Variable Frequency Drive HVAC Explained

By Brian Ross, P.Eng

Motor Control Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 4475 Fact Sheet – Being Aware of Arc Flash Hazards

- Identify root causes of arc flash incidents and contributing conditions

- Apply prevention strategies including LOTO, PPE, and testing protocols

- Understand OSHA requirements for training and equipment maintenance

A Variable Frequency Drive (VFD) in HVAC systems adjusts motor speed and torque to control fans, pumps, and compressors, thereby boosting energy efficiency, lowering costs, reducing wear, and enhancing comfort in heating, ventilation, and air conditioning.

What is Variable Frequency Drive HVAC?

A Variable Frequency Drive (VFD) in HVAC is an electronic device that regulates motor speed and torque to control fans, pumps, and compressors, thereby optimizing system efficiency.

✅ Improves energy efficiency and lowers operating costs

✅ Enhances motor performance and building comfort

✅ Extends equipment lifespan with reduced wear

Electric Motor Testing Training

Request a Free Training Quotation

Variable Frequency Drives (VFDs) in HVAC systems allow operators to adjust the speed of motors rather than running at full speed continuously. By enabling users to control the speed of fans, pumps, and compressors, variable frequency drives VFDs and variable speed drives deliver significant energy savings and help reduce energy consumption across large facilities. In addition to efficiency, VFDs provide soft starts that limit inrush current, protect equipment, and extend motor life. This smoother operation also reduces maintenance demands while improving comfort through better airflow and water flow regulation. Overall, VFDs in HVAC systems optimize performance, reliability, and sustainability.

All buildings face the same challenge: how to heat or cool the air inside to create a more comfortable environment for their occupants. In small buildings such as a house, this task is easily handled with air conditioners and heaters. Larger buildings, such as offices, hotels, or factories, pose a more challenging problem due to their size and complexity. The most typical heating and cooling solution involves circulating air around the building while adjusting the air temperature by passing it over heated or cooled water as needed. Such a system consists of a water stage and an air stage. For deeper insight into how they function, see how does a VFD work and its role in reducing wear on motors used in HVAC systems.

Test Your Knowledge About Motors and Drives!

Think you know Motors and Drives? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Water Stage

The water stage is the first step of temperature control. Air is not an efficient medium for direct heating or cooling. The most efficient and inexpensive medium for heating or cooling is water. This water can then be used to change the temperature of the air passing through it. Heating water is very simple. Municipally-supplied water is pumped into a boiler where it is exposed to heat from oil, gas, coal, or electricity. The hot water is then pumped out into coils used for heating the building's air. Cooling water is a little more complex and revolves around a device called a chiller. A chiller consists of a compressor, a condenser, and an evaporator. Two separate water circuits exist in the chiller: one circuit removes heat from the building air, and another dissipates that heat via a cooling tower. Facilities can further optimize performance by combining VFD HVAC technology with efficiency opportunities through motor maintenance, ensuring reliable long-term operation.

Air Stage

The air stage is the medium for heat exchange in the building spaces. Air is constantly circulated through a building to either bring in or carry away heat as required. If the air needs to be cooled, it is directed over coils of cool water. If the air needs to be heated, it flows over coils of hot water. Outside air is also vented in at times to save chiller energy when the outside air temperature is cool enough to help the system.

HVAC System Architecture

Every building, when designed, presents a different type of heating and cooling challenge. Correspondingly, a wide range of HVAC solutions has been developed over the years, particularly for large buildings. Professionals seeking to master this technology can expand their skills through variable frequency drive training, tailored to HVAC and industrial applications.

Single Zone System

The simplest and common of all HVAC designs is the single duct/single zone system. This system is designed to supply air at a single temperature to a single large area (or zone) of a building. Some buildings are designed with the entire structure as a single zone. Although this system is simple and inexpensive to construct, the lack of control makes it difficult to keep all of the occupants comfortable, especially if parts of the building are affected differently by wind or sunlight. This type of system also wastes energy when heating or cooling areas that do not require it. Engineers designing HVAC systems benefit from understanding electric motor efficiency, since VFDs maximize savings only when paired with efficient motors.

The most flexible part of a single-zone system is the selectable recirculation of building air. Selectable air recirculation is a common feature in most HVAC architectures and is incorporated into all the systems discussed here. In this design, outside air is only used if its temperature will move the building temperature in the desired direction, warmer or colder. If the outside air is not at a useful temperature, the outside air dampers may be closed and the intermix damper opened to allow the building air to recirculate. However, the outside air dampers do not close completely. Some outside air must be brought in for health reasons. It is a general requirement that 20 cubic feet per minute of air be brought in for each occupant at all times. When applied to HVAC, a variable frequency drive adjusts motor operation to meet real-time load demands, lowering costs and boosting efficiency.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Terminal Re-heat System

A slightly more sophisticated system is called terminal reheat. These systems distribute uniformly cool or hot air to multiple zones within a building. Each zone is equipped with a thermostat and a heating coil. When a zone’s thermostat calls for warmer air, a heating coil is activated to provide the required heat.

Cooling Systems

Providing cooling is the most complex part of HVAC systems. The two primary components used to achieve this are chillers and cooling towers. By integrating VFDs with electric motor control, HVAC systems achieve precise speed regulation for fans and pumps, improving comfort and reducing waste.

Chillers

A chiller is the primary means of heat exchange between the interior and exterior of a building. The chiller serves two basic functions: to cool the air in a building and to provide dehumidification.

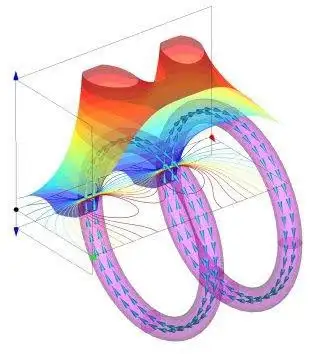

Water enters the evaporator and the condenser through external piping. Tubing inside the piping is surrounded by a chiller medium, which is a compressible gas such as freon. As the water circulates within the tubing, heat is transferred between the water and the chiller medium. The chiller medium is subjected to two stages of pressurization. First, the medium is fed into the condenser at high pressure by the compressor. When the medium is compressed, its temperature increases. The chiller medium then leaves the condenser through an expansion device that suddenly lowers the medium’s pressure before it enters the evaporator. When the medium is thus expanded, its temperature decreases. The change in pressurization between these two stages is the key to the cooling provided by the chiller.

From: Electric Motors and VFDs Handbook, Vol 4, The Electricity Forum

Related Articles