Dual Voltage Transformer Explained

Power Transformer Maintenance Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 4474 Fact Sheet – Establishing Boundaries Around Arc Flash Hazards

- Understand the difference between arc flash and electric shock boundaries

- Learn who may cross each boundary and under what conditions

- Apply voltage-based rules for safer approach distances

Dual voltage transformer for 110/220V AC mains provides step-up/step-down conversion, selectable taps, and isolation between primary and secondary windings, enabling safe worldwide power compatibility for appliances, tools, and industrial control systems.

What Is a Dual Voltage Transformer?

A transformer with dual primary taps for 110/220V, enabling step-up/step-down conversion and isolation for global AC mains.

✅ Dual primary windings with switchable 110/220V tap selection

✅ Provides galvanic isolation between mains and load

✅ Supports step-up/step-down and auto-transformer configurations

A dual voltage transformer is a versatile electrical device designed to efficiently manage and convert voltage levels for different applications. These transformers are commonly used in power distribution systems, industrial settings, and residential areas, and allow equipment operation across varying electricity requirements. With the ability to handle high and low-voltage configurations, they ensure a stable and reliable power supply, minimizing the risk of equipment damage or power loss. Whether for stepping up or stepping down electricity, dual electricity devices are essential in optimizing energy efficiency and maintaining system reliability. For foundational context, many systems rely on a well-specified voltage transformer to ensure accurate measurement and control.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Series and Parallel Configurations

One of the defining features of a dual voltage transformer is its ability to use series and parallel winding configurations. These configurations dictate how the primary windings interact with one another to achieve different electricity levels. For example, when the windings are connected in series, the output voltage is the sum of the individual winding voltages. Conversely, connecting the windings in parallel maintains the same voltage as a single winding but increases the current-carrying capacity. Understanding these configurations is crucial for the correct application of electrical equipment, ensuring they meet the specific requirements of an electrical system. These options are often implemented in a step-up and step-down transformer where configuration determines the resulting voltage and current.

Test Your Knowledge About Utility Transformers!

Think you know Utility Transformers? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Applications Across Industries

The adaptability of dual voltage transformers makes them invaluable in a wide range of industries. From audio systems and dental equipment to power distribution networks, these devices handle diverse electricity requirements with ease. In audio systems, electrical equipment facilitates smooth electricity transitions, ensuring consistent performance. Similarly, in the medical field, devices like dental equipment benefit from these devices’ ability to adapt to varying power needs, enhancing operational efficiency and safety. In distribution environments, utilities deploy high-voltage transformers to move power efficiently over long distances before local conversion.

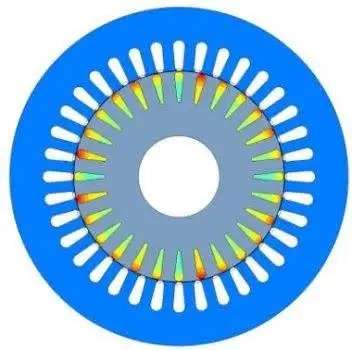

Design and Construction

The design and construction of a dual voltage transformer is integral to its functionality. Engineers use specific winding techniques to create devices that are flexible in electricity selection. These designs incorporate robust primary windings that ensure compatibility with various electrical systems while maintaining reliability. High-quality materials and precise engineering techniques are critical in producing devices capable of withstanding the demands of modern technology. For AC grids, core geometry, lamination, and flux density targets align with the characteristics of an AC transformer to reduce losses and noise.

Where rectification and filtering follow, specifying a compatible DC power transformer helps ensure stable downstream DC rails under dynamic loads.

Advantages and Limitations

Despite their many advantages, electrical equipment comes with certain limitations. One notable drawback is the lack of electrical isolation between windings in some designs, which can pose safety concerns in sensitive applications. However, their benefits often outweigh these limitations. Dual voltage transformers offer cost-effective solutions by eliminating the need for multiple single-voltage transformers, thus saving space and resources while delivering adaptability. Designs lacking isolation resemble an autotransformer, which can be compact and efficient but demands careful application for safety compliance.

Maintenance and Safety Considerations

Proper maintenance and safety considerations are vital for the long-term performance of electrical equipment. Regular inspections of winding connections, insulation integrity, and overall functionality are essential to prevent failures. This is especially critical in applications involving medical or industrial equipment, where devices malfunctions can have significant consequences. Adhering to safety guidelines, such as ensuring proper grounding and avoiding overload conditions, further enhances the reliability and safety of these devices. Comprehensive test routines mirror best practices used for a utility-grade power transformer to catch insulation degradation and connection faults early.

Frequently Asked Questions

What is the purpose of a dual voltage transformer?

A dual voltage device is designed to operate with two different input electricity levels, allowing it to function in systems or locations with varying electricity standards. For example, it might work with 120V or 240V inputs. This flexibility is particularly useful in applications like industrial machinery, HVAC systems, or international equipment compatibility, as it reduces the need for separate electrical equipment for different voltage supplies.

How to wire a dual voltage transformer?

Wiring electrical equipment involves configuring its primary windings to match the input electricity. For higher voltages, such as 240V, the primary windings are connected in series. For lower voltages, such as 120V, they are connected in parallel. Similarly, the secondary windings can be adjusted in series or parallel for the desired output voltage or current. It is essential to refer to the device's wiring diagram, verify connections with a multimeter, and ensure power is off during the process. Proper precautions must be taken to avoid damage or incorrect wiring.

How to tell if a transformer is dual voltage?

A dual voltage transformer can be identified by examining its label, which often indicates the input electricity ranges (such as 120V/240V). The presence of multiple terminals on the primary side is another indication, as it allows different wiring configurations. A wiring diagram, either printed on the device or included in its documentation, provides further confirmation. Manufacturer datasheets can also be consulted to verify dual voltage capabilities.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

What is a dual transformer?

A dual transformer refers to a device designed for flexibility in electricity handling. This may include electrical equipment that supports two input electricity levels or a device with dual secondary windings to provide multiple output options. Its versatility makes it a valuable component in applications where varying voltage requirements must be met.

A dual voltage transformer is an electrical device designed to operate at two distinct voltage levels, enabling it to serve diverse applications with varying power requirements. It is typically constructed with two sets of primary windings that can be configured in series or parallel, allowing seamless adaptation to different input electricity, such as 110V and 220V. This versatility makes electrical equipment highly efficient and practical for global usage, industrial equipment, and household appliances, ensuring compatibility with regional power standards while maintaining reliable performance.