employ hydraulic or pneumatic power. “We finally decided on an all-mechanical design that would require no batteries or motors,” said Azevedo. “One of our primary goals for this tool was simplicity.”

The finished prototype features three guide rails that surround the transformerÂ’s elbow connection. A sliding component of the device houses a clamp that grabs onto the connector. The utility technician can then use the lever and pulley system to detach the power line from a safe distance. Compared to the current hot stick procedure, their device requires the worker to exert only a third as much force, the students said.

The students’ tool also should be simple to transport and utilize during repair assignments. “We wanted to make this device as small and as light as possible so that one worker could easily operate it alone,” said Lee.

The undergraduates spent about $9,600 to make the prototype but estimated that it could be mass-produced for far less. The prototype has been turned over to BGE, which will conduct further tests and consider refinements in the device before deciding whether to deploy it in the field.

The student inventors, who recently received their diplomas, viewed the engineering design course an important part of their education. “It gave us the chance to apply a lot of the knowledge we’d been gathering over the previous three years from lectures and textbooks,” Blumreiter said. “In working through this project, we got real-life experience in the design, manufacturing and assembly processes.”

Blumreiter and Azevedo are planning to enter graduate engineering programs at Stanford University and Georgia Tech, respectively. Lee plans to begin working soon as a structural analysis engineer in New Jersey.

The utility workerÂ’s device was one of nine Johns Hopkins projects completed this year by undergraduates in the engineering design course, taught by Mike Johnson and other faculty members in the Department of Mechanical Engineering. Each team of three or four students, usually working within budgets of up to $12,000, had to design a device, purchase or fabricate the parts and assemble the final product. Corporations, government agencies and nonprofit groups provide the assignments and collaborate with the students.

The course is traditionally a well-received, hands-on engineering experience for Johns Hopkins undergraduates.

Related News

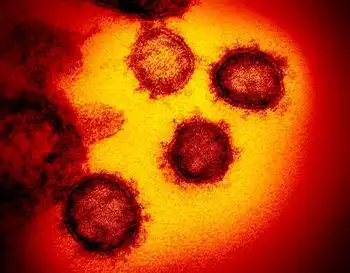

Coronavirus puts electric carmakers on alert over lithium supplies

BEIJING - The global outbreak of coronavirus will accelerate efforts by western carmakers to localise supplies of lithium for electric car batteries, according to US producer Livent.

The industry was keen to diversify away from China, which produces the bulk of the world’s lithium, a critical material for lithium-ion batteries, said Paul Graves, Livent’s chief executive.

“It’s a conversation that’s starting to happen that was not happening even six months ago,” especially in the US, the former Goldman Sachs banker added.

China produced about 79 per cent of the lithium hydroxide used in electric car batteries last year, according to consultancy CRU, a…