Electrical Substation Transformer Explained

What is an Electrical Substation Transformer?

An electrical substation transformer is a crucial component in the electricity system, facilitating the efficient transfer of electrical energy from high-voltage transmission lines to lower distribution voltages suitable for end-users. Understanding their role, types, and maintenance is vital for ensuring reliable power distribution.

An Electrical Substation Transformer is a static electrical device designed to convert electrical energy from one voltage level to another. This process of altering the voltage level is crucial in power transmission, allowing for efficient transport of electricity over long distances through transmission lines. At the distribution level, transformers are used to step down high voltages to medium or low voltages suitable for delivery to homes, businesses, and industries.

The Role of the Electrical Substation Transformer

The primary role of a transformer in an electrical substation is to manage voltage levels. At the generation stage, electrical energy is produced at relatively low voltages. This voltage is increased for efficient transmission over long distances through transmission lines. When the electricity reaches a substation near the consumption area, the transformer steps down the high voltage to medium or low distribution voltages suitable for use in homes, industries, and businesses. This process ensures the safe and efficient distribution of electrical energy within the electricity system.

Substations serve as critical hubs in the electrical grid, where transformers fulfill several key functions:

- Voltage Transformation: They either increase (step-up) or decrease (step-down) voltage levels to optimize power transmission and distribution.

- Isolation: They provide electrical isolation between different sections of the substation, enhancing safety and preventing the propagation of faults.

- Power Regulation: By adjusting their tap settings, transformers help maintain stable voltage levels in the distribution network, even under varying load conditions.

Types of Transformers Used in Substations

Various types of transformers are employed in substations, each serving specific purposes:

- Power Transformers: These large-capacity transformers handle the bulk power transfer between transmission and distribution networks.

- Distribution Transformers: Smaller in size, these transformers further reduce voltage levels for delivery to end-users.

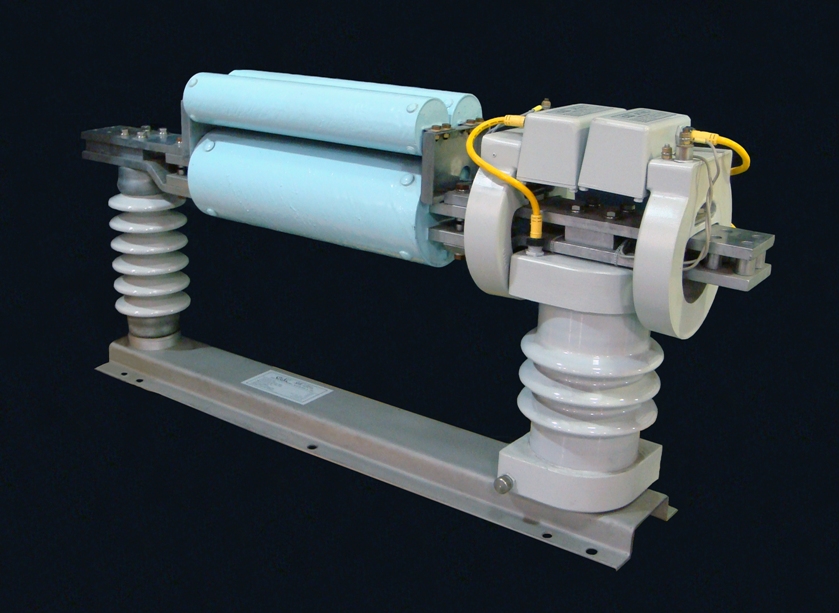

- Instrument Transformers: These specialized transformers are used for metering and protection purposes, providing accurate measurements of voltage and current.

Managing Heat Generation

Transformers generate heat during operation due to losses in the core and windings. Effective heat dissipation is crucial for preventing damage and ensuring optimal performance. Substation transformers employ various cooling methods, such as oil-immersed cooling, air-blast cooling, or water cooling, to maintain safe operating temperatures.

Heat generation is a significant concern in substation transformers due to the high power levels they handle. To manage heat, these transformers incorporate various cooling methods:

- Oil Cooling: Insulating oil is used to absorb heat generated within the transformer. The heated oil is then cooled in radiators or cooling tubes before being recirculated.

- Air Cooling: Fans or blowers are used to circulate air over the transformer surfaces to dissipate heat.

- Water Cooling: In some large transformers, water cooling systems are used to efficiently remove heat.

Safety Features

Safety is paramount in substation design. Transformers are equipped with various protective features, including:

- Buchholz Relays: These detect gas accumulation or sudden pressure changes inside the transformer, which may indicate internal faults.

- Pressure Relief Devices: These release excessive pressure buildup within the transformer tank, preventing potential explosions.

- Overcurrent and Overvoltage Protection: Circuit breakers and fuses protect the transformer from damaging current and voltage surges.

What Maintenance is Required for an Electrical Substation Transformer?

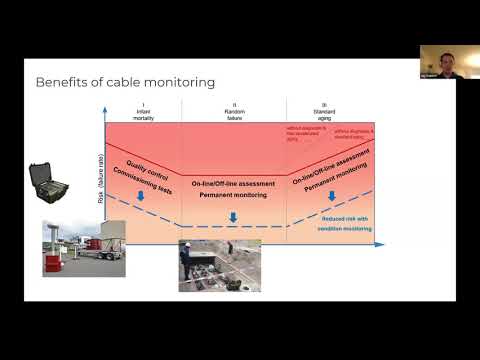

Regular maintenance is essential to ensure the long-term reliability of substation transformers. This includes visual inspections, oil sampling and analysis, infrared thermography, and electrical testing. By proactively addressing potential issues, utilities can extend the lifespan of their transformers and ensure uninterrupted power delivery.

- Oil Testing: Regular testing of insulating oil is necessary to check for moisture, acidity, and other contaminants that could affect performance.

- Physical Inspections: Periodic inspections of the transformer's physical condition, including checking for leaks, corrosion, and insulation degradation.

- Electrical Testing: Performing electrical tests to assess the condition of windings, insulation, and other critical components.

- Cooling System Maintenance: Ensuring that cooling systems, such as fans, radiators, and oil pumps, are functioning correctly.

An electrical substation transformer is an indispensable component in the modern power grid. Their ability to efficiently and safely transform voltage levels is crucial for meeting the growing demands of our electrified world. Through continuous advancements in technology and ongoing maintenance, these transformers will continue to play a vital role in ensuring a stable and reliable electricity supply for future generations.

On-Site Training

Interested in cost effective, professional on-site electrical training?

We can present an Electrical Training Course to your electrical engineering and maintenance staff, on your premises, tailored to your specific equipment and requirements. Click on the link below to request a Free quotation.

EF PARTNER MEDIA

Videos

Product Showcases

Shared Media