How does SCADA work?

By R.W. Hurst, Editor

Download Our OSHA 3875 Fact Sheet – Electrical PPE for Power Industry Workers

- Follow rules for rubber gloves, arc-rated PPE, and inspection procedures

- Learn employer obligations for testing, certification, and training

- Protect workers from arc flash and electrical shock injuries

SCADA systems gather data from sensors and RTUs, transmit it via secure networks, and display it through HMI software. Operators monitor and control remote equipment in real time using SCADA software and programmable logic controllers.

How Does SCADA Work?

✅ SCADA collects data from sensors and remote terminal units (RTUs) in real time.

✅ Transmits signals using wired or wireless communication networks to control centers.

✅ Displays system data through SCADA software and HMI user interfaces for operator action.

Supervisory Control and Data Acquisition systems are essential tools in modern electrical and industrial infrastructure. These platforms are designed to monitor, gather data from, and control equipment distributed across multiple locations. A SCADA system acts as a bridge between field operations and centralized oversight, enabling operators to make informed decisions based on real-time data.

At its core, a solution consists of sensors and control equipment installed in the field, which feed data into devices such as remote terminal units (RTUs) and programmable logic controllers (PLCs). These devices transmit collected data through a network using standard communications protocols, such as Modbus or DNP3, to centralized SCADA software. Operators interact with this software through a human-machine interface (HMI), where they can observe system status and execute control actions. If you want more information about What is SCADA, read the full article.

SCADA in Electrical Engineering

In the field of electrical engineering, this platform plays a critical role in ensuring stability, reliability, and efficiency across power generation, transmission, and distribution networks. Through automated control and remote visibility, SCADA systems help utility operators reduce system losses, detect faults early, and maintain safe voltage levels across a wide range of equipment.

Test Your Knowledge About Smart Grid!

Think you know Smart Grid? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

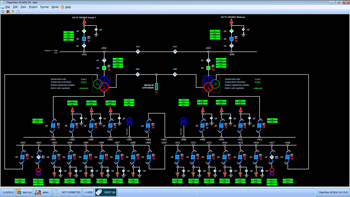

Electrical substations, for example, often rely on SCADA to manage switching operations, breaker statuses, and transformer data. PLCs provide local intelligence for local control, while SCADA manages supervisory oversight through centralized user interfaces. With a growing focus on smart grid modernization, SCADA has become the foundation for grid-wide automation and real-time coordination.

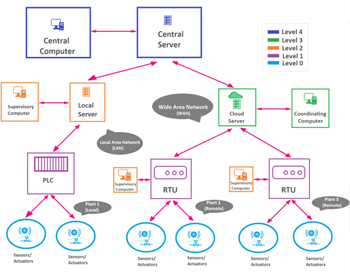

SCADA System Architecture Diagram

This diagram illustrates the core components of SCADA in electrical power systems, including sensors, RTUs, communications, and HMI interfaces.

SCADA Working Principle

The working principle of a control architecture involves four essential processes: data acquisition, communication, control, and interface. These processes work together to provide a comprehensive control system for remote infrastructure.

-

Data Acquisition:

The process begins with gathering data from field devices such as sensors that measure voltage, temperature, flow, and other parameters. RTUs or PLCs collect and digitize this information. -

Communications Protocols:

The RTUs send the collected data to a central control center over wired or wireless communication networks using robust and secure communications protocols. This ensures the reliable transfer of real-time data across long distances. -

Processing and Control:

At the master station, software processes this incoming data and applies automation logic. Operators can respond to events, trigger alarms, or change setpoints, often using built-in intelligence within the system. -

Human-Machine Interface (HMI):

All monitored values and controls are presented through the HMI SCADA screen — the most interactive part of the system. These interfaces allow human operators to visualize trends, respond to faults, and monitor and control the entire network efficiently.

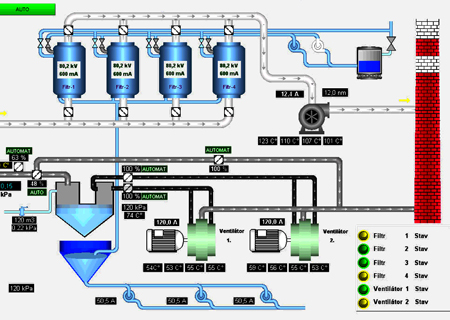

Operator HMI Interface Example

A sample HMI screen showing real-time system status, alarms, and operational controls.

Components of a SCADA System

A well-designed SCADA architecture contains multiple system components that interact seamlessly:

-

Field Sensors: Capture physical values like pressure, current, or temperature.

-

RTUs and PLCs: Process and transmit data from field devices.

-

SCADA Network: Connects remote sites to the control center using secure protocols.

-

SCADA Software: Manages data flow, logic, and visualization.

-

User Interface (HMI): Allows human operators to control and oversee operations.

These components provide operators with actionable insights, whether they are managing a power plant, substation, or pipeline.

Key Components and Functions of a SCADA System

| Component | Function | Keyword(s) Included |

|---|---|---|

| Field Sensors | Measure real-world values (e.g., voltage, pressure, flow) | collected data, gathering data |

| Remote Terminal Unit (RTU) | Acquires data from sensors and transmits it to the control center | remote terminal unit, communications protocols |

| Programmable Logic Controller (PLC) | Executes control logic and performs localized automation | programmable logic controllers plcs, local control |

| Network | Enables communication between field devices and central servers | network, communications protocols |

| Software | Processes real-time data, manages automation logic | software, automation solution |

| Human Machine Interface (HMI) | Displays data visually and allows operators to interact with the system | human machine interface hmi, hmi scada, user interface |

| Control Equipment | Responds to commands (e.g., switchgear, breakers, valves) | control system, monitor and control |

Why SCADA Matters

Despite advancements in AI and cloud computing, SCADA remains foundational for mission-critical infrastructure. A robust SCADA solution delivers reliability, operational efficiency, and centralized oversight. Its ability to collect, analyze, and respond to real-time data from a wide range of devices across long distances makes it indispensable for industries ranging from power generation to manufacturing.

Operators depend on SCADA to maintain high levels of uptime, minimize manual intervention, and ensure safe and coordinated field operations. As new technologies integrate into existing control systems, SCADA remains adaptable, scalable, and central to the evolution of industrial automation.

Related Articles