Electrical Power Distribution Transformer Explained

Power Transformer Maintenance Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our NFPA 70E Fact Sheet – 2024 Electrical Safety Edition

- Understand how NFPA 70E works with NEC and NFPA 70B standards

- Clarify the shared responsibility between employers and employees

- Learn how NFPA 70E supports OSHA compliance

Electrical power distribution transformer converts medium voltage to safe levels, step-down units for substations and load centers, optimized kVA rating, impedance, and efficiency, with oil-filled or dry-type designs, tap changers, protection, and smart grid monitoring.

What Is an Electrical Power Distribution Transformer?

Device that steps medium voltage to utilization levels, optimizing impedance and efficiency for safe, reliable power.

✅ Steps MV to LV via copper/aluminum windings and core.

✅ Includes tap changer, protection, and cooling (oil or dry-type).

✅ Rated by kVA, impedance, efficiency; meets IEEE/IEC standards.

The electrical power distribution transformer plays a critical role in modern power systems, ensuring that electricity generated at high voltages can be safely and efficiently delivered to homes and businesses. This vital component of the electric power distribution system performs the essential task of voltage transformation, stepping down the high voltage from transmission lines to a level used by the customer. Without it, the reliable and safe operation of distribution lines would not be possible. For a broader overview of functions and ratings, see this guide to the modern distribution transformer and its role across utility networks.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

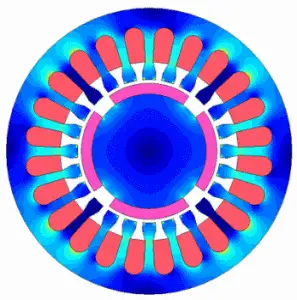

Understanding the Transformation Process

The primary purpose of a power distribution transformer is voltage transformation. Electricity generated at power plants is transmitted over long distances at high voltage to reduce energy loss. Upon reaching the local power distribution system, the voltage must be reduced to a safer and more usable level for residential, commercial, and industrial use. This final voltage transformation is achieved through the use of primary and secondary windings within the transformer. The primary winding receives high voltage power, while the secondary windings step it down to the level used by the customer. A concise primer on core operation is provided in this power transformers explained resource for engineers.

Test Your Knowledge About Utility Transformers!

Think you know Utility Transformers? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

One of the key concerns in operating a power distribution transformer is ensuring maximum efficiency. Transformers are designed to operate with minimal energy loss, but some loss is inevitable due to heat dissipation, core losses, and winding resistance. Advances in transformer design, such as improved core materials and optimized winding configurations, have significantly increased efficiency. Reducing energy loss in transformers not only improves the overall efficiency of the electric power distribution system but also lowers operational costs and supports sustainability goals. Comparative loss data and materials selection are discussed in the broader context of the power transformer family and modern efficiency standards.

Types of Distribution Transformers

There are several types of distribution transformers used in modern power systems. Each type is suited to specific applications and environments. Pole mounted transformers are commonly seen on utility poles in residential areas, where they supply single phase power to homes and small businesses. Pad mount transformers are used in areas where overhead lines are not feasible, providing power in commercial, suburban, and underground distribution systems. Three-phase pad mounted transformers are essential for larger commercial and industrial loads, where greater power capacity is required. Substation transformers, on the other hand, operate at higher capacities and are crucial for the operation of power substations. Each of these types of distribution transformers plays an important role in ensuring consistent and reliable power delivery. Field configurations for residential feeders are illustrated with examples of the power pole transformer used on overhead circuits.

The type of distribution transformer used depends on various factors, including voltage level, load capacity, and installation location. Some of the most common types of distribution transformers include:

- Pole-Mounted Transformers: These transformers are mounted on utility poles and are commonly used in residential areas.

- Pad-Mounted Transformers: These transformers are enclosed in weatherproof enclosures and are typically installed on the ground. They are often used in commercial and industrial areas.

- Substation Transformers: These large transformers are used to step down high voltage electricity from transmission lines to lower voltages for distribution.

Variations in mounting hardware and protective fusing for the electric pole transformer influence service reliability and maintenance practices.

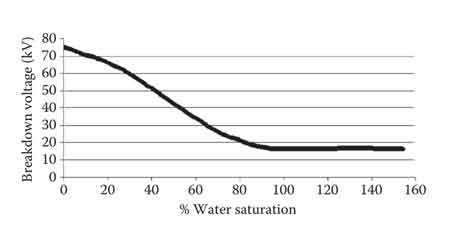

Proper installation and maintenance of power distribution transformers are essential for safe and efficient operation. When installing a mounted distribution transformer, it’s crucial to adhere to manufacturer guidelines and industry standards. Routine maintenance is equally important, as it helps identify potential issues such as insulation degradation, overheating, or moisture ingress. Regular inspections, testing of oil levels, and thermal imaging of key components are some of the measures taken to ensure transformers remain in optimal condition. Effective maintenance practices help extend the lifespan of these vital devices and reduce the likelihood of unexpected power outages.

Safety Considerations

Safety considerations are paramount when working with power distribution transformers. Since these devices handle high voltage electricity, strict adherence to safety protocols is necessary. Workers must be trained to recognize and mitigate potential hazards, such as electrical arc flashes or equipment failures. Protective gear, proper grounding, and the use of insulated tools are essential components of safety practices. Additionally, clear warning labels and safety signage around pad mount transformer enclosures help inform and protect the public and workers alike. Organizations must prioritize these measures to safeguard both employees and the communities they serve.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Another vital aspect of the electric power distribution system is the use of both single-phase and three-phase power. Single-phase power is typically used for residential and small commercial applications, while three-phase power is essential for larger industrial and commercial facilities. The ability of phase transformers to support both power needs ensures that various customer requirements are met. Single-phase power is simpler and cheaper to deploy, but three-phase systems provide greater power capacity and efficiency for heavy equipment and large facilities.

Along medium-voltage feeders, the powerline transformer topology and tap settings help balance voltage profiles across varying loads.

The power distribution system stepping process ensures that electricity is delivered at the appropriate voltage for each type of end-user. This process begins at the substation, where large power transformers reduce high transmission voltages to lower distribution levels. These distribution lines then carry the electricity to pole mounted transformers, pad mount transformers, and other types of mounted distribution transformers, where the final voltage transformation occurs. This process ensures that power is delivered at the appropriate voltage level used by the customer, supporting the needs of households, commercial enterprises, and industrial facilities. At upstream nodes, the high-capacity electrical substation transformer manages bulk voltage reduction before distribution feeders branch.

The electrical power distribution transformer is a fundamental component of the electric power distribution system. It enables the safe and efficient transmission of electricity from power plants to end-users through the voltage transformation process. By employing various types of distribution transformers, such as pole mounted, pad mount, and phase pad mounted transformers, the system can meet the diverse power demands of different sectors. Ensuring maximum efficiency, maintaining robust safety protocols, and adhering to proper installation and maintenance practices are all critical to the effective operation of these essential devices. Through these efforts, power distribution transformers continue to play an integral role in supporting the modern world’s electricity needs.