Grounding Transformers

By William Conklin, Associate Editor

Substation Maintenance Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

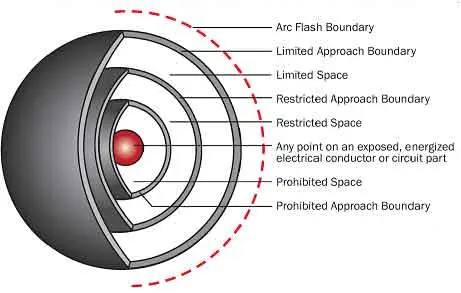

Download Our NFPA 70E Fact Sheet – 2024 Electrical Safety Edition

- Understand how NFPA 70E works with NEC and NFPA 70B standards

- Clarify the shared responsibility between employers and employees

- Learn how NFPA 70E supports OSHA compliance

Grounding transformers provide a neutral reference for ungrounded electrical systems, improving fault protection, voltage stability, and system reliability while supporting safety in distribution networks and industrial power applications.

What are Grounding Transformers?

A grounding transformer is a device used to establish a ground path in ungrounded power systems, ensuring safe operation, improved stability, and fault protection.

✅ Creates a neutral point for ungrounded systems

✅ Enhances safety through ground fault current path

✅ Improves voltage stability and system reliability

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

For a broader overview, see how power transformers incorporate grounding (earthing) as part of their fault management and system stability strategy.

Grounding transformers are a crucial component of electrical networks, providing protection against faults while maintaining voltage balance and operational stability. They are widely used in substations, wind farms, distributed generation systems, and industrial plants where ungrounded systems require a defined connection to earth. Understanding their purpose, design, methods, and standards is essential for safe and effective application. In many cases, earthing is combined with 3 phase transformers to maintain balanced voltages during abnormal conditions.

Purpose of Grounding

The grounding of transformers serves three essential purposes: safety, stability, and protection. By creating a low-impedance path to earth, earthing prevents dangerous overvoltages, reduces the risk of electric shock, and lowers the chance of fire during faults. It stabilizes voltage under both normal and fault conditions, enabling protective devices to detect and isolate faults before extensive damage occurs.

Grounding a transformer serves several essential purposes:

-

Safety: It provides a path to ground, preventing electric shocks and reducing the risk of fire in the event of a fault.

-

System Stability: It stabilizes the voltage during normal operation and faults, particularly in high voltage power systems.

-

Fault Protection: Grounding facilitates the detection and isolation of faults, thereby minimizing damage to electrical equipment.

Sign Up for Electricity Forum’s Utility Transformers Newsletter

Stay informed with our FREE Utility Transformers Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Methods of Grounding

Several methods are used to ground transformers, each with specific applications and benefits:

-

Solid Grounding: Directly connects the neutral point to the ground, providing a low impedance path for fault currents.

-

Resistive Grounding: Introduces a resistor between the neutral point and ground to limit fault current, reducing potential damage during faults.

-

Reactance Grounding: Utilizes a reactor to limit fault currents, which is beneficial in systems with high fault levels.

-

Ungrounded Wye: No intentional ground connection, allowing continuous operation under a single line-to-ground fault but requiring careful monitoring.

-

Zig Zag Transformer: Provides grounding for ungrounded or delta-connected systems, offering a path for fault currents and maintaining the system's neutral.

Typical Design and Sizing Parameters for Grounding Transformers

| Parameter | Typical Range / Value | Engineering Consideration | Impact on System |

|---|---|---|---|

| Zero-Sequence Impedance | 1–10% (varies by design) | Determines fault current magnitude | Lower impedance = higher fault current, faster relay operation |

| Short-Time Current Rating | 200–2000 A for 1–10 sec | Must carry ground fault current until protection clears | Defines thermal/mechanical duty of transformer |

| System Voltage | 2.4 kV – 34.5 kV (common MV range) | Grounding transformer must match system voltage class | Affects insulation design and sizing |

| Continuous kVA Rating | 50–2000 kVA typical | Based on system size and load requirements | Larger ratings needed for industrial and utility networks |

Design and Sizing of Grounding Transformers

Selecting the right grounding transformer depends on expected fault current, zero-sequence impedance, and operational requirements. The transformer must be sized to carry the maximum line-to-ground fault current for a sufficient duration, allowing protective devices to operate effectively. Low zero-sequence impedance ensures adequate fault current flow for relay coordination, while higher impedance may limit current but delay fault detection. Engineers balance these factors with cost, system losses, and space considerations. Typical grounding transformers are rated for short-duration fault duty, with capacity defined by system fault levels and relay operating times. The construction of a transformer directly influences how earthing components are integrated into the design.

Harmonic Mitigation and Power Quality

In addition to fault management, grounding transformers—especially those with zig-zag designs—play a crucial role in harmonic suppression. They provide a low-impedance path for triplen harmonics (3rd, 9th, 15th, etc.), reducing distortion in the system and improving power quality. This function is particularly valuable in industrial plants and renewable energy facilities with non-linear loads or inverter-based equipment, where harmonic interference can impact performance and lead to overheating.

Effect on Fault Management

Proper earthing has a direct impact on how faults are managed. With a defined earth path, protective relays and breakers detect abnormal currents quickly and isolate the affected section of the network. This reduces stress on equipment, prevents cascading outages, and ensures safe operation. Without effective earthing, ground faults may remain hidden, leading to voltage instability, excessive thermal stress, and safety hazards for personnel.

Standards and Regulations

Grounding transformer applications are governed by recognized codes and standards:

-

NEC (National Electrical Code): Defines earthing requirements in North America.

-

IEEE Standards (e.g., IEEE Std 142, IEEE Std 141): Provide technical guidance for system earthing design.

-

IEC Standards: Establish international requirements for earthing practices.

Adhering to these standards ensures not only safety but also reliable performance and consistent practices worldwide. In distribution networks, a distribution transformer may use earthing to provide reliable service and protect connected loads.

Problems from Improper Grounding

When grounding is not properly designed or maintained, several issues can occur:

-

Ground loops cause interference and malfunction.

-

High-impedance fault paths hinder protective devices from effectively detecting faults.

-

Maintenance challenges arise when unclear or inadequate earthing points compromise safety.

Systems without grounding face even greater risks, including uncontrolled fault currents, unstable voltages, and severe damage to equipment. Modern high-voltage transformers rely on earthing practices to control insulation stress and protect equipment from surges.

Best Practices

Effective grounding requires identifying the transformer’s neutral point, using adequately sized conductors, and ensuring a direct, low-impedance connection to earth. Engineers must follow NEC, IEEE, and IEC guidelines and document earthing connections clearly for ongoing maintenance. Regular inspection is equally important to confirm that earthing remains functional and reliable over time.

-

Identify and connect the neutral point.

-

Use properly sized conductors capable of carrying expected fault currents.

-

Maintain a direct, low-impedance path to earth.

-

Ensure compliance with NEC, IEEE, and IEC standards.

-

Conduct regular inspections to confirm reliability and performance.

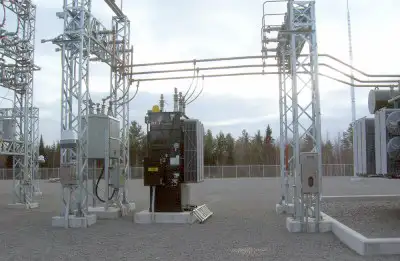

At the substation level, an electrical substation transformer often requires grounding to manage fault currents and ensure operational safety.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Ground Faults in Transformers

A ground fault occurs when energized conductors unintentionally come into contact with the earth or grounded components. Causes may include insulation breakdown, physical damage, or installation errors. These faults create short circuits and high current flows. With proper earthing, such faults can be quickly detected, isolated, and contained, preventing widespread equipment damage and protecting operator safety.

Grounding transformers are fundamental to the safety, stability, and reliability of modern power systems. By providing a neutral point, enabling effective fault detection, and ensuring voltage balance, they protect both equipment and personnel. Through careful design, adherence to standards, and ongoing maintenance, grounding transformers fulfill their role as essential safeguards in industrial, distribution, and utility networks.

Frequently Asked Questions

Is solid grounding better than resistive grounding?

Solid grounding offers faster fault clearing but results in higher fault currents. Resistive earthing limits current, reducing equipment stress, but may increase fault-clearing times. The choice depends on system design and protection strategy.

Can grounding transformers help with harmonic suppression?

Yes. Zig-zag grounding transformers provide a path for triplen harmonics, improving power quality in systems with non-linear loads.

What is zero-sequence impedance, and why is it important?

Zero-sequence impedance determines the amount of current that flows during a ground fault. A low impedance ensures protective devices operate quickly, while a higher impedance limits current but may delay detection.

Grounding transformers are fundamental to the safe, reliable, and stable operation of electrical systems. By providing a neutral point, enabling effective fault detection, and suppressing harmonics, they protect equipment and personnel across industrial, distribution, and utility applications. Through careful design, proper sizing, adherence to standards, and regular maintenance, grounding transformers remain indispensable safeguards in modern power networks.