Let's use real energy numbers

By The Mercury News

Arc Flash Training CSA Z462 - Electrical Safety Essentials

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Jim Barksdale, founding CEO of Netscape, preached "you can't manage what you don't measure." I agree. But in today's concerns about energy independence or security, numbers don't seem to matter. Examples abound from this election:

1) We're sending $700 billion abroad to buy imported oil. Fact: Our net cost of imported oil this year will be about $400 billion due to the midyear price spike.

2) We're dependent on the Middle East for our oil. Fact: We import oil from 60 countries; Canada and Mexico are our first and third largest suppliers. Persian Gulf suppliers provide less than 20 percent of imports; thus, we send about $5 billion a month to the gulf.

3) We import 70 percent of our oil. Fact: Our import percentage peaked in 2005 at 60.3 percent and now runs at 56.5 percent.

4) We have 3 percent of the world's oil reserves. Fact: There's no agreement on the size of global reserves with OPEC nations playing games to get more allocation; we continue to maintain up to a 10-year "backlog" of available oil.

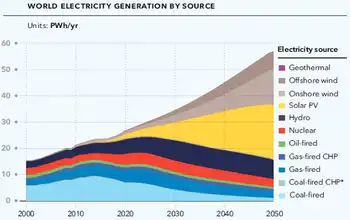

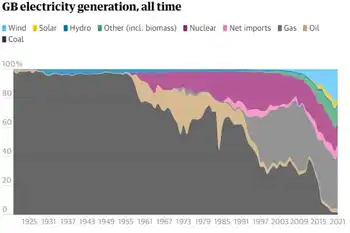

5) Turn off your lights to save imported oil. Fact: Oil plays virtually no role in electricity production, which nationally comes from coal (50 percent), nuclear power (20 percent), natural gas (18 percent), and hydro (7 percent). Wind and solar currently contribute less than 2 percent.

One commercial used words like "government is doing nothing."

Government may not have acted on many issues, but energy is not one of them.

With recent federal mandates, oil imports are actually down 10 percent since 2005 from 12.5 million barrels per day (mbpd) to an estimated 11.3 mbpd this year. Ethanol replaced 0.6 mbpd (even at $65 a barrel, that saves $14 billion a year); U.S. oil production is up 0.4 mbpd since 2005 and conservation saved 0.3-0.5 mbpd.

More important, Congress finally escaped the clutches of Rep. John Dingell, D-Mich., and allowed car and light truck fuel standards to dramatically increase after 15 years of stonewalling.

Oil serves two primary purposes in our society — 70 percent for transportation and 25 percent in manufactured products. We'll use internal combustion engines for many more decades, but increasing efficiency and using biofuels and electricity will decrease oil needs.

In manufacturing, where 300,000 commercial products from plastics to tires, to road surfaces on down to lipstick and other lubricants use oil, bio-based products hold promise.

So, bioproducts and plentiful electricity hold the key to "oil" security. We're doing well in biofuels, but we need to stick to it and keep the biofuels mandates of the 2007 mandate. Our universities and entrepreneurs are making great strides in converting biomaterials to the needs of both transportation and manufacturing.

The electricity picture is less clear. Here, in California, we may be proud of the low per capita use of electricity, but details suggest that our "progress" is due to driving electricity dependent manufacturing and the jobs that go along out of the state and even out of the country.

Electricity is essential to drive our economy; to ultimately help power our cars, trucks and, perhaps, trains; to meet our water needs through desalination. The numbers aren't encouraging. I'm as committed to renewables as anyone, but base load power that generates 24/7 is needed for industry and many residential needs. Turning nuclear and other clean base load alternatives on again makes economic as well as environmental sense.

In three years, we've reduced our demand for imported oil by 10 percent — a $40 billion a year savings. Biofuels and base load electricity will continue that progress. Let's cut out the misinformation, inform the public of the real numbers and achieve genuine energy leadership.