Do All The Transformers Use Power With No Load

Substation Maintenance Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA FS3529 Fact Sheet – Lockout/Tagout Safety Procedures

- Learn how to disable machines and isolate energy sources safely

- Follow OSHA guidelines for developing energy control programs

- Protect workers with proper lockout devices and annual inspections

Do all the transformers use power with no load? Practical units draw magnetizing current and incur core (iron) losses from hysteresis and eddy currents, causing reactive power and standby consumption even without secondary load.

Do All the Transformers Use Power With No Load?

Yes. Practical transformers draw magnetizing current with iron core losses at no load; an ideal transformer would not.

✅ No-load losses from hysteresis and eddy currents are nearly constant.

✅ Magnetizing current supplies reactive power; real power equals iron loss.

✅ Better core steel and laminated design minimize standby watts and heating.

Do all the transformers use power with no load? This question holds significant importance for electrical engineering and maintenance professionals because understanding transformer energy consumption during no-load conditions can impact operational efficiency, energy costs, and system reliability. Transformers play a vital role in electrical power distribution, but even when they aren't actively supplying power to a load, they can still draw energy from the grid. This no-load loss, primarily caused by core magnetization, directly affects energy efficiency and long-term operating costs. For engineers and facility managers, knowing how and why they consume power without a load can inform smarter decisions on equipment selection, energy audits, and system optimization, ultimately supporting more sustainable and cost-effective power management strategies. In practical networks, assets like electrical power distribution transformers must be evaluated for standby losses to align reliability with lifecycle cost goals.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

The operation of transformers is often associated with the efficient transfer of electrical energy from one circuit to another. However, a lesser-known aspect of their operation is that they consume power even when there is no load connected to the secondary winding. This power consumption is not a design flaw but an inherent characteristic of how they work. Understanding the underlying principles can offer insight into why this happens and what it means for energy efficiency. For a deeper primer on flux, turns ratio, and energy transfer, see how transformers work in AC systems to contextualize no-load behavior.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

One of the key reasons for this phenomenon lies in the concept of core losses. When a transformer is connected to a power supply, its core must be continuously magnetized and demagnetized to maintain the alternating magnetic flux. This continuous process results in power consumption due to resistance within the core material. The primary contributors to core losses are hysteresis loss and eddy current loss. Hysteresis loss occurs because the magnetic domains within the core must realign with each change in the AC current—a process that releases heat and consumes energy. Eddy current loss happens when small, swirling currents are induced within the core material itself, creating resistive heating. These two components together are responsible for a significant portion of the power consumed by transformers during no-load operation.

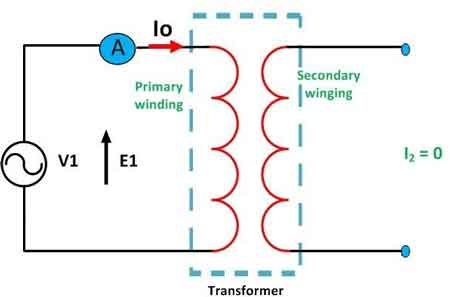

Another essential concept to understand is magnetizing current. Even in the absence of load power, they draw a small amount of current from the input power source. This magnetizing current is used to generate and maintain the magnetic flux within the core. While this current is relatively small, it is a continuous drain on the system's power supply. Since the magnetizing current is required to sustain the core’s magnetic field, it results in ongoing power consumption, even when no electricity is being delivered to an end device. This is one of the fundamental reasons why they consume power even when idle. The magnetizing branch is driven by induced emf, and understanding what causes voltage to be induced in a transformer clarifies why this current never truly falls to zero.

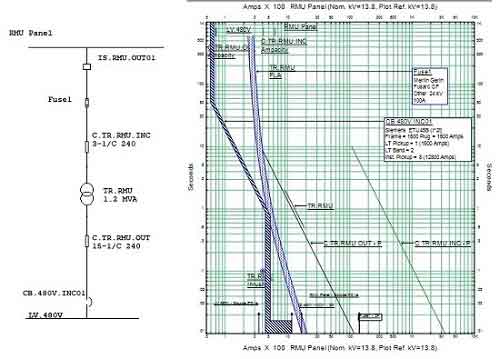

No-load power consumption is a broader concept that includes all the power used by the transformer when the secondary winding is open. This consumption is often referred to as standby power consumption. When a transformer’s load power demand is zero, the power required to overcome core losses and maintain the magnetic field is still present. This consumption is generally measured in watts or as a percentage of the transformer's total capacity. The no-load power consumption can vary depending on the size and design of the transformer. Larger units, such as those used in substations, tend to have higher no-load losses due to the larger magnetic cores required to handle high voltages and currents. For perspective, analyses of how much electricity a high-voltage transformer uses can help benchmark acceptable standby losses in large installations.

The impact of no-load consumption on energy efficiency cannot be overlooked. While they are designed to be highly efficient, the power used during no-load conditions still represents an energy loss that contributes to overall system inefficiency. This is particularly relevant in large power systems where multiple transformers may remain connected to the grid without serving active loads. Reducing these losses is a priority for utilities and industries aiming to improve energy efficiency. Some transformer designs use advanced core materials that have lower hysteresis and eddy current losses, thereby minimizing power consumption during idle periods. Addressing these issues can lead to significant cost savings, especially in facilities where multiple transformers are in operation 24/7. In many plants, specifying a modern power transformer with optimized core steel reduces no-load watts while maintaining fault withstand margins.

Sign Up for Electricity Forum’s Utility Transformers Newsletter

Stay informed with our FREE Utility Transformers Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

The role of the primary winding is another critical aspect to consider. When a transformer is connected to a power supply, the primary winding draws power to establish and maintain the magnetic flux within the core. This process happens even when the secondary winding has no connected load. As a result, power consumption occurs due to resistance within the primary winding, further adding to no-load power consumption. The induced flux in the core is necessary for the operation of the transformer, but it also means that the primary winding’s current draw cannot be eliminated. Consequently, the input power used by the primary winding is not zero, even when the output load is nonexistent. This interplay of input and output is governed by electromagnetic laws, and reviewing why power is conserved in transformers helps separate ideal behavior from real losses.

One aspect of transformer operation that often goes unnoticed is the role of voltage drop. Although voltage drop is more commonly discussed in the context of loaded conditions, it is also present during no-load operation. When current flows through the primary winding, the resistance of the winding causes a slight voltage drop. While this drop is relatively small under no-load conditions, it becomes a part of the total power loss associated with the transformer's operation. This subtle but important aspect underscores the complexities of energy efficiency in transformer design and usage.

In summary, the answer to "do all the transformers use power with no load" is a clear yes. The reasons behind this consumption are rooted in core losses, magnetizing current, and the power required to maintain magnetic flux in the core. These processes are all driven by fundamental principles of electromagnetism and the physical properties of the materials used in transformer construction. Although modern designs strive to reduce these losses, they cannot be entirely eliminated. This ongoing power consumption, which occurs due to resistance, no-load losses, and the draw of magnetizing current, affects energy efficiency and operating costs. Recognizing the factors that contribute to no-load power consumption is crucial for engineers, utilities, and facility managers who aim to optimize energy use in electrical systems. Finally, it is worth noting that a power supply is not the same device as a transformer, and this distinction is outlined in a guide comparing power supplies and transformers for common engineering contexts.