Which Is The Primary Winding On A Transformer

Substation Maintenance Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 4475 Fact Sheet – Being Aware of Arc Flash Hazards

- Identify root causes of arc flash incidents and contributing conditions

- Apply prevention strategies including LOTO, PPE, and testing protocols

- Understand OSHA requirements for training and equipment maintenance

Which is the primary winding on a transformer? The primary is the input coil on the supply side, connected to the source, energizing the core for magnetic flux; labeled H1/H2; sets turns ratio for step-up/step-down.

Which Is the Primary Winding on a Transformer?

The primary winding is the input coil connected to the supply side, energizing the core and setting turns ratio.

✅ Connected to line voltage; labeled H1/H2 on schematics and terminals

✅ Provides magnetizing current, establishing core flux

✅ Determines turns ratio, impedance matching, and polarity

Which is the primary winding on a transformer? This fundamental question holds significant importance for electrical engineering and maintenance professionals, as it directly impacts the efficiency, safety, and functionality of power distribution systems. Understanding the role and identification of the primary winding is essential for proper system design, voltage regulation, and equipment maintenance. By mastering this concept, professionals can ensure optimal performance, reduce energy losses, and prevent costly operational failures. The primary's connection to the input power source and its interaction with the secondary form the backbone of voltage transformation, making it a critical focus for industry experts. For a refresher on electromagnetic principles and system behavior, this overview of how transformers work explains the interplay between primary and secondary windings in accessible terms.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

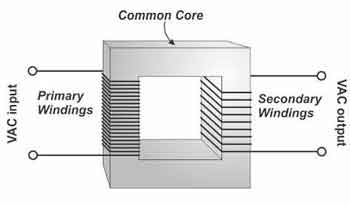

The Primary Winding

The primary winding is the part of the transformer directly connected to the input power source, whether it be an alternating current (AC) or direct current (DC) system. This connection to the power source introduces electrical energy into the system, where it undergoes a critical transformation. In an AC system, the current passing through the primary generates a fluctuating magnetic field around the winding. This magnetic field interacts with the core, which serves as a conduit for the magnetic flux. This flux is essential for inducing voltage in the secondary, a process known as electromagnetic induction. Without the input provided by the primary, the transformation process could not occur. To understand the induction mechanism in greater depth, this guide on what causes voltage to be induced in a transformer clarifies how flux changes translate into secondary EMF.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Voltage Transformation

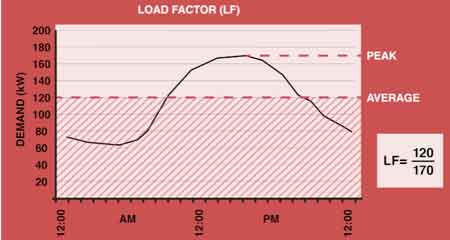

One of the key roles of the primary winding is to facilitate the step-up or step-down of voltage, depending on the specific design. This process is governed by the transformation ratios, which are determined by the number of turns in the primary relative to the number of turns in the secondary. If the number of turns in the primary is greater than in the secondary, the unit functions as a step-down transformer, reducing the voltage. Conversely, if the secondary has more turns than the primary, the system becomes a step-up transformer, increasing the voltage output. The relationship between these two windings is critical to ensuring that the system provides the necessary voltage to power downstream electrical loads. Real-world power transformer designs leverage turns ratios and tap changers to match distribution or transmission voltage targets reliably.

The Role of Turns Ratio

The concept of the turn ratio is central to understanding which is the primary winding on a transformer. This ratio is the mathematical expression of the number of turns in the primary relative to the secondary. The magnitude of this ratio dictates the extent of voltage transformation, and its accuracy is crucial for system reliability. For instance, a turn ratio of 2:1 implies that the voltage on the secondary side will be half that of the primary side. This transformation is essential in power distribution systems, where electrical power needs to be adapted for safe and efficient transmission. The geometry and insulation class of each transformer coil directly influence achievable turn counts and ratio tolerances in practice.

Identifying the Primary Winding

Distinguishing between the primary and secondary is essential for both design and maintenance purposes. While both windings are coils of conductive material, the primary is identifiable by its direct connection to the input power source. Additionally, in many types, the primary is often labeled as "P" or "Primary" on electrical schematics, while the secondary is labeled as "S" or "Secondary." Identifying these windings is critical when testing, repairing, or installing units, as improper connections can result in system failures or hazards. Standardized nomenclature across transformer components helps technicians avoid misconnections during commissioning and troubleshooting.

Another crucial aspect of the primary’s design is the materials and construction methods used in its fabrication. Typically, copper or aluminum conductors are used due to their excellent conductivity and mechanical strength. Copper is often preferred because it provides lower resistance and higher efficiency, although it is more expensive than aluminum. The construction of the winding also involves insulation materials to prevent short circuits and to support the integrity of the magnetic field. The winding’s design must consider factors like heat dissipation and mechanical stress, as these impact long-term performance. These choices are outlined in practical references on the construction of transformer assemblies, including insulation systems, cooling methods, and mechanical bracing.

Winding Design and Construction

The magnetic field generated by the primary plays a pivotal role in energy transfer. As current flows through the primary winding, it creates an alternating magnetic field that interacts with the core. The core’s primary function is to provide a low-resistance path for the magnetic flux. This magnetic field is transferred to the secondary through the core, ensuring that voltage is induced in the secondary. The efficiency of this energy transfer depends on the design of the core and the material used, typically silicon steel or other ferromagnetic materials that reduce energy losses due to eddy currents and hysteresis. In high-voltage transformers, careful core selection and flux density control are essential to minimize losses and manage dielectric stress under peak loading.

Sign Up for Electricity Forum’s Utility Transformers Newsletter

Stay informed with our FREE Utility Transformers Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.