Out-of-state hires for FPL upset local union

By Palm Beach Post

Substation Relay Protection Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

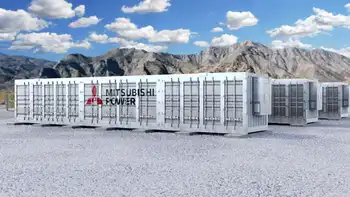

Members of the International Brotherhood of Electrical Workers say as many as 1,200 workers have been hired from as far away as Texas to work on FPL's gas-powered West County Energy Center.

"It is upsetting that so many nonresidents are currently taking jobs that should be given priority to Florida's citizens, who pay Florida taxes and in all likelihood spend the bulk of their money on local businesses and services," Cory Becker, an electrical workers' union member and second-year apprentice, wrote in an e-mail to commissioners.

Mayco Villafaña, an FPL spokesman, said roughly 1,200 workers are building the plant. Slightly more than half are from outside Florida, he said.

"As with any major and complex construction project, some specialized skilled workers have been hired from outside of the communities we serve," Villafaña said. He added that "these visiting employees have made a great contribution to the local economy."

Villafaña said the company continues to emphasize to its contractors the "importance of hiring from our local workforce."

David C. Svetlick, business manager of the electrical workers Local 728, said the union has a good relationship with FPL. Union workers have been hired to work at many other FPL plants, he said.

Union members directed much of their criticism at one of FPL's main contractors on the project, Texas-based Zachry Construction Corp. But Villafaña said multiple contractors are working on the plant.

"It is not directed at Florida Power & Light," Svetlick said. "It is the contractor. I would like to think that Florida Power & Light could specify to its contractors where they got their workforce from."

As much as 20 percent of the union's membership is out of work, he said.

"This is not a union, non-union thing," Svetlick said. "If you look around at all of the foreclosures and everything going on, why aren't we doing anything to help our Floridians that are here?"