Transformer Oil Analysis Explained

Download Our OSHA FS3529 Fact Sheet – Lockout/Tagout Safety Procedures

- Learn how to disable machines and isolate energy sources safely

- Follow OSHA guidelines for developing energy control programs

- Protect workers with proper lockout devices and annual inspections

Transformer oil analysis evaluates dielectric strength, moisture, acidity, interfacial tension, and dissolved gases in insulating oil. It ensures transformer reliability, detects faults, prevents failures, and supports predictive maintenance in power distribution.

What is Transformer Oil Analysis?

Transformer oil analysis is a diagnostic process that tests insulating oil for moisture, acidity, and gases to monitor the condition of transformers, improve reliability, and prevent failures.

✅ Identifies dielectric strength, moisture, acidity, and interfacial tension levels

✅ Detects dissolved gases that signal faults, overheating, or arcing

✅ Supports predictive maintenance and ensures compliance with IEEE and IEC standards

This form of testing is a cornerstone of preventative maintenance for electrical engineering and maintenance professionals. Ensuring the optimal condition of insulating fluids is essential for the reliable and efficient operation of high-voltage equipment. Degraded oil reduces efficiency, accelerates insulation aging, and increases the risk of failures. Regular analysis enables the early detection of potential issues, allowing for timely corrective actions that extend transformer life and ensure an uninterrupted power supply. For utility transformers, where downtime can disrupt entire networks, ongoing transformer oil analysis is as critical as proper transformer oil filling.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Transformer oil testing plays a crucial role in ensuring the health of equipment. It ensures that insulating liquids continue to provide cooling and insulation while preventing dielectric failure. With modern grids demanding greater reliability, oil analysis combined with condition monitoring has become a strategic tool for utilities and industries. Recognized standards, such as IEEE C57.104, IEC 60599, and ASTM methods, guide testing procedures, the interpretation of results, and recommended corrective actions. In modern systems, condition monitoring works in tandem with oil testing to detect early signs of faults and extend the lifespan of transformers.

Sign Up for Electricity Forum’s Dielectric Fluids Newsletter

Stay informed with our FREE Dielectric Fluids Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Dissolved Gas Analysis

Dissolved gas analysis (DGA) is the most widely used diagnostic test for assessing the condition of electrical equipment. By identifying gases such as hydrogen, methane, ethylene, and acetylene dissolved in the fluid, engineers can detect thermal faults, arcing, or overheating long before physical symptoms appear. For example, acetylene may indicate high-energy arcing, while elevated hydrogen levels often signal partial discharge. By comparing gas concentrations against IEEE and IEC thresholds, operators can implement corrective actions before problems escalate. Because distribution transformers play a critical role in voltage delivery, routine DGA ensures reliable service to residential, commercial, and industrial customers. The role of distribution transformers necessitates regular analysis to ensure stable voltage delivery to residential, commercial, and industrial users.

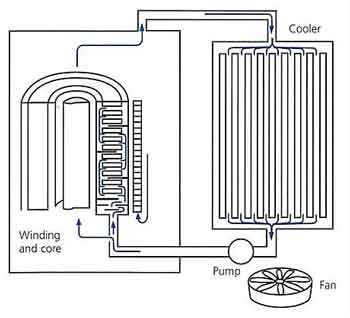

Moisture Content

Moisture is one of the leading causes of reduced dielectric strength. Even small amounts of water in insulating fluids increase the risk of flashover and accelerate the degradation of paper insulation. Regular testing identifies water contamination early, allowing timely fluid treatment or replacement. Moisture analysis not only protects winding insulation but also provides valuable insight into transformer loading, breathing, and sealing conditions. For professionals studying transformer design, moisture control illustrates the importance of oil’s dual role as coolant and insulator. For engineers studying the construction of a transformer, oil analysis provides practical insight into how insulating fluids preserve coil integrity and cooling efficiency.

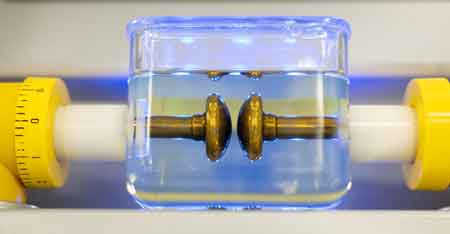

Dielectric Breakdown Voltage Testing

The dielectric breakdown voltage (BDV) test measures the maximum voltage oil can withstand before electrical breakdown occurs. This simple yet powerful test determines whether oil continues to provide adequate insulation under stress. Results guide maintenance decisions such as filtration, degassing, or replacement. When combined with advanced diagnostics, such as hydrogen detection or DGA, BDV testing provides a comprehensive picture of equipment readiness for demanding operating conditions. Advanced diagnostics, such as dissolved gas analysis, can complement specialized equipment like a hydrogen detection system, safeguarding against internal faults.

Acid Number

Acid number testing (also known as neutralization number) monitors the buildup of acidic compounds formed as oil oxidizes over time. High acid levels corrode metals, degrade insulation, and contribute to the formation of sludge, which reduces cooling efficiency. Tracking the acid number enables predictive maintenance planning and helps operators avoid accelerated transformer aging. In combination with furan analysis, acid testing provides a strong indicator of overall fluid degradation and the health of solid insulation. Understanding how oil testing supports the operation of high-voltage transformers highlights its importance in maintaining safe insulation and efficient energy transfer.

Comparison Table

| Aspect / Focus | Transformer Oil Analysis | Condition Monitoring | Hydrogen Detection System |

|---|---|---|---|

| Purpose | Evaluates insulating oil quality: moisture, acidity, dissolved gases, dielectric strength | Tracks overall transformer performance, detecting faults early | Detects hydrogen gas buildup from overheating or arcing |

| Key Parameters | Moisture, acid number, dissolved gas levels, dielectric breakdown voltage | Temperature, vibration, oil quality, load fluctuations | Hydrogen ppm levels in oil or the surrounding environment |

| Reliability Impact | Prevents insulation failure, extends transformer lifespan | Reduces unplanned outages, predicts maintenance needs | Prevents catastrophic failures and downtime |

| Maintenance Role | Guides oil treatment, replacement, or corrective action | Provides system-wide health insights for proactive maintenance | Enables fast response to internal transformer faults |

Interfacial tension (IFT)

Interfacial tension (IFT) testing, although less frequently discussed, is equally critical in evaluating quality. IFT measures the ability of an insulating fluid to separate from water. As fluid ages and becomes contaminated with byproducts of degradation, its interfacial tension decreases, indicating a loss in purity and efficiency. Ensuring high IFT values is essential for maintaining the insulating liquid's protective qualities and overall system performance.

Advanced Testing

Beyond standard tests, advanced diagnostics offer deeper insight. Furan testing detects cellulose breakdown, a key indicator of insulation aging. Power factor testing measures dielectric losses and reveals any deterioration in oil or insulation. Flash point testing evaluates fire safety by determining an oil’s resistance to ignition. Together, these tests provide a comprehensive health assessment, helping utilities maintain reliability, meet compliance requirements, and reduce lifecycle costs.

Routine transformer testing not only identifies immediate problems but also builds a historical database that improves long-term decision-making. Utilities, industrial plants, and service providers rely on these results to optimize maintenance schedules, extend equipment life, and improve grid stability.

Test Your Knowledge About Dielectric Fluids!

Think you know Dielectric Fluids? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Dielectric Fluid

Dielectric fluid examination also focuses on physical properties, such as flash point, which indicates the fluid's flammability and safety under operational conditions. A higher flash point denotes better thermal stability, ensuring the insulating liquid remains effective even in demanding environments. These parameters collectively highlight the importance of transformer oil testing and its role in safeguarding electrical systems. Maintaining the insulating fluid is just as vital as selecting the right dielectric fluid, since purity and dielectric strength directly affect operational safety.

Routine analysis not only identifies existing problems but also prevents potential failures, enabling a longer lifespan for critical assets. Electrical utilities and industries rely on these insights to maintain an uninterrupted power supply and reduce operational costs. By focusing on key themes such as dissolved gas analysis, moisture content, and acid number, this kind of analysis remains indispensable in modern power system management.

Frequently Asked Questions

What tests are done on a transformer?

Transformer oil is tested for moisture, acid number, dielectric breakdown voltage, and gases. Advanced methods include interfacial tension, furan testing, and power factor testing. Together, these tests provide a complete profile of insulation and oil condition.

How do you do oil analysis?

Oil analysis begins with proper sampling, followed by laboratory tests that utilize IEEE, IEC, and ASTM standards. Common tests include DGA, BDV, moisture, and acidity. Results are compared to benchmarks to detect issues and guide corrective maintenance.

How much does transformer oil sampling cost?

Costs vary by scope and provider. Basic testing (DGA, moisture, BDV) ranges from $200 to $500 per sample. Comprehensive packages with furan or advanced diagnostics may exceed $1,000. Despite costs, regular testing prevents failures and reduces long-term expenses.

How can the health of transformer oil be checked?

The health of insulating fluids is checked through routine tests, including DGA, BDV, moisture, acid number, and IFT. Advanced diagnostics and visual inspections supplement these methods, ensuring safe operation and extending service life.

Related Articles