Arc Flash Warning Label

By R.W. Hurst, Editor

NFPA 70e Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA FS3529 Fact Sheet – Lockout/Tagout Safety Procedures

- Learn how to disable machines and isolate energy sources safely

- Follow OSHA guidelines for developing energy control programs

- Protect workers with proper lockout devices and annual inspections

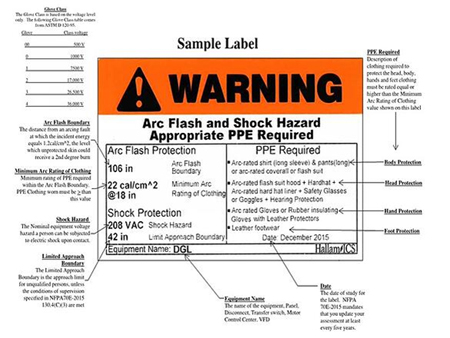

An arc flash warning label identifies electrical hazards, shows incident energy levels, and provides PPE requirements to protect workers from arc flash injuries. Required by NFPA 70E for safe electrical maintenance.

What is an Arc Flash Warning Label?

An arc flash warning label is a crucial element in electrical safety, ensuring that workers know the hazards of working near energized equipment.

✅ Clearly identifies electrical hazards and arc flash risk levels

✅ Includes incident energy and PPE requirements per NFPA 70E

✅ Helps ensure workplace safety and compliance with OSHA standards

These labels help protect individuals by providing critical information about potential dangers and required precautions.

The label plays a critical role in safeguarding workers from the devastating effects of hazards. These labels, adhering to specific requirements outlined in NFPA 70E, provide vital information about potential hazards and necessary safety precautions. Understanding the NFPA 70E labeling requirements is key to ensuring your warning labels meet compliance standards.

Request a Free Training Quotation

What is Required on an Arc Flash Warning Label?

Arc flash hazard labels must include several key pieces of information to communicate the risks and necessary safety measures effectively. According to NFPA 70E, the standard for electrical safety in the workplace, the following details are required:

-

Nominal Voltage: The voltage rating of the equipment, which helps determine the level of risk.

-

Incident Energy: The amount of thermal energy (in calories per square centimetre) that a worker could be exposed to at a specified working distance.

-

Arc Flash Boundary: The distance from the energized equipment within which a person could receive a second-degree burn.

-

PPE Requirements: The level of personal protective equipment (PPE) necessary to safely work within the AF boundary.

-

Shock Hazard Information: Details about the potential for electric shock, including approach boundaries for qualified and unqualified persons. For a complete overview of arc flash concepts and regulations, visit our Arc Flash information page.

Sign Up for Electricity Forum’s Arc Flash Newsletter

Stay informed with our FREE Arc Flash Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

How Often Does an Arc Flash Warning Label Need to Be Updated?

Arc flash safety labels should be reviewed and updated whenever there is a significant change to the electrical system. NFPA 70E recommends updating these labels every five years or sooner if modifications are made that could alter the AF hazard analysis. Regular updates ensure that the information remains accurate and reflective of the current state of the electrical system. Learn how to avoid the 10 most common errors in arc flash analysis when preparing safety labels and equipment assessments.

What Equipment Needs an Arc Flash Warning Label?

Any piece of electrical equipment that could pose an AF hazard requires a warning label. This includes:

-

Control Panels: Panels that house various electrical components and circuits.

-

Switchgear: Equipment used for controlling, protecting, and isolating electrical circuits.

-

Panelboards and Distribution Boards: Boards that distribute electrical power to different circuits.

-

Transformers: Devices that transfer electrical energy between circuits through electromagnetic induction.

-

Motor Control Centers: Assemblies of one or more enclosed sections with a common power bus, primarily containing motor control units. Our Arc Flash Assessment guide explains how to determine incident energy levels and appropriate PPE for labelling.

What Information is Required to be on an Arc Flash Warning Label?

Labels must provide comprehensive information to ensure safety. This includes:

-

Nominal Voltage: Indicates the electrical potential difference.

-

Incident Energy: Specifies the heat energy at a working distance that can cause burns.

-

AF Boundary: Defines the safe distance for personnel.

-

PPE Level: Lists the necessary personal protective equipment based on the hazard level.

-

Shock Hazard Approach Boundaries: Details the distances within which different levels of PPE are required.

Where Should a Label be Placed on the Equipment?

Labels should be placed on the exterior of the electrical equipment, in a location that is easily visible to workers before they perform any tasks. For example, they should be affixed to the door of a control panel or the cover of a switchgear. The placement should ensure that the label is readable from the working distance specified on the label, enhancing visibility and awareness. For deeper insights into labelling and documentation best practices, explore our Arc Flash Analysis and Labelling Solutions.

Why Do I Need to Have Two Arc Flash Warning Labels for Some Equipment?

Some equipment may require multiple labels due to the presence of different sections with varying levels of hazard. For instance, a control panel might have a section for low-voltage circuits and another for high-voltage circuits, each with different incident energy levels and PPE requirements. Having two labels ensures that workers are aware of the specific hazards associated with each section and can take appropriate precautions.

Labels are a fundamental part of maintaining electrical safety in the workplace. They provide essential information about potential hazards and the necessary precautions to protect workers. By adhering to NFPA 70E standards and regularly updating these labels, organizations can ensure that their electrical safety programs remain effective and compliant with industry regulations. Proper placement and comprehensive information on these labels are crucial for safeguarding the health and safety of all personnel working with or near electrical equipment. To ensure workplace safety, refer to the required Arc Flash PPE categories aligned with the label incident energy values.

While labels are essential, they are just one component of a comprehensive electrical safety program. Proper training, adherence to safe work practices, and the use of appropriate PPE are equally important for mitigating risks.

Arc flash warning labels are vital tools for communicating hazards and ensuring worker safety. By understanding the requirements, placement, and importance of these labels, employers and workers can create a safer work environment and minimize the risk of electrical explosions. If you're preparing to update your labels, our 70E Arc Flash Training course provides essential education for staying compliant and informed.

Related Articles: