Electrical Distribution System

Download Our OSHA 4475 Fact Sheet – Being Aware of Arc Flash Hazards

- Identify root causes of arc flash incidents and contributing conditions

- Apply prevention strategies including LOTO, PPE, and testing protocols

- Understand OSHA requirements for training and equipment maintenance

An electrical distribution system delivers electricity from substations to homes and businesses. It includes transformers, feeders, and circuit breakers that ensure a safe and reliable power flow. Learn how these systems support energy efficiency, grid stability, and electrical load management.

What is an Electrical Distribution System?

An electrical distribution system safely delivers power from transmission lines to end users through a network of interconnected components:

✅ Ensures reliable power delivery through feeders, transformers, and switches

✅ Manages voltage levels for safe residential, commercial, and industrial use

✅ Supports energy efficiency, fault protection, and load balancing

The backbone of reliable supply depends on electricity transmission seamlessly connecting with local distribution systems to deliver power where it’s needed.

Electrical Distribution System Topologies

The structure of an electrical distribution system greatly influences its reliability, fault tolerance, and maintenance flexibility. The three primary system topologies used in power distribution are radial, loop, and network configurations. Each has its benefits and applications depending on the load density, geographic area, and service reliability requirements. Understanding electric power distribution helps explain how energy moves from substations to end-use facilities.

Radial Distribution System

A radial system delivers power from a single substation outward through individual feeders to end users. This single-source distribution model is widely used in rural power systems and smaller suburban developments due to its simplicity and lower installation cost.

While easy to design and maintain, radial feeders offer limited fault tolerance. If a fault occurs along the line, all customers downstream lose power until repairs are made. Service interruption risk is therefore higher compared to more complex topologies.

-

Advantages: Cost-effective, simple to design and maintain.

-

Disadvantages: Limited reliability — a fault on a single feeder can interrupt service to all downstream customers.

Loop Distribution System

Loop, or ring-type, distribution systems are designed with feeders arranged in a closed path. Although only one segment of the loop is normally energized, alternate supply paths can be quickly activated in the event of a fault. This configuration improves fault isolation and enhances service continuity without significantly increasing system complexity.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Ring main units (RMUs) are commonly used in these systems to control flow and protection at various nodes in the loop. Loop distribution is ideal for commercial zones and medium-density residential areas where uninterrupted service is a priority.

-

Advantages: Improved reliability and fault isolation.

-

Disadvantages: More complex control and slightly higher installation costs.

Network Distribution System

In high-demand environments such as city centers, hospitals, airports, and industrial parks, network distribution systems are used to ensure maximum reliability. These systems consist of interconnected transformers and multiple power sources, allowing electricity to flow through various routes to the same load center.

The urban electrical grid often relies on such interconnected networks to avoid single points of failure. Even during equipment outages or scheduled maintenance, power remains available through redundant paths. This level of fault-tolerant distribution is essential for critical load centers and high-reliability applications.

-

Advantages: Extremely reliable; service is maintained even during multiple failures.

-

Disadvantages: High initial cost and complex protection coordination.

Typical Voltage Levels in an Electrical Distribution System

| System Segment | Voltage Range (Volts) | Purpose |

|---|---|---|

| Generation | 11,000 – 33,000 V | Power generated at medium voltage before step-up for transmission. |

| High-Voltage Transmission | 69,000 – 765,000 V | Bulk power transferred over long distances via transmission lines. |

| Primary Distribution | 4,160 – 35,000 V | Power delivered from substations to local distribution transformers. |

| Secondary Distribution | 120 – 600 V | Final voltage supplied to residential, commercial, or light industrial users. |

| Utilization Voltage (Residential) | 120/240 V (single-phase) | Standard voltage for home appliances and lighting. |

| Utilization Voltage (Commercial/Industrial) | 208Y/120 V, 480Y/277 V (three-phase) | Common voltages for commercial buildings, factories, and heavy equipment. |

The integration of distributed energy resources is transforming traditional distribution systems into more dynamic, flexible grids.

Choosing the Right Topology

Choosing the appropriate topology requires a careful analysis of current and projected load requirements, voltage level optimization, and consideration of geographic constraints. In many modern systems, a combination of radial and loop structures is employed to strike a balance between cost efficiency and fault protection. Smart technologies, such as distribution automation, improve reliability by enabling operators to remotely monitor and reconfigure feeders.

As the grid evolves with the integration of distributed energy resources, electric vehicles, and smart monitoring systems, future-ready distribution networks must be adaptable to meet these changes. Building flexible infrastructure now ensures resilience, reduces the impact of outages, and supports long-term power reliability across diverse service areas.

Transformers in the Electrical Distribution System

The role of power transformers is central to the operation of an AC system. Without these devices, the step-up and step-down voltage functions necessary for power transmission and distribution would not be possible. Transformers enable the efficient delivery of electrical energy from generators to end users by adjusting voltage levels to match transmission, distribution, and utilization requirements. Understanding electric power distribution helps explain how energy moves from substations to end-use facilities.

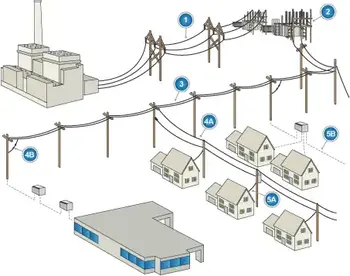

In its broadest sense, the electrical distribution includes generation, high-voltage transmission, and local distribution infrastructure. As shown in Figure 1, the transition from long-distance transmission to localized distribution typically occurs at a substation, where step-down transformers reduce voltage to medium levels suitable for primary distribution circuits.

Distribution substations are increasingly equipped with remote control, monitoring, and automation capabilities, allowing operators to manage switchgear, breakers, and auxiliary systems from centralized control rooms. These technologies improve grid responsiveness, load balancing, and fault isolation.

Fig. 1. Typical electrical distribution system.

A significant amount of protection, voltage regulation, and power flow control takes place within the distribution system, particularly in industrial and commercial applications. Figure 2 illustrates the various stages in the delivery of electrical power to an industrial facility, from substation input to final utilization equipment.

Fig. 2. Stages in the delivery of power to an industrial user

Primary and Secondary Distribution

The distribution system is commonly divided into primary and secondary segments, distinguished by their voltage levels and function:

-

Primary distribution refers to the medium-voltage circuits (typically 4.16 kV to 35 kV) that carry electricity from substations to localized areas or service transformers.

-

Secondary distribution delivers power at lower voltages (120 V to 600 V) to homes, businesses, and smaller industrial users.

-

The distribution transformer acts as the interface between these two segments, stepping down the voltage for end-use applications. Voltages connected to the transformer’s primary side are referred to as distribution voltages, while the secondary side supplies utilization voltages.

Interpreting Single-Line Diagrams

In industrial and commercial settings, single-line diagrams are widely used to represent power distribution layouts. These simplified schematics use a single line to indicate multi-phase conductors and identify all major components such as transformers, feeders, breakers, and grounding systems.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Wye and Delta transformer connections can be displayed in a single-line diagram. Each transformer symbol indicates whether the primary and secondary windings are configured in a Wye (Y) or Delta (Δ) arrangement, which affects phase relationships, load balancing, and grounding practices. Operators use devices such as the fault indicator to quickly pinpoint and isolate issues within distribution feeders.

Key Design Considerations

A well-designed distribution system must be able to serve all customers, from single-family residences to large industrial complexes, safely, efficiently, and economically. Effective design involves planning for both current and future energy needs. Major considerations include:

-

Structure type: Choice of radial, loop, or network topology based on load size and reliability needs

-

Present and future utilization: Load forecasting, energy growth projections, and planned system upgrades

-

System lifespan: Design based on the projected life of the facility or infrastructure

-

Flexibility: Capacity to expand, reconfigure, or isolate faults as needed

-

Service entrance and equipment location: Optimization of switchgear, panels, and wiring routes

-

Installation method: Overhead lines vs. underground cabling, based on terrain, aesthetics, and risk factors

Essential components, such as electrical insulators, maintain safety and system integrity by supporting conductors on overhead lines.

Related Articles