Protection System Using Open Network Architecture

By Takashi Kobayashi, Hitachi, Ltd.

Substation Relay Protection Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our NFPA 70E Fact Sheet – 2024 Electrical Safety Edition

- Understand how NFPA 70E works with NEC and NFPA 70B standards

- Clarify the shared responsibility between employers and employees

- Learn how NFPA 70E supports OSHA compliance

Open network architecture streamlines power systems with modular design, interoperability, IEC 61850, Ethernet-based substation automation, SDN orchestration, and scalable protection, monitoring, and control for smart grids and microgrids, with edge computing and real-time visibility.

What Is Open Network Architecture?

A standards-based network enabling interoperable control, protection, and monitoring across electric power systems.

✅ Uses IEC 61850, Ethernet, and TCP/IP for substation automation

✅ Enables SDN/NFV, network segmentation, and deterministic control

✅ Improves interoperability, reliability, and scalability in smart grids

Paralleling the rapid penetration of the Internet and corporate intranets, protection and control system for power systems have been quick to exploit these technologies to make the remote control and monitoring of power systems more convenient. By leveraging these networking technologies to achieve a new level of openness, there is now a protection and control system that features an IEC (International Electrotechnical Commission)-compliant network protocol: a standardized interface in the area of protection and control systems for power systems. For utilities standardizing on IEC-based messaging, resources on complex protective relays can clarify how advanced logic maps onto interoperable data models.

In addition, a compact protection and control unit was developed that incorporates Web server functionality and has the ability to be controlled and monitored over general-purpose browser software, and we are now evaluating the unit for use with various applications. Finally, efforts are also underway to develop a maintenance support navigation system that supports operations and maintenance work using an intelligent (ubiquitous) controller.

INTRODUCTION

The systems that protect and control power systems demand the high reliability and functionality. At the same time, relentless pressure to hold down costs of protection and control systems has accompanied the deregulation of the power industry, so our efforts have focused on achieving more compact, lower cost systems that provide equivalent or better performance and reliability than previous systems. And finally, there is a strong demand to leverage IT and communication technologies in the adoption of open networks, and to adopt remote control capabilities to streamline and raise the efficiency of operations and maintenance. This article will highlight some of Hitachi’s recent initiatives to address these needs. We will describe the features of a protection and control system for power systems intended for domestic and overseas markets, and a maintenance work support system that was developed to boost the efficiency of operations and maintenance work. Understanding the fundamentals of what is a protective relay helps frame feature trade-offs when balancing cost and reliability.

Sign Up for Electricity Forum’s Electrical Protection Newsletter

Stay informed with our FREE Electrical Protection Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

TREND TO INCORPORATE IT IN PROTECTION AND CONTROL SYSTEMS

A diverse range of protection and control systems for power systems has been proposed that attempts to leverage and make good use of all the recent advances involving the Internet, corporate intranets, wireless communications, and other ITs (information technologies. Looking at the power industry from a global perspective, it has generally been assumed that protection and control systems will be constructed using different manufacturers’ equipment, so they have employed standardized interfaces such as the IEC 60870-5-101/103 communication protocols based on RS- 232C and RS-485 and standardized field buses such as represented by PROFIBUS.

Consider the main network protocols that are currently available for protection and control systems. Against this backdrop, headway has been made in recent years in IEC TC57 toward standardized communication protocols that can be applied from the process and bay levels to the station level, and systems employing high-speed general communications technologies based on Ethernet* are now emerging as the mainstream approach2).

In mixed-vendor substations, selecting the appropriate protective relay depends on protocol support, latency, and cyber-security requirements.

PROTECTION AND CONTROL UNIT FOR OPEN NETWORKS

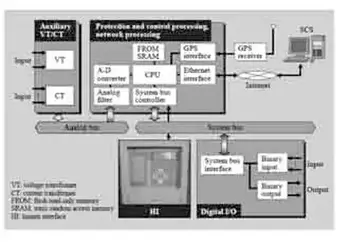

Hardware configuration addressing this new reality: Hitachi developed new series of digital PCUs (protection and control units) that can be flexibly adapted to Ethernet-based open networks. The key features of the PCUs are summarized as follows: Modern multifunction relays illustrate how integrated protection schemes reduce panel footprint while improving visibility.

(1) Communication with SCS (substation control system) is supported by the industry standard communications protocol IEC 60870-5-104 (which is based on the TCP/IP: Transmission Control Protocol/Internet Protocol). This ensures full connectivity between different manufacturers’ equipment.

(2) Protection and control functions have been combined in one unit, so the overall size of Hitachi’s new digital PCUs has been substantially reduced (compared to previous Hitachi’s models). This consolidation still supports power transformer protection use cases with deterministic performance.

(3) Hitachi’s new series of digital PCUs are extensible and can be flexibly adapted to various protection and control applications (functions can be readily added via the system bus).

(4) Clock can be precisely synchronized (1 ms resolution) using a GPS (global positioning system). Accurate time stamping enhances fault location and overcurrent protection coordination during post-event analysis.

APPLICATION OF IT TO A MAINTENANCE LAN

Implementation of New Digital Relay Unit as Series. One objective in applying IT to digital protection and control systems is to enable remote control and monitoring capabilities by employing an operations/maintenance LAN (local area network). By implementing remote control and monitoring using ordinary PC browser software over a network connection, data can be accessed anytime, from anywhere, and over the same user interface. This approach should also support simple operability while maintaining high-speed responsiveness. To meet these needs, we have developed a new networkready digital relay unit. Building on Hitachi’s previous model, the concept behind the new relay unit was to develop a system that maintained compatibility with a previous model yet was implemented much more compactly and supported interconnection over general networks. Browser-based diagnostics also aid relay and circuit breaker coordination reviews during planned switching.

From: Electrical Relays, Protection & Control Handbook, Vol 5, The Electricity Forum