What An Electrical Safety Program Includes

CSA Z462 Arc Flash Training - Electrical Safety Essentials

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA FS3529 Fact Sheet – Lockout/Tagout Safety Procedures

- Learn how to disable machines and isolate energy sources safely

- Follow OSHA guidelines for developing energy control programs

- Protect workers with proper lockout devices and annual inspections

What an Electrical Safety Program Includes

A proper program includes several critical elements to protect workers from hazards and ensure compliance with NFPA 70E and CSA Z462. These elements include risk assessments, safe work procedures, training requirements, PPE standards, and program audits.

It is essential for reducing the risk of workplace accidents involving arc flash, shock, and energized equipment. These programs provide a structured approach to identifying hazards, implementing controls, and ensuring compliance with standards such as NFPA 70E in the United States and CSA Z462 in Canada. Whether in industrial, commercial, or utility settings, a well-designed program supports a workplace culture that protects workers and assets.

Electrical Safety Program Development Training

What Is an Electrical Safety Program?

An electrical safety program is a documented system of policies, procedures, and training designed to protect employees who work on or near electrical systems. It outlines responsibilities, protocols, risk assessments, and methods for controlling hazards. The program applies to all personnel who may encounter energy in the course of their work, including electricians, maintenance staff, engineers, and contractors. Our How Often Must Employers Audit Their Electrical Safety Programs has lots of detail about ESP compliance.

Key Elements of a Successful Program

They typically include the following key elements:

A comprehensive program includes the following components:

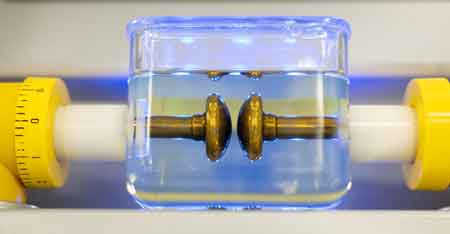

- Hazard Identification and Arc Flash Risk Assessment: Recognizing potential hazards such as arc flash, arc blast, and shock risk.

- Written Procedures: Establishing safe work practices for de-energizing equipment, testing, grounding, and lockout/tagout.

- Training and Competency: Ensuring workers are trained and qualified to perform tasks safely and recognize warning signs.

- Personal Protective Equipment (PPE): Selecting and using appropriate PPE based on the hazard level and task at hand.

- Incident Investigation and Recordkeeping: Documenting incidents, near-misses, and inspections for continual improvement.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Compliance with NFPA 70E and CSA Z462

Standards like NFPA 70e and CSA Z462 provide detailed requirements for workplace compliance, including guidance on risk assessments, labelling, arc flash boundaries, and PPE categories. Compliance with these standards helps reduce liability, improves audit readiness, and demonstrates a commitment to safety. Organizations are encouraged to integrate these standards into their programs and keep them up to date as revisions are published.

Training as a Foundation for Safety

Employee training is a crucial component of any effective safety program. Workers must be educated on identifying hazards, following safe work procedures, and using Arc Flash PPE properly. Training should be tailored to specific job roles and updated regularly to reflect new standards and technologies. New hires, apprentices, and contractors must receive orientation before beginning work on energized systems.

To support EHS managers, electrical supervisors, and arc flash protection specialists in building and maintaining strong programs, The Electricity Forum offers two specialized training courses. Our Electrical Safety Program Development Course is a one-day, in-depth session focused on developing, managing, and auditing compliant programs aligned with NFPA 70E, CSA Z462, and OSHA standards. Additionally, our Electrical Safety Training for EHS Managers and Supervisors offers comprehensive leadership training, equipping participants with the knowledge to oversee processes, manage documentation, and ensure effective contractor compliance. Together, these courses equip leaders with the tools to create safer and more resilient workplaces.

What An Electrical Safety Program Includes and How to Update It

When developing an electrical safety program, employers should:

- Conduct a workplace hazard analysis.

- Review applicable standards and regulations.

- Create or update written procedures and documentation.

- Schedule regular training sessions for all affected employees.

- Perform audits to measure program effectiveness.

Employers should also appoint a safety coordinator or committee to oversee program implementation and ensure continuous improvement.

How The Electricity Forum Can Help

The Electricity Forum provides expert-led Arc Flash Training courses that align with NFPA 70E and CSA Z462 standards. Our programs are tailored to industrial, commercial, and utility environments' unique needs, helping organizations meet regulatory requirements and build safer workplaces.

Request a free safety training quotation to get started or explore our course catalog for more information on how to strengthen your company's safety culture.

Related Articles: