Synchronous Motors

By Jim Parrish, Lion Oil

Motor Control Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 4475 Fact Sheet – Being Aware of Arc Flash Hazards

- Identify root causes of arc flash incidents and contributing conditions

- Apply prevention strategies including LOTO, PPE, and testing protocols

- Understand OSHA requirements for training and equipment maintenance

Synchronous motors deliver constant speed, high efficiency, and reliable torque for industrial applications. Using AC power and rotor excitation, they enhance performance in pumps, compressors, and conveyors, ensuring energy savings and durable operation.

What are Synchronous Motors?

Synchronous motors are AC machines that operate at a speed precisely synchronized with the supply frequency, providing high efficiency and dependable power in industrial systems.

✅ Operate at fixed synchronous speed

✅ Provide precise torque and efficiency

✅ Widely used in pumps, fans, compressors, and process industries

If you want a broader perspective, see our introduction to what is a synchronous motor, which outlines their principles and practical uses.

Electric Motor Testing Training

Request a Free Training Quotation

Types of Synchronous Motors

Synchronous motors are available in several important forms. Wound-field designs use external excitation, offering flexible power factor correction. Permanent magnet synchronous motors (PMSMs) utilize rare-earth magnets, resulting in compact and efficient machines that come with higher costs and some supply chain challenges. Reluctance designs generate torque through rotor saliency, striking a balance between efficiency and affordability. Line-start synchronous motors include damper windings, allowing them to start directly on line power before locking into synchronism.

A good way to think about these designs is in terms of trade-offs:

-

Wound-field – flexible but requires excitation equipment.

-

PMSM – compact and efficient, but higher cost and magnet dependency.

-

Reluctance – cost-effective, lower complexity, moderate efficiency.

-

Line-start – easier starting, less control flexibility.

Synchronous vs Induction Motors

Induction motors remain popular in industry for their ruggedness and simplicity, yet they often create lagging power factor issues that demand correction with capacitor banks. Synchronous motors not only avoid slip losses but also actively improve system power factor when properly excited. Many industries still rely heavily on induction machines, and our resource on what is an induction motor explains why they remain so widely used.

Test Your Knowledge About Motors and Drives!

Think you know Motors and Drives? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

One real-world example of synchronous motors is the Lion Oil Refinery in Arkansas. To meet stricter clean-air regulations, the refinery replaced large induction motors with synchronous machines for driving the hydrogen compressors. The switch reduced reactive loading, improved energy efficiency, and lowered overall operating costs, while maintaining compliance with emissions regulations. Improving reliability and lowering costs often begins with proactive care, which is why efficiency opportunities through motor maintenance are so important.

Efficiency and Losses

Every motor has losses, but the profile differs in synchronous machines. Copper losses occur in stator and rotor windings, iron losses are created in the core, and friction, windage, and stray losses also contribute. Because they operate in step with the supply frequency, synchronous motors avoid the slip losses found in induction designs, which means they maintain efficiency even at partial loads.

In efficiency curves, this translates to stable performance across a wide range of loads. At low speeds and high torques, where induction motors often struggle, synchronous motors continue to deliver reliable output. For applications that require flexible speed control, a VFD variable frequency drive can be paired with synchronous or induction motors to maximize performance.

Applications in Industry

Synchronous motors serve industries that require constant speed, reliable torque, and precise power factor control. They are widely used in refineries, cement plants, steel mills, paper production, and water treatment facilities. Applications include driving pumps, crushers, compressors, and conveyors, where performance consistency is essential. With PMSM and reluctance designs advancing, they are also finding roles in high-efficiency HVAC systems, renewable energy integration, and robotics.

Applications of Synchronous Motors

| Industry | Typical Applications | Key Benefits | Common Motor Types |

|---|---|---|---|

| Refineries & Petrochemicals | Hydrogen compressors, pumps, fans | Power factor correction, constant speed, efficiency | Wound-field, PMSM |

| Cement Plants | Crushers, mills, conveyors | High torque at low speed, reliable operation | Synchronous reluctance, wound-field |

| Steel Mills | Rolling mills, blast furnace blowers | Precise speed control, durability | Line-start, wound-field |

| Pulp & Paper | Digesters, refiners, large fans | Energy savings, stable speed | PMSM, synchronous reluctance |

| Water & Wastewater | High-capacity pumps, aerators | Reduced reactive loading, efficiency curves hold under partial load | Wound-field, line-start |

| HVAC & Building Systems | Chillers, large fans, compressors | Compact design, energy efficiency | PMSM, synchronous reluctance |

| Renewable Energy | Wind turbines, hydro generators | Grid synchronization, efficiency, reliability | PMSM, brushless synchronous |

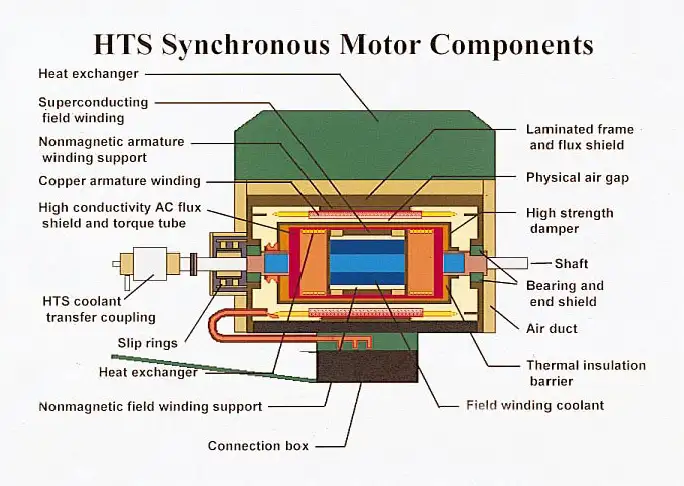

Design Considerations

The performance of synchronous motors depends on their internal design. Rotor and stator geometry, pole count, and slot structure affect torque ripple and acoustic noise. Materials for insulation and windings determine the durability, while cooling methods — ranging from forced air to liquid cooling — protect the motor during continuous, heavy-duty operation. Engineers weigh these factors when selecting motors for specific applications such as mills, crushers, and conveyors. Understanding that an electric motor transforms potential energy into mechanical energy is fundamental to grasping how synchronous machines fit into industrial systems.

Control and Startup

One of the challenges of synchronous motors is that they cannot self-start. To overcome this, engineers utilize auxiliary systems such as pony motors, damper windings, or, increasingly, variable frequency drives (VFDs), which provide smooth ramp-up and flexible control. Once the motor reaches near-synchronous speed, excitation locks the rotor to the stator field.

Modern controls add even more flexibility. Flux-weakening techniques enable motors to operate above their base speed, while advanced sensors and controllers ensure stable operation in demanding processes.

Standards and Efficiency Ratings

Synchronous motors play a central role in global efficiency initiatives. The IEC classifies motors from IE1 to IE5, while NEMA Premium ratings set benchmarks in North America. Higher classes, especially IE4 and IE5, are driving greater use of PMSMs and reluctance designs. Compliance with these standards is not only a regulatory requirement in many regions but also an opportunity for companies to reduce long-term costs through higher efficiency. ecause energy costs dominate motor ownership, our article on electric motor efficiency shows how design and operation affect long-term savings.

Cost, Lifecycle, and Maintenance

Although synchronous motors have higher initial costs, they often outperform induction motors over the lifecycle. Their ability to correct power factor reduces penalties and auxiliary equipment needs, while their efficiency lowers energy bills year after year.

Maintenance varies by design. Brush-type motors require inspections of brushes and slip rings, while brushless PMSMs reduce servicing needs but still require checks of bearings and insulation. When factored into lifecycle analysis, many industries find synchronous motors provide the best balance of performance, efficiency, and cost.

Challenges and Limitations

Synchronous motors are not a universal solution. Their starting requirements increase system complexity, and the need for excitation equipment or advanced controls can lead to higher costs. In designs that utilize rare-earth magnets, environmental and supply chain risks also play a significant role. For highly variable-speed applications, induction motors may remain the better option due to their simpler construction and adaptability.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Frequently Asked Questions

What are the main challenges in starting synchronous motors?

They require external methods, such as pony motors or variable frequency drives, to reach near-synchronous speed before excitation can lock the rotor in.

How do synchronous motors compare in cost to induction motors?

While purchase costs are higher, their efficiency, torque stability, and ability to correct power factor often reduce long-term operating expenses.

What industries benefit most from synchronous motors?

They are commonly used in refineries, steel mills, cement plants, and paper production facilities, where constant speed, high torque, and efficiency are crucial.

What maintenance considerations apply to synchronous motors?

Brush designs need regular inspection of brushes and slip rings, while brushless motors reduce maintenance but still require checks of bearings and insulation.

How do synchronous motors support power factor correction?

By adjusting rotor excitation of synchronous motors, they can operate at a lagging, leading, or unity power factor, thereby reducing reactive power and stabilizing the plant's electrical systems.

Related Articles