Grounding and Bonding - How To Improve Your NEC/CSA Installations

Substation Grounding Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

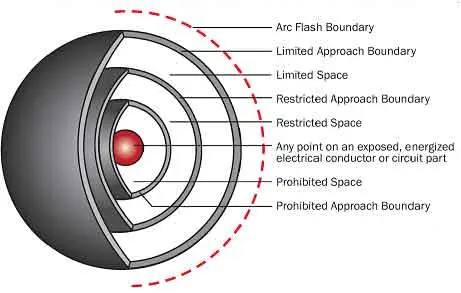

Download Our OSHA 4474 Fact Sheet – Establishing Boundaries Around Arc Flash Hazards

- Understand the difference between arc flash and electric shock boundaries

- Learn who may cross each boundary and under what conditions

- Apply voltage-based rules for safer approach distances

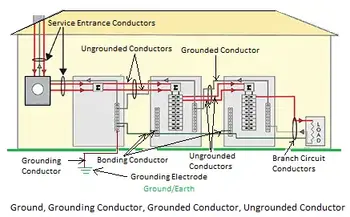

Grounding Bonding CSA NEC aligns earthing practices, equipment grounding conductors, bonding jumpers, and grounding electrode systems to ensure low-impedance fault current paths, overcurrent device operation, and electrical code compliance across commercial and industrial installations.

What Are Grounding Bonding CSA NEC Requirements?

They set earthing and bonding criteria to ensure safe fault return paths and operation of overcurrent protection.

✅ Defines EGC, GEC, and bonding jumper sizing per code.

✅ Ensures low-impedance fault paths for rapid OCPD clearing.

✅ Harmonizes NEC 250 and CSA/CEC sections for compliance.

Grounding and Bonding are the least understood, the most misinterpreted and confusing elements in modern electrical and electronic systems and leads to poor design and installation work — especially as it relates to the Canadian Electrical Code (CEC) and to the National Electrical Code (NEC) requirements. For a concise overview of common pitfalls and best practices in grounding and bonding, practitioners can review industry guidance to align design choices with CEC and NEC intent.

Misinterpretation of the rules causes their misapplication and consequently improper installation of critical systems such as “Telecommunications”, “Instrumentation & Control, “Lightning Protection Systems’ and protections against “Electrostatic Discharges”. The overall result ends up in Power Quality problems, electric shock risks and catastrophic damages such as fires and explosions in some industries such as the Petrochemical Industry, hazardous military installations where weapon systems are stored and improper grounding during aircraft refueling. Deeper understanding of electrical grounding helps prevent these misapplications in high-risk environments.

Metal parts are grounded to the earth to help prevent build-up of high voltage static charges where the discharge (arcing) could cause failure of electronic equipment. Clarifying the formal electrical grounding definition underscores why static charge dissipation protects sensitive electronics.

Test Your Knowledge About Power Quality!

Think you know Power Quality? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

It is important to note that electrical codes only provide the “minimum requirements for personnel safety” and for the industrial world we must go beyond the code to ensure the proper design, installation, maintenance and operation of equipment. Industry standards such as “IEEE standard 1100” (Emerald Book) “Recommended Practice for Powering and Grounding Sensitive Electronic Equipment” and “IEEE standard 142” (Green Book) “Recommended Practice for Grounding of Industrial and Commercial Power Systems” and others such as NFPA and military standards provide recommendations for particular environments. Beyond minimum code language, applied guidance on electrical grounding can inform design reviews and maintenance planning.

Improper terminology and definitions not authorized by the electrical code and industry standards causes confusion and misunderstandings. Lack of understanding of the differences between, important terms such as "bond, bonded, bonding, ground, grounded, grounding, and effectively grounded," and their intended application are often misunderstood, or worst yet, they are improperly used.

Another important lack of understanding of the differences between “ground resistance”, “ground impedance “, “resistance- to -ground”, and “ground resistivity” are very often misunderstood and improperly used.

When grounding and bonding is implemented correctly it can help the facility during its normal operations and during some type of power disturbances such as a lightning strike, transient over voltages, power surge and even voltage fluctuations. Proper grounding also protects electronic systems from “electromagnetic interferences’ (EMI), “radiofrequency interferences” (RFI) and “electrostatic discharge” (ESD). For teams new to fundamentals, a primer on what is electrical grounding explains how bonding strategies mitigate EMI and surge events.

It is important to clarify many misconceptions about bonding and grounding and break down CEC Section 10 and NEC Article 250. It will clear up confusing or seemingly conflicting NEC and CEC rules and give tips on proper installations, cautions, and warnings of dangers related to improper installations.

Technical requirements of the Canadian Electrical Code are very similar to those of the U.S National Electrical Code and installations acceptable under one Code may not entirely comply with the other but correlation of technical requirements between the two Codes is ongoing.

There is also the need to eliminate some of myths that cloud this subject and give a better understanding by clearing up misconceptions, lift some of the veils of mystics and simplify code requirements for acceptable field installations of grounding. Grounding obeys the laws of electricity, and when examining piece-by-piece and conductor-by- conductor, all elements fit together to form an effective grounding system.

In the construction industry, the first step when erecting a building is to prepare the ground for the building to set on. The ground supports the weight of the building. Unless the building is set firmly on the ground, it may have continuing structural and electrical problems. The grounding electrode must be properly installed in the ground, and all the grounding paths must be directed to it. The grounding system must be effectively connected to the grounding electrode. This includes correct sizing and routing of the grounding electrode conductor to maintain effective fault-clearing performance.

Grounding is the reference zero and the foundation of the of the electrical system.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Electrical grounding starts with the discussion of the ground and the grounding electrode, because the grounding electrode supports the entire grounding system, and all grounding paths lead to the grounding electrode. Documenting how each electrode, connector, and bond integrates into the overall grounding system supports inspection, testing, and long-term reliability.

The first rule is to make it safe; the second is to make it work.