Minnesota Signs Deal With Manitoba Hydro

WINNIPEG -- - The Minnesota Public Utilities Commission has unanimously approved a $1.7 billion power export deal with Manitoba Hydro.

It allows Minneapolis-based Xcel Energy to import power from Manitoba Hydro, despite the objections of aboriginal groups.

The 500-megawatt, 10-year deal was given the go-ahead.

It's an extension of an existing deal and will allow power to be exported until 2015.

Approval by Canada's National Energy Board is pending.

The Minnesota decision is a blow to the Pimicikamak Cree Nation of Cross Lake, Manitoba. They had asked the commission to first call a formal hearing into the social and economic impact of historic hydro development on their homeland.

Related News

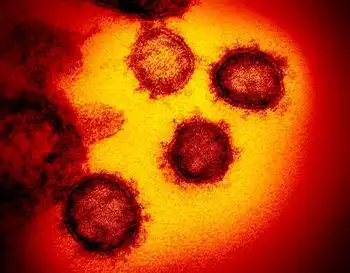

BC Hydro launches program to help coronavirus-affected customers with their bills

VANCOUVER - BC Hydro COVID-19 Bill Relief provides payment deferrals, no-penalty payment plans, Crisis Fund grants up to $600, and utility bill assistance as customers face pandemic layoffs, social distancing, and increased home power usage.

Key Points

A BC Hydro program offering bill deferrals, no-penalty plans, and up to $600 Crisis Fund grants during COVID-19.

✅ Defer payments or set no-penalty payment plans

✅ Apply for up to $600 Customer Crisis Fund grants

✅ Measures to ensure reliable power and remote customer service

BC Hydro is implementing a program, including bill relief measures, to help…