Arc Flash

Arc Flash Meaning Explained

Arc Flash Meaning explains the hazardous energy released by arc faults in switchgear and panels, guiding electrical safety per NFPA 70E, incident energy calculations, PPE selection, short-circuit studies, and effective arc flash hazard analysis.

Understanding Arc Flash Meaning in Electrical Safety

Arc Flash Meaning - Simply put, it is a sudden release of energy due to an arcing fault between electrical conductors or between a conductor and a ground. This arc flash event occurs when an electrical arc forms, creating a high-temperature plasma that can cause severe damage and injury. An arc flash (AF) typically happens when energized electrical equipment experiences a short circuit, often triggered by equipment failure, human error, or conductive dust. The intense heat and light produced during an AF can be catastrophic, making understanding and preventing these events crucial for electrical safety. For a concise overview, see the detailed arc flash definition provided by industry experts today.

What Are the Physical Characteristics?

The physical characteristics of an AF are both dramatic and dangerous. When arc flash occurs, the temperature can reach levels comparable to the surface of the sun, melting and vaporizing metal parts. Key characteristics include:

Understanding how an electrical arc blast intensifies pressure and debris hazards can guide equipment layout decisions.

- Heat and Light: AF emits intense heat and brilliant light, capable of causing severe burns (degree burns) and temporary or permanent blindness.

- Arc Blast: Alongside the flash, an arc blast occurs, generating a pressure wave that can damage equipment, rupture eardrums, and throw workers across a room.

- Molten Metal: The intense heat liquefies metal parts, producing molten metal that can cause additional injuries and ignite fires.

- Incident Energy: This is the energy released during an AF, measured in calories per square centimeter (cal/cm²), which directly impacts the severity of burns and the damage radius.

Documented cases of arc flash injuries underscore the need for robust PPE and emergency response planning.

Why is Understanding the Arc Flash Meaning Important for Electrical Safety?

Understanding AF is critical for maintaining a safe working environment in any setting that involves electrical systems. The risks of arc flash include severe injuries, such as degree burns, electric shocks, and potential fatalities. Awareness and proper precautions can significantly reduce these risks. Key reasons for understanding AF include:

Recognizing the triggers outlined in this overview of common causes supports targeted risk assessments and maintenance priorities.

- Worker Safety: Proper knowledge and training help protect workers from the severe consequences of AF incidents.

- Regulatory Compliance: Compliance with safety standards, such as those outlined by OSHA and NFPA 70E, is essential to avoid legal penalties and ensure a safe workplace.

- Preventive Measures: Understanding common causes of arc flash, such as faulty circuit breakers, short circuits, and arcing faults, enables the implementation of effective preventive measures.

Guidance from NFPA 70E arc flash resources helps standardize labeling, boundaries, and PPE selection across facilities.

What Distinguishes It from Other Electrical Hazards?

An AF is distinct from other electrical hazards due to its unique characteristics and the extreme energy release involved. Unlike electric shocks, which typically occur due to direct contact with live electrical parts, an AF results from an arcing fault that creates an explosive release of energy. Key distinctions include:

A practical comparison of arc flash versus arc blast illuminates the different controls required for thermal versus pressure hazards.

- Energy Release: The incident energy in an AF is much higher than in typical electric shock scenarios, leading to more severe injuries and damage.

- Heat and Light: The intense heat and light produced are specific to AF events, causing burns and blindness that are not common in other electrical hazards.

- Pressure Wave: The arc blast that accompanies an AF is a unique phenomenon, capable of causing structural damage and additional injuries beyond electrical burns.

How Do the Concepts of Incident Energy and AF Boundaries Relate?

Incident energy and AF boundaries are critical concepts in managing the risks associated with AF events. Understanding the sequence of an arc flash incident supports more accurate modeling and training exercises.

-

Incident Energy: This refers to the amount of thermal energy (measured in cal/cm²) that a worker might be exposed to during an AF. Higher incident energy levels increase the severity of potential injuries and dictate the type of personal protective equipment (PPE) required. Protective clothing and other PPE must be rated to withstand the calculated incident energy to protect workers effectively.

-

AF Boundaries: These are safety zones established around potential hazards to protect workers. There are typically three boundaries:

- Flash Protection Boundary: The distance at which the incident energy equals 1.2 cal/cm², the threshold for curable burns.

- Limited Approach Boundary: The distance within which only qualified workers, with appropriate training and PPE, may enter.

- Restricted Approach Boundary: A closer boundary that requires a documented work plan and special equipment to enter.

AF events present significant risks in any environment involving electrical systems. By understanding the meaning of AF, recognizing its physical characteristics, and implementing appropriate safety measures, organizations can protect their workers and ensure compliance with safety standards. Key concepts such as incident energy and AF boundaries play a vital role in defining safety protocols and selecting the right protective devices. With proper education, preventive maintenance, and adherence to safety guidelines, the risks of arc flash can be effectively managed and minimized.

Related Articles

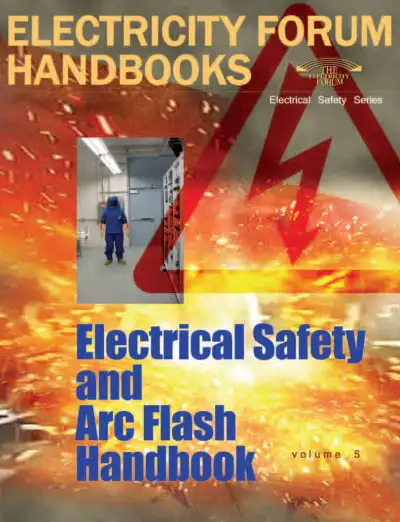

Download Our FREE Arc Flash Handbook

Electrical Safety and Arc Flash Handbook, Vol. 5

The most popular of our handbook series, the Electrical Safety and Arc Flash Handbook Volume 5 is a highly coveted source of information for electricians, electrical engineers and utility professionals who are exposed to the deadly risk of arc flash incidents. This 100+ page handbook examines such safety issues and arc flash mitigation requirements as Establishing an Arc Flash Loss Prevention Program; Arc Flash Safety Basics: Testing Update; Controlling Electrical Hazards; Creating a Lock-out Tag-out Program; and Compliance Takes More Than a Label.

In this edition, we dive deep into the science behind arc flash, including its causes, the catastrophic effects it can have on both personnel and equipment, and the latest standards and technologies for protection. With the evolving landscape of electrical safety, this handbook provides up-to-date guidance on hazard identification, risk assessment, and the implementation of safe work practices.

Volume 5 offers practical insights into designing, managing, and enforcing electrical safety programs, with a strong focus on arc flash risk analysis, protective equipment selection, and the development of safety protocols that comply with national and international regulations. Through real-world examples, case studies, and expert recommendations, we aim to enhance the understanding of arc flash dynamics and the critical need for effective protection and safety planning in the electrical industry.

Latest Arc Flash Articles

Arc Flash Labels Explained

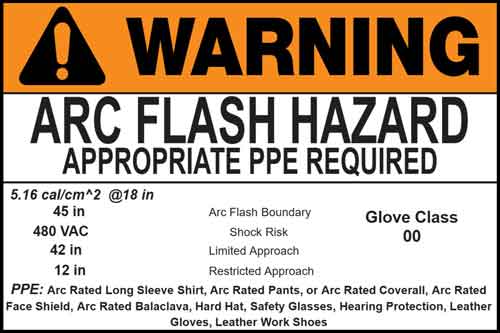

Arc flash labels warn workers of electrical hazards by displaying incident energy, PPE requirements, and approach boundaries. NFPA 70E and OSHA standards require these safety labels to improve compliance and reduce arc flash accident risks.

What are Arc Flash Labels?

Arc flash labels are essential for communicating electrical hazards in workplaces, and may also be referred to as electrical panel labels or safety warning labels in compliance programs.

✅ Identify arc flash hazard levels and PPE needs

✅ Display approach boundaries for electrical safety

✅ Support NFPA 70E and OSHA compliance requirements

Request a Free Training Quotation

Arc flash labels are not just compliance items—they must also satisfy NFPA 70E labelling requirements, which state that every energized electrical panel likely to be serviced requires a clear hazard label. Aligning with ANSI Z535 standards enhances clarity, for example, by using signal words like DANGER for high-risk hazard situations and WARNING for moderate risks. Whether placed on industrial switchboards or motor control centers, well-crafted electrical hazard warning stickers support quick recognition and safe work planning.

Beyond placement, they need to convey specifics like PPE category labelling or incident energy marking requirements. For example, a label may denote a 25 cal/cm² boundary for Category 3 protection. Such equipment hazard signage plays a critical role in high-energy environments—like manufacturing plants, data centers, and utilities, by signalling required safety precautions before maintenance begins.

Crucial Information

Arc flash labels provide information such as voltage, incident energy, and PPE requirements, fulfilling AF labeling requirements for industrial facilities, manufacturing plants, and data centers. By following the labelling specifications set forth by NFPA 70E Arc Flash Label Requirements and keeping the analysis or study up to date, employers can help ensure that workers are protected from the risks of electrical explosion and other electrical hazards.

AF and shock hazards pose serious safety risks to anyone working on or near energized electrical equipment. To help prevent injury or death, read our What is Arc Flash Labelling article, which clearly identifies potential hazards and documents the required personal protective equipment (PPE) needed before any work begins.

Arc Flash Labeling for Electrical Panels and Equipment

Arc flash labels are essential hazard signage for identifying shock and electrical hazard risks on energized electrical equipment. In compliance with NFPA 70E and OSHA AF labelling requirements, these safety warning plates communicate critical details such as incident energy, arc rating, PPE category, and approach boundaries. Proper equipment labelling not only ensures compliance but also helps protect workers in industrial facilities, manufacturing plants, and data centers where electrical hazards are common.

An arc flash label must be securely attached to the electrical panel or relevant equipment, remaining legible even in challenging environments. These decals display vital information — including nominal system voltage, restricted approach boundary, and incident energy levels in cal/cm² — enabling workers to select the right PPE before performing maintenance. In many cases, customized electrical panel labels can include site-specific hazard data from a hazard analysis or study, ensuring the signage reflects actual conditions and remains accurate over time.

Placement and Visibility

Electrical equipment is often labelled with warnings about potential hazards and indicate that specific PPE and tools are required. They must be durable and remain legible in harsh environments, functioning as hazard signage that withstands heat, moisture, and abrasion. The markers should be placed in a location that is easily visible and readable from a safe distance. Consistency in the labels’ format and location also helps comply with PPE specifications. Our When is Equipment Labeling Required for Arc Flash Hazards? guide explains which equipment types and conditions must have hazard labels.

Arc Flash Label Components and Compliance Requirements

| Label Element | Purpose | NFPA 70E/OSHA Requirement | Example Information Shown |

|---|---|---|---|

| Incident Energy Rating | Shows calculated heat energy from an AF | Must be displayed in cal/cm² | 8.5 cal/cm² |

| PPE Category | Indicates minimum PPE needed for protection | Required for worker safety compliance | Category 2 PPE |

| Approach Boundaries | Defines safe working distances for qualified persons | Required to prevent accidental contact | Limited: 42 inches, Restricted: 12 inches |

| Equipment Identification | Identifies specific panel, breaker, or equipment | Helps trace hazard source and maintenance logs | Panel ID: SWBD-01 |

| Date of Analysis | Shows when AF study was last conducted | Ensures up-to-date hazard assessment | July 2024 |

NFPA 70E Minimum Label Requirements

NFPA 70E labeling requirements ensure that every energized panel or piece of equipment has hazard signage displaying voltage, approach boundaries, and PPE details. Many companies also follow ANSI Z535 standards for color codes and signal words, which makes these electrical hazard warning stickers clear and consistent.

OSHA requires arc flash safety signs and equipment hazard signage in any facility where workers may be exposed to electrical risks. This includes PPE category labeling and incident energy marking requirements, so that anyone approaching the equipment can quickly identify the correct protective gear.

NFPA 70E-2021 Article 130.5(H) outlines the minimum specifications for arc flash labelling and the information that must be included on the label. At a minimum, the label must display:

-

Nominal system voltage

-

Restricted approach boundary

-

Hazard-appropriate PPE

Additionally, the label must include at least one of the following:

-

Available incident energy and the corresponding working distance

-

AF PPE category from NFPA 70E Table 130.7(C)(15)(a) or Table 130.7(C)(15)(b) (but not both)

They should follow NFPA 70E standards for format and content, which specify equipment labelling details for AF safety. The minimum arc rating of clothing and the site-specific PPE level must also be listed. For more on these specifics, see Arc Flash Warning Label for examples of compliant label designs.

Design, Size, and Customization

Although NFPA 70E does not specify label size, location, or quantity, it’s important they remain clearly visible and easy to read. Many facilities choose custom label templates to ensure their design meets arc flash labelling and electrical safety best practices. While including shock risk assessment information is common, it is not required by NFPA 70E.

Exceptions and Alternate Documentation

An exception in 130.5(H) allows other forms of documentation instead of signs in supervised industrial installations. For example, if a maintenance mode setting is used to reduce incident energy and PPE requirements, the label must clearly indicate this, or it should show the worst-case energy release, with the maintenance mode reduction detailed in the Energized Work Permit.

Accuracy and Updating

One of the key steps in an AF analysis is ensuring that the correct label is applied to each piece of electrical equipment. The equipment names on the one-line diagram should match those on the labels to avoid errors.

NFPA 70E requires studies to be reviewed for accuracy whenever power system changes occur and at least once every five years. It is not necessary to update them solely because NFPA 70E specifications change—only if the electrical system itself has been modified.

For detailed compliance solutions, see Arc Flash Analysis and Labeling Solutions.

Related Context for Safety

A key distinction is explained in Arc Flash vs Arc Blast, showing how pressure waves add to the danger of AF incidents.

The risk of uncontrolled discharge is especially high in systems with high fault current capacity and where NFPA 70E and CSA Z462 safety procedures are not followed.

Explore the role of electrical explosions in accidents and how they threaten safety.

Learn more in our Arc Flash PPE Clothing guide.

With proper maintenance, hazard assessment, and compliance to NFPA 70E, CSA Z462, and IEEE 1584, these events are largely preventable.

Related Articles

Arc Flash Boundary Calculation: How to Determine Safe Working Distances

Arc flash boundary calculation is a critical process used to determine the safe distance from energized electrical equipment where the thermal energy from an arc flash drops to 1.2 cal/cm² — the threshold for second-degree burns. This assessment helps define a protective zone around potential arc sources and is essential for selecting appropriate PPE, labeling equipment, and maintaining regulatory compliance. For electrical engineers, understanding how to perform and interpret calculations is not just a code requirement — it’s a vital skill for designing safer systems, protecting workers, and reducing operational risk in industrial and commercial environments.

Request a Free Training Quotation

To determine the arc flash boundary, safety professionals must calculate the incident energy expected at various distances from the potential arc source. The goal is to identify the point at which the incident energy equals 1.2 cal/cm², which is recognized as the threshold for a second-degree burn. This value is critical in power system studies because it defines the minimum safe distance a worker can stand without sustaining serious thermal injuries. By using formulas provided in standards like IEEE 1584, engineers can calculate the incident energy based on system parameters and establish safe working boundaries accordingly.

What Is an Arc Flash Boundary?

The arc flash boundary is the distance from an energized electrical part within which a person could receive a second-degree burn if an arc flash were to occur. Defined in NFPA 70E, this boundary helps determine the minimum safe approach distance for personnel working on or near energized equipment. It’s a key element of an arc flash risk assessment and directly influences personal protective equipment (PPE) selection.

Why Accurate Boundary Calculation Matters

Calculating the arc flash boundary isn’t just a regulatory formality — it’s essential for workplace safety. If the boundary is underestimated, personnel could be exposed to dangerous energy levels without adequate PPE. If it’s overestimated, it could lead to unnecessary protective measures and reduced efficiency. Proper boundary determination protects lives, reduces liability, and ensures compliance with OSHA and NFPA 70E standards.

Arc Flash Boundary Formula (with example)

The arc flash boundary calculation is based on this formula (from IEEE 1584-2018):

The arc flash boundary calculation is based on this formula (from IEEE 1584-2018):

D = √(4.184 × Cf × En × (t ÷ 0.2)) ÷ Ei

Where:

- D = distance in mm (arc flash boundary)

- Cf = conversion factor

- En = incident energy in J/cm²

- t = arc duration in seconds

- Ei = incident energy limit for second-degree burns (typically 1.2 cal/cm² or 5 J/cm²)

Example Calculation:

- En = 8 cal/cm²

- t = 0.5 sec

- Cf = 1.0

- Ei = 5 J/cm²

D = √(4.184 × 1.0 × 8 × (0.5 ÷ 0.2)) ÷ 5 = √(4.184 × 8 × 2.5) ÷ 5 = √(83.68) ÷ 5 = 9.15 mm (adjusted for units)

This calculated distance would then be used to establish the arc flash boundary for this specific scenario.

Key Inputs for the Calculation

Accurate arc flash boundary calculation requires several critical inputs:

-

Incident energy (cal/cm²): Calculated based on system voltage, fault current, and clearing time.

-

Working distance (inches/mm): The distance between the worker and the potential arc source.

-

Arcing current: Estimated using IEEE 1584 equations or software tools.

-

System configuration: Equipment type (open air, in a box, etc.) and electrode configuration affect results.

These inputs must be measured or modeled using arc flash analysis software, often based on IEEE 1584 guidelines.

Using IEEE 1584 in Real-World Scenarios

The IEEE 1584 standard is the most widely accepted methodology for performing arc flash calculations. The updated IEEE 1584-2018 version introduces more refined models based on equipment enclosure sizes, voltage ranges, and gaps between conductors.

In practice:

-

Facilities use software like SKM PowerTools or EasyPower to model systems.

-

Field data (breaker clearing times, conductor spacing) must be accurate.

-

Default values should only be used when site-specific data isn't available.

This method ensures calculations are representative of actual conditions and provide realistic protection boundaries.

Common Mistakes and Safety Tips

Mistakes in arc flash boundary calculation can expose workers to fatal risks. Common pitfalls include:

-

Using default values without site validation

-

Applying incorrect working distances

-

Misidentifying equipment configuration

-

Failing to update calculations after system changes

-

Ignoring transient operating conditions or upstream failures

Tip: Always have boundary values reviewed by a qualified electrical engineer and update them whenever equipment is added, modified, or maintained.

Boundary Calculation vs PPE Category Chart

PPE CategoryIncident Energy RangeTypical BoundaryCategory 11.2–4 cal/cm²19–25 inchesCategory 24.1–8 cal/cm²36–48 inchesCategory 38.1–25 cal/cm²60–120 inchesCategory 425.1–40 cal/cm²120+ inches

When to Use Software vs Manual Calculation

Use manual calculations for:

-

Educational purposes

-

Verifying software outputs

-

Low-complexity systems

Use software tools for:

-

Complex or large power systems

-

High-accuracy requirements

-

Generating arc flash labels and documentation

Most facilities rely on software due to the volume of variables and required updates.

Related Pages

Arc Flash Boundary Table By Incident Energy

What's the Arc Flash Boundary for 8 cal/cm²?

Electrical Arc Flash

Electrical arc flash is a high-energy hazard from fault currents, releasing intense heat and pressure; NFPA 70E compliance, PPE, incident energy analysis, arc flash boundaries, and labeling support risk assessment and mitigation in switchgear.

Electrical Arc Flash and Its Impact on Workplace Safety

An electrical arc flash is a dangerous and potentially deadly event that can occur when an arcing fault travels through the air instead of its intended conductor, creating a short circuit or arc. This can happen in a variety of settings, such as power plants, manufacturing facilities, and even in homes and offices. For a concise overview, see the arc flash definition and key concepts explained.

Electrical Arc Flash occurs more often than you think. It produces some of the highest temperatures on earth - up to 35,000 degrees Fahrenheit at the arc terminals. The heat energy is four times the surface temperature of the sun. These extreme thermal conditions are central to the arc flash blast explosion mechanisms documented in industry research.

Visit our CSA Z462 Arc Flash Training Page

During an explosion, arc flash can reach several thousand degrees Celsius, causing an intense and explosive release of energy, light, and sound. This can result in burns, injuries, and even death to those in close proximity to the blast. As a result, the National Fire Protection Association nfpa has produced a workplace electrical safety standard called NFPA 70E. To understand when these events are most likely, review the circumstances under which an arc flash can occur to support risk assessments.

In Canada, CSA Z462 is the recommended standard for workplace safety.

Technicians and supervisors benefit from clarifying how an arc flash occurs before drafting or updating procedures.

Visit our NFPA 70E Arc Flash Training Page

To prevent an arc flash, it is essential to follow safety protocols, such as using proper personal protective equipment, de-energizing equipment before servicing or maintenance, and maintaining a safe distance from equipment when it is energized. Employers should also ensure that their employees are trained in electrical safety and that safety procedures are always followed. Understanding the destructive forces associated with an electrical explosion reinforces the need for strict lockout/tagout and verification practices.

Causes of Electrical Arc Flash

There are various causes, some of which include:

-

Equipment failure: Electrical explosions can occur when equipment fails, leading to a short circuit or an arc.

-

Accidental contact: Accidental contact with live parts, such as when someone touches or drops a tool onto an energized conductor, can also cause an explosion.

-

Improper installation: Explosions can be caused by improper installation of equipment or components, such as inadequate grounding, loose connections, or overloading in circuit breakers.

-

Human error: Human error can also cause explosions, such as miscommunication during maintenance or repair work, failure to follow safety procedures or inadequate training.

-

Environmental factors: Environmental factors such as humidity, dust, or corrosion can also contribute to explosions, increasing the likelihood of equipment failure or electrical discharge.

It is essential to identify the causes of an arc flash event to prevent such events from happening. Employers should train their employees on the causes and risks of accidents and ensure that safety protocols are always followed. Regular equipment maintenance and inspections can also help identify potential hazards and prevent incidents. For foundational context that aids hazard recognition, revisit what an arc flash is and how it differs from shock hazards.

The Nature of Electrical Arc Flash

An electrical arc flash is a sudden, explosive release of energy that occurs when an current flows through the air instead of its intended path, such as through a conductor. The energy released during an explosion can be extremely high, causing temperatures to rise to several thousand degrees Celsius, creating a bright light and loud noise. In addition, the AF can cause an intense blast of pressure, debris, and hot gases, resulting in serious injuries, burns, or even fatalities to people nearby. These dynamics often manifest as an intense electrical arc blast that propels shrapnel and superheated gases.

The duration and intensity of an explosion depend on several factors, including the amount of energy released, the proximity of individuals to the blast, and the type and condition of the equipment involved. Electrical explosions can also produce a large amount of molten metal, which can cause additional damage to equipment and nearby structures.

In addition to the physical damage caused by an explosion, it can also have long-term effects on the health of individuals exposed to it. For example, the bright light and loud noise produced by a blast can cause vision and hearing damage, and the intense heat can cause burns and other thermal injuries. In addition, the pressure wave generated by the AF can cause traumatic injuries, such as concussion, blunt force trauma, or even permanent hearing loss.

Preventing such occurrences is critical to protecting individuals and property from harm. Therefore, employers should take appropriate measures to identify and mitigate potential hazards associated with systems, provide employees with proper training and protective equipment, and ensure that safety protocols are always followed.

How can I protect myself from electrical arc flash?

Protecting yourself from the electrical arc is essential to prevent injuries or fatalities. Here are some ways to protect yourself from the dangers of arc flash:

-

Wear appropriate personal protective equipment (PPE): Protective equipment such as fire-resistant clothing, gloves, safety glasses, and face shields can help protect against the heat, light, and debris produced by an explosion.

-

Follow safety procedures: Always follow safety procedures when working with or around systems, including de-energizing equipment before servicing or maintenance, using lockout/tagout procedures, and maintaining a safe distance from energized equipment.

-

Get proper training: Ensure you are trained on electrical safety procedures and best practices, and keep up-to-date with any changes or updates to safety protocols.

-

Use insulated tools: Insulated tools can help prevent accidental contact with live components.

-

Conduct regular maintenance: Regular maintenance and inspection of equipment can help identify potential hazards and prevent explosion incidents.

-

Install protective barriers: Installing protective barriers, such as enclosures or barricades, can help prevent accidental contact with energized equipment.

-

Stay alert and aware: Be aware of your surroundings and alert for potential hazards, such as damaged equipment, exposed wiring, or improperly installed components.

Following these safety measures and taking appropriate precautions can help protect yourself from the electrical arc and reduce the risk of injury or harm.

Related Articles

NFPA 70E – Arc Flash Electrical Workplace Safety

NFPA 70E electrical safety standard outlines standards for electrical safety in the workplace, helping prevent arc flash and shock hazards. It mandates the proper use of PPE, risk assessments, and safe work practices to protect workers.

What Is NFPA 70E?

NFPA 70E is a critical standard that helps reduce electrical workplace hazards.

✅ Defines best practices for electrical safety and arc flash prevention

✅ Requires PPE selection and maintenance for worker protection

✅ Mandates training, risk assessments, and safety procedures

Request a Free Training Quotation

Practical Guidance in NFPA 70E

NFPA 70E is more than just a set of compliance requirements—it offers practical tools that employers can apply directly to reduce electrical hazards in the workplace. The standard outlines structured procedures for energized work permits, job safety planning, and task-specific risk assessments. These actionable frameworks help organizations build a proactive safety culture by identifying and mitigating electrical risks before work begins. By following NFPA guidelines and methodologies, employers can standardize safe work practices, ensure worker accountability, and reduce the likelihood of injury due to human error or oversight.

For real-world examples and deeper insight into how these principles apply, see our Practical Guidance in NFPA 70E page.

NFPA 70E 2024 Updates: Key Changes You Need to Know

The 2024 edition introduces several important updates designed to clarify requirements and improve workplace electrical safety. Among the key changes are enhancements to the arc flash risk assessment process, updates to the incident energy analysis methodology, and refinements to the use of the arc flash PPE category tables. The latest revision also enhances the language surrounding the hierarchy of risk controls, making it easier for employers to prioritize hazard elimination, engineering controls, and administrative procedures over relying solely on PPE.

Additionally, new guidance was added to help facilities apply the standard more consistently across complex electrical systems. These changes reflect the NFPA's ongoing efforts to align with real-world work conditions and enhance clarity for both safety managers and electrical workers.

For a complete breakdown of what’s changed, visit our NFPA 70E 2024 Update page.

Why Was NFPA 70E Developed? OSHA and Safety Gaps Explained

NFPA 70E was created in response to a critical gap in workplace safety regulations for electrical hazards. While OSHA sets the legal framework for electrical safety, it does not provide detailed instructions for how to perform risk assessments, issue protective equipment, or establish safe work procedures. Recognizing this, OSHA requested that the National Fire Protection Association develop a standard that would offer the practical guidance needed to implement electrical safety programs in the field.

First published in 1979, the arc flash standard has since evolved into the definitive resource for managing arc flash, arc blast, shock, and electrocution hazards in the workplace. It provides employers with a clear methodology to protect workers from live electrical exposures, ensuring compliance with OSHA requirements while fostering safer work environments.

For a deeper look into how this standard originated, visit our NFPA 70E development history page.

Arc Flash Risk Assessment and Protection Requirements

One of the core components of this electrical safety document is its detailed guidance for managing arc flash hazards. The standard outlines a structured approach to performing arc flash risk assessments, which includes identifying energized equipment, calculating incident energy levels, and determining appropriate protection boundaries. Employers are required to document this analysis and ensure that workers understand the risks associated with performing tasks on or near live equipment.

The standard also specifies when arc flash warning labels must be applied, what information those labels must include, and how to select proper PPE based on calculated incident energy or the arc flash PPE category method. These requirements ensure that all personnel are properly informed and protected when working in areas where arc flash hazards are present.

To explore specific risk assessment methods and labelling criteria, visit our NFPA 70E Arc Flash Requirements page.

NFPA 70E PPE Requirements: Categories, Ratings, and Gear

NFPA 70E provides clear guidance on the selection and use of personal protective equipment (PPE) to safeguard workers from electrical hazards, including arc flash and shock. PPE requirements are based on either incident energy analysis or predefined arc flash PPE categories. These categories range from CAT 1 to CAT 4, each specifying the minimum arc rating of flame-resistant clothing and additional protective gear, such as gloves, balaclavas, face shields, and insulated tools.

The standard emphasizes that PPE is the last line of defence in the hierarchy of risk control methods. Workers must wear properly rated gear for the specific level of hazard identified in the risk assessment. Additionally, garments must meet standards for arc thermal performance (ATPV) and be maintained in good condition to remain compliant.

For a full breakdown of clothing ratings, equipment combinations, and selection methods, see our NFPA 70E PPE Requirements guide.

Arc Flash Labelling Requirements Under NFPA 70E

Labelling is a critical component of this workplace safety framework, ensuring that workers can quickly identify electrical hazards and make informed decisions before beginning any task. The standard requires that arc flash labels be affixed to electrical equipment likely to require examination, adjustment, servicing, or maintenance while energized. These labels must clearly display information such as nominal system voltage, arc flash boundary distance, and either the calculated incident energy or the appropriate PPE category.

Effective labelling improves safety awareness and reinforces the use of proper personal protective equipment. Labels must be kept up to date, especially after modifications to the electrical system or following an updated arc flash risk assessment.

To review the specific label formatting and content requirements, visit our Arc Flash Labeling Requirements page.

How to Use the NFPA 70E Arc Flash Table (130.7(C)(15))

NFPA 70E includes arc flash PPE category tables that provide a simplified method for selecting protective equipment without performing a full incident energy analysis. These tables—most notably Table 130.7(C)(15)(a) and (b)—list specific tasks, equipment types, and voltage levels, along with the corresponding PPE category required for safe operation.

To use the tables effectively, the equipment must meet specific conditions, including proper maintenance and a short-circuit current within defined limits. If any conditions fall outside of the table’s scope, a full arc flash study is required. The tables also include approach boundaries, helping employers determine safe working distances for shock protection.

For guidance on how to interpret and apply these tables in real-world scenarios, visit our NFPA 70E Arc Flash Table Guide.

NFPA 70E Training Requirements and Certification Guidelines

NFPA 70E requires that employees working on or near energized electrical equipment receive proper training to recognize electrical hazards and understand how to apply safe work practices. Training must be provided to both qualified and unqualified workers, with the content tailored to their specific job duties and level of exposure.

Qualified workers must be trained to distinguish exposed live parts, determine the nominal voltage, and understand the approach boundaries. Unqualified workers, although not expected to perform energized work, must still receive training on the hazards and restricted access areas. The standard also requires refresher training at intervals not to exceed three years, or whenever job duties or safety procedures change.

Many employers choose to provide formal certification to document compliance and demonstrate due diligence in the event of an audit or incident.

To learn more about certification options and training delivery methods, visit our NFPA 70E Certification and Training page.

NFPA 70E Compliance Checklist: Steps to Ensure Electrical Safety

Ensuring full compliance requires more than just training and PPE—it involves a structured, ongoing process of hazard identification, documentation, and enforcement of procedures. From conducting arc flash risk assessments to properly labelling equipment and verifying employee qualifications, every step must be carefully documented and reviewed.

To help you stay organized and meet regulatory expectations, we’ve created a dedicated NFPA 70E Compliance Checklist that outlines all the essential steps for a compliant electrical safety program.

Frequently Asked Questions About NFPA 70E

What is NFPA 70E, and why is it important?

NFPA 70E is the Standard for Electrical Safety in the Workplace, developed by the National Fire Protection Association. It provides guidelines to protect workers from electrical hazards, including arc flash, electric shock, electrocution, and arc blast. Employers use this electrical safety document to implement safe work practices, comply with OSHA requirements, and minimize the risk of electrical incidents.

How often is NFPA 70E updated, and why should I stay current?

NFPA 70E is revised every three years to reflect changes in technology, work practices, and safety research. The latest edition was released in 2024. Staying current ensures that your electrical safety program complies with the most effective methods for risk assessment, PPE selection, and hazard mitigation.

Who needs NFPA 70E training?

Both qualified and unqualified workers who may be exposed to electrical hazards require training. Qualified workers must be trained to recognize and avoid energized conductors, assess incident energy levels, and follow proper lockout/tagout procedures to ensure their safety. Unqualified workers should be trained to recognize hazards and understand how to avoid restricted areas.

What is the difference between NFPA 70 and NFPA 70E?

NFPA 70 is the National Electrical Code (NEC), which governs the installation of electrical wiring and systems. NFPA 70E, on the other hand, focuses on electrical safety in the workplace and outlines procedures for preventing injuries related to working on or near energized equipment. While NFPA 70 focuses on design and installation, this electrical safety document primarily concerns worker protection and hazard control.

Is 70E compliance legally required by OSHA?

NFPA 70E itself is not a law, but OSHA recognizes it as an industry consensus standard. Following NFPA guidelines is one of the most effective ways to comply with OSHA’s General Duty Clause, which requires employers to provide a workplace free from recognized hazards. Non-compliance may result in OSHA citations if electrical risks are not properly addressed.

How do I select the correct PPE under NFPA 70E?

PPE selection is based on either an incident energy analysis or the use of arc flash PPE category tables in the standard. The NFPA electrical safety document outlines the minimum arc rating for each PPE category (CAT 1–CAT 4), depending on the electrical task and system conditions. Employers must ensure that all PPE is properly rated, maintained, and used in accordance with the standard’s guidelines.

What is an Electrically Safe Work Condition (ESWC)?

An Electrically Safe Work Condition is a state in which electrical conductors and equipment have been de-energized, locked out, tested for the absence of voltage, and confirmed safe for work. The arc flash electrical safety standard provides specific steps for establishing an ESWC, which is the preferred condition before performing any maintenance, testing, or repair tasks.

Explore More Arc Flash Topics:

Explore our Arc Flash Training Programs or contact us to Request a Free Training Quotation for group safety sessions and PPE consultation.

Electrical Safety Ontario

Electrical Safety Ontario 2015 covers ESA-enforced OESC updates, wiring standards, grounding and bonding rules, permits, inspections, and code compliance for residential, commercial, and industrial installations to mitigate shock, arc-fault, and fire hazards.

Why Understanding Electrical Safety in Ontario (2015) Is Important

Electrical Safety in Ontario is a major concern for law makers and citizens, employers and employees. Ontario’s electrical safety watchdog, the Electrical Safety Authority (ESA), tracks electrical accidents and penalizes companies in violation of the Ontario Electrical Code, the province’s rules and regulations that protect the province’s workers from electrical accidents. Electrocutions in the workplace in the last ten years account for 60 per cent.

For a broader overview of best practices and current risks, the resources at electrical safety can help contextualize these Ontario trends.

Electrical Safety Ontario – Electrical Mortality Rates

In a report, the Electrical Safety Authority (ESA) has determined that 70 per cent of the electrical safety injuries that occur in Ontario happen in five areas. In the last ten years, 49 per cent of all electrocutions (fatal electric shocks) happen due to human contact with power lines. Since then, there have been at least 1,000 cooking fires from electric stove-tops that resulted. Electrocutions in the workplace make up 60 per cent of the total number of electrocutions in the last 10 years. Most of these electrical fatalities and injuries are from working on live electric panels. ESA’s Ontario Electrical Safety Report indicates that fatalities resulting from electrical fire have declined 56 per cent in the last decade. According to that same report, electrocution rates have dropped to 43 per cent in the last 10 years. For more on ESA oversight, see how the Electrical Safety Authority investigates incidents and promotes compliance.

These figures mirror patterns seen in many plants and facilities, where guidance on industrial electrical safety emphasizes lockout, verification, and task planning.

Electrical Safety Ontario – Employees

The Electrical Safety Authority’s primary targets for improving Ontario’s electrical safety include: reducing contact with power lines, lowering electrical accidents and incidents to Ontario’s electrical workers, and reducing situations that come from misusing electrical products, using unapproved electrical products, or using electrical counterfeit products. ESA’s secondary targets for improving Ontario’s electrical safety include: implementing safety regulation for installation, design and maintenance of street lights, reducing incidents that comes from aging electrical equipment, improve safety regulations on 347-volt systems, addressing issues concerning electrical devices and bathtubs, among others. Organizations can also consult guidance on selecting and verifying electrical safety products to reduce hazards from counterfeits and misuse.

Understanding evolving electrical safety regulation helps align procurement and maintenance policies with ESA priorities.

Electrical Safety Ontario – ESA Mandate

ESA has a mandate to regulate the safe use of electricity and equipment in Ontario. It also enforces the Ontario Electrical Safety Code, and appoints Electrical Inspectors. It believes that its mandate is there to ensure that:

Detailed requirements are compiled in the Ontario Electrical Safety Code, guiding inspections and installations.

- Electrical workers and non electrical workers have the highest level of technical and service knowledge about the hazards of electricity in the workplace.

- The best technical expertise is accessed to define and modify electrical standards.

- Programs and services meet customer needs and are delivered in an effective and efficient manner.

- Systems and processes are updated to respond to changing technology.

- Information sources are clearly defined to assist in assessing public safety needs and priorities.

- Ongoing consultation with all stakeholders.

- New electrical safety opportunities are vigorously pursued.

- Safety partnerships are developed to extend the reach of important safety messages.

Electrical Safety Ontario – Infrastructure Healh and Safety Association

The Infrastructure Healh and Safety Association (IHSA) was created in 2010 by merging the Construction Safety Association of Ontario (CSAO), the Electrical & Utilities Safety Association of Ontario (EUSA), and the Transportation Health and Safety Association of Ontario (THSAO). The Infrastructure Health & Safety Association (IHSA) works with employers and workers in Ontario to eliminate electrical injury and illness. IHSA training often reinforces safe job planning and energized work controls outlined under electrical safety work methods for field crews.

Related Articles

Arc Flash Analysis – Incident Energy and Boundary Calculations

Arc flash analysis evaluates incident energy, fault current, and protective device coordination to meet NFPA 70E and IEEE 1584, enabling PPE selection, labeling, risk assessment, and mitigation for switchgear and MCCs.

Understanding Arc Flash Analysis for NFPA 70E Compliance

Arc flash analysis is a critical component of a comprehensive arc flash study — not a standalone procedure, but the phase where precise calculations determine the level of thermal energy that could be released during a fault. While the full arc flash study involves system-wide data collection and risk evaluation, arc flash analysis focuses narrowly on modelling specific hazards at individual points in the electrical system. This analytical phase feeds the broader program described in our arc flash study framework, aligning calculations with system-level risk controls.

Request a Free Training Quotation

What Is Arc Flash Analysis?

It is the phase in which electrical engineers calculate the incident energy at key locations in a facility. This involves evaluating system parameters to identify the severity of a potential event and determining how far the resulting thermal energy could travel — known as the arc flash boundary.

This data is used to:

-

Specify the required PPE categories for safe work,

-

Mark electrical equipment with appropriate warning labels, and

-

Help organizations meet NFPA 70E and CSA Z462 compliance standards.

Unlike the broader study, which encompasses short-circuit analysis and coordination studies, the arc flash analysis itself focuses solely on the energy hazard associated with potential hazardous incidents.

For readers new to the topic, what an arc flash study entails helps contextualize how analysis fits within the complete safety workflow.

Key Components

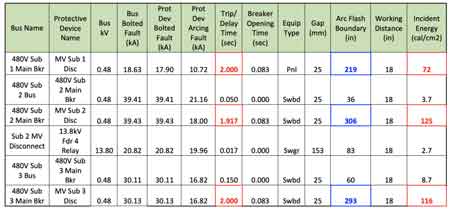

Arc flash analysis involves several technical steps that work together to assess the severity of potential uncontrolled incident energy events. Engineers begin by calculating available fault current at key points in the system, followed by precise calculations using IEEE 1584 formulas. These results are used to define appropriate PPE categories and boundaries. Specialized software tools streamline the process, ensuring accurate results and code-compliant documentation. A practical orientation is outlined in seven essential steps to arc flash analysis that many teams use to standardize execution.

It is a critical process used to evaluate the potential for an explosion within an electrical system. By conducting a thorough arc flash risk assessment, safety professionals can identify the areas with the greatest hazards and determine the necessary steps to minimize them. This process involves a short circuit study to identify fault current levels and the behavior of protection devices under fault conditions. These devices play a vital role in limiting the release of energy during an electrical fault, helping to reduce injury and equipment damage. The analysis also accounts for working distance, which significantly affects the incident energy to which a worker may be exposed during a hazardous incident. It is essential to select the appropriate personal protective equipment (PPE) and establish safety boundaries.

Determining Available Fault Current

Engineers begin by calculating the maximum fault current at various points in the system, which directly affects the intensity of a potential explosion.

Calculating Incident Energy Levels

This is the heart of arc flash analysis. Using IEEE 1584 equations, the analysis determines the amount of energy (in cal/cm²) to which a worker could be exposed during a hazardous incident. Many facilities adopt a dedicated incident energy analysis approach to validate results across common work distances.

Defining PPE Categories

Once the energy levels are known, appropriate PPE categories (CAT 1 through CAT 4) are assigned to each piece of equipment, based on its hazard level.

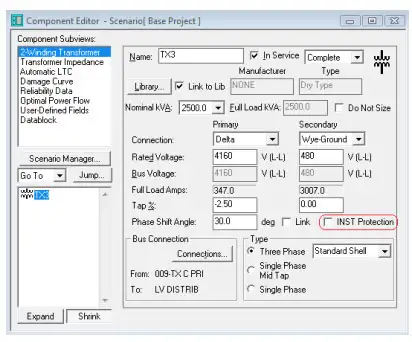

Using Software Tools

Professional-grade software such as SKM PowerTools, ETAP, or EasyPower is commonly used to model system data, automate calculations, and generate detailed reports and one-line diagrams.

Use Cases for Arc Flash Analysis

The analysis is often employed in specific situations where a comprehensive study is not necessary. Common use cases include reviewing individual panels after equipment changes, verifying or updating warning labels, and performing spot checks to maintain compliance. It’s also used post-study to refine energy calculations or reassess hazard levels when system conditions change. Integrating a formal arc flash risk assessment ensures that calculated energies are considered alongside likelihood and task-based exposures.

Targeted Equipment Reviews

Sometimes an arc flash analysis is performed on a single panel or circuit after changes are made or when labels need updating, without repeating the entire system study.

Spot Checks and Label Verifications

If maintenance or system updates occur, facilities may re-analyze only affected areas, ensuring ongoing compliance without a full study refresh.

Post-Study Refinements

Even after a study is complete, engineers may revisit the analysis portion to fine-tune results or respond to operational changes that affect energy levels.

Why Arc Flash Analysis Matters

It is essential for protecting workers and ensuring regulatory compliance. Accurately calculating incident energy levels and defining Personal Protective Equipment (PPE) requirements helps prevent serious injuries from electrical explosions. The analysis also supports the creation of accurate warning labels and helps companies meet safety standards like NFPA 70E and CSA Z462, making it a critical part of any electrical safety program. Organizations should verify that documentation aligns with arc flash study requirements to demonstrate due diligence during audits.

By isolating and calculating the most dangerous points of potential incident energy, this analysis supports:

-

Worker safety by ensuring proper PPE is worn,

-

Label accuracy that informs workers of specific hazards, and

-

Regulatory compliance with OSHA, NFPA 70E, and CSA Z462.

It ensures that the energy levels associated with a hazardous incident are not just estimated, but precisely calculated, documented, and mitigated.

Arc flash analysis plays a crucial and focused role within the broader arc flash study. It provides organizations with the data they need to make safety actionable, from assigning the right PPE to establishing accurate protection boundaries. For a deeper understanding of the entire process, refer to our Arc Flash Study overview page.

Arc Flash Analysis vs Arc Flash Hazard Analysis

While arc flash analysis refers specifically to the technical calculations used to determine PPE requirements, it’s important not to confuse it with an arc flash hazard analysis. The hazard analysis is a broader risk assessment process that includes an analysis but also considers the likelihood of a hazardous incident. mitigation strategies, labeling, and compliance with safety standards like NFPA 70E or CSA Z462. When evaluating overall risk, the broader arc flash hazard analysis framework informs mitigation priorities and labeling strategy.

Related Articles: