OSHA Lockout Tagout Hazardous Energy Control

OSHA Lockout Tagout (LOTO) standard establishes requirements for the control of the release of hazardous energy sources during maintenance, repair, or servicing work on machinery or equipment. The standard protects workers from accidental startup, the release of stored energy, or other hazardous conditions that could cause serious injury or death.

Visit our OSHA Lockout Tagout Training Page

What is the Purpose of the OSHA Lockout Tagout Standard?

The primary purpose of the OSHA LOTO standard is to prevent the unexpected startup or release of stored energy in machines or equipment, which can cause serious injuries or fatalities. The standard outlines specific procedures for controlling hazardous energy to ensure the safety of employees who perform servicing and maintenance tasks. By following these procedures, companies can significantly reduce the risk of accidents and enhance workplace safety.

Who is Required to Follow OSHA Procedures?

LOTO procedures apply to all employees involved in servicing and maintaining machinery and equipment. This includes:

- Authorized Employees: These individuals are responsible for implementing the hazardous energy lockout tagout procedures and applying lockout devices and tagout devices to control hazardous energy.

- Affected Employees: These workers operate or work near the machines or equipment being serviced and need to understand the procedures to stay safe.

- Other Employees: Any other employees who might be in the vicinity must be aware of the procedures to ensure their safety.

What are the Key Components of an OSHA LOTO Program?

An effective LOTO program comprises several key components:

- Energy Control Program: A documented program that outlines the procedures and practices for controlling hazardous energy during servicing and maintenance.

- Energy Control Procedures: Detailed instructions on how to lock out and tag out specific machinery and equipment to ensure the control of hazardous energy.

- Training and Communication: Training for all employees on the proper use of lockout tagout procedures, as well as regular communication to keep everyone informed about the program.

- Periodic Inspections: Regular audits to ensure that the lockout tagout procedures are being followed correctly and that all equipment is maintained properly.

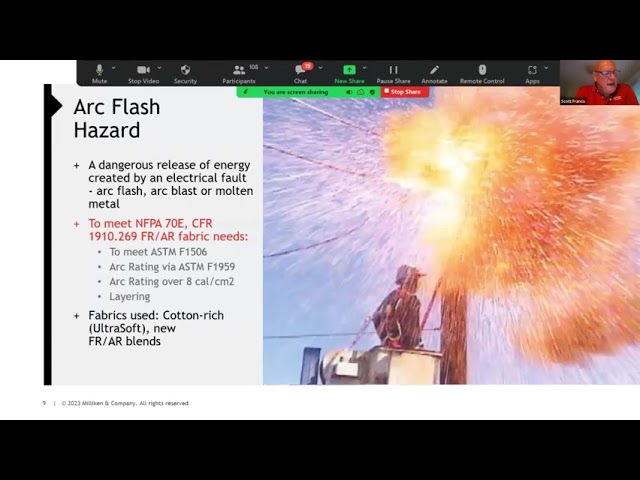

What Types of Energy Sources Need to Be Controlled Under OSHA?

The LOTO standard requires the control of various energy sources that could pose a hazard to workers. These energy sources include:

- Electrical Energy: Power from electrical sources that can cause electric shock or other injuries.

- Mechanical Energy: Moving parts, such as gears, belts, and springs, that can cause injury if released unexpectedly.

- Hydraulic Energy: Pressurized fluids that can cause injury if released suddenly.

- Pneumatic Energy: Pressurized air that can cause injury if released unexpectedly.

- Thermal Energy: Hot surfaces, steam, and other sources of heat that can cause burns.

- Chemical Energy: Reactive chemicals that can cause harm if not properly controlled.

What are the Consequences of Not Complying with the Standard?

Non-compliance with the LOTO standard can lead to severe consequences, including:

- Injuries and Fatalities: Failure to control hazardous energy can result in serious injuries or deaths, significantly impacting the lives of employees and their families.

- Legal Penalties: OSHA can impose significant fines and penalties on organizations that do not comply with the standard, leading to financial losses.

- Increased Liability: Non-compliance increases the liability for organizations, potentially resulting in lawsuits and higher insurance premiums.

- Operational Disruptions: Injuries and incidents can cause downtime and productivity losses, affecting the overall efficiency of operations.

- Reputation Damage: Non-compliance can harm the organization's reputation, leading to a loss of trust among employees, customers, and the public.

The LOTO standard is essential for ensuring the safety of employees who service and maintain machinery and equipment. By implementing a comprehensive energy control program, training employees, and conducting regular inspections, organizations can effectively control hazardous energy sources and prevent accidents. Compliance with the OSHA standard not only protects workers but also enhances operational efficiency and reduces liability. Investing in a robust lockout tagout program is a critical step toward creating a safer workplace for all.

EF PARTNER MEDIA

Videos

Product Showcases

Shared Media