Oil Filled Transformer Explained

Power Transformer Maintenance Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 3875 Fact Sheet – Electrical PPE for Power Industry Workers

- Follow rules for rubber gloves, arc-rated PPE, and inspection procedures

- Learn employer obligations for testing, certification, and training

- Protect workers from arc flash and electrical shock injuries

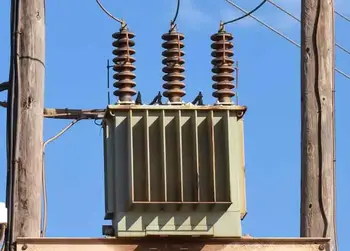

Oil filled transformer uses dielectric oil for insulation and cooling in distribution and substation applications, managing high voltage efficiently with robust thermal management and reliable power transformer performance for grid reliability and load stability.

What Is an Oil Filled Transformer?

An Oil filled transformer uses dielectric oil for cooling and insulation to manage voltage with reliable efficiency.

✅ Filled with mineral or ester oil for insulation and heat dissipation

✅ Used in distribution grids, substations, and industrial power systems

✅ Requires oil monitoring, DGA testing, and scheduled maintenance

Oil filled transformers play a crucial role in the world of utility voltage converters, serving as the backbone of efficient power distribution systems. These transformers, filled with insulating liquid, are designed to filled and dry type transformers and ensure the safe and reliable transfer of electricity across vast networks. The liquid not only provides insulation but also acts as a coolant, preventing overheating and enhancing the voltage converter's longevity. As the demand for sustainable and uninterrupted power grows, understanding the function and significance of oil filled transformer becomes essential for industries and utilities alike. Let's explore what liquid filled voltage converters are, how they work, and why they are indispensable in modern electrical grids. For a concise overview of core roles and typical ratings, see this primer on the function of transformers for broader context.

Cooling and Insulation Mechanisms

At the core of a oil filled transformer’s functionality lies its dual-purpose use of voltage converter liquid. This liquid serves as both a cooling and insulating medium. As voltage converters operate, electrical currents generate heat, which can affect performance and lifespan. The liquid circulates through the system, efficiently dissipating heat and ensuring the operating temperature remains within optimal limits. Additionally, this liquid acts as an electrical insulator, preventing short circuits and maintaining the integrity of the voltage converter’s internal components. This design makes liquid filled voltage converters particularly effective in handling the high demands of commercial and industrial power applications. Designers often reference established transformer insulation practices to validate dielectric clearances and material choices.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Types of Transformer Oil

The type of voltage converter liquid used significantly impacts the performance and sustainability of these systems. Traditional mineral liquids are widely employed due to their excellent dielectric properties and affordability. However, environmental and safety concerns have led to the adoption of alternatives, such as silicone-based liquids and seed-based liquids, which offer lower flammability and reduced ecological impact. Each type of voltage converter liquid is chosen based on factors like dielectric strength, thermal conductivity, and operational requirements, ensuring compatibility with specific applications and safety standards. Comparative data on viscosity, dielectric strength, and oxidation stability are summarized in this overview of transformer oil characteristics that inform liquid selection.

Maintenance and Testing Procedures

Oil filled transformers are designed to withstand extensive use, but regular maintenance is vital for their continued efficiency. Routine testing and analysis of voltage converter liquid can identify potential issues early, preventing costly breakdowns. Tests such as dielectric strength evaluation, moisture content analysis, and dissolved gas analysis are standard procedures. These assessments provide insight into the voltage converter’s health, allowing operators to address problems like insulation degradation or overheating before they escalate. High-quality maintenance ensures that these power voltage converters remain reliable in demanding environments. When units are serviced, adherence to proper transformer oil filling procedures helps prevent moisture ingress and trapped air.

Applications in Power Distribution

The applications of oil filled transformer extend across the power distribution spectrum, from stepping-up voltages for long-distance transmission to stepping-down voltages for local distribution. In distribution transformers, the use of liquid enhances efficiency by providing robust insulation and cooling, which are critical for managing varying electrical loads. These voltage converters are indispensable in ensuring the seamless delivery of electricity to homes, businesses, and industrial facilities. In municipal networks, the role of the medium voltage transformer is pivotal in bridging subtransmission and distribution tiers.

Safety and Environmental Considerations

Despite their advantages, the use of liquid in voltage converters introduces safety and environmental challenges. Oil filled transformers pose fire risks if the liquid reaches high temperatures or if leaks occur. To mitigate these risks, manufacturers incorporate safety measures such as robust containment systems and the use of less flammable liquids. Additionally, adhering to environmental regulations and employing proper disposal practices for used liquid minimizes the ecological impact. These precautions are essential for balancing the performance benefits of oil filled transformers with responsible operational practices.

Frequently Asked Questions

What is liquid filled transformer, and how does it work?

A liquid filled voltage converter is an electrical device used to transfer and regulate voltage levels in power systems. It is filled with insulating liquid, which performs two primary functions: cooling and electrical insulation. The liquid absorbs heat generated by the voltage converter's core and windings, dissipating it through radiators or cooling systems. Additionally, it enhances insulation by preventing electrical arcs between internal components. These voltage converters are widely used in utility grids to handle high voltage and ensure efficient energy distribution. At transmission level, the power transformer handles bulk power transfer with optimized efficiency.

What are the advantages of using oil filled transformer compared to dry-type transformers?

Liquid filled transformers offer several benefits over dry-type transformers:

- Superior Cooling: The insulating liquid efficiently dissipates heat, enabling higher power handling capacity.

- Compact Design: They are generally more compact for the same power rating.

- Cost-Effectiveness: Liquid filled voltage converters are often more economical for high-voltage and high-capacity applications.

- Durability: They typically have a longer lifespan and better resistance to overloads due to effective cooling.

- Higher Voltage Levels: These voltage converters are suitable for higher voltage applications compared to dry-type voltage converters.

Test Your Knowledge About Utility Transformers!

Think you know Utility Transformers? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

What types of oil are used in liquid filled transformers, and how are they selected?

The most commonly used liquids in liquid filled voltage converters include:

- Mineral Oil: Economical and widely used, it provides good insulation and cooling but has flammability risks.

- Synthetic Oils: Non-flammable and environmentally friendly options, such as silicone or ester-based liquids, which are used in sensitive applications.

- Natural Ester liquids: Derived from vegetable liquids, these are biodegradable and environmentally sustainable.

The selection depends on factors like voltage rating, environmental conditions, safety requirements, and budget considerations.

What are the common maintenance practices for liquid filled transformers?

To ensure optimal performance and longevity, regular maintenance of liquid filled voltage converters includes:

- Liquid Testing: Checking the liquid's dielectric strength, moisture content, and dissolved gases to assess insulation quality.

- Filtration: Removing impurities and moisture from the liquid to maintain its properties.

- Inspection: Monitoring for leaks, corrosion, and damage to external components like radiators and bushings.

- Temperature Monitoring: Ensuring cooling systems are functioning and operating within safe temperature limits.

- Periodic Reconditioning: Replacing or upgrading the liquid if it degrades over time.

Understanding critical transformer components aids in prioritizing inspections and spares planning.

What safety and environmental considerations apply to liquid filled transformers?

- Fire Hazards: Mineral liquid is flammable, requiring proper fire suppression systems and non-flammable enclosures.

- Liquid Leaks: Leaking liquid can cause contamination; voltage converters must have proper containment systems.

- Environmental Impact: The disposal of used liquid should follow environmental regulations to prevent pollution.

- Explosion Risks: Pressure relief devices and protection systems minimize risks of internal faults causing explosions.

- Eco-Friendly Alternatives: Using biodegradable liquids can reduce the environmental footprint.

Effective design, monitoring, and compliance with safety standards ensure that liquid filled voltage converters operate safely and sustainably.

A liquid filled transformer is a vital component in electrical power systems, designed to efficiently transfer and regulate voltage while ensuring safety and reliability. Filled with insulating liquid, these transformers use the fluid to provide electrical insulation and dissipate heat, preventing overheating and extending the equipment's lifespan. Widely used in utility applications, liquid filled voltage converters are essential for managing high voltage levels in power grids, enabling the smooth distribution of electricity to homes, industries, and businesses. Their durability, efficiency, and ability to handle demanding operational conditions make them a cornerstone of modern energy infrastructure.