Arc Flash Clothing - NFPA 70E-Rated FR PPE

CSA Z462 Arc Flash Training - Electrical Safety Essentials

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA 4474 Fact Sheet – Establishing Boundaries Around Arc Flash Hazards

- Understand the difference between arc flash and electric shock boundaries

- Learn who may cross each boundary and under what conditions

- Apply voltage-based rules for safer approach distances

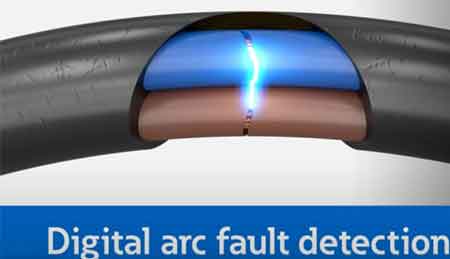

Arc flash clothing protects workers from electrical arc hazards by reducing burn risk and meeting NFPA 70E standards. Flame-resistant shirts, pants, coveralls, and hoods guard against intense heat, fire, and thermal energy.

What is Arc Flash Clothing?

Arc flash clothing protects workers from high heat and burn injuries during electrical explosions. These flame-resistant garments meet NFPA 70E and CSA Z462 standards for thermal protection in energized electrical environments.

✅ Protects against high-temperature electrical hazards

✅ Meets NFPA 70E and CSA Z462 safety standards

✅ Available in multiple ratings (e.g., 8 to 100 cal/cm²)

Request a Free Training Quotation

Arc flash clothing is specialized protective gear designed to safeguard electrical workers from the intense thermal energy released during electric arcs. Engineered with flame-resistant fabrics and tested for high ATPV ratings, this clothing minimizes the risk of serious injury, including second- and third-degree burns. Whether rated at 25 cal/cm² or 40 cal/cm², arc-rated garments are essential for compliance with NFPA 70E electrical safety standards. Unlike standard FR fabric, electrical hazard gear is built to withstand specific incident energy levels and offers superior thermal protective performance in environments where energized equipment poses a constant hazard. Flame-resistant clothing is essential for protecting workers from serious injuries during a flash fire by providing a thermal barrier that resists ignition and minimizes burn severity.

Arc Flash Clothing PPE Category Comparison Table

| PPE Category | Minimum Arc Rating (cal/cm²) | Typical Clothing | Use Case |

|---|---|---|---|

| Category 1 | 4 cal/cm² | Arc-rated FR shirt and pants or FR coverall | Panelboards, lighting control panels |

| Category 2 | 8 cal/cm² | Arc-rated FR shirt and pants + arc-rated face shield or suit hood | Motors, starters, MCCs |

| Category 3 | 25 cal/cm² | Arc-rated FR coverall + suit hood, gloves, boots | Switchgear, cable trays, high-energy circuits |

| Category 4 | 40 cal/cm² | Suit with multi-layer FR protection + full PPE ensemble | Main switchgear, transformer terminals |

Why Arc Flash Clothing Matters

Electric arcs can reach temperatures of over 35,000°F and produce explosive force and molten metal. These conditions can cause life-altering injuries in less than a second. Arc-rated PPE garments create a protective barrier between the worker and the thermal blast, absorbing and deflecting energy that would otherwise penetrate the skin. For workers in electrical maintenance, troubleshooting, and testing, this clothing is a critical last line of defence.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Understanding Arc Flash Clothing Ratings

The rating of arc flash clothing indicates how much incident energy (in cal/cm²) the garment can withstand before the wearer is at risk of a second-degree burn. Common protective thresholds include:

-

25 cal/cm²: Moderate-risk environments

-

40 cal/cm²: High-energy tasks such as live switchgear operation

The minimum arc rating for any garment must meet or exceed the potential energy level determined through a proper hazard assessment. For comprehensive guidance on selecting and using suits rated at 40 cal/cm², visit our detailed 40 Cal Arc Flash Suit page. Need clothing for extreme hazards? Check out our 100 Cal Arc Flash Suit to understand high-energy task protection.

Selecting the Right Arc Flash Clothing

Choosing proper protective garments starts with evaluating the work environment. For high-risk jobs involving switchgear, energized panels, or live testing, garments with a 40 cal/cm² rating may be required. For lower-energy tasks, 25 cal/cm² rated suits could be sufficient. The right gear includes arc-rated shirts, pants, coveralls, balaclavas, and face shields—all designed to form a complete protective system. Employers should also decide between daily wear vs task-based PPE, based on the frequency and severity of exposure. Learn how PPE ratings and performance impact worker safety on our dedicated PPE Performance page.

NFPA 70E Compliance and Worker Protection

The NFPA 70E standard outlines how employers must assess hazards, assign hazard risk categories, and implement an effective PPE program. Compliance includes selecting protective apparel that matches the calculated incident energy and ensuring employees are trained in proper use. This goes beyond wearing PPE—it's about using the right gear, in the right way, for the specific job task. Ensure your protective clothing meets industry standards by reviewing the NFPA 70E PPE Requirements.

Maintenance and Longevity

Even the highest-quality PPE loses its protective value if not properly cared for. Garments should be cleaned according to the manufacturer's instructions and stored in a dry, protected area. Regular inspections are necessary to identify signs of wear, damage, or contamination that could compromise performance. Replacing worn gear is not optional—it’s a safety requirement.

Properly selected and maintained FR clothing is vital to electrical safety. It reduces injury risk, supports regulatory compliance, and saves lives. When incident energy is high, only the right arc-rated protection will do.

Frequently Asked Questions

Why Is AF Clothing Is Needed?

PPE is essential for protecting workers from the thermal hazards associated with incidents. This clothing typically includes arc-rated (AR) suits, jackets, pants, bib overalls, gloves, and face shields. The primary purpose of this gear is to provide a barrier against intense heat, molten metal, and explosive force, reducing the risk of severe burns and injuries. The rating of the clothing indicates its protective capability against specific incident energy levels measured in calories per square centimetre (cal/cm²). To better understand the PPE categories applicable to your gear, explore our Arc Flash PPE Category guide.

What Is the Difference Between FR and Arc Flash Clothing?

FR clothing is designed to resist ignition and self-extinguish once the ignition source is removed. While FR clothing provides protection against fire hazards, it may not offer adequate protection against the thermal energy produced by an electrical explosion. PPE, on the other hand, is specifically designed and tested to withstand the intense energy released during an explosion. Arc-rated clothing meets FR standards and provides additional protection against the extreme temperatures and molten metal associated with electric arc incidents.

Sign Up for Electricity Forum’s Arc Flash Newsletter

Stay informed with our FREE Arc Flash Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

When Should It Be Worn?

PPE should be worn whenever there is a risk of exposure to electrical hazards that can produce an explosion. This includes tasks such as maintenance, testing, and troubleshooting of energized electrical equipment. NFPA 70E requires workers to wear appropriate PPE, including arc-rated clothing, when the calculated incident energy exceeds 1.2 cal/cm², which can cause second-degree burns.

Related Articles: