VFD Drives

By Paul Wright, P.Eng.

VFD Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our NFPA 70E Fact Sheet – 2024 Electrical Safety Edition

- Understand how NFPA 70E works with NEC and NFPA 70B standards

- Clarify the shared responsibility between employers and employees

- Learn how NFPA 70E supports OSHA compliance

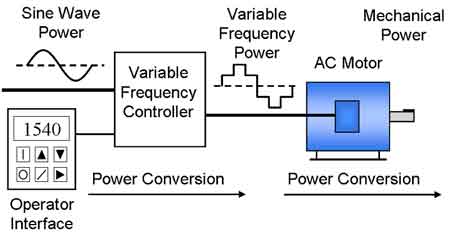

VFD drives regulate motor speed, torque, and energy efficiency by adjusting frequency and voltage. They improve process control, reduce power consumption, and extend equipment life across industrial, commercial, and HVAC systems.

What are VFD Drives?

VFD drives, or variable frequency drives, are electronic devices that control AC motor speed by varying voltage and frequency for improved efficiency and performance.

✅ Optimize energy use and reduce operational costs

✅ Enhance motor control for precise speed and torque

✅ Extend equipment lifespan in industrial applications

Electric Motor Testing Training

Request a Free Training Quotation

VFD drives, also known as variable speed drives, AC drives, or adjustable frequency drives, have become indispensable in nearly every application that utilizes induction motors. Initially designed in the 1980s to reduce energy consumption in centrifugal fans and pumps, they are now integrated into a wide range of equipment supported by advanced electric motor control. With improved semiconductor reliability and digital control, VFDs offer precise motor speed regulation, reduce downtime, and extend the time between maintenance shutdowns.

Figure 1. VFDs replace Inlet & Outlet Dampers and Throttling Valves

Beyond energy savings, VFDs deliver significant economic benefits. A properly applied VFD can reduce electric motor efficiency losses by 20–50% depending on the load profile. For example, a 50-hp motor on a centrifugal pump operating at variable flow may save 35,000 kWh annually, translating into $3,000–$5,000 in annual savings at typical industrial energy rates.

VFD Benefits and Performance Features

VFDs offer benefits well beyond simple energy reduction:

-

Unlimited starting without overheating the motor

-

Electrical and mechanical soft starting with no significant inrush current or voltage dip

-

Increased gearbox and belt drive life due to mechanical soft start

-

Unlimited drive direction changes at full speed

-

Operation above 60 Hz to increase production throughput

-

Longer equipment life with less wear and tear

-

Elimination of water hammer in pumping systems

-

Increased pump impeller life through reduced wear at lower speeds

-

AC to DC conversion and improved DC link stability

-

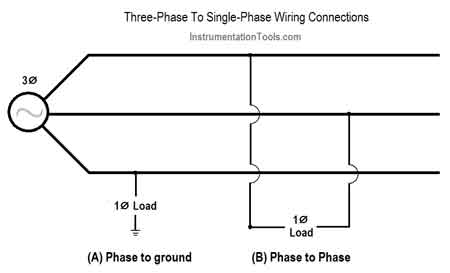

Phase converter control for three-phase loads on a single-phase supply

-

Output frequency and voltage control with advanced pulse width modulation

-

Enhanced sine wave generation and reduced harmonic distortion

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Sizing and Selection of VFD Drives

Selecting the right VFD for an application requires more than matching VFD sizing to motor horsepower. Engineers must also consider overload requirements, ambient conditions, harmonics, and payback period. Engineers must consider:

-

Motor type, rated current, and constant vs variable torque load profile

-

Overload requirements and starting torque

-

Ambient temperature, altitude, and need for derating

-

Harmonics and the use of line reactors or filters

-

Installation location and enclosure rating (IP/NEMA) for environmental protection

-

Budget, life-cycle cost, and expected payback period

For example, a 10-hp HVAC fan motor may require a 12-hp-rated VFD if operated in high ambient temperatures or at altitude, where cooling is limited. A derating factor of 10–15% is common in such conditions. In pumping systems, oversizing the VFD slightly ensures the drive can handle the higher torque required during startup without nuisance trips.

Comparison of VFD Control Methods

Different control strategies define VFD performance, from simple volts-per-hertz to advanced VFD programming for robotics and high-performance drives.

-

V/f (volts per hertz) control: simple, cost-effective, suitable for fans and pumps

-

Sensorless vector control: improved torque and speed control without feedback devices

-

Closed-loop vector control: encoder feedback for precise torque regulation, ideal for cranes, elevators, and heavy loads

-

Direct torque control (DTC): an advanced method delivering the fastest response and tightest regulation

Each method has its advantages, depending on the application's needs for speed, accuracy, torque response, and cost.

| Control Method | Description | Advantages | Typical Applications |

|---|---|---|---|

| V/f (Volts per Hertz) | Maintains a constant V/f ratio | Simple, low cost, reliable | Fans, pumps, HVAC systems |

| Sensorless Vector | Uses algorithms to estimate motor flux/torque | Better torque & speed control without feedback | Mixers, conveyors, compressors |

| Closed-Loop Vector | Uses encoder/tachometer feedback | High precision torque & speed regulation | Cranes, elevators, hoists, presses |

| Direct Torque Control | Direct calculation of torque/flux | Fastest response, superior dynamic control | Robotics, high-performance drives |

Power Quality, Harmonics, and System Effects

While VFDs improve efficiency, they also introduce harmonic currents into the supply, which can potentially reduce power quality. Harmonic distortion can cause overheating of cables and transformers, as well as interference with sensitive equipment. Mitigation methods include using input reactors, harmonic filters, or 12-pulse/18-pulse VFD designs.

Another consideration is power factor. Although the displacement power factor of VFDs is high (0.95 or better), harmonic distortion can reduce the true power factor. Many utilities now offer incentives for VFD adoption when combined with harmonic mitigation, recognizing their role in reducing demand and emissions.

Environmental and Safety Considerations

VFDs must be properly selected for environmental conditions. IP20 enclosures are commonly used in clean electrical rooms, whereas IP54 or higher ratings are required in environments with dust or moisture. NEMA 1, 12, or 4X ratings provide similar protection levels. Drives in high-humidity or corrosive atmospheres may require conformal coating of circuit boards. Cooling fans and capacitors are wear items and should be inspected or replaced as part of preventive maintenance.

Installation must comply with safety standards such as UL 508C and IEC 61800, and follow safe wiring, grounding, and EMC/EMI practices. Proper grounding reduces electromagnetic interference and protects sensitive control circuits. Lockout/tagout procedures are essential during installation or maintenance. When applied correctly, VFDs not only extend motor life but also complement ongoing electric motor maintenance programs, ensuring reliable long-term performance.

Case Study Applications

One facility installed VFDs on three 100-hp chilled water pumps. By reducing motor speed during partial load conditions, the site saved over 250,000 kWh annually, with a payback period of just 14 months. Another manufacturer using VFDs on conveyor drives reduced mechanical failures by 40% and extended motor insulation life from 10 to nearly 20 years.

In another example, a centrifuge originally operating with a fixed-speed motor faced repeated overheating issues. After installing a VFD, the motor operated with 15 amperes lower current draw, eliminating overheating and reducing downtime. The improved acceleration and deceleration also minimized equipment vibration, protecting personnel safety and equipment integrity.

Sign Up for Electricity Forum’s Motors and Drives Newsletter

Stay informed with our FREE Motors and Drives Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Variable frequency drives are no longer optional but essential in modern industry. They provide precise control, reduce energy costs, improve equipment reliability, and extend asset life. With the growing integration of IoT, predictive analytics, and advanced semiconductors such as silicon carbide (SiC), the future of VFDs is closely tied to smarter, more efficient, and sustainable industrial systems. While the upfront cost can appear significant, the combination of energy savings, reduced maintenance, and improved performance ensures that VFDs pay for themselves many times over during their operational life.

Frequently Asked Questions

Can VFD drives be used with any type of AC motor?

VFDs are most effective with three-phase induction motors, but many models can also control synchronous motors and permanent magnet motors. Using a VFD with older motors may require checking insulation ratings to avoid premature failure.

Do VFDs create harmonics, and how can they be managed?

Yes. VFDs generate harmonics that can distort power quality, overheat cables, and affect sensitive electronics. To mitigate, facilities use line reactors, harmonic filters, or multi-pulse VFD designs. Utilities may also have harmonic compliance requirements.

What is VFD derating, and when is it necessary?

Derating means applying a VFD at a lower output than its rated capacity to compensate for harsh conditions, such as high altitude, high ambient temperature, or continuous overload. For example, a 50-hp drive at 40°C may need to be derated to 45 hp.

Can VFDs improve motor insulation life?

Yes. By reducing thermal and electrical stress during startup and operation, VFDs can extend motor insulation life from around 10–12 years to nearly 20 years. Proper grounding, cabling, and filtering provide further protection for motor windings.

What industries benefit most from VFD drives?

While HVAC and pumping remain the largest markets, VFDs are increasingly critical in mining, oil and gas, food processing, and automated manufacturing. They help balance productivity with energy reduction and regulatory compliance.

How do VFDs impact power factor?

Most VFDs maintain a high displacement power factor (typically above 0.95), but harmonics can lower the true power factor. Adding harmonic filters or utilizing 12-pulse/18-pulse drives can help facilities comply with utility requirements.

What are the main components of a VFD?

A VFD consists of three key sections: the rectifier (converts AC to DC), the DC link (stores and smooths energy), and the inverter (reconverts DC to variable-frequency AC). Modern drives also include control boards, cooling fans, and protective sensors.

What are the latest trends in VFD technology?

Advances include silicon carbide (SiC) semiconductors for higher efficiency, integration with IoT platforms for predictive maintenance, regenerative VFDs that feed energy back into the grid, and smaller, more compact designs with enhanced cooling.

Related Articles