What organizations enforce arc flash standards?

By R.W. Hurst, Editor

NFPA 70e Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our NFPA 70E Fact Sheet – 2024 Electrical Safety Edition

- Understand how NFPA 70E works with NEC and NFPA 70B standards

- Clarify the shared responsibility between employers and employees

- Learn how NFPA 70E supports OSHA compliance

What organizations enforce arc flash standards? Key regulators include OSHA, NFPA (70E), and state authorities, with IEEE 1584 guiding calculations, ensuring compliance, PPE selection, labeling, and electrical safety program governance across facilities.

What Organizations Enforce Arc Flash Standards?

OSHA enforces workplace safety; NFPA 70E sets practices; IEEE 1584 guides calculations; AHJs ensure compliance.

✅ OSHA mandates electrical safety under 29 CFR 1910 Subpart S

✅ NFPA 70E defines arc flash PPE, labeling, and work practices

✅ IEEE 1584 provides arc flash hazard analysis methodology

What organizations enforce arc flash standards?

Arc flash standards are primarily enforced by OSHA and guided by the NFPA. While not always legally binding, these standards are widely adopted to reduce arc flash risks. OSHA references NFPA 70E through the General Duty Clause, requiring employers to assess and protect against electrical hazards. For context, the evolving interplay between OSHA and NFPA 70E shapes how policies are interpreted across industries today.

Role of NFPA and OSHA

OSHA's Role

OSHA is a key agency dedicated to improving workplace safety across various industries. While OSHA does not always create new safety standards, it often adopts proven guidelines from other organizations. For arc flash safety, OSHA has incorporated standards established by the NFPA. These standards mandate the use of arc flash labels on systems capable of causing arc flashes, ensuring workers are aware of potential hazards. For a practical overview of employer duties under the General Duty Clause, see OSHA arc flash requirements and how they apply in typical facilities.

NFPA's Contribution

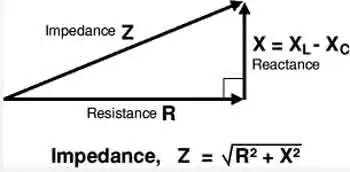

The NFPA provides comprehensive guidelines on arc flash safety, including recommendations for arc flash testing and the establishment of arc flash boundaries. These boundaries define safe distances from electrical systems, helping to determine the necessary personal protective equipment (PPE) based on proximity to the potential arc flash source. By performing arc flash analyses, employers can create safer work environments and better inform their employees about potential risks. To align procedures with current best practices, consult NFPA 70E arc flash requirements for the latest guidance on risk assessment and work practices.

Test Your Knowledge About Arc Flash!

Think you know Arc Flash? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Importance of Following Arc Flash Standards

Although not legally required, adhering to NFPA and OSHA standards is crucial for several reasons: For example, questions about whether an arc flash analysis is required are addressed in OSHA interpretations on arc flash analysis, clarifying how employers should evaluate risk.

-

Proven Effectiveness: These standards are based on extensive research and have been shown to significantly reduce the risk of arc flash incidents.

-

Enhanced Safety: Implementing these guidelines helps create a safer work environment, protecting employees from severe injuries or fatalities.

-

Compliance and Best Practices: Following these standards ensures compliance with industry best practices, demonstrating a commitment to worker safety.

Providing Arc Flash Training

Employers aiming to improve workplace safety should offer comprehensive arc flash training based on NFPA and OSHA guidelines. Effective training programs educate employees about the dangers of arc flashes, proper use of PPE, and safe work practices. Key components of arc flash training include: Many organizations align their curricula with NFPA 70E arc flash training so workers practice consistent, compliant procedures.

-

Identifying Hazards: Educating workers about potential arc flash hazards in their work environment.

-

Using PPE: Training employees on the correct selection and use of PPE to protect against arc flash injuries. Selection should reflect the hazard category described in arc flash levels of protection to ensure adequate thermal resistance.

-

Establishing Boundaries: Teaching workers to recognize and respect arc flash boundaries to maintain a safe distance from potential arc flash sources.

-

Emergency Response: Preparing employees to respond appropriately in the event of an arc flash incident.

While arc flash standards are not legally enforceable, the guidelines provided by the NFPA and OSHA are essential for ensuring workplace safety. By adopting these standards and offering thorough arc flash training, employers can significantly reduce the risk of arc flash incidents and protect their employees from serious harm. Prioritizing arc flash safety not only complies with industry best practices but also fosters a culture of safety within the organization. Accountability for creating and maintaining safe conditions is detailed in who is responsible for protecting you from arc flashes, helping teams assign duties clearly.

Related Resources