TagEnergy France Battery Storage Platform enables grid flexibility, stability, and resilience across France, storing wind and solar power, balancing supply and demand, reducing curtailment, and supporting carbon neutrality with fast-response, utility-scale capacity.

Key Points

A utility-scale BESS in France that stores renewable energy to stabilize the grid, boost flexibility, and cut emissions.

✅ Several hundred MW utility-scale capacity for peak shaving.

✅ Fast-response frequency regulation and voltage support.

✅ Reduces fossil peaker use and renewable curtailment.

In a significant leap toward enhancing France’s renewable energy infrastructure, TagEnergy has officially launched the country's largest battery storage platform. This cutting-edge project is set to revolutionize the way France manages its electricity grid by providing much-needed flexibility, stability, and resilience, particularly as the country ramps up its use of renewable energy sources and experiences negative prices in France during periods of oversupply,

The new battery storage platform, with a total capacity of several hundred megawatts, will play a crucial role in facilitating the country's transition to a greener, more sustainable energy future. It marks a significant step forward in addressing one of the most pressing challenges of renewable energy: how to store and dispatch power generated from intermittent sources such as wind and solar energy.

The Role of Battery Storage in Renewable Energy

Battery storage systems are key to unlocking the full potential of renewable energy sources. While wind and solar power are increasingly important in reducing reliance on fossil fuels, their intermittent nature—dependent on weather conditions and time of day—presents a challenge for grid operators. Without an efficient way to store surplus energy produced during peak generation periods, when negative electricity prices can emerge, the grid can become unstable, leading to waste or even blackouts.

This is where TagEnergy’s new platform comes into play. The state-of-the-art battery storage system will capture excess energy when production is high, and then release it back into the grid during periods of high demand, supporting peak demand strategies or when renewable generation dips. This capability will smooth out the fluctuations in renewable energy production and ensure a constant, reliable supply of power to consumers. By doing so, the platform will not only stabilize the grid but also increase the overall efficiency and utilization of renewable energy sources.

The Scale and Scope of the Platform

TagEnergy's battery storage platform is one of the largest in France, with a capacity capable of supporting a wide range of energy storage needs across the country. The platform’s size is designed to handle significant energy loads, making it a critical piece of infrastructure for grid stability. The project will primarily focus on large-scale energy storage, but it will also incorporate cutting-edge technologies to ensure fast response times and high efficiency in energy release.

France’s energy mix is undergoing a transformation as the country aims to achieve carbon neutrality by 2050. With ambitious plans to expand renewable energy production, particularly from offshore wind such as North Sea wind potential, solar, and hydropower, energy storage becomes essential for managing supply and demand. The new battery platform is poised to provide the necessary storage capabilities to keep up with this shift toward greener, more sustainable energy production.

Economic and Environmental Impact

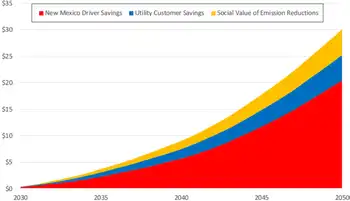

The launch of the battery storage platform is a major boon for the French economy, creating jobs and attracting investment in the clean energy sector. The project is expected to generate hundreds of construction and operational jobs, providing a boost to local economies, particularly in the areas where the storage facilities are located.

From an environmental perspective, the platform’s ability to store and release renewable energy will greatly reduce the country’s reliance on fossil fuels, decreasing greenhouse gas emissions. The efficient storage of solar and wind energy will mean that more clean electricity can be used, with solar-plus-storage cheaper than conventional power in Germany underscoring cost competitiveness, even during times when these renewable sources are not producing at full capacity. This will help France meet its energy and climate goals, including reducing carbon emissions by 40% by 2030 and achieving carbon neutrality by 2050.

The development also aligns with broader European Union goals to increase the share of renewables in the energy mix. As EU nations work toward their collective climate commitments, energy storage projects like TagEnergy’s platform will be vital in helping the continent achieve a greener, more sustainable future.

A Step Toward Energy Independence

The new battery storage platform also has the potential to enhance France’s energy independence. By increasing the storage capacity for renewable energy, France will be able to rely less on imported fossil fuels and energy from neighboring countries, particularly during periods of high demand. Energy independence is a key strategic goal for many nations, as it reduces vulnerability to geopolitical tensions and fluctuating energy prices.

In addition to bolstering national security, the platform supports France’s energy transition by facilitating the deployment of more renewable energy. As storage capacity increases, grid operators will be able to integrate larger quantities of intermittent renewable energy without sacrificing reliability. This will enable France to meet its long-term energy goals while also supporting the EU’s ambitious climate targets.

Future of Battery Storage in France and Beyond

TagEnergy’s launch of France’s largest battery storage platform is a monumental achievement in the country’s energy transition. However, it is unlikely to be the last of its kind. The success of this project could pave the way for similar initiatives across France and the wider European market. As battery storage technology advances, and affordable solar batteries scale up, the capacity for storing and utilizing renewable energy will only grow, unlocking new possibilities for clean, affordable power.

Looking ahead, TagEnergy plans to expand its operations and further invest in renewable energy solutions. The French market, along with growing demand for storage solutions across Europe, presents significant opportunities for further development in the energy storage sector. With the continued integration of renewable energy into the grid, large-scale storage platforms will play an increasingly critical role in shaping a low-carbon future.

The launch of TagEnergy’s battery storage platform marks a pivotal moment for France’s renewable energy landscape. By providing critical storage capacity and ensuring the reliable delivery of clean electricity, the platform will help the country meet its ambitious climate and energy goals. As technology advances and the global transition to renewables accelerates, with over 30% of global electricity now coming from renewables, projects like this one will play an essential role in creating a sustainable, low-carbon energy future.

Related News