Electric Motor Testing Explained

By R. W. Hurst, The Electricity Forum

High Voltage Maintenance Training Online

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

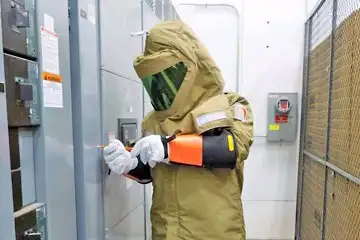

Download Our OSHA 4475 Fact Sheet – Being Aware of Arc Flash Hazards

- Identify root causes of arc flash incidents and contributing conditions

- Apply prevention strategies including LOTO, PPE, and testing protocols

- Understand OSHA requirements for training and equipment maintenance

Electric motor testing evaluates performance, insulation resistance, power quality, vibration, efficiency, and overall reliability. These tests detect faults early, prevent costly downtime, and support predictive maintenance for industrial power systems.

What is Electric Motor Testing?

Electric motor testing is the process of evaluating electrical and mechanical performance to ensure reliability, safety, and efficiency.

✅ Identifies insulation and winding defects

✅ Measures efficiency, vibration, and load performance

✅ Supports predictive maintenance and system reliability

Why Motor Testing Matters

Electric motor testing is often the first thing sacrificed when cutting back on operational expenses. However, smart companies recognize that skipping this step leads to billions of dollars in lost revenue due to increased repair costs, downtime, and wasted resources. Modern maintenance practices sometimes overlook the importance of thorough motor diagnostics; however, examination remains essential for ensuring uptime, competitiveness, and plant safety. Thorough electrical testing verifies insulation, load balance, and overall motor health, reducing the risk of sudden breakdowns.

Electric Motor Testing Training

Power maintenance and management programs are designed to enhance equipment readiness and uptime while reducing capital expenditures. These programs include specialized tools and training to help maintenance engineers properly evaluate and care for motor systems.

Electric Motor Testing Training

Recommended Electric Motor Testing Tasks

Maintenance and management programs are designed to enhance equipment readiness and uptime while minimizing capital expenditures. This program comprises specialized maintenance and management tools designed to assist the maintenance engineer in maintaining and caring for motor systems. When problems arise, structured electrical troubleshooting techniques help maintenance teams pinpoint the root cause quickly. Specialized electric motor testing equipment provides deeper insight into winding condition, vibration, and power quality.

The following are Recommended Tests:

Electric Motor Impulse

Impulse (surge) testing is central to predictive maintenance. It identifies weak turn-to-turn insulation and detects hidden winding faults. Questions often asked include: Can impulse analysis damage insulation? Can other tests, such as DC resistance, inductance, Megger, or Hi-Pot, diagnose weak insulation? In practice, surge testing provides one of the clearest indicators of motor health, helping avoid failures before breakdown.

Sign Up for Electricity Forum’s Test Equipment Newsletter

Stay informed with our FREE Test Equipment Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Electric Motor Rotation

Rotation testing ensures fans or pumps are spinning in the correct direction under operating conditions. Even offline, fans may rotate due to airflow, and pumps may rotate from shared headers. These conditions can distort test results and create resistive or inductive imbalances, making rotation verification important.

Wound Rotor Electric Motor

Wound rotor motors contain three-phase windings connected to startup resistors for current and speed control. Faults in resistor banks are common yet often overlooked. Testing these components is critical for troubleshooting, as failed resistors can significantly impact overall motor operation.

Electric Motor Insulation Resistance

Motor insulation exhibits a negative temperature coefficient, meaning its resistance decreases as the temperature rises. IEEE 43 requires correction to 40°C, which can cause acceptable readings to become failures after adjustment. This highlights the importance of proper temperature correction and moisture management. Using space heaters and regular polarization index tests ensures winding health and extends motor life.

Summary Table of Key Tests

| Test Type | Purpose | Tools Used | Benefit |

|---|---|---|---|

| Insulation Resistance | Detect winding and insulation defects | Megohmmeter, HiPot tester | Prevents breakdown and downtime |

| Surge (Impulse) Test | Identify weak turn-to-turn insulation | Surge tester | Catches faults before failure |

| Vibration Analysis | Detect imbalance, bearing or rotor wear | Accelerometers, vibration sensors | Supports predictive maintenance |

| Thermal Test | Identify overheating or cooling issues | Infrared thermal camera | Extends motor life |

| Acoustic/Noise Test | Monitor sound levels and mechanical wear | Microphone, sound meter | Ensures compliance and reliability |

| Efficiency Test | Measure energy use and power quality | Power analyzer, torque transducer | Improves performance and saves costs |

| Dynamic/Blocked Rotor Test | Assess torque and slip behavior | Standard lab setup, sensors | Validates motor under stress |

Expanded Testing for Complete Coverage

Thermal Testing

Thermal analysis identifies overheating and cooling issues, helping prevent winding failures and efficiency losses. Infrared thermal cameras are widely used to visualize hotspots during operation.

Noise and Acoustic Testing

Excessive noise can signal bearing wear, imbalance, or mechanical stress. Sound-level meters and microphones help identify these issues and ensure compliance with noise standards.

Dynamic and Blocked Rotor Testing

Dynamic tests, such as blocked rotor analysis, measure slip and locked-rotor behavior. These tests provide critical data on torque, efficiency, and load performance under extreme conditions.

Efficiency and Power Quality Testing

Efficiency evaluation ensures motors meet IEC 60034 standards for energy performance. Power analyzers and torque sensors measure losses, harmonics, and energy use, supporting cost savings and regulatory compliance.

Tools and Equipment Used

-

Megohmmeters and HiPot testers for insulation resistance

-

Surge testers for turn-to-turn faults

-

Thermal cameras for hotspot detection

-

Vibration sensors and accelerometers for imbalance and bearing issues

-

Tachometers for speed measurement

-

Torque transducers and power analyzers for efficiency analysis

By linking each test to practical tools, maintenance teams can translate diagnostic data into real-world solutions. Advanced monitoring tools, such as a data logger, help capture long-term performance data to detect trends in motor behaviour.

Industry Standards

-

IEEE 43 – Insulation resistance and polarization index

-

IEC 60034 Series – Motor performance, efficiency, and power quality

-

NEMA MG1 – U.S. motor design and test requirements

Referencing these standards ensures compliance, safety, and reliability across diagnostic programs.

Emerging Trends in Motor Diagnostics

Predictive maintenance is evolving through the integration of machine learning, smart sensors, and advanced analytics. Real-time vibration analysis, automated test benches, and AI-driven condition monitoring systems are transforming the way facilities detect faults. This trend enables earlier fault detection, reduces downtime, and enhances lifecycle management for motors. Technicians often rely on analog multimeters for quick voltage and continuity checks when beginning a motor diagnostic process.

Related Articles