Ground Grid: Important Electrical Design

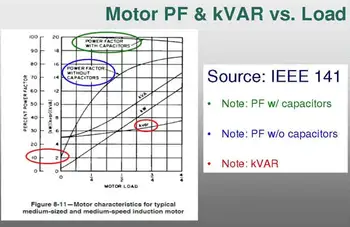

Power Factor Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

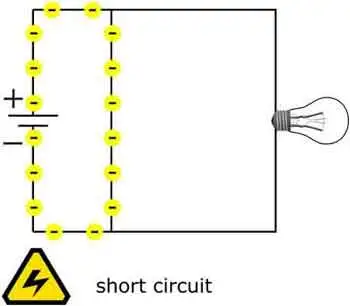

Download Our OSHA 3075 Fact Sheet – Understanding Electrical Hazards in the Workplace

- Learn the effects of electric current on the human body

- Understand OSHA safety standards and protective devices

- Discover essential lockout/tagout and grounding practices

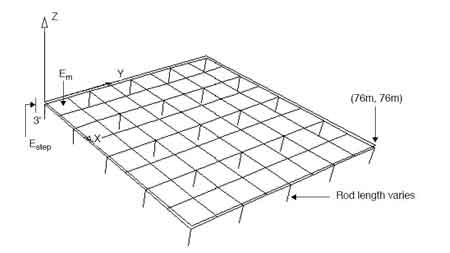

Ground grid provides a buried earthing mesh for substations, managing fault current, reducing ground resistance, controlling step-and-touch voltage, and ensuring equipotential bonding per IEEE Std 80 for personnel and equipment safety.

What Is a Ground Grid in Electrical Substations?

A ground grid is a conductor network managing fault current and touch/step voltages to protect equipment and personnel.

✅ Limits touch and step voltages per IEEE Std 80

✅ Copper conductor meshes and ground rods lower resistance

✅ Design uses soil resistivity, fault current, and clearance

A ground grid is a critical component in electrical systems, especially in high-voltage environments like substations and power plants. This system ensures that electrical faults are safely dissipated into the earth, reducing the risk of equipment damage and protecting personnel. The ground grid provides a low-resistance path for fault currents, preventing the buildup of dangerous voltages. Understanding its design, installation, and maintenance is essential for ensuring the safe and efficient operation of electrical systems. For readers new to the topic, understanding electrical grounding provides essential context about the principles that underpin ground grid performance.

What is a Ground Grid in Electrical Systems?

A ground grid refers to a network of conductors buried underground to create a low-resistance path for electrical fault currents. It is an essential part of grounding systems, designed to safely direct excess electricity into the earth. These systems are typically installed in electrical substations, power plants, and large industrial facilities where grounding is required to prevent electrical hazards. The grid also helps to create a solid and stable foundation for electrical equipment by stabilizing the soil and enhancing the structural integrity of the installation. In broader practice, effective grounding system strategies help ensure these networks integrate safely with adjacent facilities and equipment.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Why is a Ground Grid Important for Electrical Safety?

The primary function of a ground grid is to ensure the safety of electrical installations. Without a proper grounding system, electrical faults could result in dangerous voltage levels on equipment and structures, posing significant risks to both personnel and equipment. The grid helps maintain stable voltage levels by quickly dissipating fault currents, making it a crucial safety measure in power systems. Properly installed systems also allow water to flow through mineral infill or gravel, preventing water accumulation that could cause further electrical hazards. If you need a refresher on fundamentals, what is electrical grounding explains how grounding manages fault energy and touch potentials in practical settings.

How Do You Design and Install a Ground Grid for a Substation?

Designing and installing a ground grid requires careful planning. Engineers must consider factors such as soil resistivity, the size of the installation, and the fault current levels expected in the system. Typically, the grid is constructed using conductors that form a mesh or honeycomb structure. These conductors are buried underground and connected to key equipment in the substation. Fill materials such as gravel, soil, or sand are often used to stabilize the installation and improve the grid’s effectiveness. Creating a stable surface for the installation is important for ensuring long-term performance.

In certain networks, adopting high-resistance grounding can limit fault current magnitude while maintaining service continuity during single-line-to-ground events.

The layout must be designed to cover a large area to distribute fault currents evenly, and grounding stabilization techniques such as using mineral infill may be employed to enhance soil conductivity. These materials ensure that the grid remains effective over time, providing a reliable path for fault currents. Complementary grounding and bonding practices also reduce potential differences between structures and cable trays, improving overall safety.

What Materials are Commonly Used for Ground Grids?

Ground grids are usually made from highly conductive materials, with copper and galvanized steel being the most common choices. Copper is favored for its superior conductivity and corrosion resistance, while galvanized steel is often used in cost-sensitive installations. In some cases, a combination of materials is used to create a durable and efficient grounding system. When backup power is present, best practices for grounding a generator help ensure neutral references and fault clearing remain consistent with the facility grid.

Gravel, soil, and sand are typically used as infill materials to stabilize the ground grid. The honeycomb structure formed by the grid allows water to flow easily through the system, preventing water buildup and enhancing grounding performance. These materials also provide a stable surface for heavy equipment, such as transformers and circuit breakers, to be placed on top of the grid.

How Do You Test and Maintain a Ground Grid to Ensure Effectiveness?

Once installed, regular testing and maintenance are critical to ensuring the effectiveness of a ground grid. Over time, corrosion, soil movement, and other factors can degrade the system’s performance. Testing typically involves measuring the system’s resistance and verifying that it remains within acceptable limits. Periodic visual inspections are also necessary to ensure that the conductors and fill materials are in good condition. As part of commissioning or periodic checks, methods on how to check if an area is grounded can guide field teams in verifying compliance and documenting results.

Ground stabilization methods like using mineral infill can extend the life of the system, but ongoing monitoring is necessary to catch potential issues before they become dangerous. Regular maintenance ensures that the grid continues to provide a stable surface and effective fault current dissipation, protecting both equipment and personnel.

Test Your Knowledge About Power Quality!

Think you know Power Quality? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

In summary, a well-designed and maintained ground grid is crucial for ensuring electrical safety in high-voltage environments. These systems create a solid and stable foundation for electrical equipment while providing an efficient path for fault currents to flow safely into the earth. With proper design, materials, and maintenance, a ground grid can significantly reduce the risk of electrical hazards in substations, power plants, and other industrial settings. By regularly testing and maintaining the system, engineers can ensure its long-term effectiveness and reliability.