Gas Insulated Substation Explained

By Earl Williams-Conkllin, Senior Technical Editor

Substation Relay Protection Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our NFPA 70E Fact Sheet – 2024 Electrical Safety Edition

- Understand how NFPA 70E works with NEC and NFPA 70B standards

- Clarify the shared responsibility between employers and employees

- Learn how NFPA 70E supports OSHA compliance

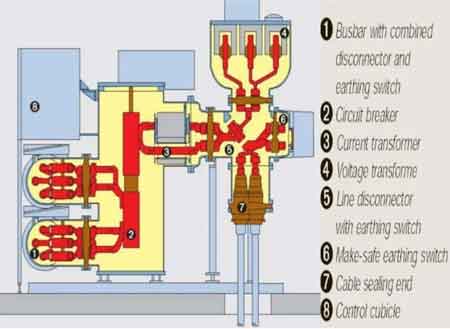

A Gas Insulated Substation (GIS) utilizes SF6 gas for insulation in compact switchgear, thereby enhancing reliability, safety, and efficiency in high-voltage systems. GIS supports the integration of smart grids and advanced substation automation.

What is a Gas Insulated Substation?

A GIS is a high-voltage substation where electrical equipment is enclosed in SF6 gas for compact design, reliability, and safety.

✅ Provides compact switchgear for limited space applications

✅ Enhances system reliability and arc fault protection

✅ Supports smart grid, automation, and efficient urban power delivery

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Compact Design and Space Efficiency

One of the defining advantages of a gas-insulated substation is its ability to minimize space requirements. Traditional air-insulated substations often require ten times the footprint of GIS installations due to the need for open-air clearance between energized parts. In contrast, GIS integrates all major components—including circuit breakers, disconnectors, and instrument transformers—within compact, gas-filled chambers.

This compactness makes GIS the preferred option for city centers, underground facilities, and industrial plants. Explore how these configurations fit into broader electrical substation design approaches, particularly in high-density areas.

While Gas Insulated Substations are valued for their compact design, they are often compared with air insulated switchgear used in AIS substations, which rely on air rather than SF6 gas for insulation. Although switchgear AIS installations require more physical space, they have a lower global warming potential, making them an attractive alternative in regions prioritizing environmental sustainability.

Gas Insulated Substation (GIS) vs Air Insulated Substation (AIS)

| Feature | Gas Insulated Substation (GIS) | Air Insulated Substation (AIS) |

|---|---|---|

| Insulation Medium | SF6 gas, providing high dielectric strength | Ambient air, requires larger clearances |

| Space Requirement | Very compact, ideal for urban or limited space areas | Requires large footprint, more suited to rural sites |

| Reliability & Safety | High reliability, resistant to pollution and weather | More exposure to environmental factors, lower reliability |

| Maintenance | Minimal, sealed enclosure reduces risk of faults | Higher, requires regular inspection and cleaning |

| Initial Cost | Higher upfront investment due to advanced technology | Lower initial cost but higher long-term maintenance |

| Service Life | Long life span with stable performance | Shorter life span in harsh environmental conditions |

| Applications | Urban power networks, smart grids, underground systems | Rural grids, large open spaces, traditional utilities |

Use of SF₆ Gas: Benefits and Challenges

At the heart of gas insulated switchgear GIS is sulphur hexafluoride (SF₆) gas. This insulating medium excels in dielectric strength and arc-quenching capability, enabling reduced equipment size and safer switching operations. However, SF₆ is also a potent greenhouse gas with a long atmospheric life, prompting global efforts to explore eco-friendlier substitutes.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Environmental concerns are driving the industry toward alternatives to fluorinated gases and vacuum-based solutions. While SF₆ remains standard, future-proofing GIS installations now involves balancing technical performance with sustainability. For details on protective equipment in these systems, see our page on circuit breaker in substation technology.

Reliability and Low Maintenance

Another core strength of GIS substations is their reliability. The sealed design protects internal components from dust, salt, moisture, and pollution—common causes of failures in outdoor air-insulated substations. Due to this enclosed structure, GIS requires less frequent maintenance and exhibits an extended service life.

Although low maintenance, GIS systems must still be monitored regularly. Routine diagnostics such as SF₆ gas analysis, partial discharge testing, and thermal imaging are essential to prevent internal breakdowns. For more insight into equipment durability, see our guide on electrical substation maintenance.

Applications in Challenging Environments

A gas insulated substation is uniquely suited to challenging environments. Its enclosed design benefits underground substations, coastal zones, offshore platforms, and industrial areas with high particulate or corrosive pollution significantly. GIS systems maintain stability where AIS systems would otherwise degrade quickly in such settings.

Its role in supporting urban infrastructure, renewable energy grids, and high-speed rail systems demonstrates how GIS plays a crucial part in meeting growing global energy demands. Explore how substation automation enhances GIS efficiency and adaptability through intelligent monitoring and control systems.

Cost Considerations and Lifecycle Value

While the initial capital cost of GIS can be higher than that of air-insulated substations, the long-term benefits often outweigh the upfront investment. Savings result from reduced land use, minimal maintenance, and improved reliability, leading to lower lifecycle costs and enhanced asset performance.

GIS’s modularity also makes it easier to expand or retrofit, supporting future grid evolution. Our article, 'What is a Tie Substation,' discusses how a substation can incorporate GIS elements to facilitate grid interconnectivity with minimal spatial impact.

Frequently Asked Questions

What makes GIS more space-efficient than AIS?

GIS utilizes a sealed metal enclosure with SF₆ gas, eliminating open-air clearances and reducing physical size by up to 90%.

Is SF₆ gas dangerous to the environment?

Yes. SF₆ is an effective insulating medium but is also a strong greenhouse gas. Efforts are underway in the industry to find greener alternatives.

Where are GIS installations most common?

They are commonly used in urban areas, underground, offshore platforms, and environments with pollution or space limitations.

Conclusion

A gas-insulated substation offers a modern, compact, and reliable solution for managing high-voltage systems. While SF₆ gas offers operational benefits, environmental considerations are leading the industry toward more sustainable alternatives. With superior performance in harsh environments and reduced lifecycle costs, GIS is helping reshape how utilities plan and manage electrical infrastructure.

Related Articles