Brazilian utility uses 3M ACCR technology

SAO PAULO STATE, BRAZIL - EDP Bandeirante, the power distribution unit of EDP Group in Brazil, has become the third Brazilian utility to install the 3M Aluminum Conductor Composite Reinforced 3M ACCR for completion of a line upgrade while avoiding problems associated with building larger towers or expanding rights-of-way in an environmentally sensitive area.

3M ACCR provides more than twice the capacity of conventional conductors of similar size without requiring new or enlarged towers, thereby accommodating new demands being placed on the grid without costly and problematic construction, right-of-way expansion or permitting in crowded urban neighborhoods or environmentally sensitive areas.

EDP Bandeirante applied the advanced lightweight, low-sag, high-capacity conductor to a 4.9-kilometer section of a line in eastern São Paulo State that intersects an �rea de Preservação Permamente Permanent Environmental Protected Area.

Tower construction and right-of-way expansion would have entailed lengthy permitting delays, severe costs and logistical problems with respect to the movement and size of equipment, plus the need to build a temporary parallel line while the existing line was de-energized for rebuilding, according to Fernando Peixoto Saliba, EDP BandeiranteÂ’s engineering, planning and environmental executive manager.

“We originally considered a conventional ACSR upgrade, but the difficulties posed by construction in the protected area were significant,” says Saliba. “The innovative 3M ACCR solution saves us a lot of time and expense, allowing us to improve service about one year sooner on a line that was already operating at full capacity.”

EDP Bandeirante supplies power to 1.5 million customers in the regions of Alto Tietê, Vale do ParaÃba and Norte Coast of São Paulo State. The 3M ACCR installation was done on the two-circuit 88kV Cesar de Souza line, which serves residential customers in the city of Mogi das Cruzes and major industrial sites.

Two other utilities in Brazil – Companhia de Transmissão de Energia Elétrica Paulista, and CPFL – recently employed the 3M ACCR in upgrade applications that included river crossings and densely populated communities. Power companies in China, India and Canada, in addition to some two dozen U.S. utilities, also have embraced the 3M ACCR for similar applications.

Tim Koenig, director of the 3M High Capacity Conductor Program, says 3M ACCR’s growing international use, “especially in those countries whose economies and need for electrical power are most rapidly expanding, indicates that this conductor has become the reliable first-choice solution for upgrades where new construction would pose social, economic and regulatory obstacles. It is a proven, dependable, versatile and technologically advanced problem solver.”

3M ACCR was developed with the support of the U.S. Department of Energy, which tested the conductor at its Oak Ridge National Laboratory ORNL in Tennessee, and with early contributions by the Defense Advanced Research Projects Agency. The ORNL tests demonstrated that the conductor retains its integrity after exposure to temperatures even higher than the rated continuous operating temperature of 210 degrees Celsius and the emergency operating temperature of 240 degrees Celsius. It has the durability and longevity of traditional steel core conductors, even when operated continuously at high temperatures.

The conductorÂ’s strength and durability result from its core, composed of aluminum oxide alumina fibers embedded in high-purity aluminum, utilizing a highly specialized and patented process. The constituent materials can withstand high temperatures without appreciable loss in strength, even over long periods of time.

Also, since 3M's ACCR is based on aluminum, it is as not susceptible to environmental conditions such as moisture or UV exposure, as are other traditional conductors, and it has the corrosion resistance typically associated with aluminum-based conductors.

Related News

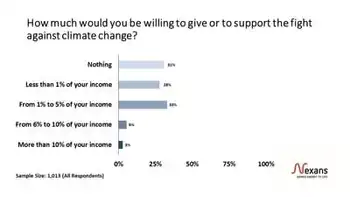

More than Two-thirds of Americans Indicate Willingness to Give or Donate Part of their Income in Support of the Fight Against Climate Change

NEW YORK - A new study of American consumers' attitudes toward climate change finds that more than two-thirds of respondents (70%) indicate their willingness to give or donate a percentage of their personal income to support the fight against climate change.

Twenty-eight percent indicated they were willing to provide less than 1% of their income; 33% said they would be willing to contribute 1-5% of their income; 6% said they would give between 6-10% of their income; and 3% indicated they would contribute more than 10% of their income. Just under one-third (31%) of those surveyed indicated they were unwilling to…