NFPA 70E Arc Flash Label Requirements

By R.W. Hurst, Editor

NFPA 70e Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our NFPA 70E Fact Sheet – 2024 Electrical Safety Edition

- Understand how NFPA 70E works with NEC and NFPA 70B standards

- Clarify the shared responsibility between employers and employees

- Learn how NFPA 70E supports OSHA compliance

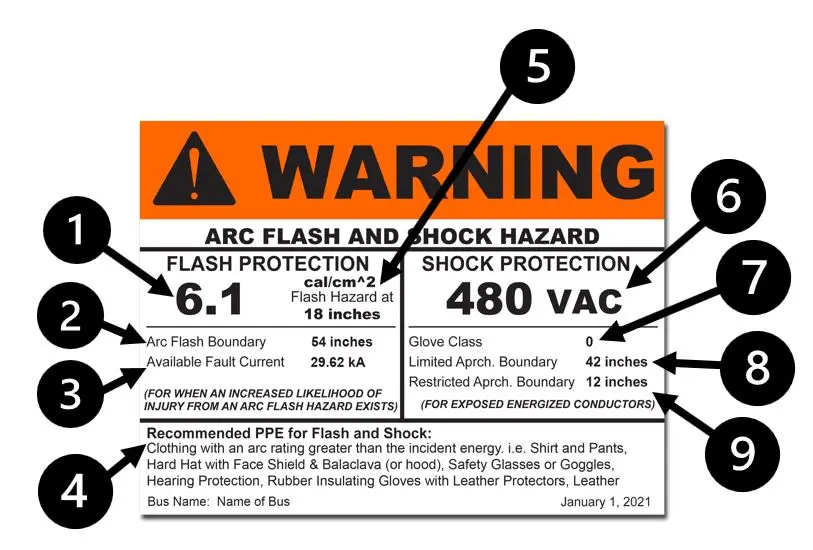

NFPA 70E Arc Flash Label Requirements define what electrical safety labels must display, including incident energy, approach boundaries, voltage, and PPE. Clear, updated labels improve compliance, reduce arc flash hazards, and guide workers toward safe electrical practices.

What are the NFPA 70E Arc Flash Label Requirements?

NFPA 70E Arc Flash Label Requirements mandate standardized hazard markers on electrical equipment to communicate arc flash risks, PPE categories, and safe approach boundaries.

✅ Labels must display incident energy or PPE category

✅ Include shock and arc flash boundaries

✅ Ensure compliance with OSHA and NFPA 70E

NFPA 70E Arc Flash Label Requirements are extremely important. Ensuring electrical safety in the workplace is paramount, and the National Fire Protection Association (NFPA) 70E standards play a critical role in protecting workers from electrical hazards. One crucial aspect of these standards is the requirement for arc flash (AF) markers. These labels provide essential information to ensure safe work practices around electrical equipment. This article delves into the requirements for AF signage, what information should be included, and the importance of these signs in maintaining a safe work environment.

Request a Free Training Quotation

NFPA 70E Arc Flash Label Requirements

NFPA 70E Arc Flash Label Requirements define how electrical equipment must be marked to warn qualified workers of potential arc flash hazards. These signs communicate incident energy, approach boundaries, voltage, and PPE guidance, ensuring safe practices and compliance with OSHA regulations.

Purpose of Arc Flash Labels

Arc flash studies and risk assessments provide the data, but labels are the point where safety information meets the worker. Without a clear, durable sign, technicians may underestimate risks or choose the wrong protective equipment. NFPA 70E labeling rules make sure vital details are visible at the equipment itself, not buried in a report.

Sign Up for Electricity Forum’s Arc Flash Newsletter

Stay informed with our FREE Arc Flash Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Required Information on a Label

NFPA 70E requires specific details to be displayed on each arc flash label:

-

Nominal system voltage – to identify the level of shock risk.

-

Arc flash boundary – distance from the equipment where PPE is required.

-

Incident energy or PPE category – showing calculated energy exposure in cal/cm² or the assigned PPE level.

-

Minimum PPE required – details such as arc-rated clothing, gloves, or face shields.

For a deeper dive into the calculations behind these values, see our guide on arc flash analysis and labeling solutions.

Placement and Visibility

Signs must be clearly visible before any examination, adjustment, or maintenance begins. They are typically applied to the front of switchboards, panelboards, industrial control panels, and motor control centers.

While NFPA 70E does not dictate exact dimensions, common sizes range from 4 x 6 inches to 5 x 7 inches, large enough to be visible from a safe distance. For best practices, review our article: arc flash warning label.

Updating NFPA 70E Arc Flash Labels

Arc flash signs are not permanent; they must be reviewed and updated whenever system changes occur. This includes:

-

Equipment replacements or upgrades

-

System reconfigurations that alter fault current or clearing times

-

Updates in protection devices

NFPA 70E also recommends labels be reviewed at least every five years. Out-of-date or faded markings are a common compliance issue, and the 10 most common errors in arc flash analysis.

PPE Categories on NFPA 70E Arc Flash Labels

Arc flash signs often guide workers toward the correct PPE by listing either the incident energy or the PPE category. The four NFPA 70E PPE categories range from Category 1 (minimum 4 cal/cm²) to Category 4 (minimum 40 cal/cm²). Each category specifies the required protection, including items such as arc flash suits, gloves, hoods, and other necessary gear.

Learn more about how categories are determined in our resource on arc flash PPE clothing.

Common Mistakes to Avoid

Employers often fall short of compliance in labeling by:

-

Using generic or incomplete signs

-

Failing to update signs after system changes

-

Placing signs where they are not visible during normal operation

-

Omitting critical details such as incident energy or boundaries

These oversights increase risk and can leave workers without the guidance they need at the equipment itself.

NFPA 70E Arc Flash Label Requirements translate complex hazard data into simple, actionable instructions at the point of work. By displaying incident energy, voltage, boundaries, and PPE needs, signs help workers make safe decisions and maintain compliance.

For a comprehensive overview of arc flash safety programs and training, visit our NFPA 70E training course page.

Frequently Asked Questions

Do arc flash labels need to include the date of the analysis?

While NFPA 70E does not mandate a printed date, many facilities add one so it’s clear when the sign was last verified. This helps ensure regular updates and prevents workers from relying on outdated information.

Are standardized colors or symbols required on arc flash labels?

NFPA 70E does not prescribe colours, but the ANSI Z535 standards recommend using orange or red for warnings and standardized pictograms for consistency. Many companies adopt this practice to make hazards immediately recognizable.

Can digital labels or QR codes be used in accordance with NFPA 70E?

Yes. NFPA 70E allows flexibility as long as the required hazard information is accessible. Some employers use QR codes linked to arc flash studies or detailed PPE charts for quick reference in the field.

How often should labels be inspected in day-to-day operations?

In addition to the five-year review cycle, signs should be visually checked during routine maintenance. If a label is damaged, unreadable, or missing, it should be replaced immediately to maintain compliance.

What happens if equipment is mislabeled or unlabeled?

Improper labeling can lead to workers using insufficient PPE or crossing unsafe boundaries, which may result in severe arc flash accidents. OSHA citations and penalties are also likely if compliance is not demonstrated.

Test Your Knowledge About Arc Flash!

Think you know Arc Flash? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Do temporary or rental electrical systems require labels?

Yes. Any system that may be worked on while energized requires labeling. Even short-term setups, such as construction panels, must display clear hazard information to protect electricians and contractors.

Visit our Arc Flash Electrical Safety Channel