Arc Flash Fatality: Lessons from Tragic Incidents

Arc Flash Training CSA Z462 - Electrical Safety Essentials

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA 4475 Fact Sheet – Being Aware of Arc Flash Hazards

- Identify root causes of arc flash incidents and contributing conditions

- Apply prevention strategies including LOTO, PPE, and testing protocols

- Understand OSHA requirements for training and equipment maintenance

An arc flash fatality occurs when a high-energy electrical explosion causes fatal burns or shock. With proper PPE, NFPA 70E training, and risk assessment, a deadly arc flash incident can be prevented. Learn how to improve electrical safety at work.

What is an Arc Flash Fatality?

It is a death caused by the violent energy release during an arc flash incident.

✅ Caused by extreme heat, pressure, and sound from the arc blast

✅ Often linked to lack of PPE or improper safety practices

✅ Can be prevented through NFPA 70E training and risk controls

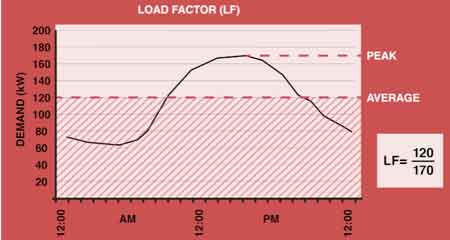

A thorough incident energy analysis determines the potential heat exposure and approach boundaries for safe work. Understanding the shock protection boundary is critical for preventing accidental contact with energized conductors.

Request a Free Training Quotation

Arc flash explosions can cause devastating injuries or death when an arc flash occurred while working on energized electrical equipment. Electrical fatality rates in industrial settings often stem from preventable causes, such as a high-voltage incident or a worker fatality due to an electrical explosion. These tragic events frequently result in severe burn injuries and are typically linked to a compliance violation or a lack of proper arc flash safety measures. A thorough arc flash risk assessment, combined with strict adherence to OSHA compliance standards, is crucial for mitigating the dangers of an electrical explosion. Employers must implement comprehensive training and enforce safety protocols, including energized work permits and electrical maintenance programs, to minimize the risk of electrical fatalities.To prevent serious incidents, it’s essential to know What Causes Arc Flash and how to mitigate the associated risks.

Sign Up for Electricity Forum’s Arc Flash Newsletter

Stay informed with our FREE Arc Flash Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Case Study 1: The 2007 Colombia Explosion

In 2007, a maintenance electrician in Colombia tripped a 13.8 kV circuit breaker during routine substation maintenance. An electrical explosion erupted, engulfing the worker in a fireball hotter than industrial furnaces. The explosion highlighted the dangers of electrical safety hazards, which resulted from worn insulation and improper racking procedures. Fault current levels were not adequately calculated, and fault arc initiation occurred due to insulation breakdown.

Causes: The investigation revealed failures in electrical safety protocols, including the electrician's lack of arc-rated personal protective equipment (PPE), the facility's failure to conduct a recent arc flash hazard analysis, and outdated high-voltage training. Neglected breaker insulation exacerbated the risk.

Outcomes: The worker suffered severe burns over 80% of their body, succumbed days later. This workplace electrical injury left a grieving family and led to significant legal and financial consequences for the company.

Lesson Learned: Comprehensive PPE and regular equipment inspections are crucial for preventing electrical hazards. NFPA 70E compliance mandates the use of arc-rated clothing for tasks such as racking breakers, and arc-resistant switchgear can greatly reduce the effects of an arc flash. Thermal imaging inspection during routine maintenance can help detect hotspots before failures occur. Understanding the proper gear is critical—review our guide on Arc Flash PPE Requirements to ensure workers are adequately protected.

Watch The Video: Electrical explosion that happened in a plant in Colombia, South America, in 2007.

Case Study 2: The 2015 Manufacturing Plant Tragedy

In 2015, a technician at a U.S. manufacturing plant was troubleshooting a 480V electrical panel. Unaware that the panel was energized, the technician triggered an incident by touching a live busbar, causing a blast of molten metal and debris. This tragedy highlights the importance of implementing robust electrical safety measures.

Causes: The primary failure was neglecting lockout/tagout (LOTO) procedures, a cornerstone of electrical accident prevention. The technician relied on verbal instructions instead of verifying that the equipment was de-energized. The facility also lacked training on the hazards lurking in low-voltage systems and did not conduct an electrical safety audit to verify compliance.

Outcomes: The technician died instantly from the blast’s pressure wave and shrapnel, a preventable workplace electrical injury. The incident halted operations for weeks, with OSHA fines exceeding $100,000 for non-compliance.

Lesson Learned: Strict LOTO protocols are vital, even for low-voltage systems. Workers must verify de-energization with proper testing equipment and consider current-limiting devices to reduce arc flash severity. Watch the Video: Arc Flash Accident At An Outdoor Electrical Substation

Case Study 3: The 2019 Construction Site Incident

In 2019, an electrician at a Canadian construction site was installing temporary power for a new building. A fault during a 600V feeder cable connection triggered an arc flash incident, exposing the worker to intense light and heat. This case highlights hazards in transient work environments.

Causes: Inadequate training for temporary power setups, a common issue in construction, contributed to the incident. The electrician’s PPE was not rated for the potential incident energy, and the site lacked a proper hazard risk assessment, violating electrical safety standards and hazard risk category requirements.

Outcomes: The worker’s fatal burns led to a project shutdown and exposed gaps in safety protocols for temporary installations. This workplace electrical injury deeply affected coworkers and the worker’s family.

Lesson Learned: Temporary setups demand rigorous risk assessments and preventive maintenance schedules to keep equipment safe. A robust equipment grounding system also minimizes fault hazards. For a comprehensive overview of best practices and compliance strategies, explore our CSA Z462 Arc Flash Training course.

Test Your Knowledge About Arc Flash!

Think you know Arc Flash? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Prevention Through Lessons Learned

Conduct Arc Flash Studies: Regularly assess incident energy levels and establish boundaries in accordance with NFPA 70E to guide PPE selection and ensure compliance. Consider incident energy reduction methods such as zone-selective interlocking or differential relays to limit exposure.

These incidents reveal recurring issues, including insufficient PPE, inadequate training, and a failure to assess potential hazards. To prevent loss of life, facilities must adopt proactive electrical safety measures:

-

Conduct Arc Flash Studies: Regularly assess incident energy levels and establish boundaries in accordance with NFPA 70E to guide PPE selection and ensure compliance.

-

Enforce PPE Compliance: Mandate arc-rated clothing, gloves, and face shields rated for the task’s incident energy to mitigate workplace electrical injuries.

-

Implement Lockout/Tagout: Verify de-energization with LOTO procedures to eliminate hazards before work begins.

-

Invest in Training: Provide NFPA 70E and CSA Z462 training to educate workers on electrical safety and prevention practices.

-

Adopt Remote Technologies: Use remote racking or monitoring systems to reduce exposure to live equipment and enhance workplace safety.

Watch Our Arc Flash Fatality Video:

Call to Action

These stories highlight the human cost of such incidents. Strengthen your workplace electrical safety protocols today and ensure NFPA 70E compliance. Enroll in The Electricity Forum’s NFPA 70E training to equip your team with skills to prevent arc flash accidents. Visit the Electricity Forum NFPA 70e Training for details.

Related Articles:

Explore our Arc Flash Training Programs or contact us to Request a Free Training Quotation for group safety sessions and PPE consultation.