Transformer Cooling

Download Our NFPA 70E Fact Sheet – 2024 Electrical Safety Edition

- Understand how NFPA 70E works with NEC and NFPA 70B standards

- Clarify the shared responsibility between employers and employees

- Learn how NFPA 70E supports OSHA compliance

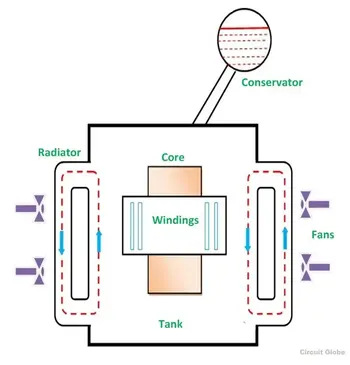

Transformer cooling enhances thermal management via oil-immersed and air-cooled systems, radiators, fans, and pumps. Methods like ONAN, ONAF, and OFAF reduce temperature rise, limit insulation aging, and improve efficiency under varying load.

What Is Transformer Cooling?

Transformer cooling removes heat from windings and core via oil or air circulation to control temperature and slow aging.

✅ Common types: ONAN, ONAF, OFAF, OFWF for various ratings.

✅ Components: radiators, fans, oil pumps, heat exchangers.

✅ Benefits: lower temperature rise, higher efficiency, longer life.

A little energy lost in a transformer must be dissipated as heat. Although this energy is but a small portion of the total energy undergoing transformation, it becomes quite large in amount in transformers of larger kVA ratings. To maintain efficiency and life expectancy the transformer's cooling system needs to be operating at peak performance. For dry-type transformers, the ventilation system of the room should be inspected to make sure it is operating efficiently. For forced air-cooled systems, the fan motors should be checked for proper lubrication and operation. Water-cooled systems must be tested for leaks and proper operation of pumps, pressure gauges, temperature gauges and alarm systems.

In liquid-filled designs, the choice and maintenance of oil in transformers directly influence heat removal performance and long-term reliability.

When a liquid coolant is used its dielectric should be tested. Water in the coolant will reduce its dielectric strength and the insulation quality. In cases where the dielectric strength of the coolant is reduced significantly, conducting arcs may develop causing short-circuits when the transformer is energized. A standard oil dielectric test involves applying high voltage to a sample taken from the transformer and recording the voltage at which the oil breaks down. If the average breakdown voltage is less than 20 kilovolts, the oil will need to be filtered until a minimum average breakdown of 25 kilovolts is achieved. Technicians often reference breakdown voltage of oil guidelines to interpret test results and schedule remediation.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Comprehensive transformer oil analysis can reveal moisture ingress, dissolved gases, and particulate contamination before failures occur.

Oil-insulated transformers use mineral oil for cooling. This oil is thin enough to circulate freely and does a good job of providing insulation between the transformer windings and the core. It is however subject to oxidation and if any moisture enters the oil, its insulating value is substantially reduced. In addition, mineral oil is flammable and therefore should not be located near combustible materials indoors or outdoors. In critical applications, selecting a high-quality transformer insulating oil mitigates oxidation, moisture effects, and thermal aging.

These behaviors align with the fundamental dielectric characteristics that govern insulation performance under electrical and thermal stress.

There are several types of transformer oil cooling solutions:

- oil air

- forced oil

- oils water

- oil natural

- air forced

- heated oil

- oil forced

- natural

In practice, each configuration must be evaluated alongside the properties of the chosen dielectric fluid to balance cooling effectiveness, safety, and service life.

Outdoor liquid-cooled transformers usually use mineral oil, and liquid cooled transformers for inside use are filled with a synthetic liquid that is nonflammable and nonexplosive. Synthetic oil coolants must be handled with care as they sometimes cause skin irritations. One type, askarelinsulated transformers used in past years contained polychlorinated biphenyls (PCBs), which are known to cause cancer. Askarel has been banned by the Environmental Protection Agency and its use as a transformer coolant is being phased out. However, askarel coolants are still found throughout the electrical industry in older transformers and direct contact with them should be avoided. The NEC still contains provisions for installing askarel transformers. The following is a list of the different types of liquid-filled transformers recognized by the NEC:

Facility engineers should review application requirements, fire codes, and material compatibility when selecting oil for transformers to ensure compliance and dependable operation.

- Oil-Insulated--uses chemically untreated insulating oil

- Askarel—uses nonflammable insulating oil

- Less-Flammable Liquid-Insulated--uses reduced flammable insulating oil

- Nonflammable Fluid-Insulated--uses noncombustible liquid