Efficiency Opportunities Through Motor Maintenance

By Peter A. Darbee, Pacific Gas and Electric Company

Motor Control Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

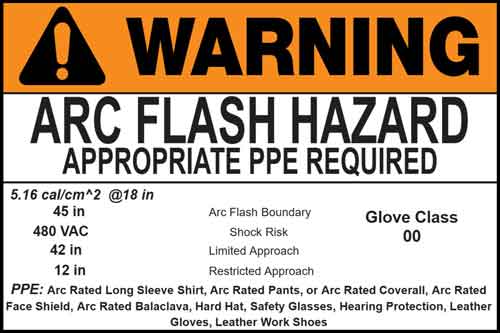

Download Our OSHA 4474 Fact Sheet – Establishing Boundaries Around Arc Flash Hazards

- Understand the difference between arc flash and electric shock boundaries

- Learn who may cross each boundary and under what conditions

- Apply voltage-based rules for safer approach distances

Efficient motor maintenance presents significant opportunities to enhance energy efficiency, prolong equipment lifespan, and lower operating costs. By focusing on reliability, predictive strategies, and performance optimization, facilities can capture long-term efficiency gains.

What are the Efficiency Opportunities Through Motor Maintenance?

Efficiency opportunities through motor maintenance involve proactive practices that optimize energy use, reduce downtime, and extend the operational life of motors.

✅ Improves energy efficiency and lowers operating costs

✅ Extends equipment lifespan with proactive care

✅ Enhances reliability through predictive maintenance

The electricity consumed by a motor in one year costs more than the motor itself, by as much as 10 times. Multiplying this cost by the motor's lifespan puts the necessity of maintaining optimum electric motor control performance into true perspective. Motor maintenance is more than making sure the motor itself is operating correctly. It also involves ensuring that the power supplied to the motor is within acceptable tolerances, that the motor’s output power is efficiently transmitted to the load, and that the load itself is properly maintained so as not to require the motor to work harder than necessary. Record keeping is an essential part of motor maintenance. By comparing the results of recent tests with historical records, maintenance staff can more readily identify degraded performance and potential breakdowns and take steps to adjust the system and prevent costly unscheduled downtime. Motor maintenance programs must be customized. Hot, dirty, humid conditions require more frequent checks of performance and attention to maintaining the physical condition of the motor. It may also be necessary to isolate motors from extreme conditions or to blow conditioned air over them for cooling purposes.

Test Your Knowledge About Motors and Drives!

Think you know Motors and Drives? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Motor Maintenance Practices and Their Efficiency Benefits

| Maintenance Area | Key Focus | Efficiency Impact | Example Actions |

|---|---|---|---|

| Lubrication | Bearings and moving parts | Reduces friction, prevents overheating, and extends service life | Apply correct lubricant periodically, and avoid over-lubrication |

| Shaft Alignment | Couplings and belt drives | Minimizes wear, improves power transmission efficiency | Ensure alignment during installation, recheck after thermal shifts |

| Bearings | Sleeve and anti-friction types | Lowers downtime, prevents premature failure | Keep clean, lubricated, and within rated load |

| Power Quality | Voltage and frequency tolerances | Prevents overheating, improves motor performance | Monitor supply, correct harmonics, stabilize voltage |

| Record Keeping | Maintenance logs and test data | Enables predictive maintenance and cost control | Track test results, compare with historical data |

| Environmental Control | Dust, heat, and humidity protection | Extends motor lifespan and reliability | Use barriers, filters, cooling air, or isolation enclosures |

How Motor Maintenance Saves Energy

Motors eventually become less efficient due to wear, breakdown of lubricants, and loss of alignment. Scheduled maintenance is the best way to keep the whole system operating within acceptable tolerances. Properly applied, maintenance will also provide valuable information on potential motor failures, allowing for the minimization of unscheduled downtime.

Motor Maintenance Energy-saving Strategies

The greatest enemies of efficient electric motor design are improper installation or adjustments, low-quality electrical power, adverse environmental conditions (e.g., dust, dirt, moisture, extreme temperature) and wear. The general guidelines in this section address these issues.

Motor Maintenance Logs

A motor maintenance program is of most value when it is consistently applied. The system should remind staff when it is time to perform specific maintenance functions on individual motors; provide a means of recording the functions performed; and act as an historical record to track the performance of individual motors. Each motor should have a maintenance form that records the load served (e.g., supply fan #1 or boiler feedwater pump #3) and the motor’s make, model, serial number, and ratings. Specifications for ancillary equipment (e.g., drive belts, pulleys) should be recorded for quick reference. Space should be provided for recording observations of unusual motor performance. Computerized maintenance programs are available that will notify plant personnel of upcoming motor maintenance. These programs also provide a convenient repository for information on all electric motors and drives (as well as other systems that require maintenance) and analysis tools for determining how effectively maintenance is being carried out.

Proper Lubrication

Proper lubrication is essential for the long-term operation of motors and all mechanical equipment. It must be done periodically and consistently — it is too late when the motor audibly communicates its needs. Often, service personnel attempt to quiet a noisy motor by pumping lubricant into the bearing. This may work for a short while, but the life of a noisy bearing is limited, and over-lubrication (as described below) may result.

Shaft Alignment

Larger motors are typically coupled to their loads, and proper shaft alignment is crucial for achieving adequate bearing life. In belt-driven applications, belts must be perpendicular to the shaft axes, or they will wear and bearing life will be shortened. Alignments made under one set of circumstances can change due to temperature, loading, foundation movement and rotational speeds.

Bearing Maintenance

All bearings require regular maintenance to perform properly and achieve their intended service life. Bearings can be classified into two types: sleeve and anti-friction types. In sleeve bearings, the shaft rides in a thin film of lubricant between the shaft and the bearing. Antifriction bearings have ball or roller bearings that spin between the shaft and the bearing housing. There is considerable overlap in the use of both types in electric motors. Proper maintenance consists simply of keeping the bearing clean, lubricated and loaded not in excess of its rating. Proper maintenance consists simply of keeping the bearing clean, lubricated and loaded not in excess of its rating.

Power Quality

Power quality can significantly impact motor performance. Motors are designed with the assumption that electric power will be provided within certain tolerances. It is easy to assume that because motors are operating, the power is within acceptable tolerances, but this is not always true. Power quality can be degraded as it is supplied from the utility or at the facility; in either case, it is necessary to identify the cause and correct it. Important power quality issues are discussed below.

Factors Affecting Motor Maintenance Costs

Motor maintenance costs will be influenced by ongoing expenses such as testing, inspection, cleaning, and drying; parts for repairs; consumables (e.g., lubricants, belts); and labour. Costs will increase directly as the frequency of maintenance activities is increased. Additionally, one-time costs may be incurred to correct problems associated with the power supplied to the motors from time to time. The level of testing performed on motors determines the cost of such testing. These tests can range from simple measurements, such as having maintenance personnel take voltage and current draw readings, to more sophisticated, comprehensive motor overload protection tests. Actual costs for testing and repairs should be obtained from providers of these services. If the motor is in a particularly dirty or hot location, it will require up to six times as much attention. It is essential that motors be selected based on the environment in which they will be operating. It may also be desirable to isolate the motor from the environment using barriers or filters, along with a cooling air system, allowing the motor to operate within its design limits.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

From: Electric Motors and VFDs Handbook, Vol 3, The Electricity Forum

Related Articles