Rising Electricity Prices are driven by inflation, climate change, and the clean energy transition, affecting energy bills, grid resilience, and supply. Renewables, storage, and infrastructure upgrades shape costs, volatility, and long-term sustainability.

Key Points

Rising electricity prices stem from inflation, climate risk, and costs of integrating clean energy and storage into modern grids.

✅ Inflation raises fuel, materials, and labor costs for utilities

✅ Extreme weather damages infrastructure and strains peak demand

✅ Clean energy rollout needs storage, backup, and grid upgrades

In recent months, consumers have been grappling with a concerning trend: rising electricity prices across the country. This increase is not merely a fluctuation but a complex issue shaped by a confluence of factors including inflation, climate change, and the transition to clean energy. Understanding these dynamics is crucial for navigating the current energy landscape and preparing for its future.

Inflation and Its Impact on Energy Costs

Inflation, the economic phenomenon of rising prices across various sectors, has significantly impacted the cost of living, including electricity and natural gas prices for households. As the price of goods and services increases, so too does the cost of producing and delivering electricity. Energy production relies heavily on raw materials, such as metals and fuels, whose prices have surged in recent years. For instance, the costs associated with mining, transporting, and refining these materials have risen, thereby increasing the operational expenses for power plants.

Moreover, inflation affects labor costs, as wages often need to keep pace with the rising cost of living. As utility companies face higher expenses for both materials and labor, these costs are inevitably passed on to consumers in the form of higher electricity bills.

Climate Change and Energy Supply Disruptions

Climate change also plays a significant role in driving up electricity prices. Extreme weather events, such as hurricanes, heatwaves, and floods, have become more frequent and severe due to climate change. These events disrupt energy production and distribution by damaging infrastructure, impeding transportation, and affecting the availability of resources.

For example, hurricanes can knock out power plants and damage transmission lines, leading to shortages and higher costs. During periods of extreme summer heat across many regions, heatwaves can strain the power grid as increased demand for air conditioning pushes the system to its limits. Such disruptions not only lead to higher immediate costs but also necessitate costly repairs and infrastructure upgrades.

Additionally, the increasing frequency of natural disasters forces utilities to invest in more resilient infrastructure, as many utilities spend more on delivery to harden grids and reduce outages, which adds to overall costs. These investments, while necessary for long-term reliability, contribute to short-term price increases for consumers.

The Transition to Clean Energy

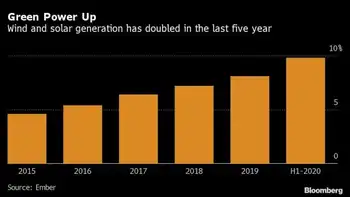

The shift towards clean energy is another pivotal factor influencing electricity prices. While renewable energy sources like wind, solar, and hydro power are crucial for reducing greenhouse gas emissions and combating climate change, their integration into the existing grid presents challenges.

Renewable energy infrastructure requires substantial initial investment. The construction of wind farms, solar panels, and the associated grid improvements involve significant capital expenditure. These upfront costs are often reflected in electricity prices. Moreover, renewable energy sources can be intermittent, meaning they do not always produce electricity at times of high demand. This intermittency necessitates the development of energy storage solutions and backup systems, which further adds to the costs.

Utilities are also transitioning from fossil fuel-based energy production to cleaner alternatives, a process that involves both technological and operational shifts and intersects with the broader energy crisis impacts on electricity, gas, and EVs nationwide. These changes can temporarily increase costs as utilities phase out old systems and implement new ones. While the long-term benefits of cleaner energy include environmental sustainability and potentially lower operating costs, the transition period can be financially burdensome for consumers.

The Path Forward

Addressing rising electricity prices requires a multifaceted approach. Policymakers must balance the need for immediate relief, as California regulators face calls for action amid soaring bills, with the long-term goals of sustainability and resilience. Investments in energy efficiency can help reduce overall demand and ease pressure on the grid. Expanding and modernizing energy infrastructure to accommodate renewable sources can also mitigate price volatility.

Additionally, efforts to mitigate climate change through improved resilience and adaptive measures can reduce the frequency and impact of extreme weather events, thereby stabilizing energy costs.

Consumer education is vital in this process. Understanding the factors driving electricity prices can empower individuals to make informed decisions about energy consumption and conservation. Furthermore, exploring energy-efficient appliances and practices can help manage costs in the face of rising prices.

In summary, the rising cost of electricity is a multifaceted issue influenced by inflation, climate change, and the transition to clean energy, and recent developments show Germany's rising energy costs in the coming year. While these factors pose significant challenges, they also offer opportunities for innovation and improvement in how we produce, distribute, and consume energy. By addressing these issues with a balanced approach, it is possible to navigate the complexities of rising electricity prices while working towards a more sustainable and resilient energy future.

Related News