Electric Motor Efficiency

By R.W. Hurst, Editor

Motor Control Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

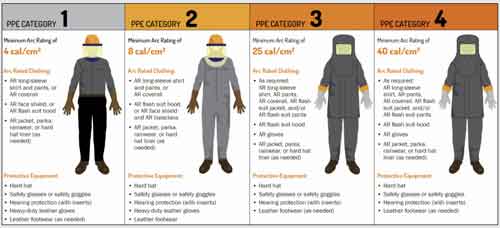

Download Our OSHA 3873 Fact Sheet – Minimum Approach Distance and Training Requirements

- Calculate MAD using voltage and overvoltage values

- Ensure proper communication between host and contract employers

- Meet OSHA training requirements for qualified electrical workers

Electric motor efficiency measures how well motors convert electrical energy into mechanical power with minimal losses. High efficiency improves performance, saves electricity, reduces operating costs, lowers heat, and supports sustainability in industrial power systems.

What is Electric Motor Efficiency?

Electric motor efficiency is the ratio of useful mechanical output to electrical input, indicating the motor's ability to convert electrical energy into mechanical energy.

✅ Reduces wasted electricity and lowers costs

✅ Extends motor lifespan and reliability

✅ Supports energy efficiency and sustainability

Electric Motor Testing Training

Request a Free Training Quotation

Why Electric Motor Efficiency Matters

Focusing on the efficiency of electric motors, such as single-phase and DC motors, is essential for both economic and environmental reasons. By understanding the factors that affect performance and implementing measures to enhance output, businesses and industries can enjoy long-term energy savings and contribute to a sustainable future.

In an environmentally conscious world, energy efficiency is paramount. Single-phase and DC motors, which convert electrical power into mechanical power, play a crucial role in various industries. Optimizing their performance can lead to significant energy savings and promote sustainability. This article explores ways to enhance motor efficiency and provide valuable insights for improvement.

Efficiency Standards and Classifications

Motor efficiency is often defined by international standards. IEC efficiency classes (IE1 through IE4) and the NEMA Premium label in North America establish benchmarks for performance. For example:

-

IE1 = Standard efficiency

-

IE2 = High efficiency

-

IE3 = Premium efficiency

-

IE4 = Super-premium efficiency

Many regions, including Canada, the USA, and the EU, require minimum performance standards (MEPS). Using motors that meet or exceed IE3/NEMA Premium ensures compliance and long-term savings.

Quantitative Examples and Losses

Typical industrial induction motors operate at:

Sign Up for Electricity Forum’s Motors and Drives Newsletter

Stay informed with our FREE Motors and Drives Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

-

80–85% efficiency for small (<1 kW)

-

90–93% for mid-range (10–100 kW)

-

95–97% for large industrial (>200 kW)

Losses include:

-

Copper losses: ~30–40% of total losses

-

Iron/core losses: ~20–30%

-

Mechanical losses (friction/windage): ~10–20%

-

Stray load losses: ~10%

These values highlight the importance of targeting multiple factors to maximize performance.

How to Calculate Efficiency

Motor efficiency can be expressed as:

η = (Output Power ÷ Input Power) × 100

Where:

-

Output Power = Torque × Speed × (2π/60)

-

Input Power = Voltage × Current × Power Factor

In the field, optimization can be estimated using power meters, torque transducers, and dynamometers. Laboratory testing provides more precise measurements, but in-service monitoring is increasingly available through smart sensors.

Table 1. Typical Motor Efficiency by Size and Power Rating

| Motor Size / Rating | Typical Efficiency Range | Notes / Applications |

|---|---|---|

| Small (<1 kW) | 75–85% | Used in appliances, fans, small pumps; less efficient due to proportionally higher core & friction losses. |

| Medium (10–100 kW) | 88–93% | Widely used in industrial pumps, compressors, conveyors; good balance of size and efficiency. |

| Large (>200 kW) | 95–97% | Heavy industry, power plants, steel mills; best efficiency due to lower relative losses. |

| Premium efficiency (IE3) | 92–96% | Meets NEMA Premium/IE3 standards; typical in modern industrial systems. |

| Super-premium efficiency (IE4) | 94–98% | State-of-the-art; required in some regions, common in advanced manufacturing and EVs. |

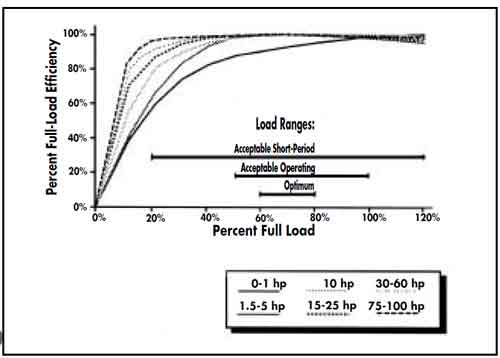

Behavior Under Load

Efficiency is highest near rated load (75–100%). At light loads, copper and core losses dominate, reducing efficiency. Overloaded motors run hotter, which accelerates wear and shortens their lifespan. An efficiency curve typically shows a peak around 80% load, with significant drops below 50% load or above 110%. Effective electric motor control systems ensure they run at the right load and speed, a key factor in maximizing optimization and minimizing wasted energy.

Thermal Effects and Cooling

Heat is a significant hindrance to efficiency. Winding resistance increases with temperature, raising copper losses. Magnetic materials also lose performance when overheated. Effective cooling—through the use of fans, liquid cooling, or enhanced thermal design - keeps them within optimal operating ranges and prevents performance degradation. The fundamentals of how an electric motor works reveal why losses occur and how performance can be measured and improved in real-world settings.

Material and Design Innovations

Modern high-efficiency motors use advanced materials such as:

-

High-grade silicon steel laminations to reduce core losses

-

Rare-earth permanent magnets for synchronous motors

-

Soft magnetic composites for innovative topologies

Emerging designs like axial-flux motors and switched reluctance motors are gaining popularity for their compact size and high efficiency, particularly in EVs and renewable systems. Engineers can boost performance by optimizing electric motor design, focusing on materials, winding configurations, and innovative topologies.

Monitoring and Degradation Over Time

Even efficient motors lose performance as they age. Bearing wear, misalignment, insulation degradation, and rotor/stator imbalances all contribute to reduced performance. Predictive maintenance tools—such as vibration analysis, thermal imaging, and online condition monitoring—help detect issues before they cause major energy or reliability losses.

Table 2. Breakdown of Typical Losses

| Type of Loss | Share of Total Losses | Description / Impact |

|---|---|---|

| Copper (I²R) losses | 30–40% | Heating in the stator and rotor windings due to resistance. |

| Iron / Core losses | 20–30% | Hysteresis and eddy current losses in the magnetic core. |

| Mechanical losses | 10–20% | Bearing friction, windage, and other moving parts. |

| Stray load losses | ~10% | Additional losses from leakage flux, harmonics, and load imperfections. |

| Additional degradation | Variable | Caused by aging, misalignment, insulation breakdown, or poor maintenance. |

Cost, ROI, and Lifecycle Analysis

Although high-efficiency motors have a higher upfront cost, payback periods are typically short. For example, upgrading to a premium-efficiency type may recover its cost within 1–3 years through reduced electricity bills. Considering the total lifecycle (purchase, operation, maintenance, and energy use), efficient devices deliver the lowest long-term costs.

Regulations and Incentives

Governments worldwide encourage performance upgrades through rebates, tax credits, or compliance requirements. In North America, DOE and NRCan regulations require minimum efficiencies for certain classes. The EU’s Ecodesign directive enforces IE2/IE3 as the minimum standard. These policies accelerate adoption of energy-saving technologies.

Practical Measures to Improve Efficiency

Our guide on efficiency opportunities through motor maintenance explores how predictive strategies and proactive care deliver measurable energy savings.

Implementing the following measures can improve electric motor performance for single-phase and DC motors:

-

Proper maintenance: Regularly inspect and maintain bearings, windings, and insulation to minimize losses.

-

Power factor correction: For AC motors, use correction capacitors to reduce reactive power.

-

Upgrade to high-efficiency: Replace old units with IE3 or NEMA Premium-rated motors.

-

Optimize sizing: Ensure the motor matches the load to avoid under- or over-loading.

-

Variable speed drives (VSDs): Adjust motor speed to match load demand.

-

Brushless DC: Improve efficiency by eliminating brush friction and commutator losses.

Many improvements in electric motor maintenance directly enhance performance by reducing friction, preventing wear, and extending the operational life of the motor.

Comparisons and Use Cases

Efficiency strategies vary by motor type:

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

-

AC induction motors: Benefit from VFDs and improved design.

-

Synchronous motors: Offer higher efficiency and better power factor.

-

Brushless DC motors: Deliver efficiency with reduced maintenance.

-

Switched reluctance motors: Rugged and efficient for high-speed applications.

Applications include pumps, fans, conveyors, compressors, and electric vehicles—each with unique performance considerations. Installing variable frequency drives is one of the most effective methods to optimize electric motor efficiency by matching speed to load requirements.

Emerging Trends

Digitalization and Industry 4.0 are transforming motor efficiency. Smart controllers, IoT-enabled sensors, and real-time monitoring enable continuous optimization. Wide-bandgap semiconductors (such as SiC and GaN) in inverters enhance performance in motor drives. Regenerative braking systems in EVs showcase how modern control strategies maximize energy recovery and sustainability.

Electric motor efficiency is critical for reducing energy consumption, lowering costs, and supporting sustainability. By considering standards, design innovations, thermal management, and lifecycle economics, industries can achieve significant gains. With regulatory support, advanced materials, and digital monitoring, the path toward higher performance and greener energy use is clear.

Related Articles